Patents

Literature

31results about How to "Suppress glitch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

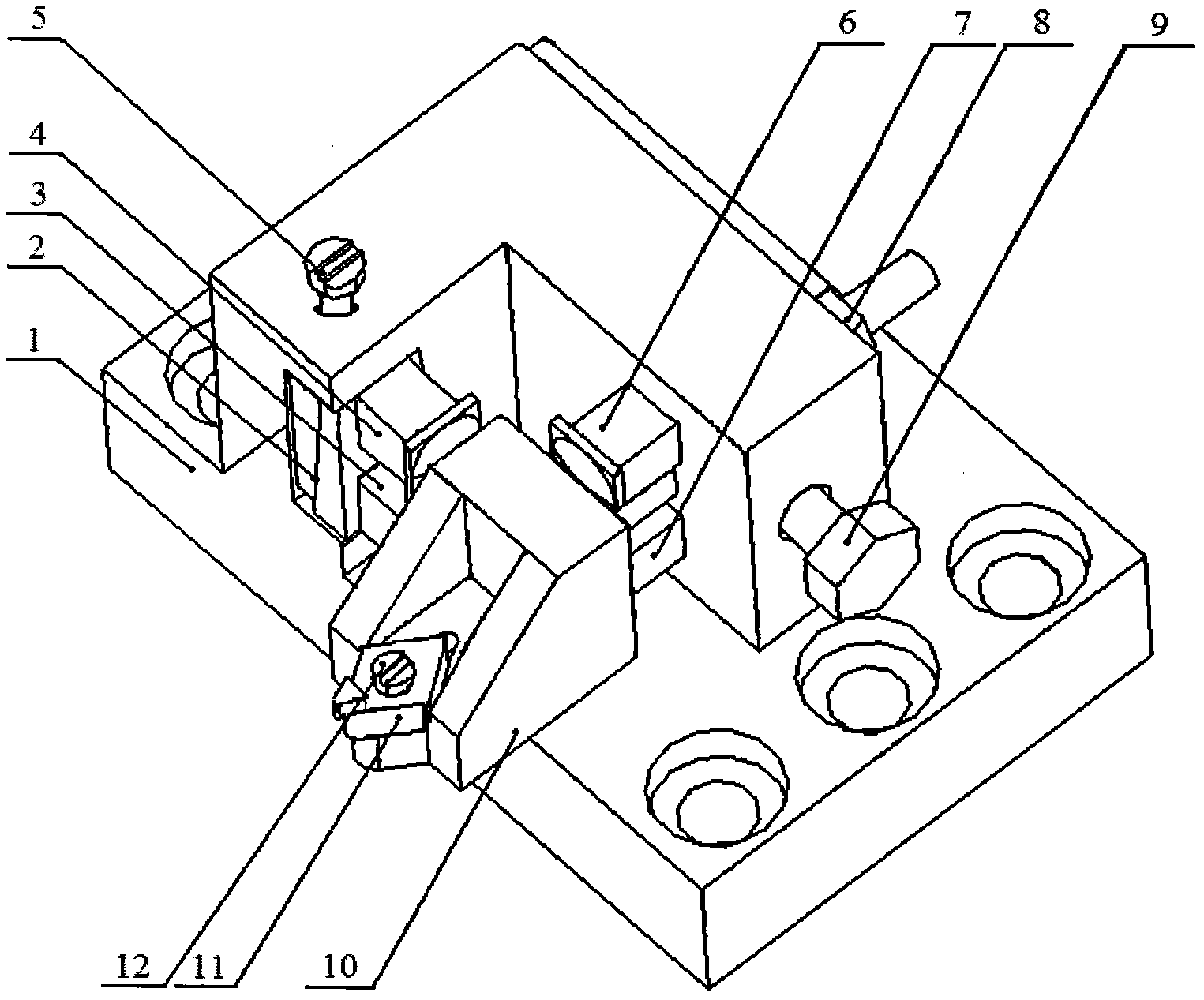

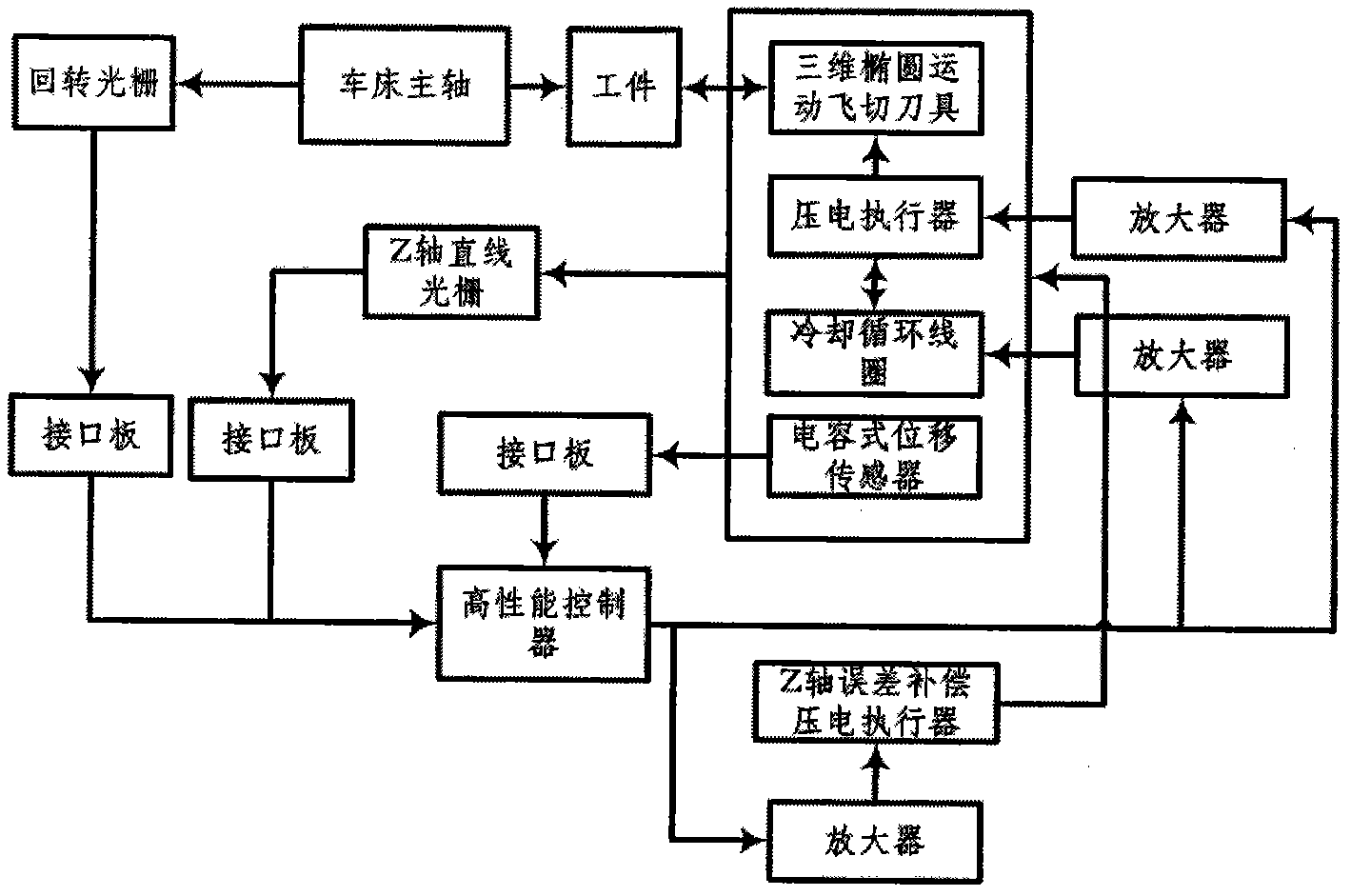

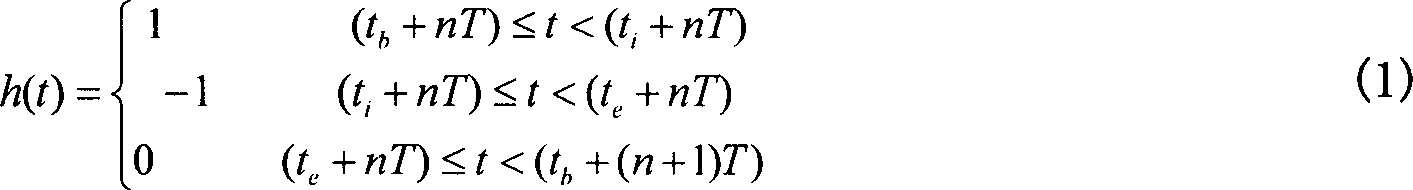

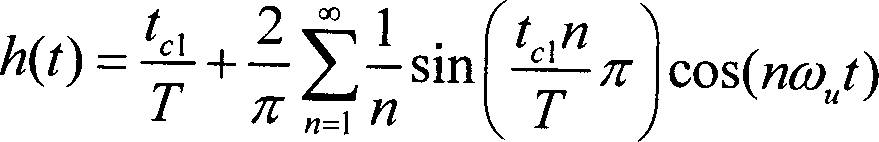

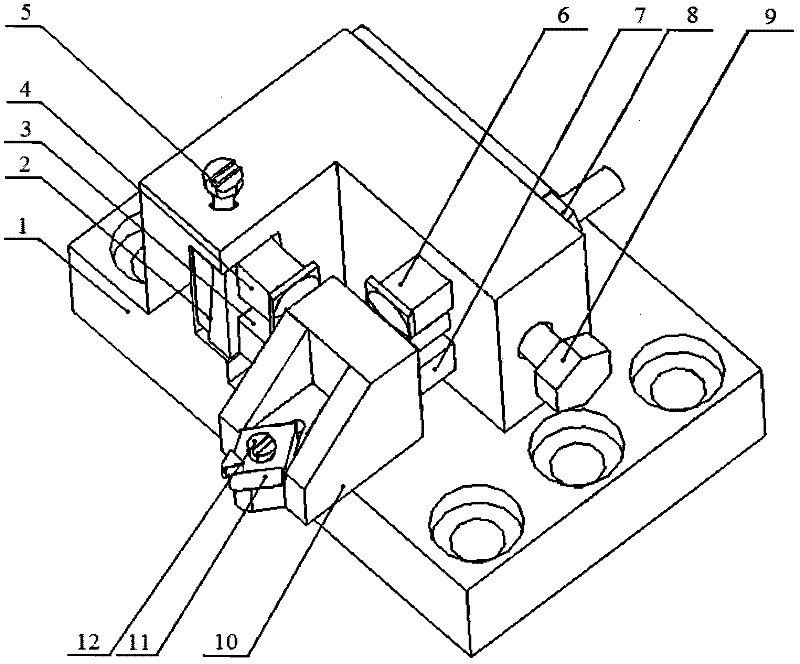

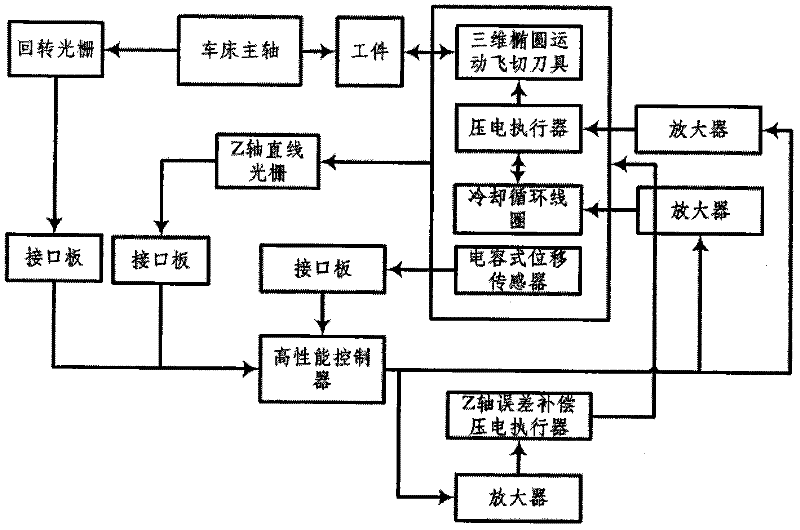

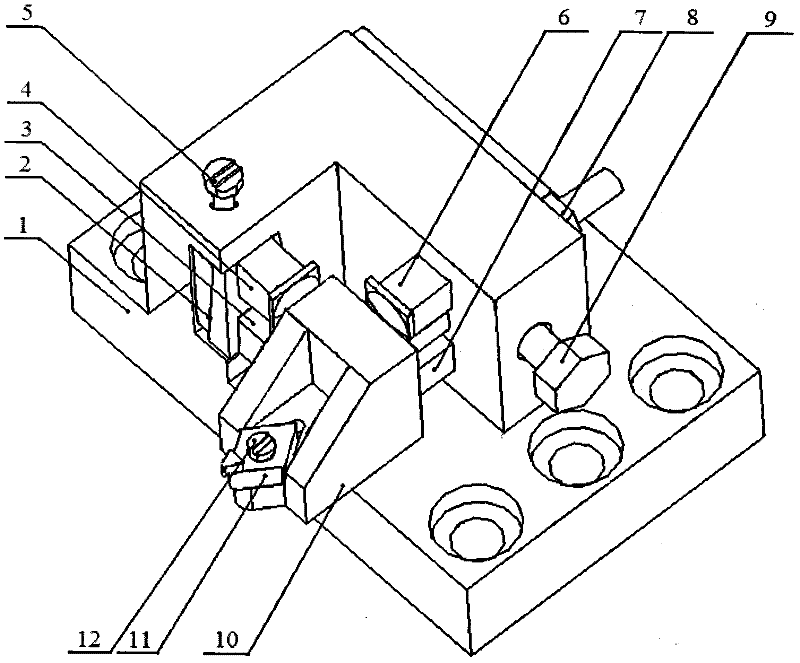

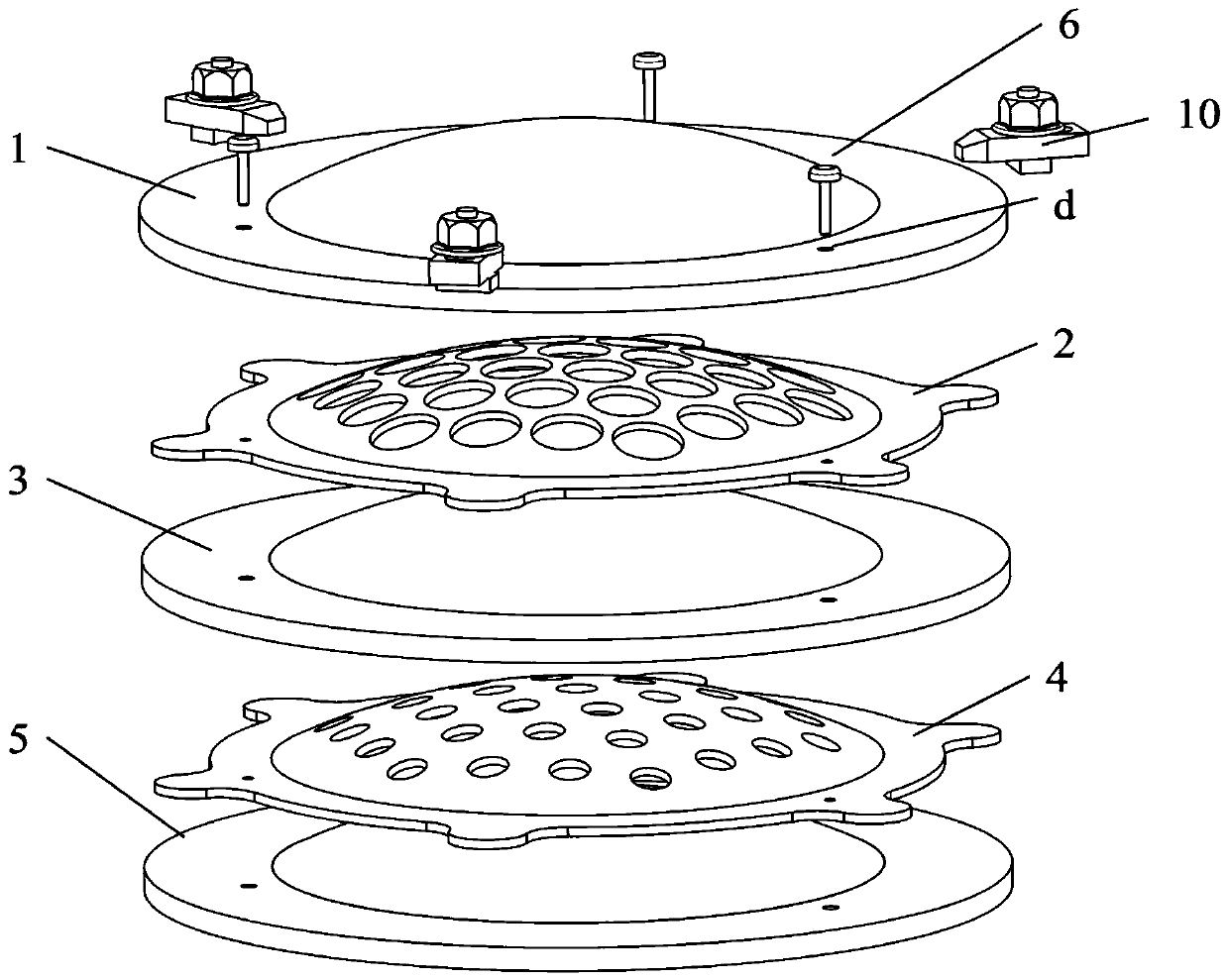

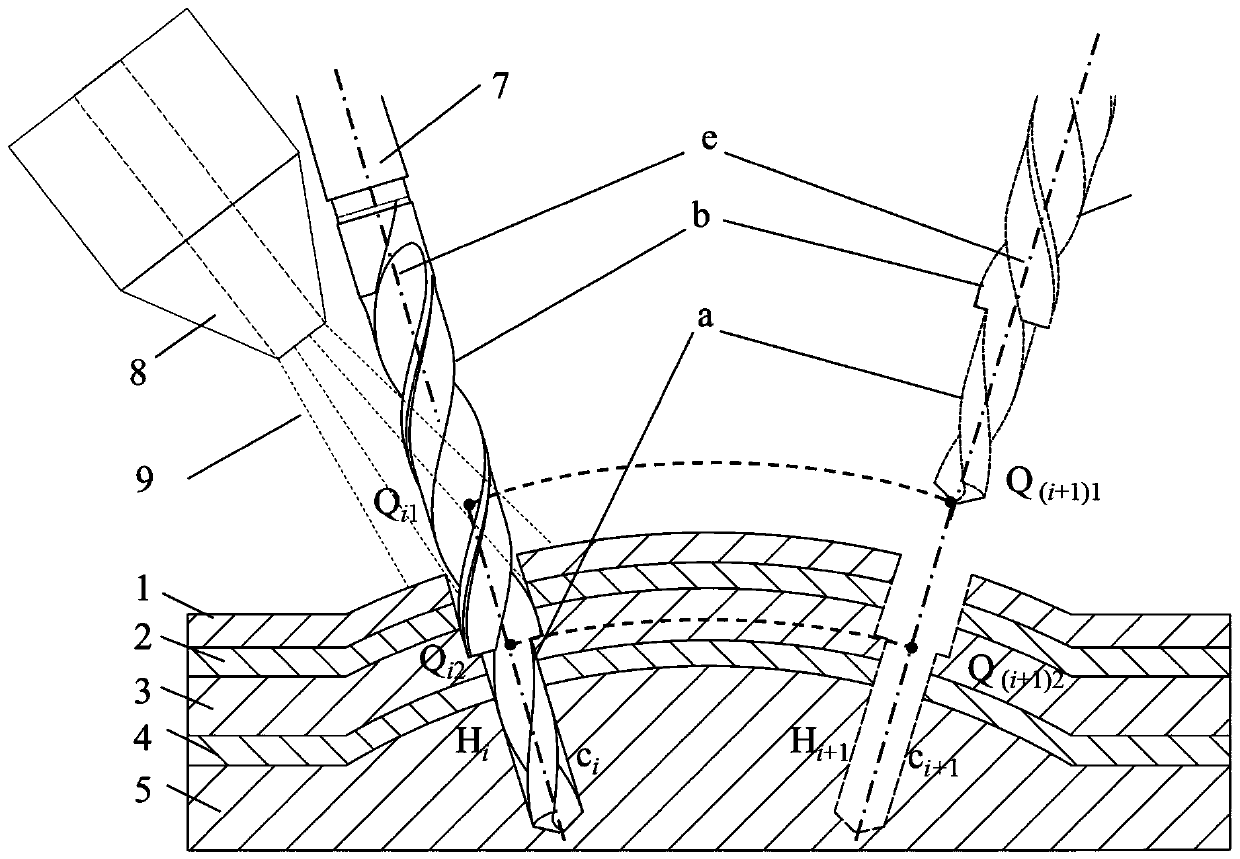

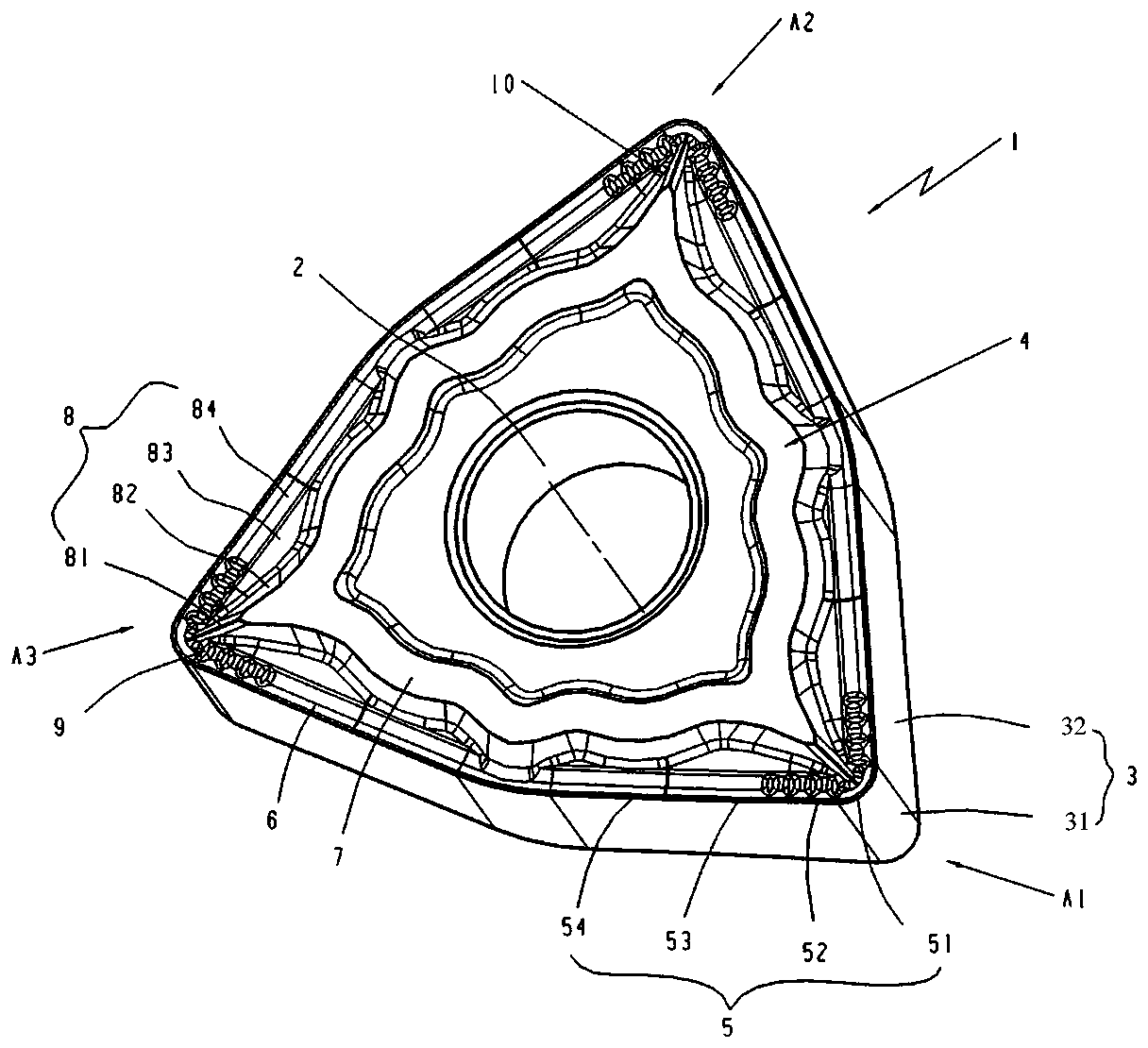

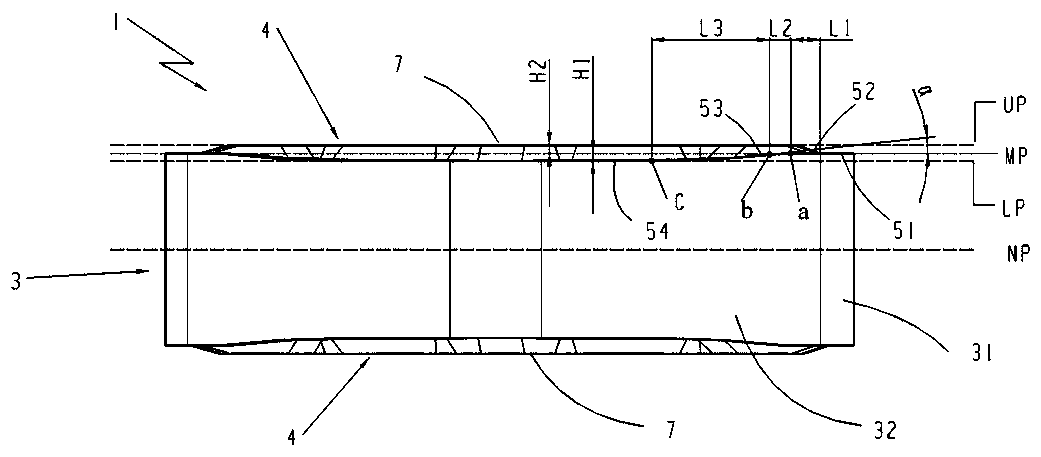

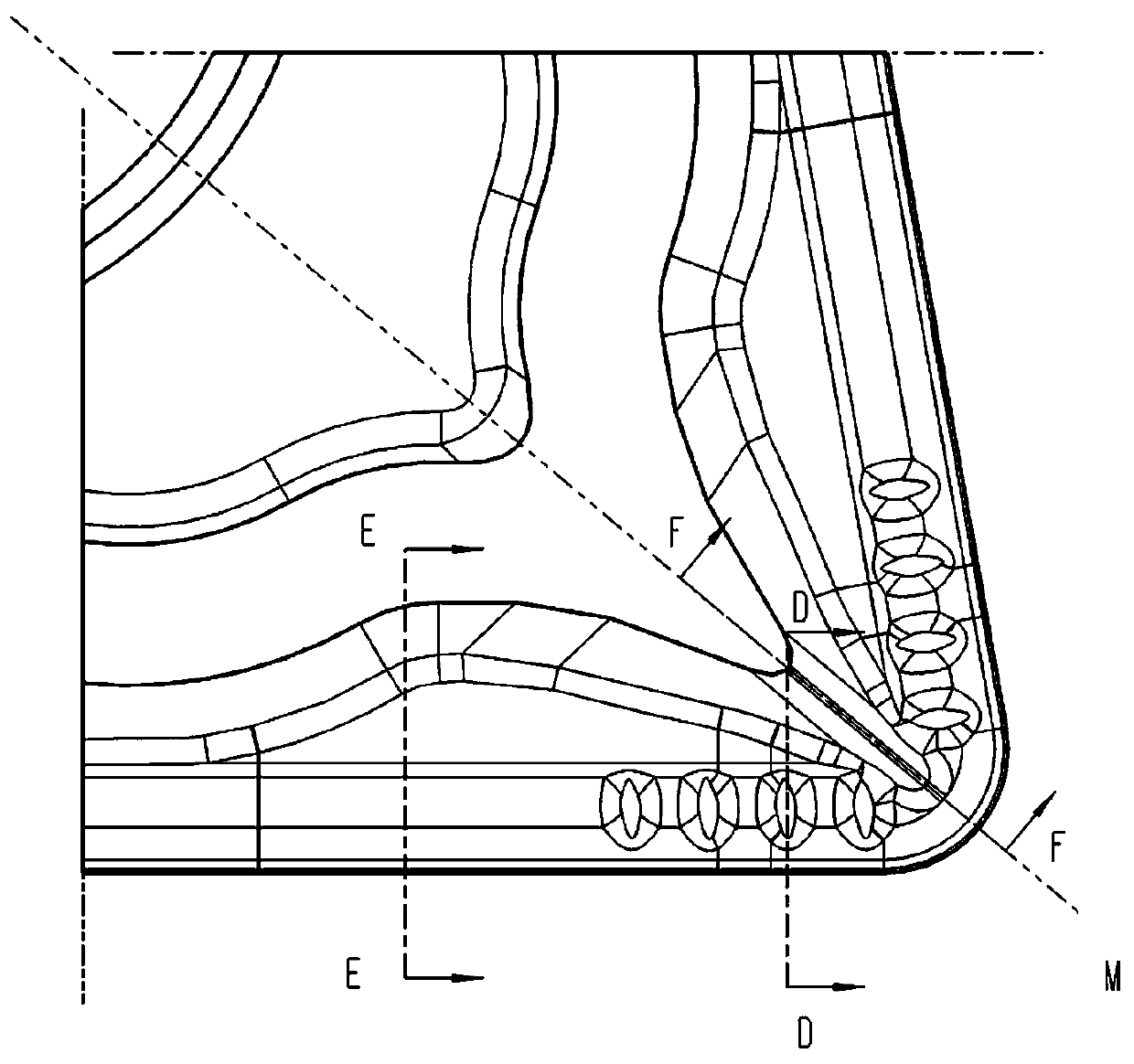

Non-resonant three-dimensional elliptical diamond fly-cutting optical free curved surface method and special device

The invention discloses a non-resonant three-dimensional elliptical diamond fly-cutting optical free curved surface method and a special device, belonging to the field of cutting technology of free curved surface of hard-processing materials. In the invention, a non-resonant driving mode is used to enable a diamond cutter to generate medium-high frequency or ultrahigh frequency three-dimensional elliptical movement in order to form high-speed or ultrahigh-speed diamond fly-cutting main movement; a cutter edge motion track is projected as reciprocating rectilinear movement on an x-z plane and is respectively projected as elliptical movement on an x-y plane and a y-z plane; the optical free curved surface is created on the basis of the combination of the movements of three-dimensional elliptical diamond fly cutting, X-axis feeding, Z-axis reciprocating