Pinhead tea continuous shaping system based on automatic weighing and control method thereof

An automatic weighing and pearl tea technology, which is applied in automatic feeding/discharging weighing equipment, weighing, tea treatment before extraction, etc., can solve the problem of low degree of automation, inability to realize automatic mixing of pots, and feeding weight accuracy not enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

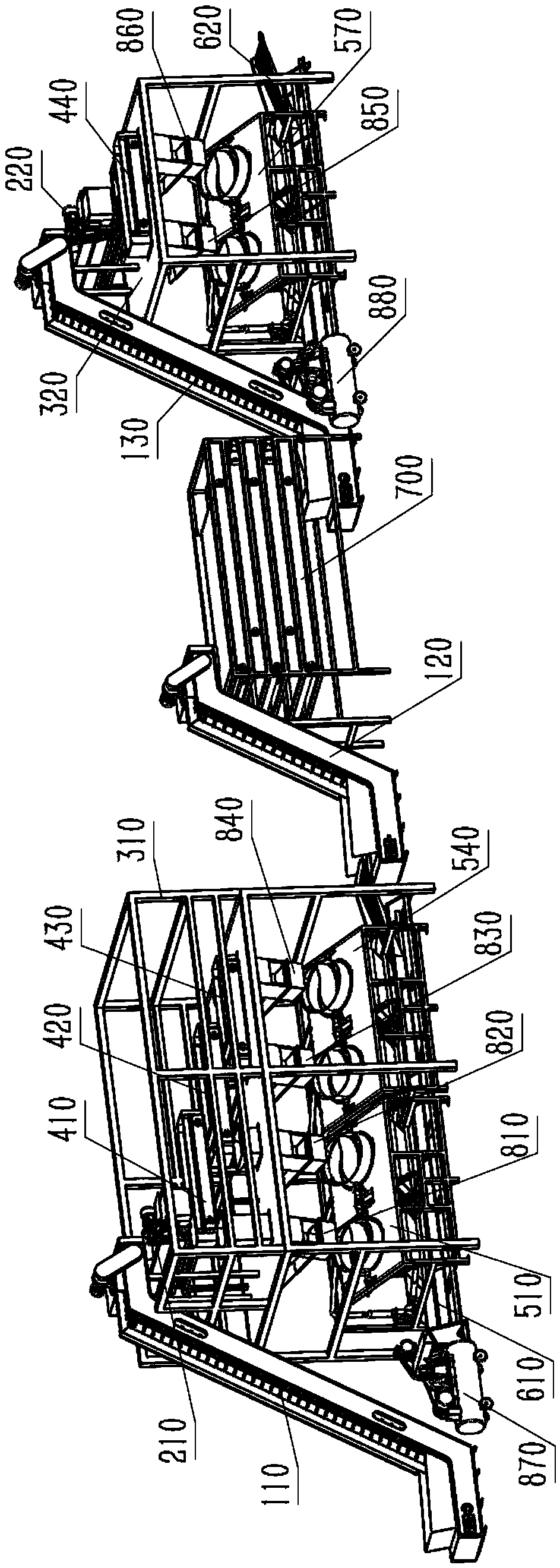

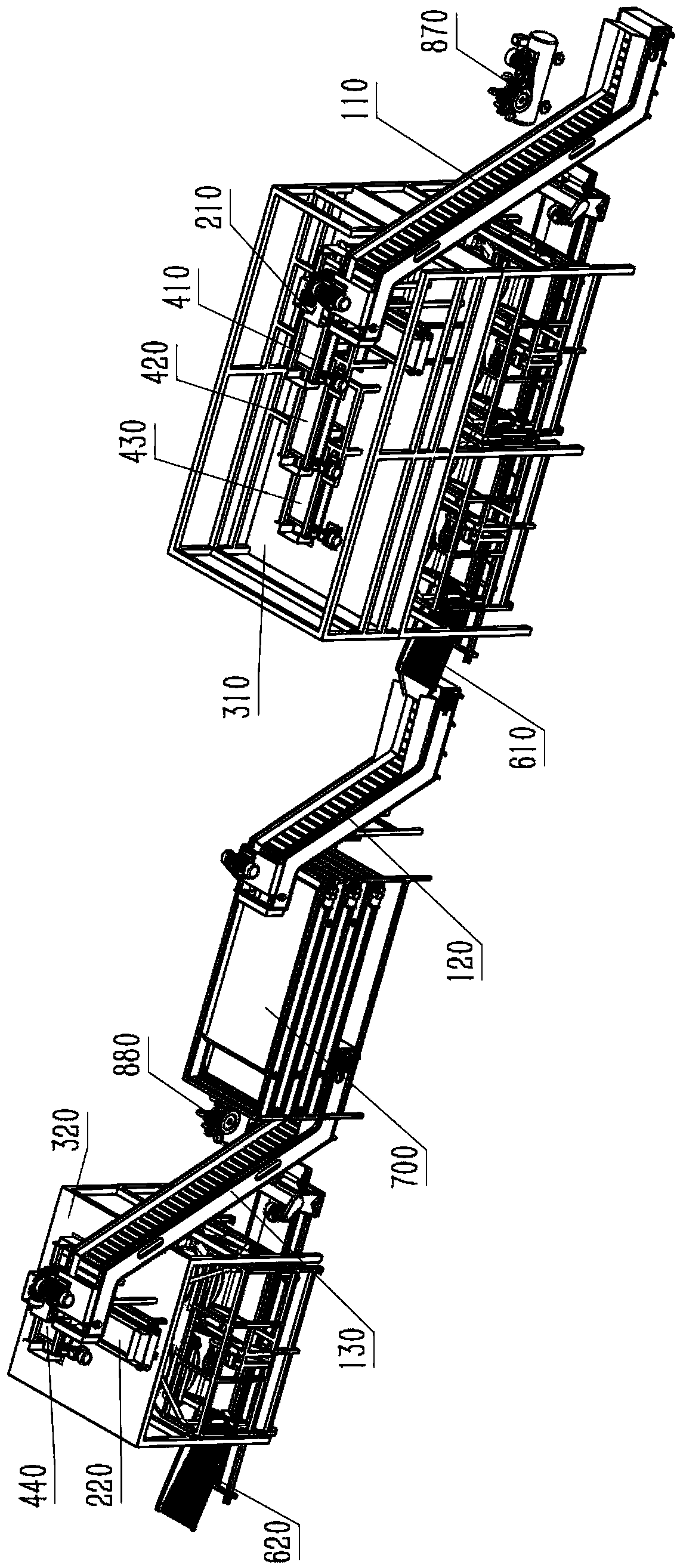

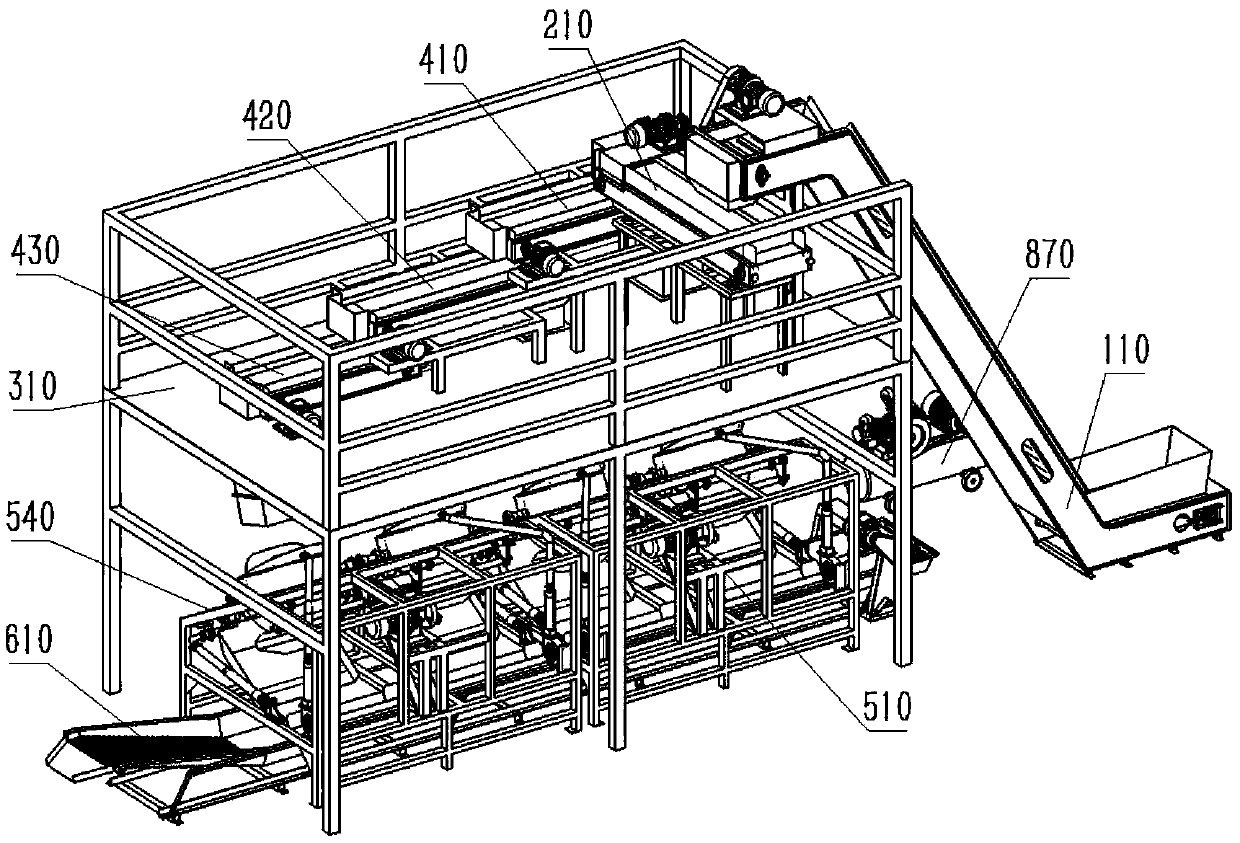

[0065] Such as figure 1 , 2 Shown: A continuous shape-making system for pearl tea based on automatic weighing, including a PLC control unit, an initial frying unit, a cooling unit, and a re-stirring unit for sequentially processing tea leaves;

[0066] The initial frying unit includes a first vertical hoist 110, a first weighing conveyor 210, a first material distribution mechanism, a first vibrating conveyor 610, and multiple double-pot bent mills; the double-pot bent mills Each frying pan of the machine is respectively equipped with a pneumatic storage device for feeding into the corresponding frying pan; the discharge of the first vertical elevator 110 falls on the first weighing conveyor 210, and the first weighing conveyor The discharge of the machine 210 falls on the first material distribution mechanism, which is used to put the tea leaves into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com