Superfine carbide high-alloy tool steel shear-steel splicing mechanical blade

A technology of alloy tool steel and mechanical blade, applied in the field of preparation of mechanical blade, can solve the problem of not completely improving the product yield and other problems, and achieve the effect of easy implementation and control, smooth and clean cutting board surface, and sharp cutting edge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

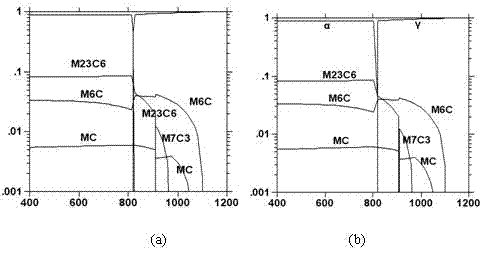

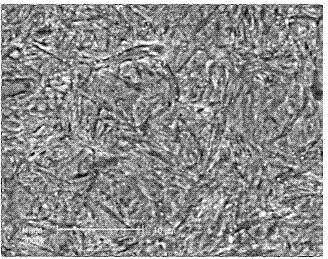

[0020] An ultra-fine carbide high-alloy tool steel blade steel inlaid mechanical blade. First, an ultra-fine carbide high-alloy tool steel blade steel is prepared. The ultra-fine carbide high-alloy tool steel blade steel contains (wt%) C0.52 ~0.62, Si0.40~0.60, Mn0.25~0.50, Cr5.2~6.2, W2.20~2.70, Mo1.40~1.70, V0.40~0.50, Co or Ni is 0.18~0.30, S≤0.015 , P≤0.02, Fe margin; its preparation includes the use of induction electric furnace or induction electric furnace + electroslag remelting and its 870℃~1100℃ forging and rolling process steps;

[0021] Secondly, use high-temperature non-oxidation press-rolling inlaid on low-carbon steel plates to make mechanical blades;

[0022] Finally, the annealing, quenching and tempering process steps are carried out, and the process conditions are:

[0023] (1) Annealing, heating at 830℃~840℃, keeping for 4~6 hours and then cooling with furnace;

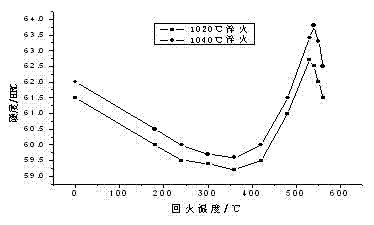

[0024] (2) Quenching, heating at 1010℃~1050℃, heat preservation for 1.2 minutes / mm, oil cooling or air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com