feeding, worepiece rotary feeding, and the like. The invention also discloses a diamond cutter three-dimensional elliptical movement track generating device which are directly driven by four piezoelectric stacks, the three-dimensional elliptical movement parameters can be independently controlled, which is beneficial to the obtaining of optimal cutting performance, and the follow-up control of the three-dimensional elliptical movement avoids distortion in a real cutting process.

Owner:CHANGCHUN UNIV OF TECH

Ultrasonic elliptically vibrating boring process

InactiveCN1672839AEnsure adequate lubricationSolve the lack of cooling capacitySurface finishEllipse

The ultrasonic elliptically vibrating boring process in the field of precise machining technology includes the following steps: 1) adhering two piezoelectric ceramic chips onto two orthogonal surfaces of elliptically vibrating amplitude-varying rod; 2) applying sinusoidal voltage across the chips to make the chips to stretch and contract and the rod to bend and vibrate; 3) strengthening the bending and vibration of the rod; 4) making the boring cutter fixed to the tip of the rod obtain maximum elliptic vibration; 5) synthesizing the horizontal and vertical bending vibrations to obtain the elliptic vibration track in the edge of the boring cutter; and 6) fixing the elliptically vibrating amplitude-varying rod onto the boring rod via the vibration node. The present invention has greatly reduced boring force, reduced boring rod deformation, raised stability of the boring system and raised boring precision and surface smoothness.

