Robotic hole making end effector

An end-effector, industrial robot technology, applied in the direction of manufacturing tools, boring/drilling, drilling/drilling equipment, etc., can solve the problems of thermal damage to the base material, severe tool wear, poor hole wall roughness, etc. Achieve the effect of improving delamination and tearing, enhancing process flexibility, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below in conjunction with the accompanying drawings.

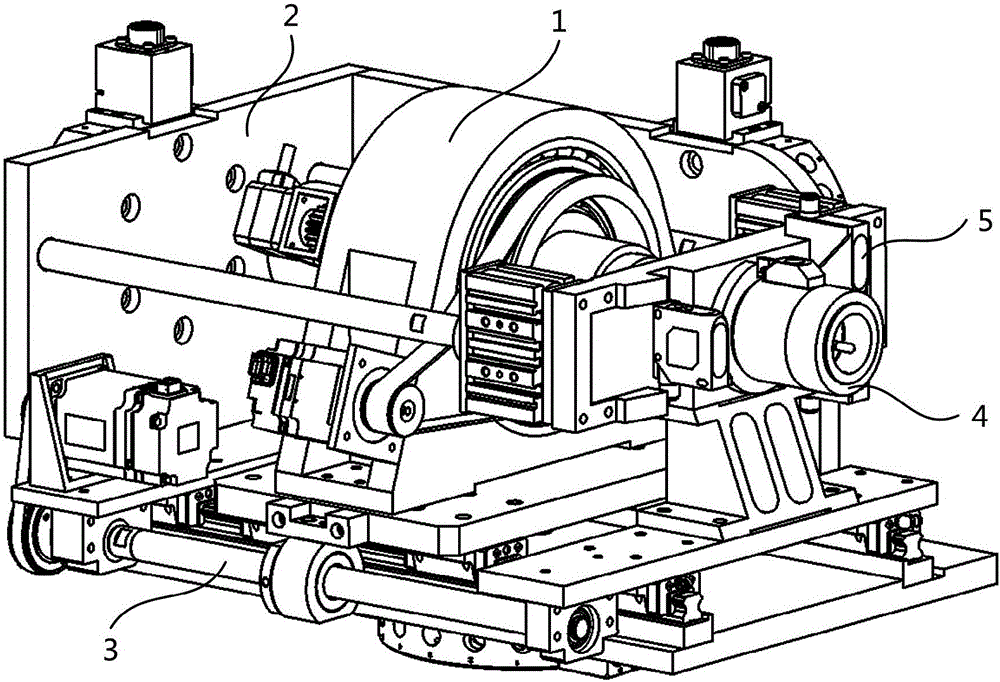

[0058] see figure 1 As shown, the robotic hole making end effector includes a cutting unit 1 , a connecting unit 2 , a feeding unit 3 , a pressing unit 4 and a measuring unit 5 . Before implementing hole making, the hole making end effector needs to move to the target hole position with the robot first; Numerical value, cooperate with verticality adjustment algorithm, complete the cutter 103 verticality adjustments before pressing; The measured value of the photoelectric distance sensor 52C cooperates with the verticality adjustment algorithm to complete the verticality adjustment of the tool 103 after pressing; the feed unit 3 drives the cutting unit 1 to perform planetary drilling and hole making on the workpiece.

