An ultra-precision machining method of titanium alloy based on ultrasonic elliptical vibration cutting technology

An ultra-precision machining and elliptical vibration technology, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of fast tool wear, high cutting temperature, large processing surface, etc., to improve the quality of the processed surface, reduce the Effect of cutting temperature and tool chatter suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the scope of the technical solution of the present invention should be covered by the protection of the present invention. in range.

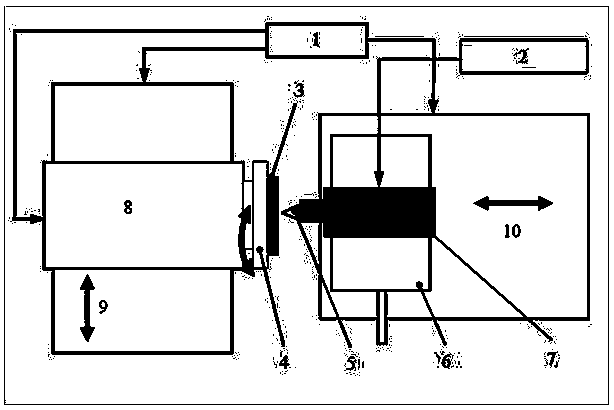

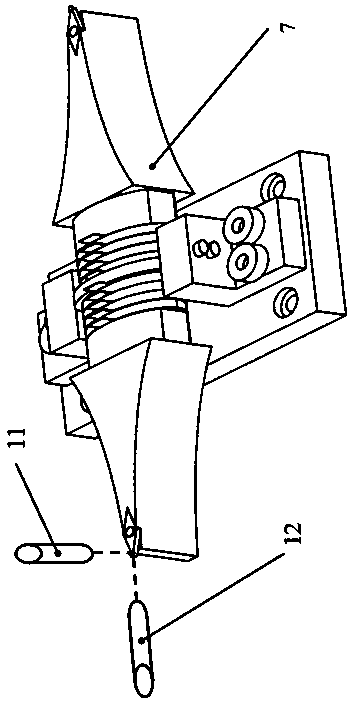

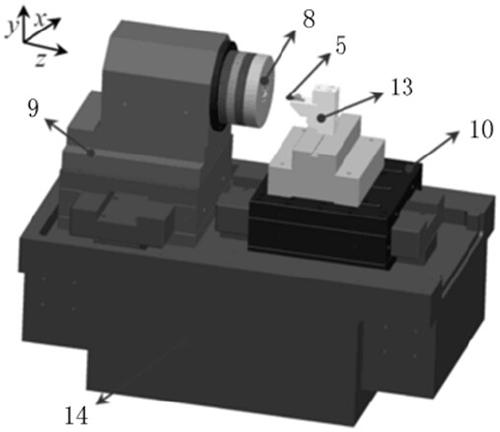

[0031] The invention provides a titanium alloy ultra-precision machining method based on ultrasonic elliptical vibration cutting technology, such as figure 1 As shown, the method is specifically completed according to the following steps:

[0032] 1. Preparatory work: Adjust and control the temperature, humidity and air cleanliness of the ultra-precision processing laboratory, among which: the temperature is controlled at 20±0.1°C, the humidity is controlled at 35±5%, and the cleanliness is controlled above 1000 grades.

[0033] 2. Test run of the machine tool: star...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com