Owner:SHANGHAI JIAO TONG UNIV

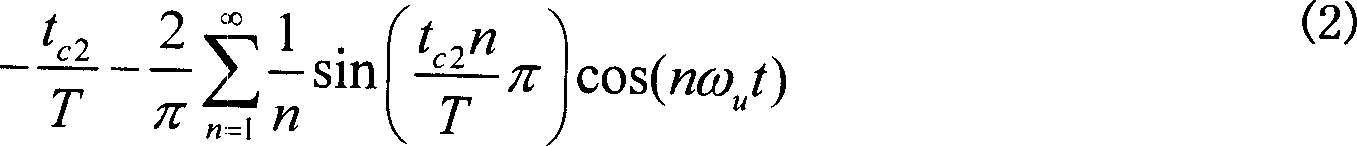

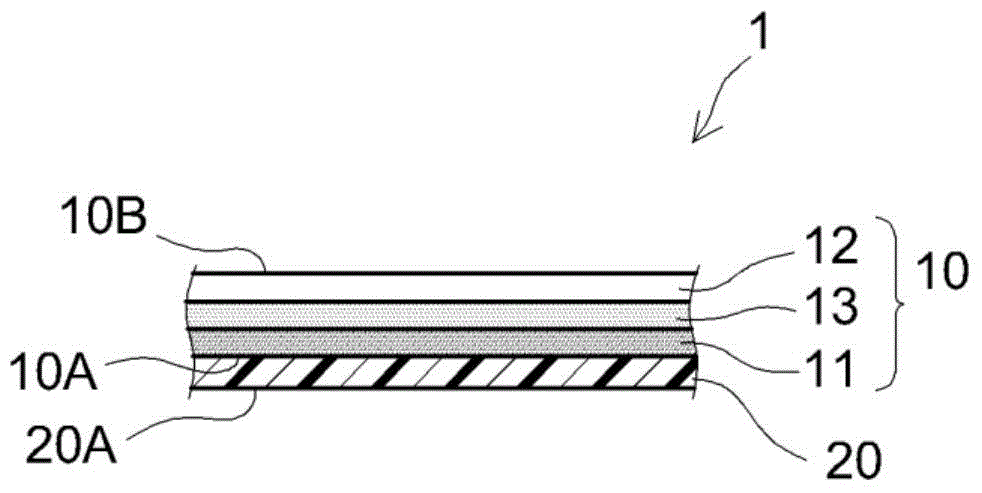

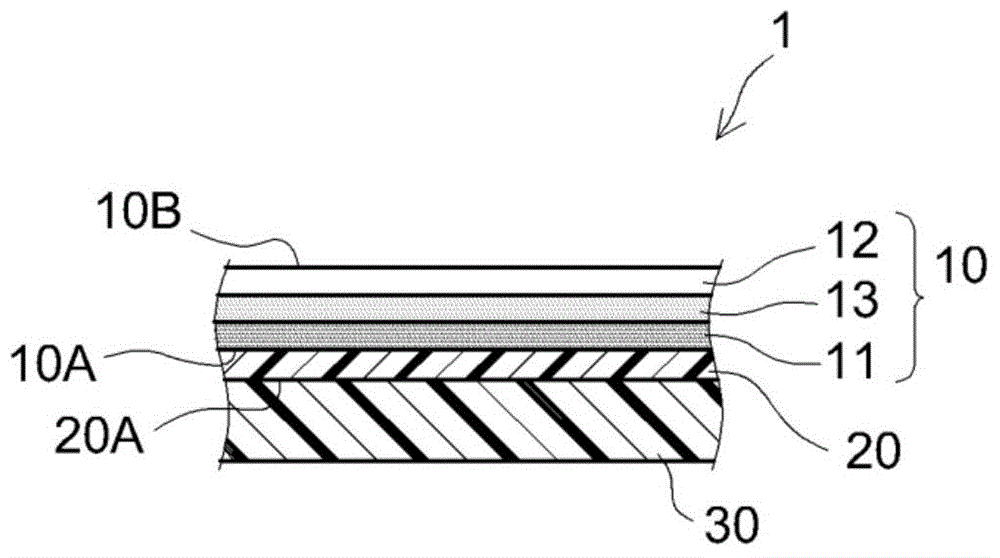

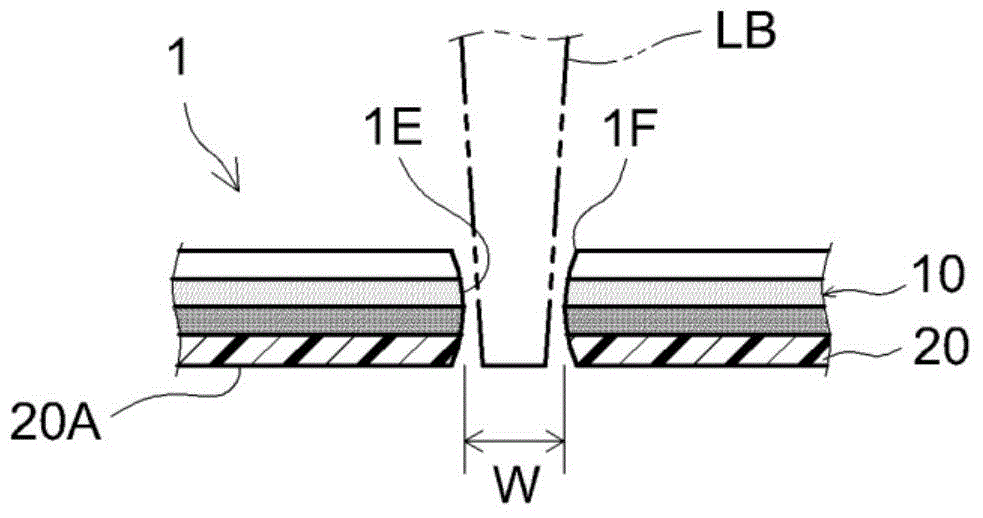

Pressure-sensitive adhesive film for laser beam cutting applications

InactiveCN105542672APrevent discolorationSuppress glitchFilm/foil adhesivesAdhesive articlesEngineeringLength wave