[0059] (1) Cutting unit

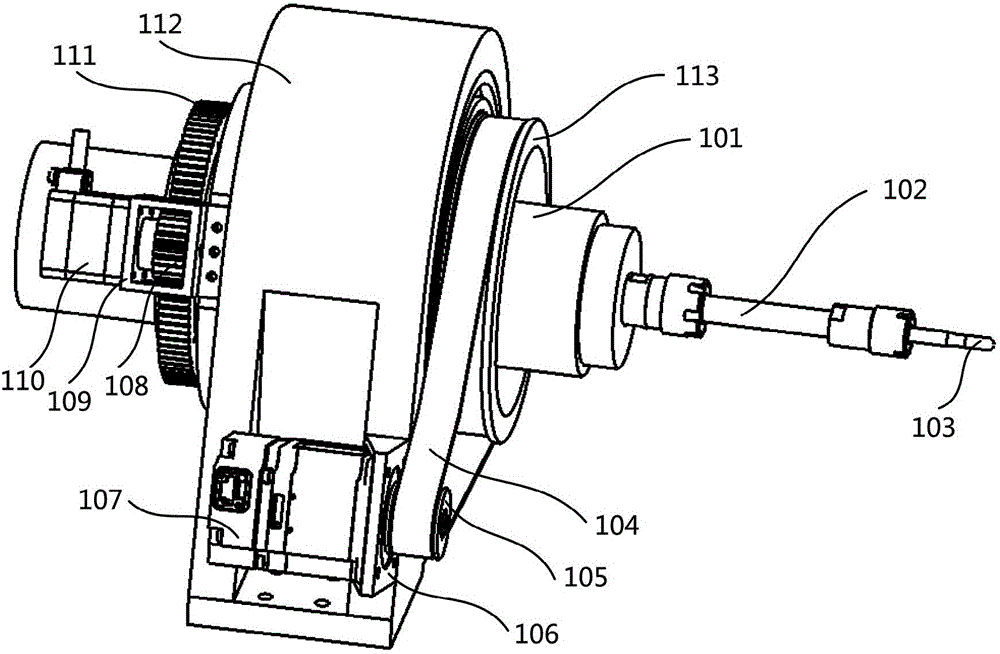

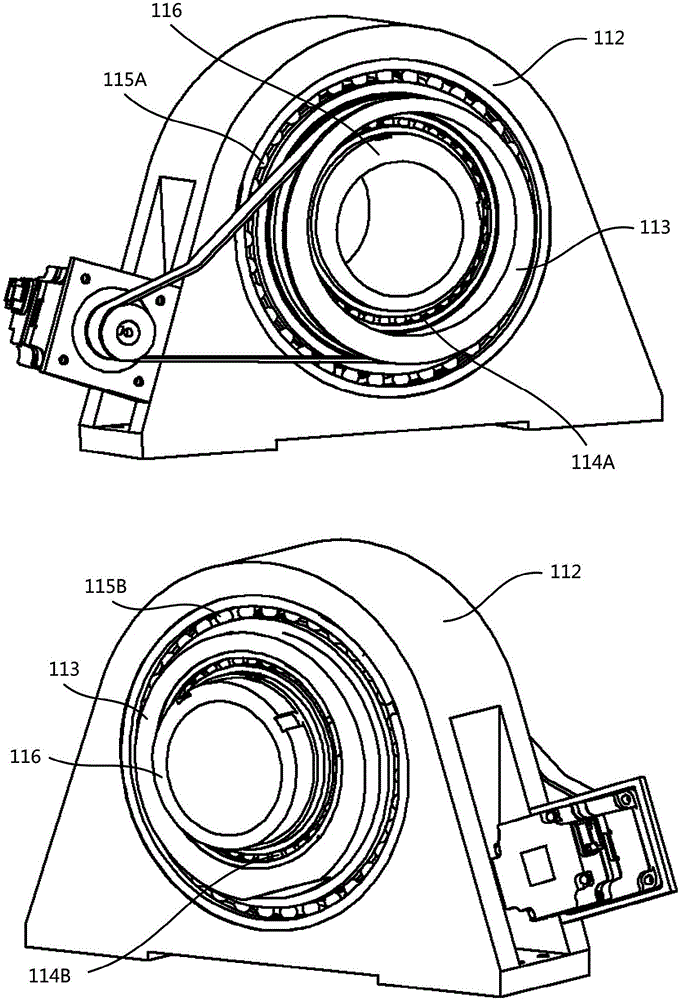

[0060] see figure 2 , Figure 2A and Figure 2B As shown, the cutting unit 1 includes an electric spindle 101,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com