Hole helical milling device

A technology of helical hole milling and milling cutter, applied in the field of milling processing, can solve problems such as affecting tool life and machining accuracy, unable to meet hole making requirements, poor local heat dissipation conditions, etc., to save tool inventory and tool change time, heat dissipation and Reduced chip evacuation difficulties and improved tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

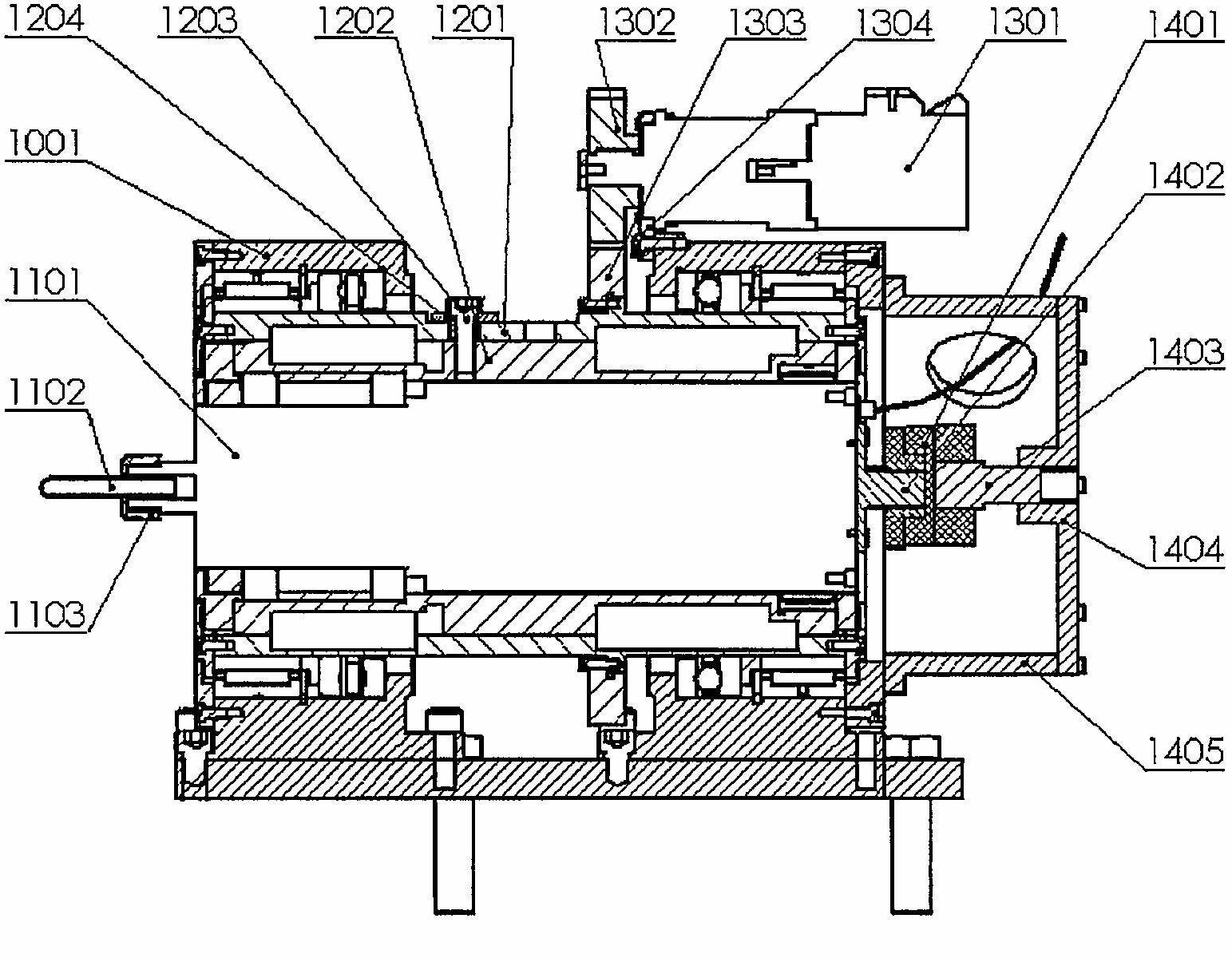

[0035] If you want to use a Φ8 milling cutter to process a Φ12 hole, you only need to fix the Φ8 milling cutter on the output shaft of the electric spindle 1101, manually screw the screw head taper pin 1203 through the threaded hole on the pin cover plate 1204, and screw it into the corresponding offset on the inner cylinder 1202 The taper pin hole is 2mm, and the equipment unit can start to power on and position and process the Φ12 hole.

[0036] Use the same Φ8 milling cutter to process Φ14 holes, only need to manually unscrew the screw head taper pin 1203 from the threaded hole on the pin cover plate 1204 after power off and stop, and use tools to make the inner cylinder 1202 relative to the outer cylinder 1201 is rotated until the taper pin hole corresponding to the offset distance of 3mm on the inner cylinder is aligned with the threaded hole on the pin cover plate 1204, and then re-screwed into the screw head taper pin 1203, and the machining of the Φ14 hole can be restar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com