Owner:NITTO BELGIUM NV +1

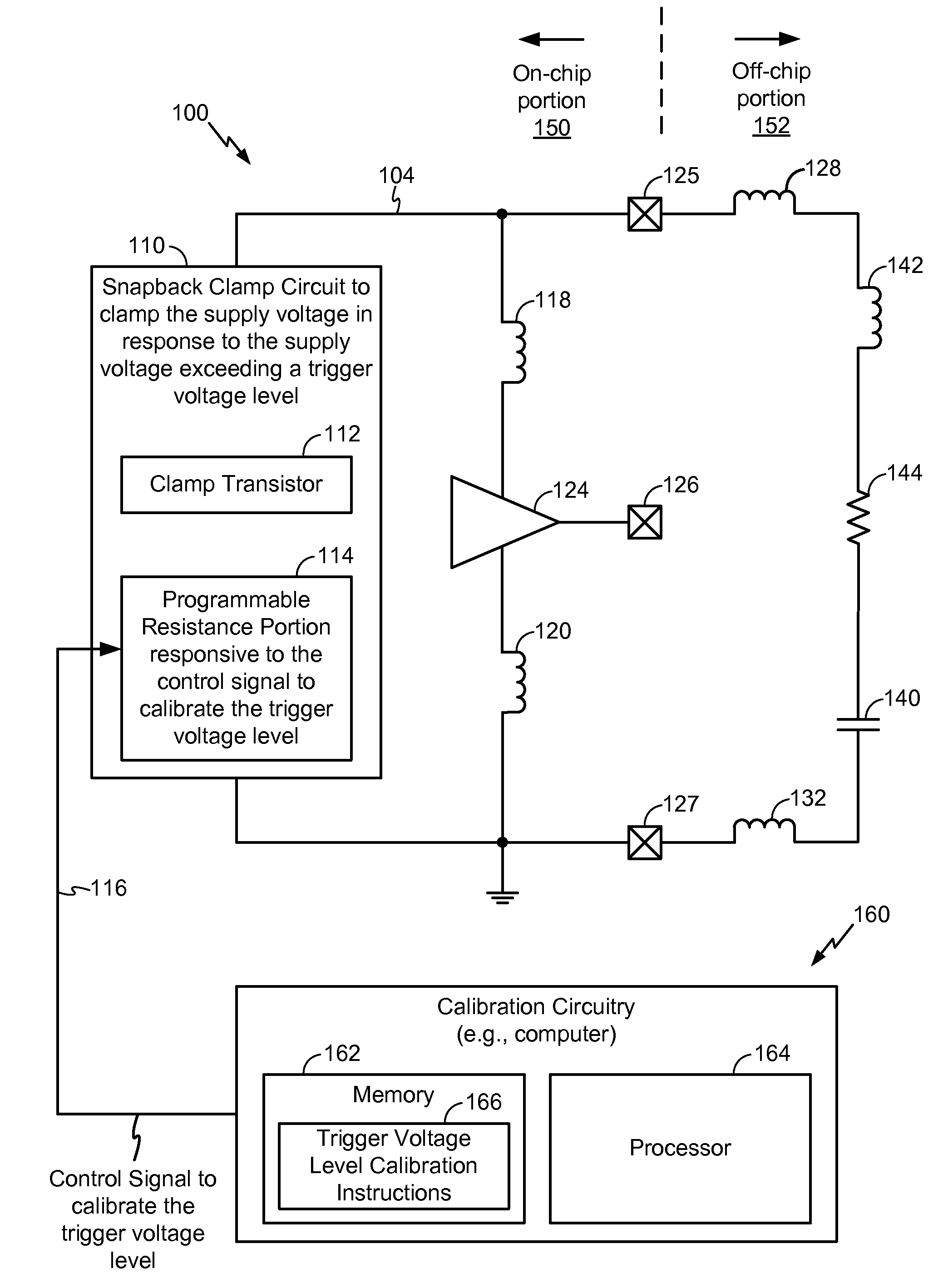

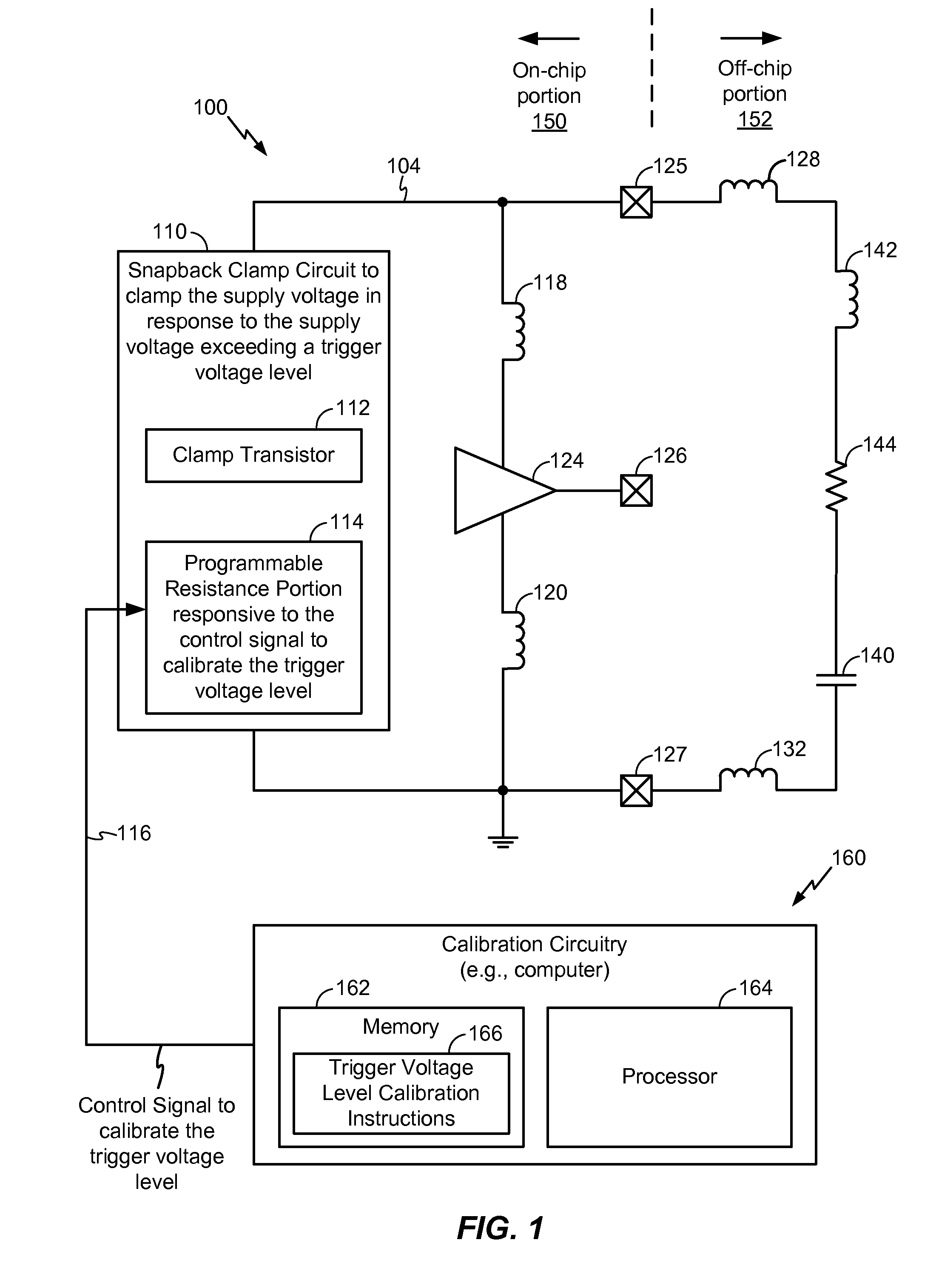

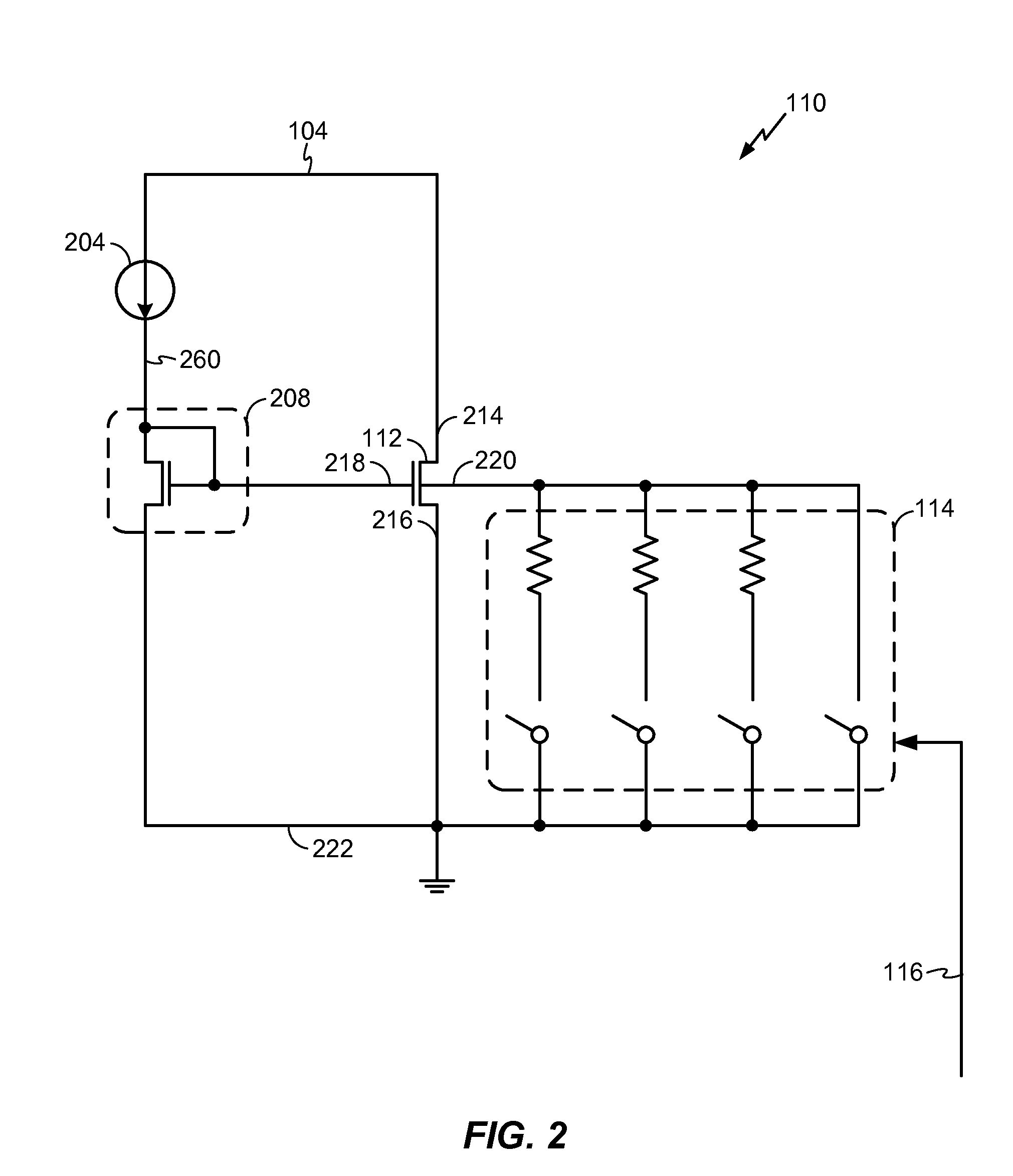

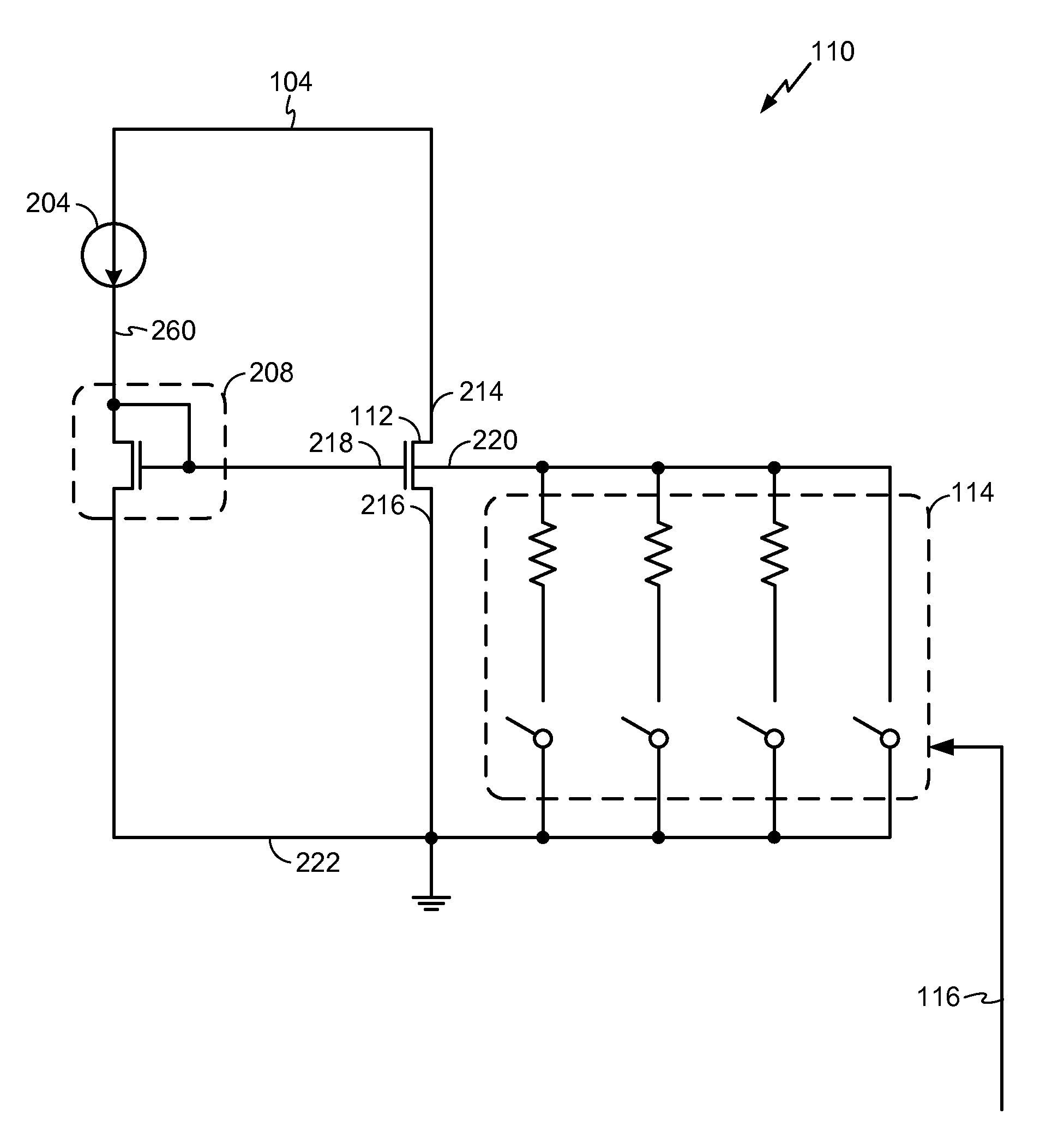

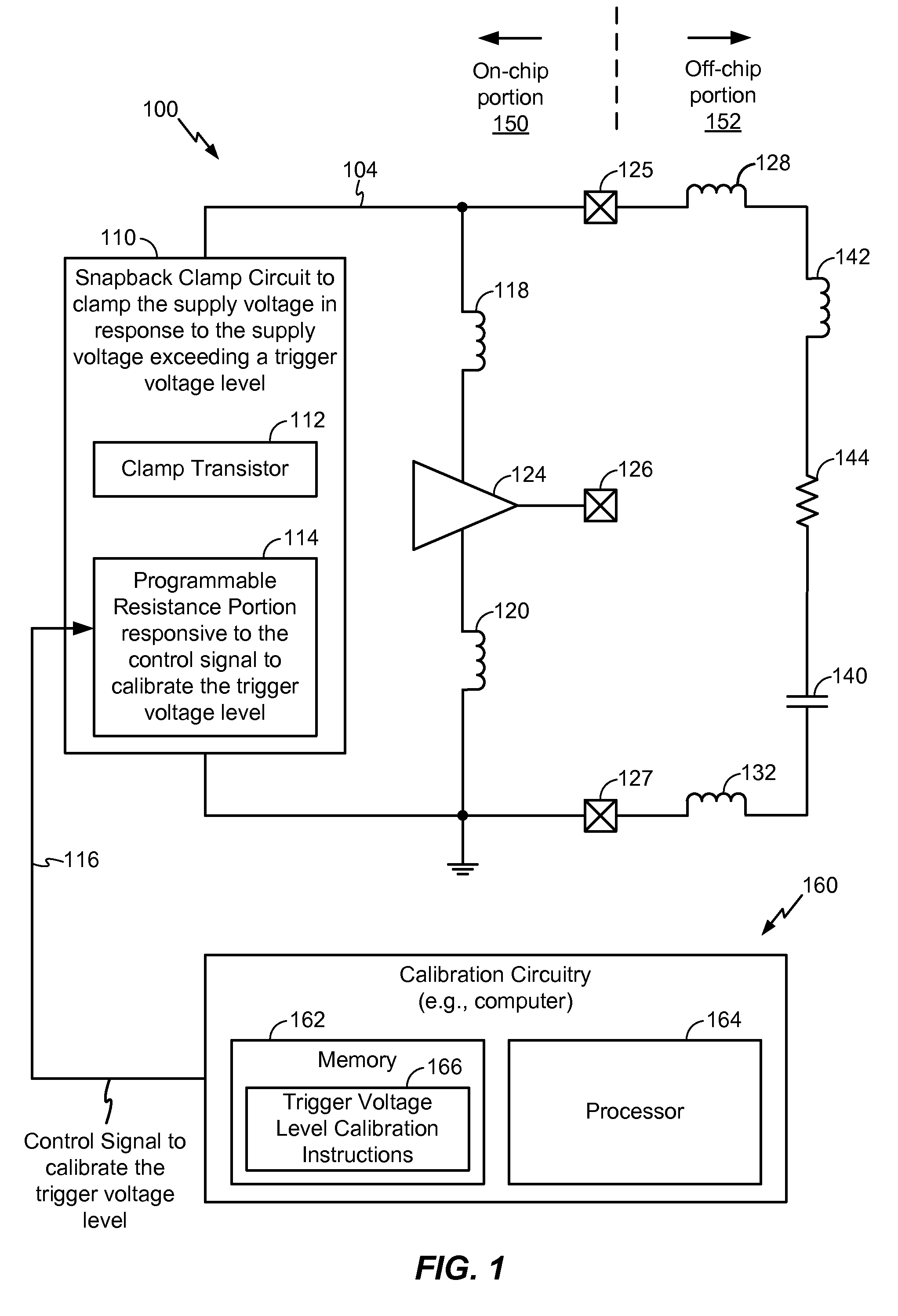

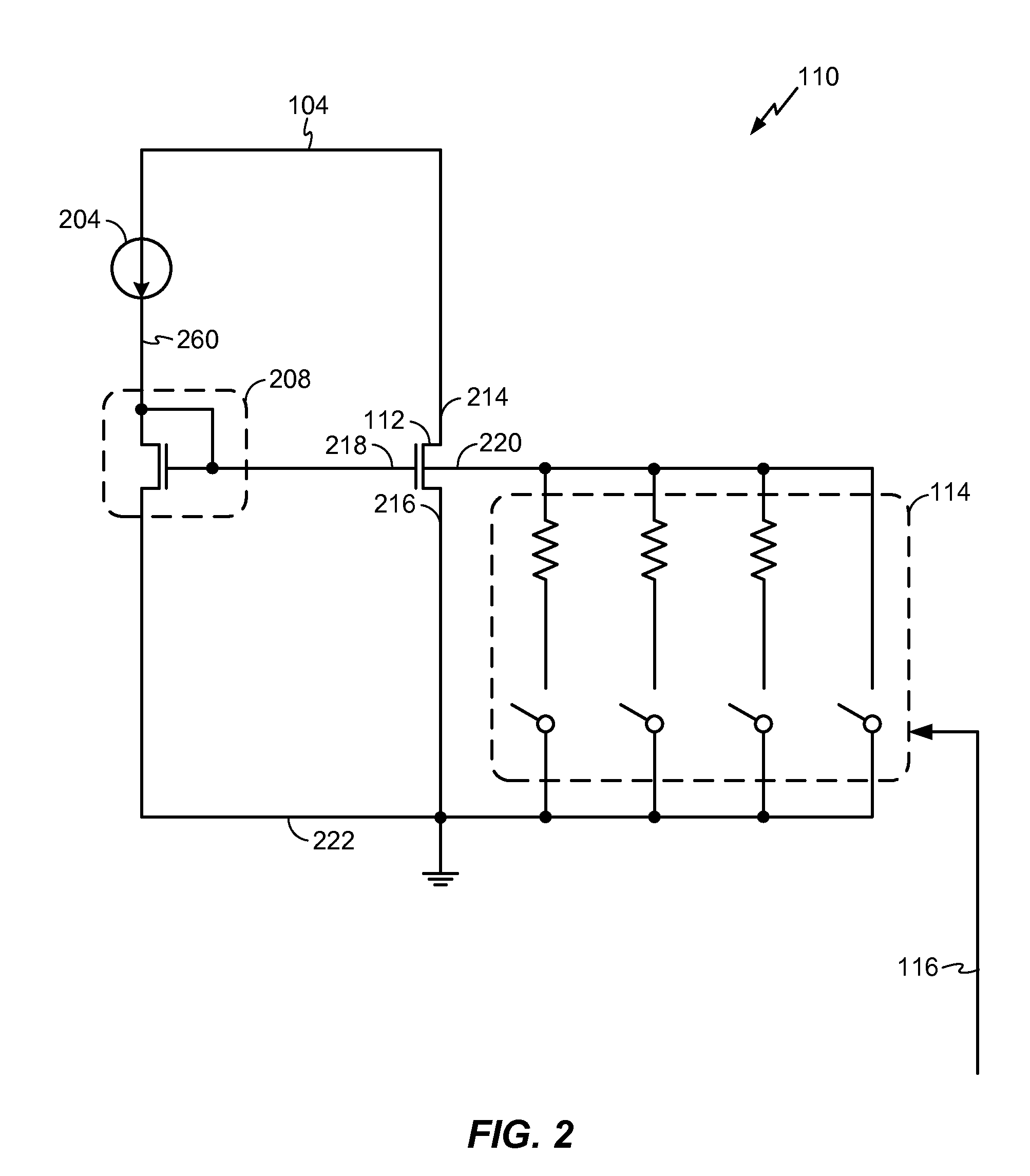

Devices and methods for calibrating and operating a snapback clamp circuit

ActiveUS20140254051A1Dissipate currentFast response timeTransistorParameter calibration/settingControl signalIntegrated circuit

A device includes a snapback clamp circuit configured to clamp a supply voltage in response to the supply voltage exceeding a trigger voltage level. In at least one embodiment, the snapback clamp circuit includes a clamp transistor and a programmable resistance portion that is responsive to a control signal to calibrate the trigger voltage level. Alternatively or in addition, the snapback clamp circuit may include a programmable bias device configured to calibrate the trigger voltage level by biasing a gate terminal of the clamp transistor. In another particular embodiment, a method of calibrating a snapback clamp circuit is disclosed. In another particular embodiment, a method of operating an integrated circuit is disclosed.

Owner:QUALCOMM INC

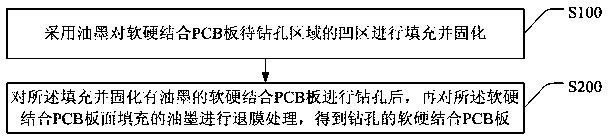

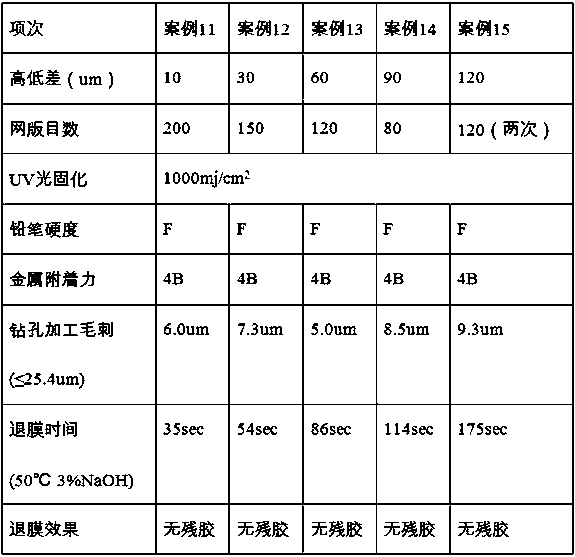

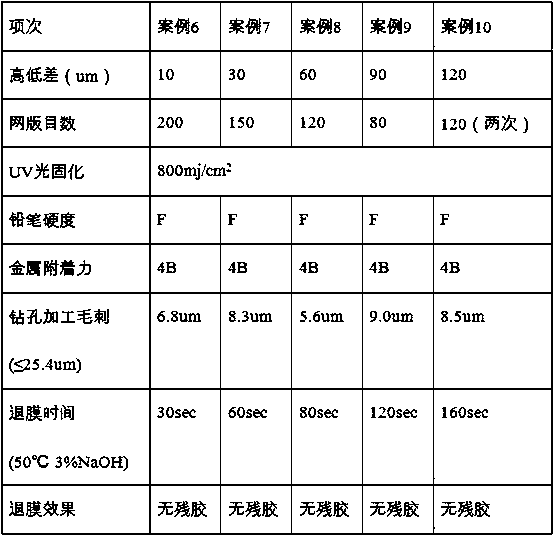

A method for improving height difference drilling of a soft-hard bonded PCB

InactiveCN108990283AImprove the problem of height difference drillingLower control costsPrinted circuit manufactureHardnessHeight difference

The invention discloses a method for improving the height difference drilling of a soft-hard bonded PCB, wherein, the method comprises the following steps: filling and curing the concave area of the area to be drilled of the soft-hard bonded PCB board by using ink; After drilling the soft-hard bonded PCB board filled with the ink and solidified, the ink filled on the surface of the soft-hard bonded PCB board is subjected to film demoulding treatment to obtain the soft-hard bonded PCB board drilled. As that ink is selectively filled in the concave area of the area to be drilled of the PCB board, the cost can be control better than that of the whole board surface coating; And the soft-hard bonded PCB after filling and solidifying ink can effectively restrain burr produced in the drilling process of the soft-hard bonded PCB due to no dead-angle filling of ink and high coating hardness after bonding the cover plate and the pad plate, thereby effectively improving the problem of PCB heightdifference drilling.

Owner:SHENZHEN NEWCCESS IND

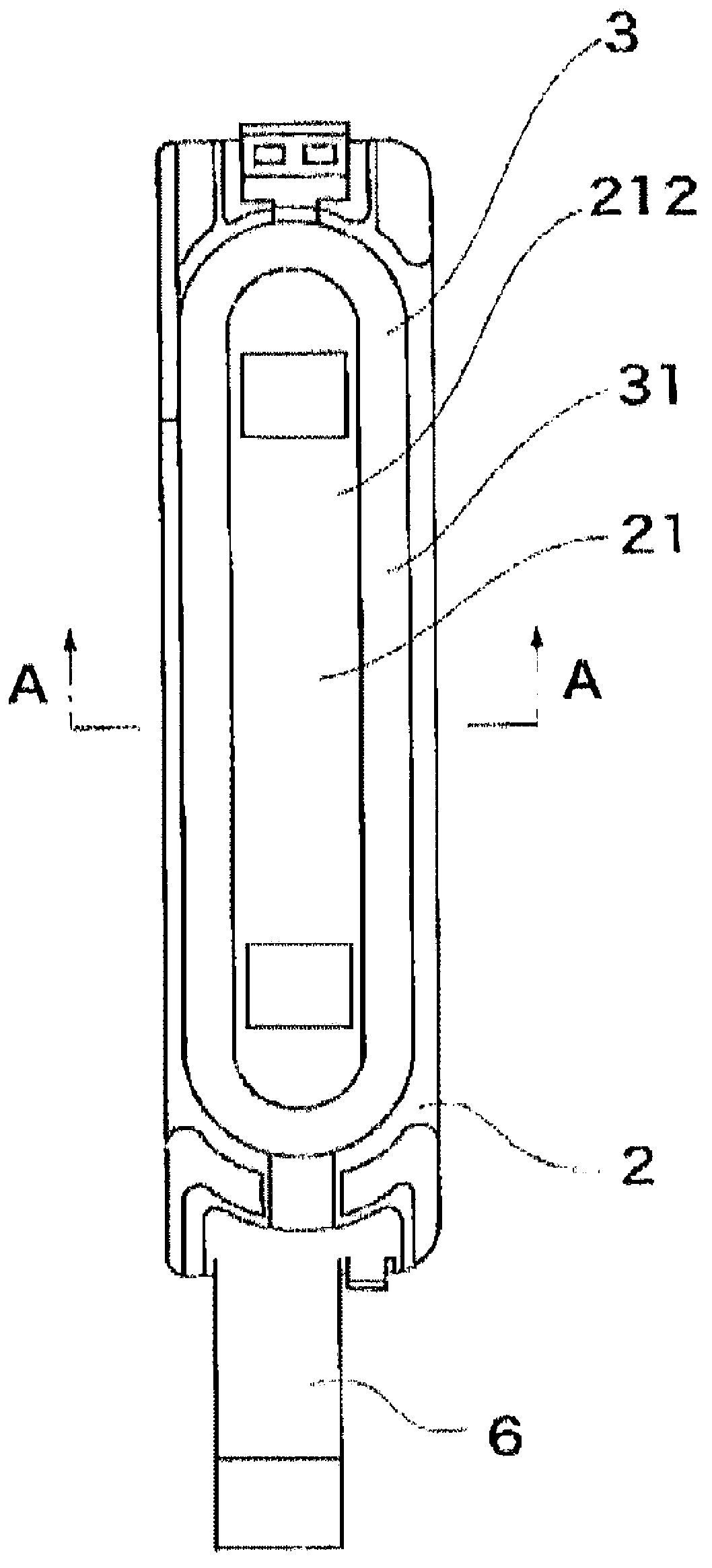

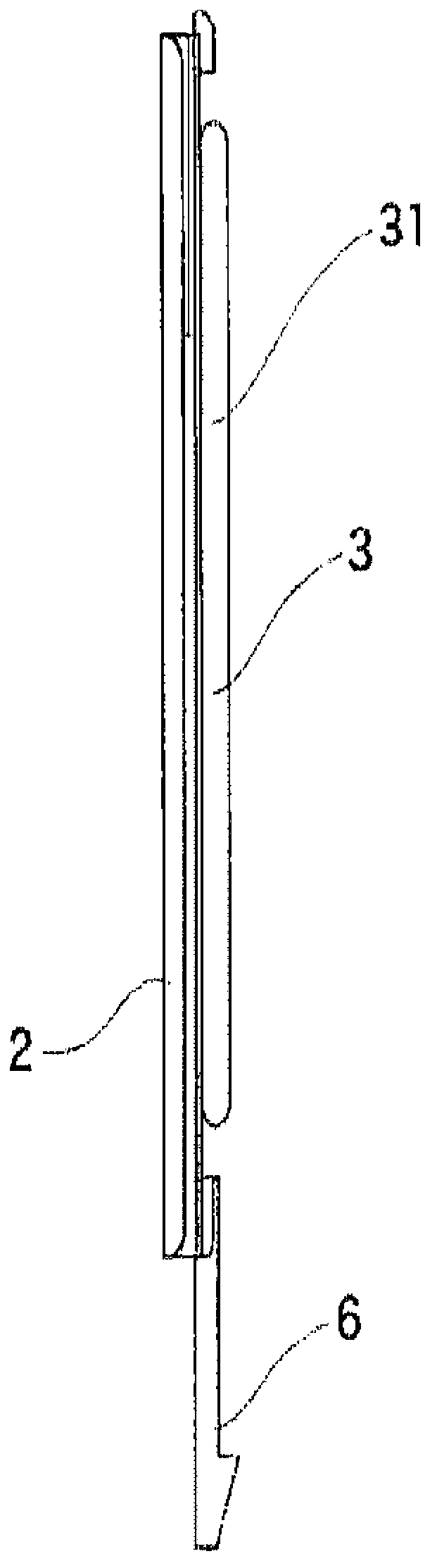

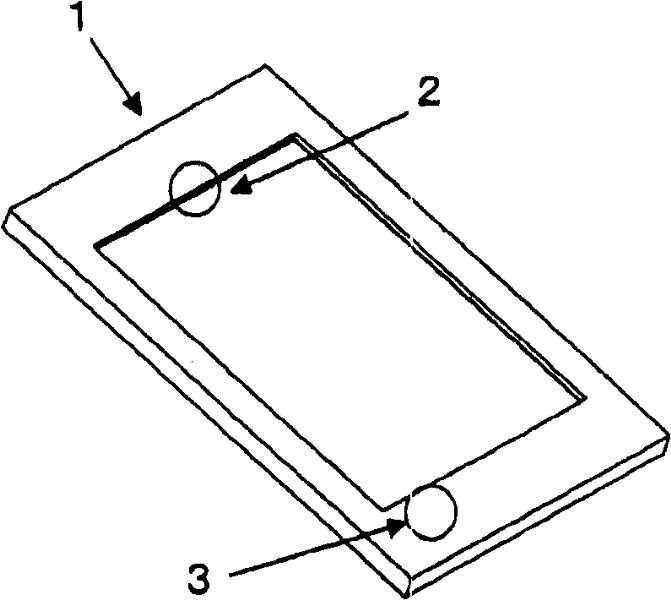

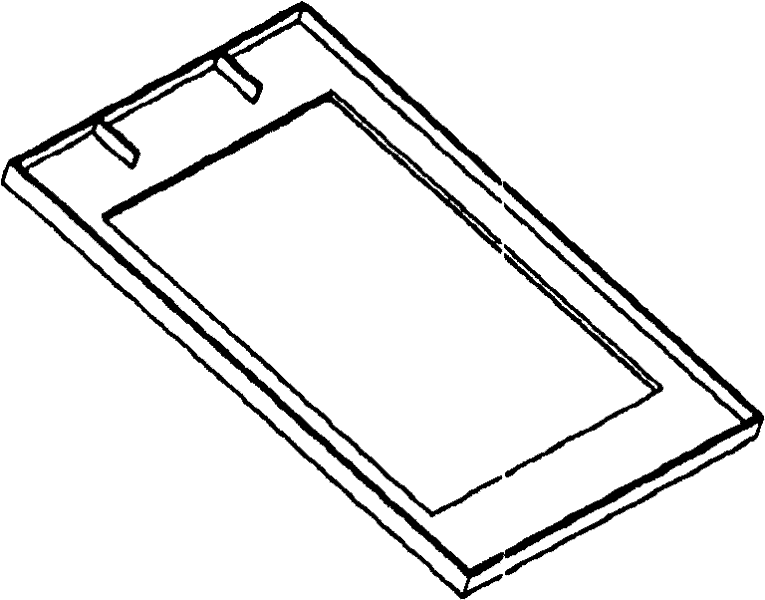

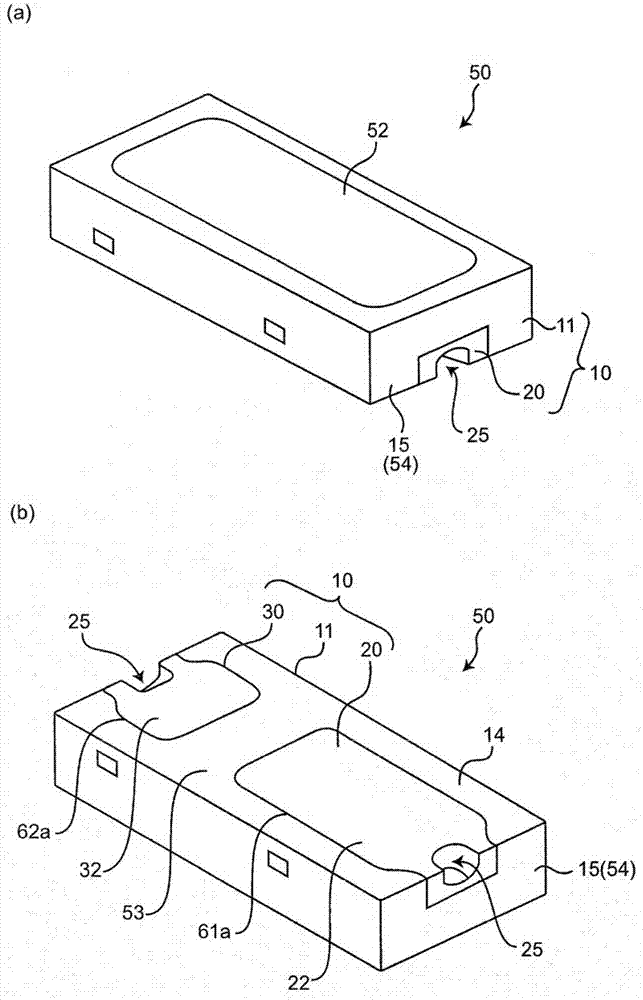

Lid member with waterproof function, and method of manufacturing thereof

InactiveCN103262354AAppropriate useWith waterproof functionCouplings bases/casesSubstation equipmentThermoplastic elastomerEngineering

The objective of the present invention is to be able to provide a lid member with a waterproof function that can be made thinner, and wherein burr leaking can be inhibited, damages to the lid member can be eliminated, and peeling off between the lid member and a sealing section can be prevented, by having the sealing section, which is made of rubber-like elastic material, formed in integration to the lid member. Provided, in order achieve this objective, is a lid member with a waterproof function that opens / closes an opening section formed on a housing, and that is configured to be composed of: a protruding section that is formed integrally onto one face of a resin body of the lid member, and that fits into the opening section; a ring-shaped protruding section that is formed integrally onto an outer circumference face of the protruding section, and that comes in close contact with the circumferential face of the opening section; a sealing section that is made of rubber-like elastic material, and that is equipped with a reinforcement section that extends from the ring-shaped protruding section to the vicinity of a joining section between the outer circumference face and the body; and a holding section that is made of a thermoplastic elastomer material, that is formed integrally onto the body side, and that is in close contact with the outer circumference face side of the reinforcement section.

Owner:NIPPON MEKTRON LTD

Adhesive film for semiconductor, composite sheet, and method for producing semiconductor chip using them

InactiveCN101641766AExcellent moisture resistance reliabilitySuppression of chip cracks or burrsFilm/foil adhesivesSolid-state devicesDiamineChemistry

There is provided an adhesive film for a semiconductor, which can be attached to a semiconductor wafer at low temperature and which allows semiconductor chips to be obtained at high yield from the semiconductor wafer while sufficiently inhibiting generation of chip cracks and burrs. The adhesive film for a semiconductor comprises a polyimide resin that can be obtained by reaction between a tetracarboxylic dianhydride containing 4,4'-oxydiphthalic dianhydride represented by chemical formula (I) below and a diamine containing a siloxanediamine represented by the following general formula (II) below, and that can be attached to a semiconductor wafer at 100 DEG C or below.

Owner:HITACHI CHEM CO LTD

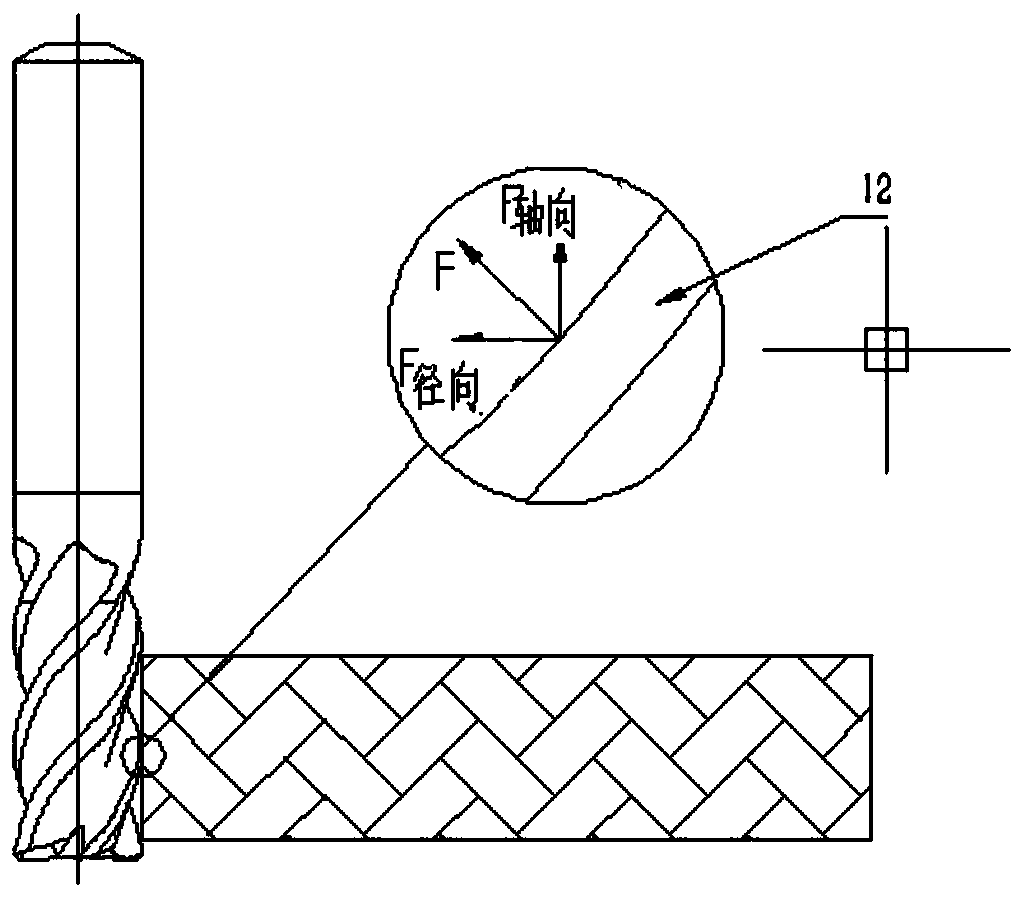

Diamond fly-cutter milling method for micro grooves in ferrous metal material base

InactiveCN106270686AHas separation propertiesSuppresses rapid spreading wearMilling equipment detailsTransducerMetallic materials

The invention discloses a diamond fly-cutter milling method for micro grooves in a ferrous metal material base. The method comprises the steps that a cutter bar of a diamond fly-cutter is connected with a two-dimensional ultrasonic elliptical vibration transducer, and the diamond fly-cutter is fixed to the end of the cutter bar; the elliptical vibration transducer is fixed to a spindle of a diamond fly-cutter milling machine; a sine-wave voltage is exerted on the elliptical vibration transducer, the diamond fly-cutter conducts ultrasonic elliptical vibration along with two-dimensional elliptical vibration generated by the elliptical vibration transducer, meanwhile, the diamond fly-cutter conducts axial and radial feeding milling motion on the ferrous metal material base along with the spindle of the milling machine, and therefore ultrasonic elliptical vibration and diamond fly-cutter milling are realized. Through the method, sharp diffusive wear of the diamond fly-cutter in the process of milling the micro grooves in the ferrous metal material base can be effectively restrained, generation of burrs at the edges of the micro grooves is restrained, the morphological precision of the micro grooves is improved, and diamond fly-cutter precise milling of the micro grooves is realized.

Owner:SHANGHAI JIAO TONG UNIV

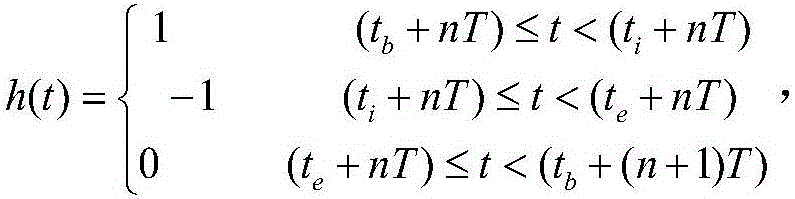

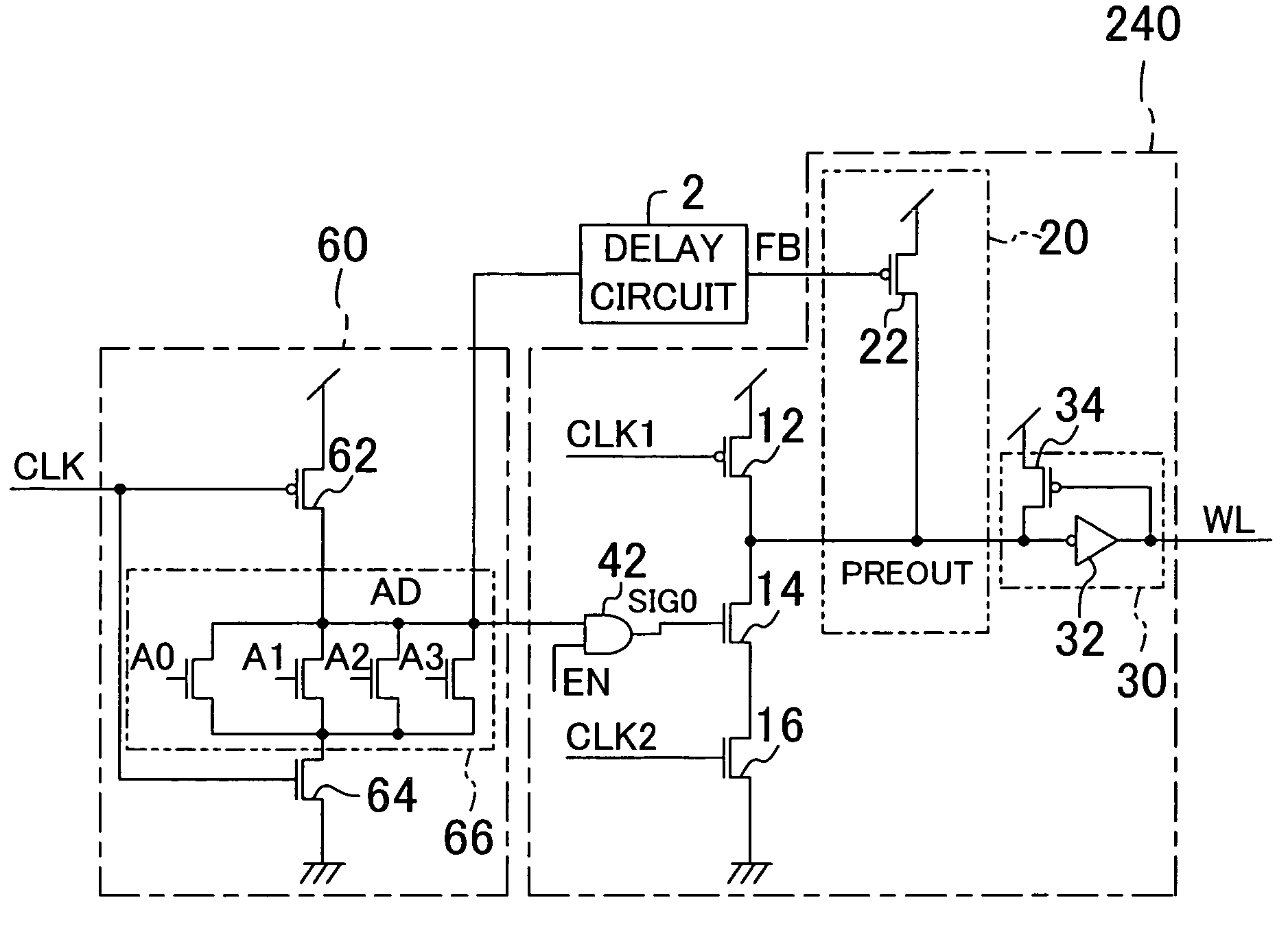

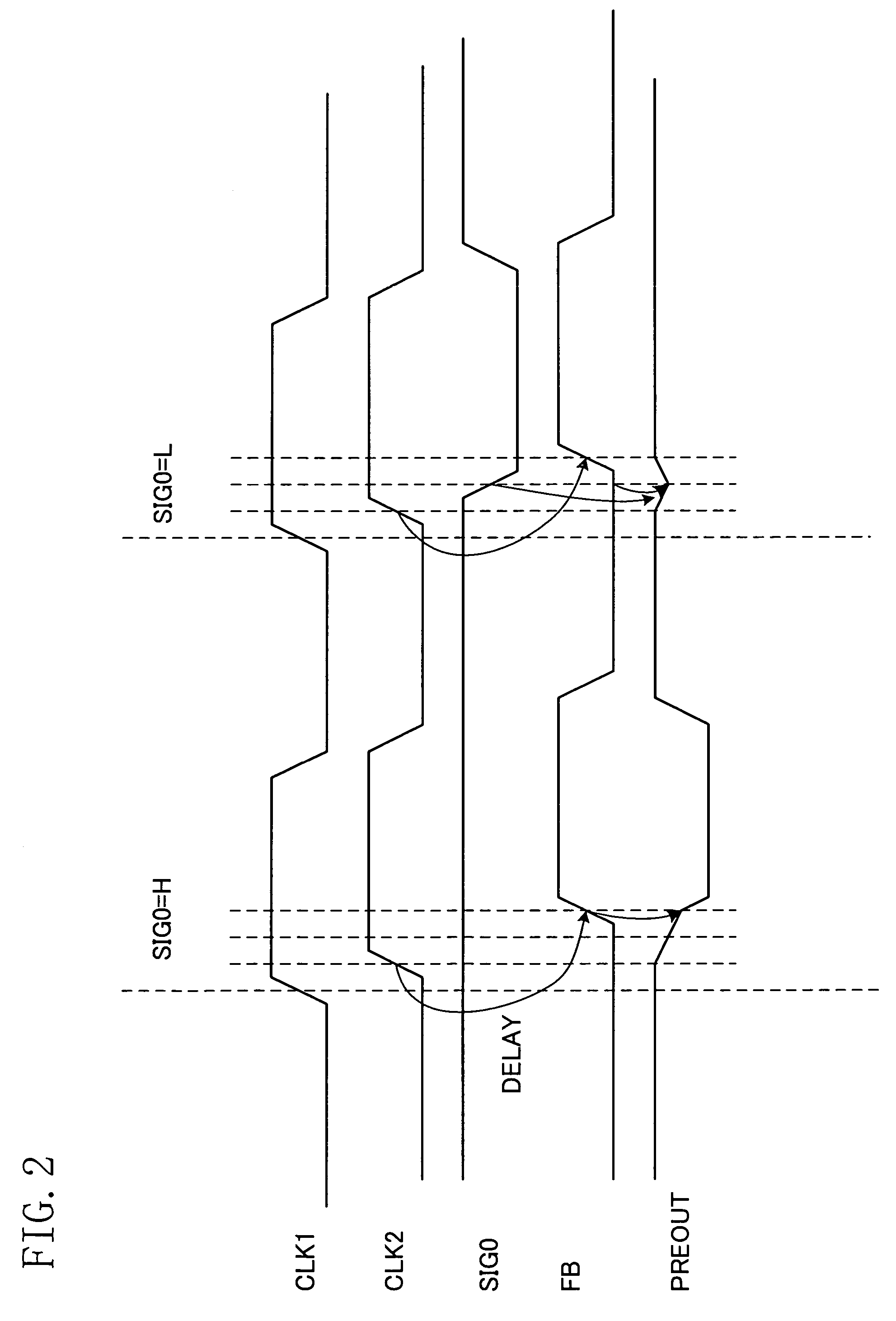

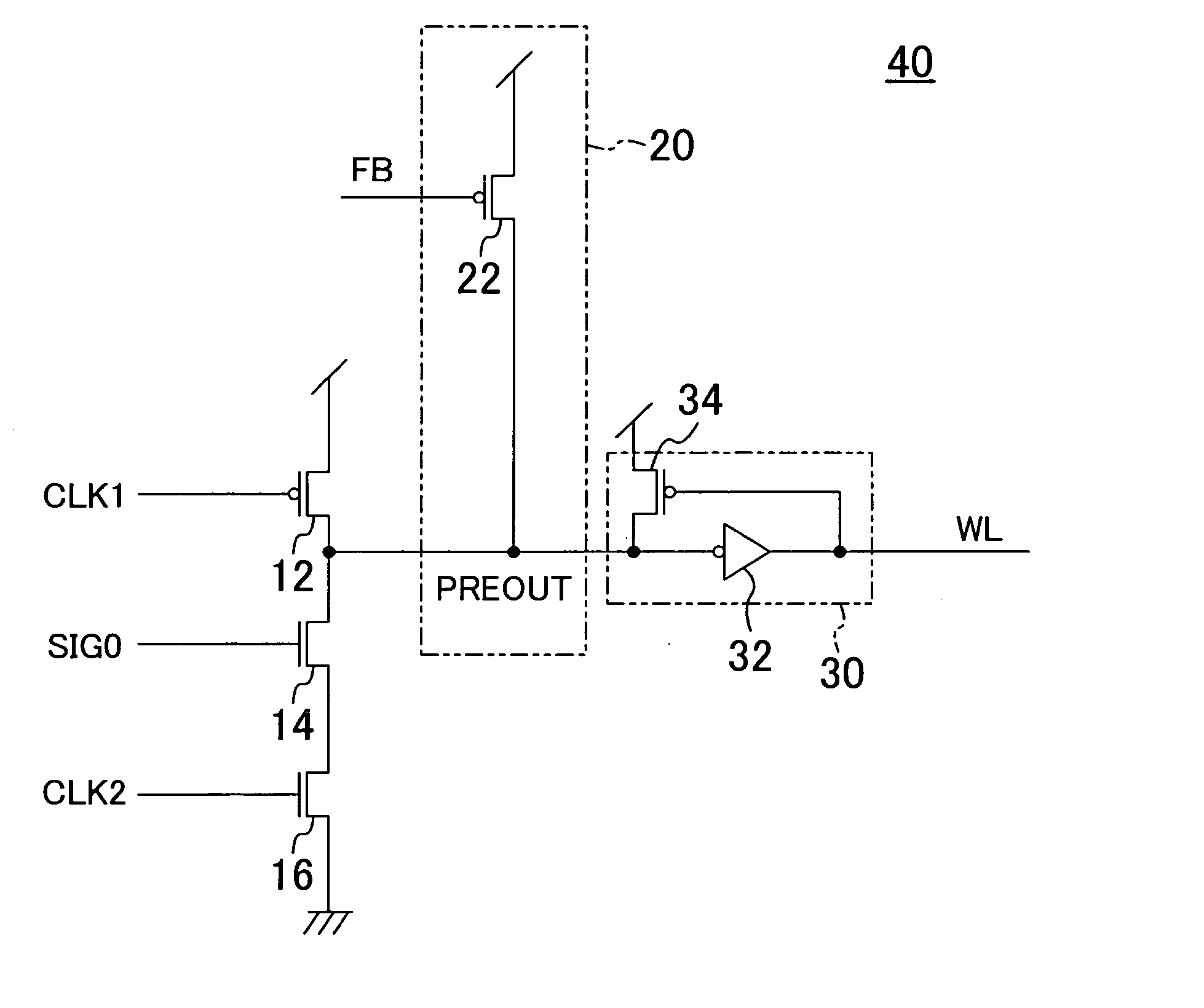

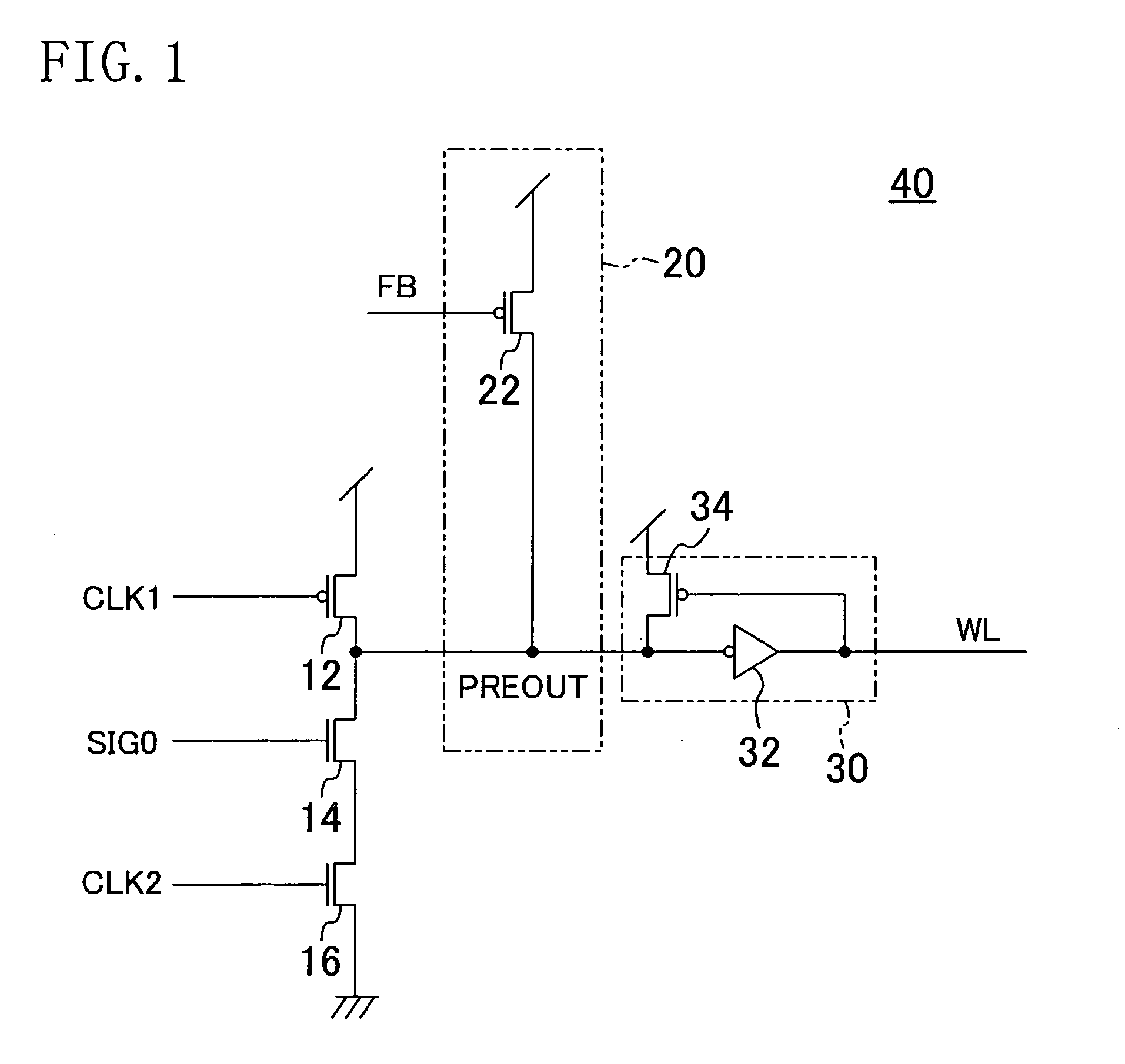

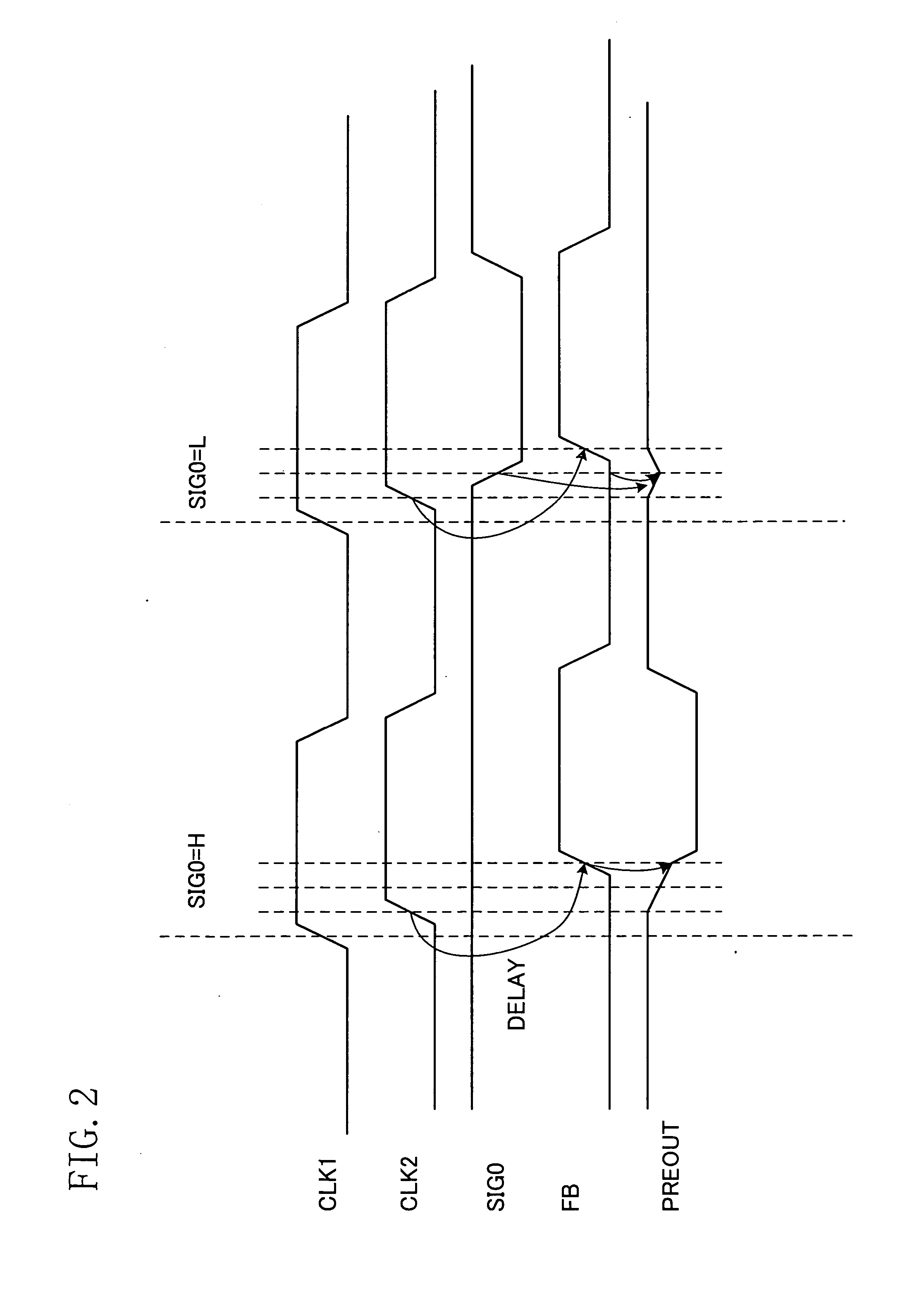

Semiconductor integrated circuit

ActiveUS7482840B2Malfunction protectionOccurrence of a glitch at the output node can be suppressedLogic circuitsEngineeringSemiconductor

The semiconductor integrated circuit includes: a first transistor of a first conductivity type connected between a first power supply and an output node and turned ON according to a first clock to put the output node to a first logic level; a second transistor of a second conductivity type turned ON according to an input signal; a third transistor of the second conductivity type connected in series to the second transistor and turned ON according to a second clock; and a fourth transistor of the first conductivity type connected between the first power supply and the output node and turned ON according to a feedback signal. The second and third transistors are connected between the output node and a second power supply. The fourth transistor is turned from ON to OFF after both the second and third transistors are turned ON.

Owner:CETUS TECH INC

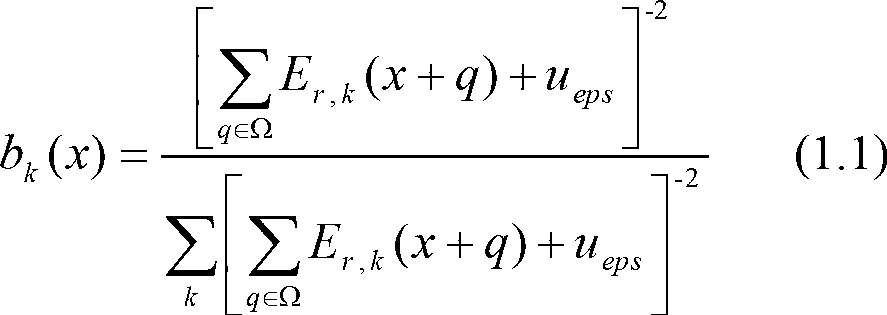

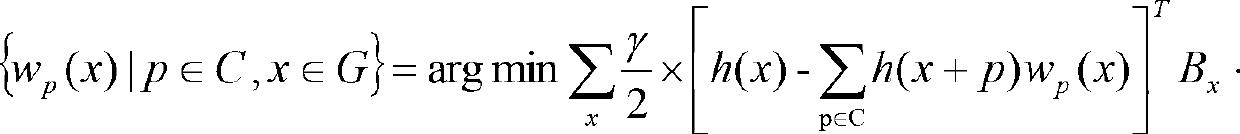

Refactoring method for optimizing super resolution of facial images

InactiveCN102999748AHigh precision reconstructionSuppress glitchCharacter and pattern recognitionImage resolutionLow resolution

The invention belongs to the field of refactoring of the super resolution of facial images and particularly provides a refactoring method for optimizing the super resolution of the facial images. The method includes step one, inputting a low-resolution facial image and K low-resolution reference facial image; step two, calculating a local embedding coefficient; step three, substituting a local embedding system into a refactoring model to calculate a refactored image with a high resolution; and step four, taking the image solved in the last step as an input image. The method can improve the face recognition accuracy.

Owner:HUBEI WEIJIA TECH

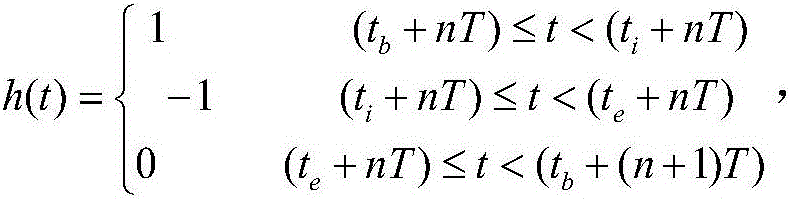

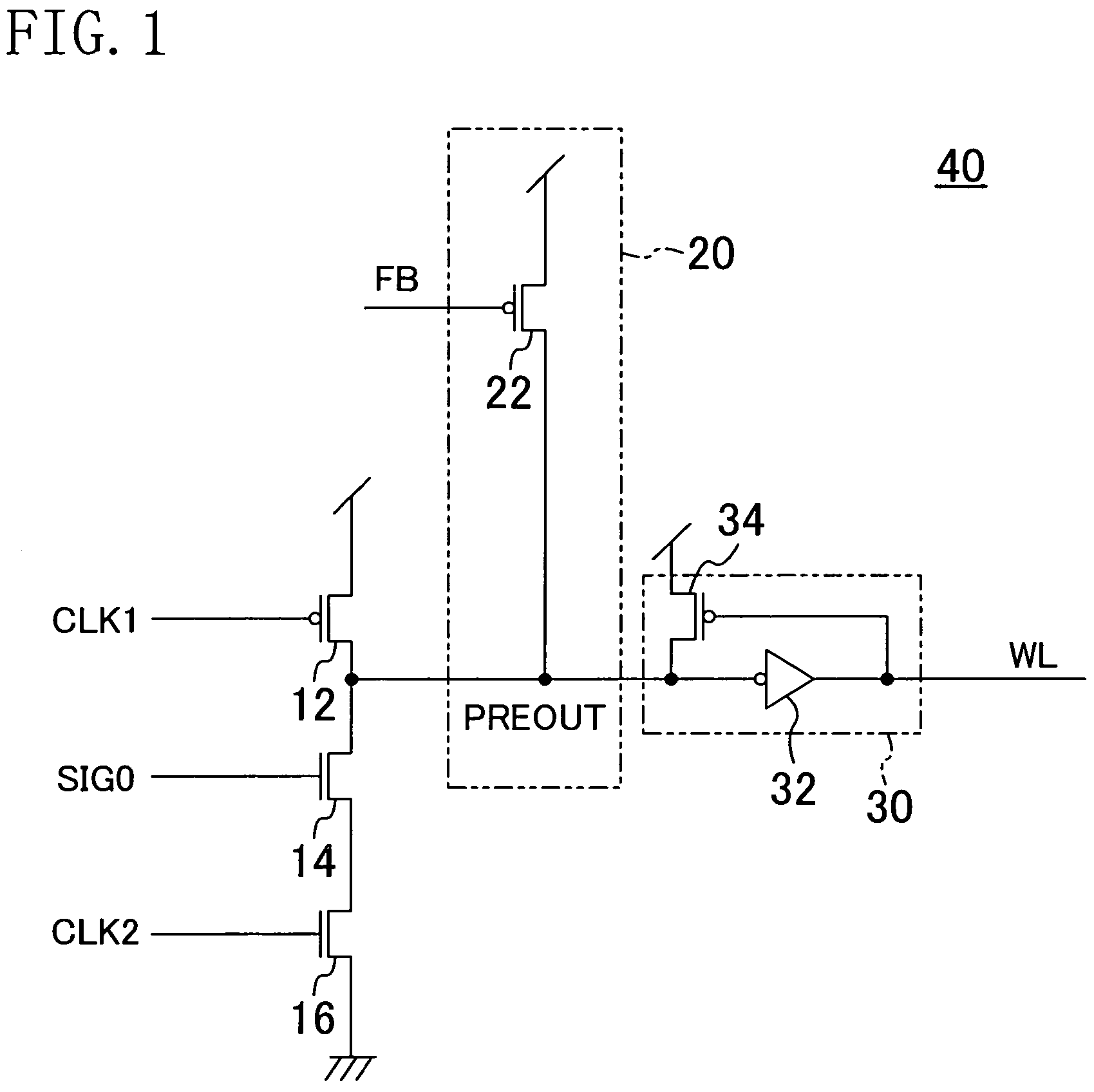

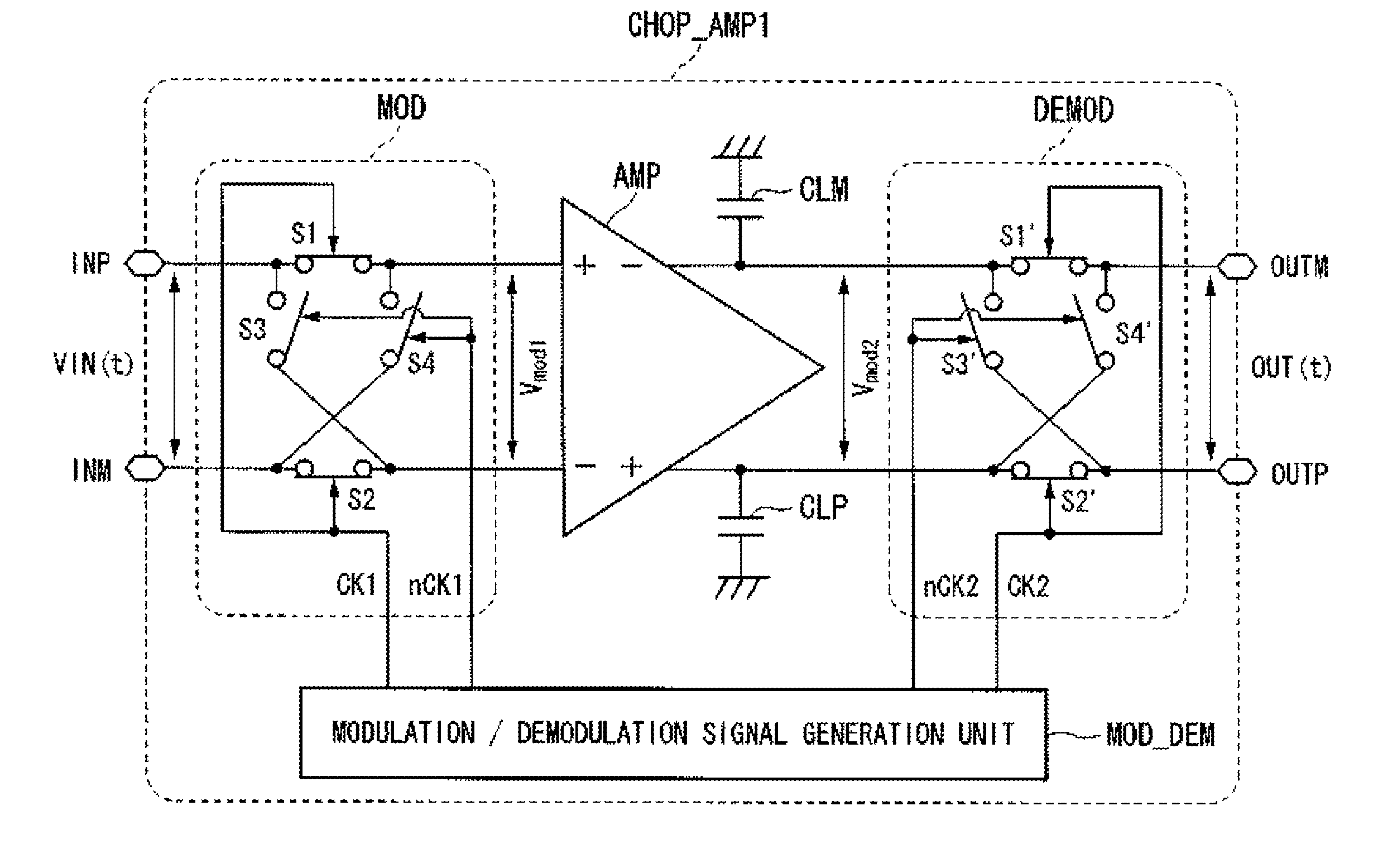

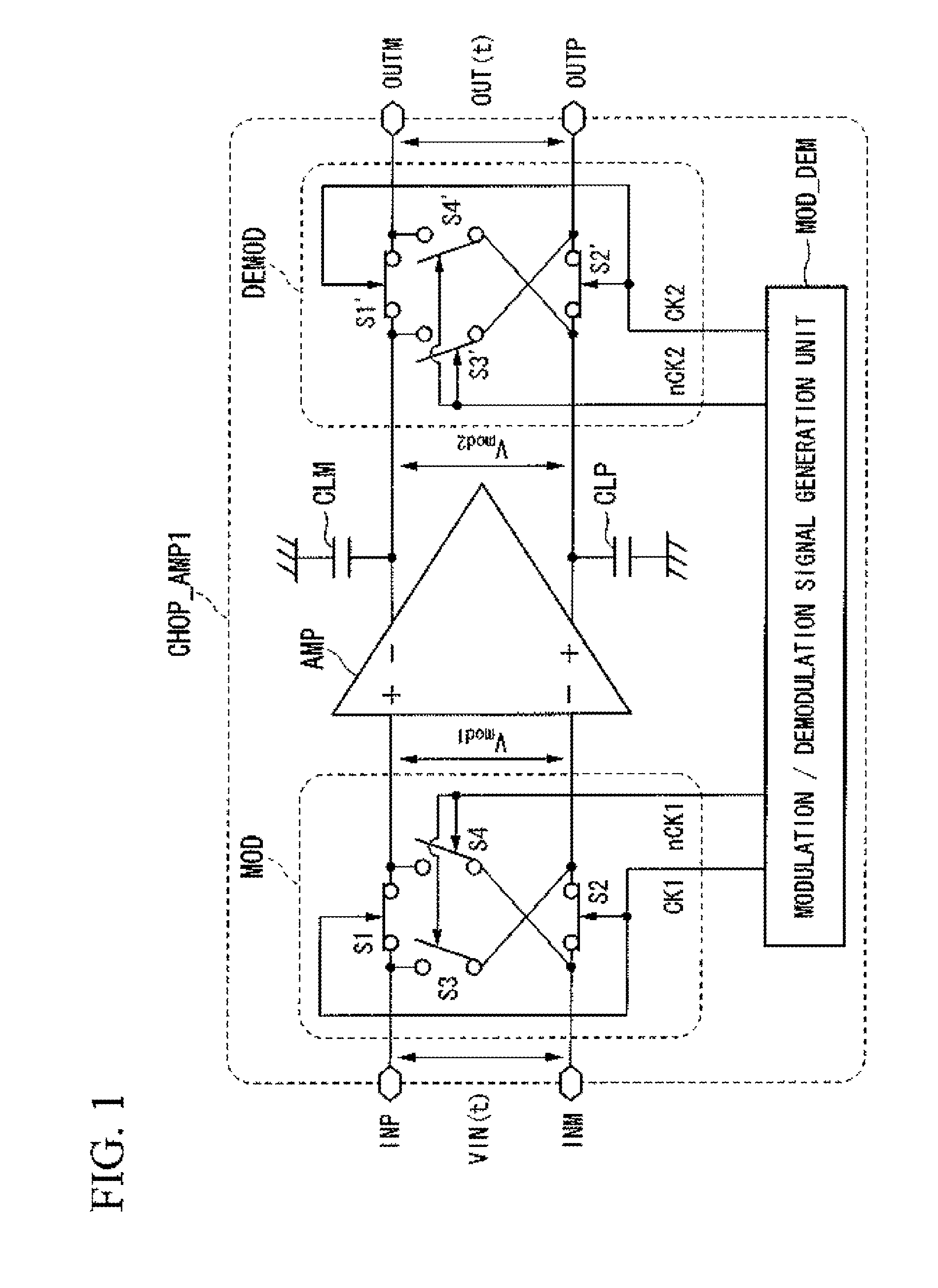

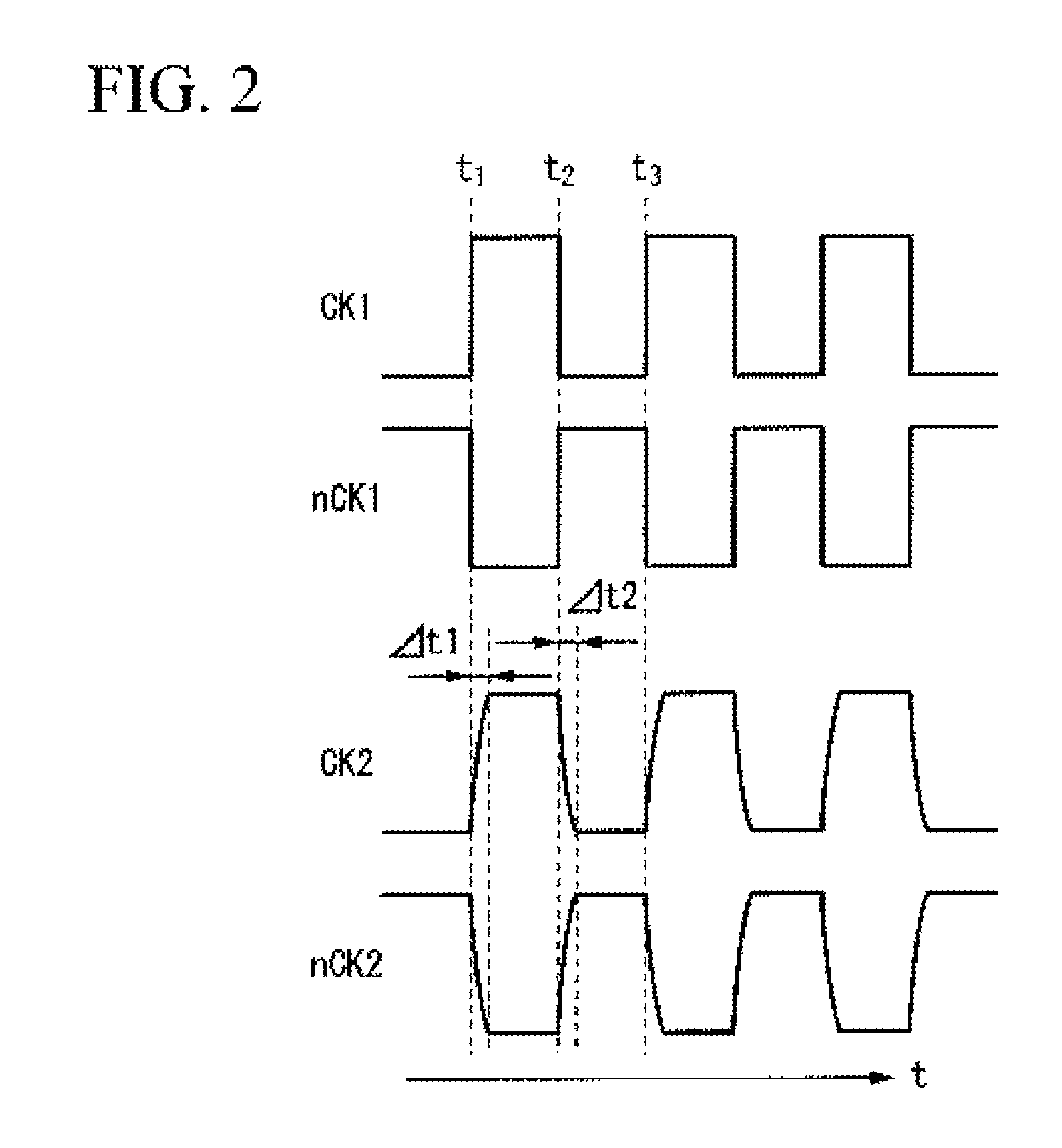

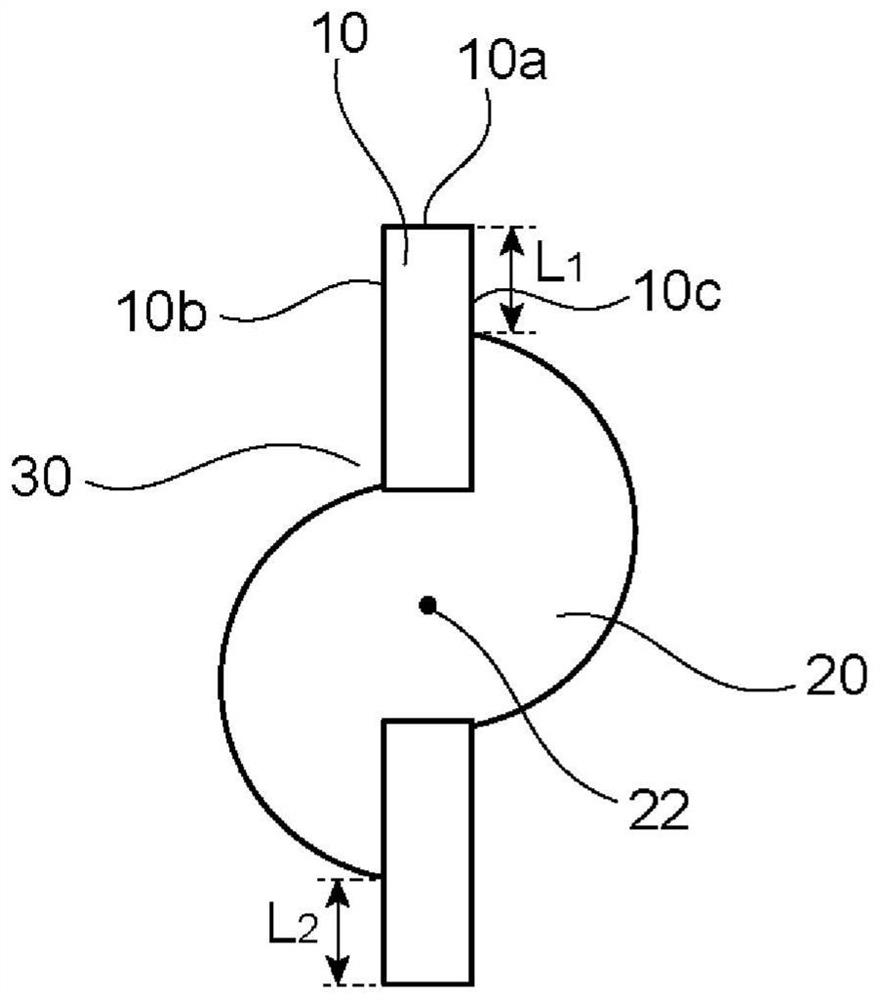

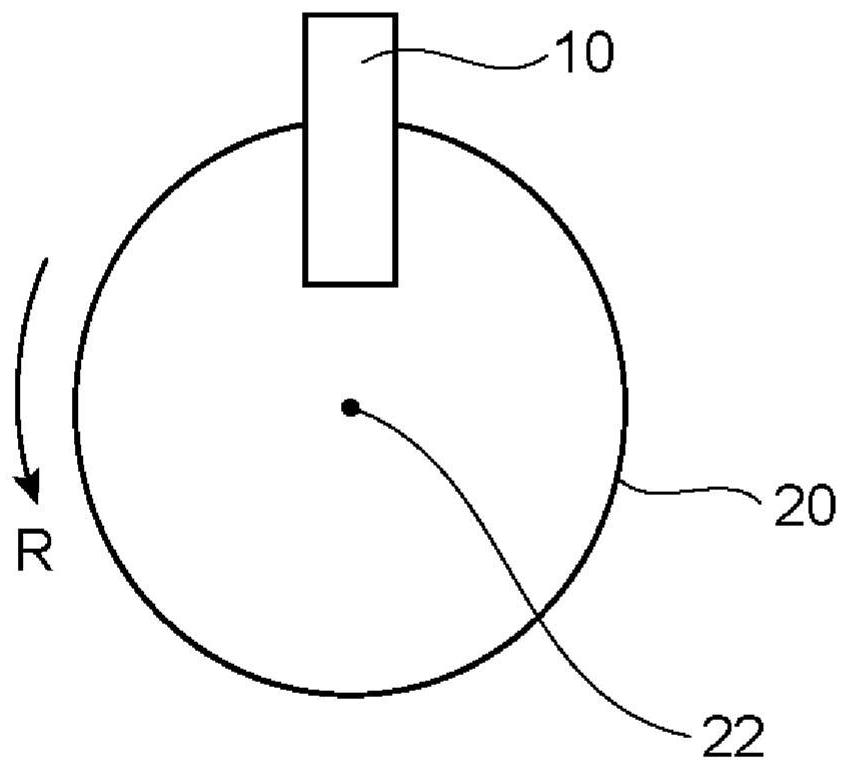

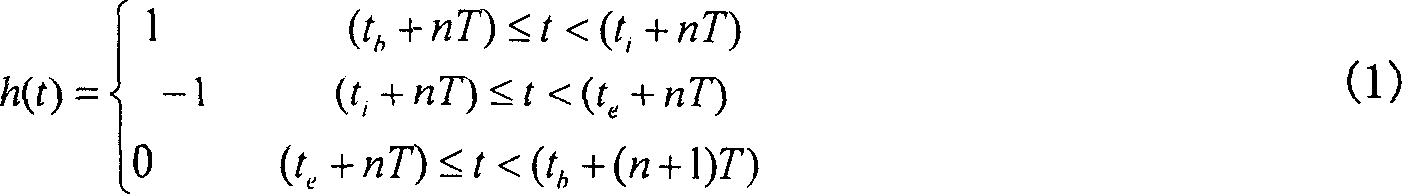

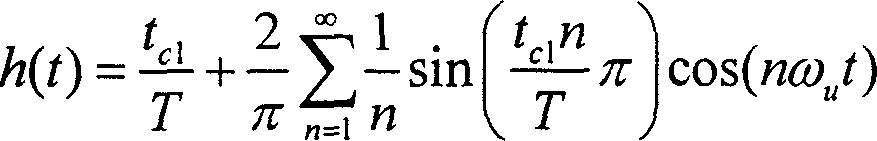

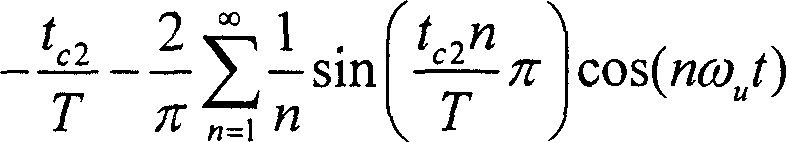

Chopper stabilized amplifier

ActiveUS8248158B2Less distortionSuppress glitchPulse automatic controlAmplifier modifications to raise efficiencyAudio power amplifierEngineering

A chopper stabilized amplifier may include a modulation circuit that performs a digital conversion on an input signal so as to convert the input signal into a first modulated signal by using a modulation signal, the modulation signal being a rectangular wave having a predetermined frequency, an operational amplifier circuit that amplifies the first modulated signal so as to convert the first modulated signal into a second modulated signal, and a demodulation circuit that performs analog conversion on the second modulated signal so as to convert the second modulated signal into an output signal by using a demodulation signal, the demodulation signal having a waveform that corresponds to the differences between frequency components of the first modulated signal and the second modulated signal.

Owner:OLYMPUS CORP

Semiconductor integrated circuit

ActiveUS20070080720A1Range of power supply voltageMalfunction protectionLogic circuitsEngineeringSemiconductor

The semiconductor integrated circuit includes: a first transistor of a first conductivity type connected between a first power supply and an output node and turned ON according to a first clock to put the output node to a first logic level; a second transistor of a second conductivity type turned ON according to an input signal; a third transistor of the second conductivity type connected in series to the second transistor and turned ON according to a second clock; and a fourth transistor of the first conductivity type connected between the first power supply and the output node and turned ON according to a feedback signal. The second and third transistors are connected between the output node and a second power supply. The fourth transistor is turned from ON to OFF after both the second and third transistors are turned ON.

Owner:CETUS TECH INC

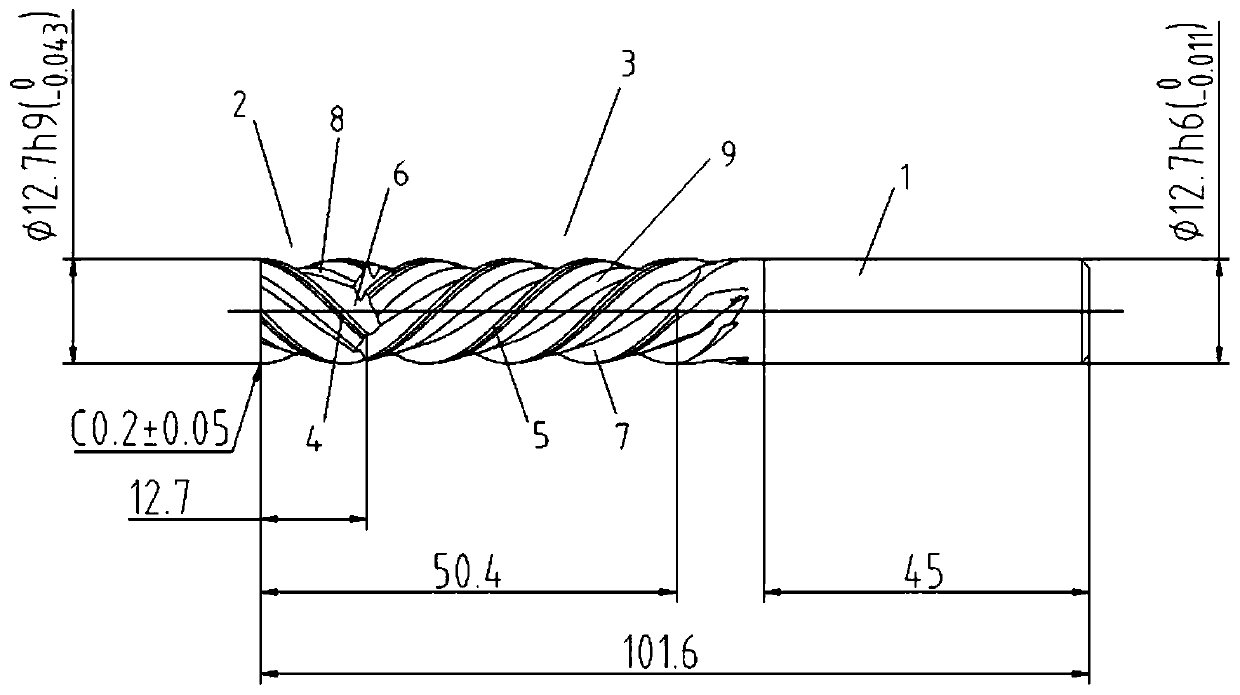

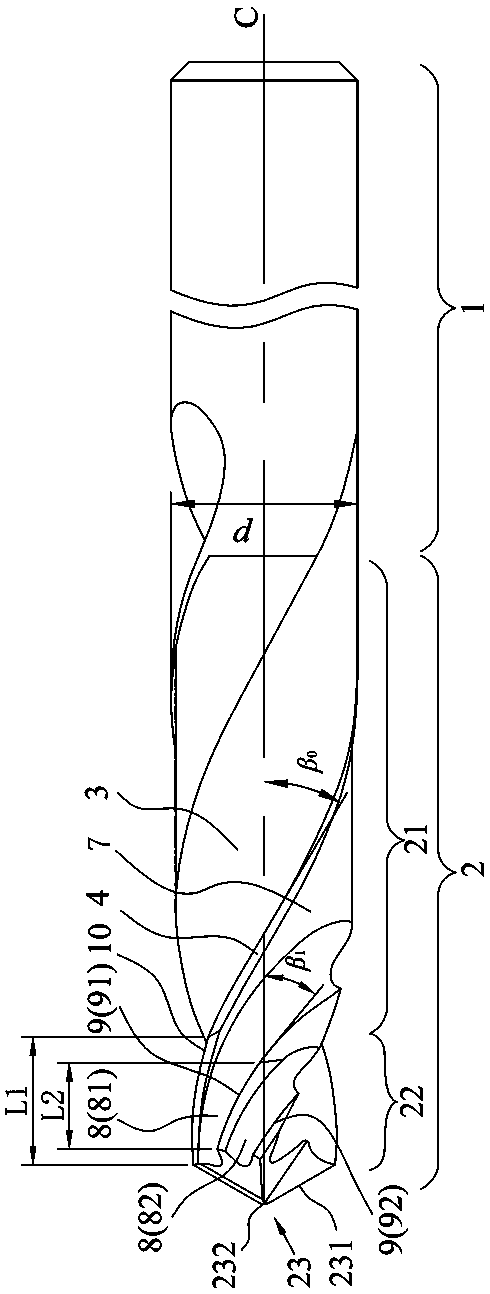

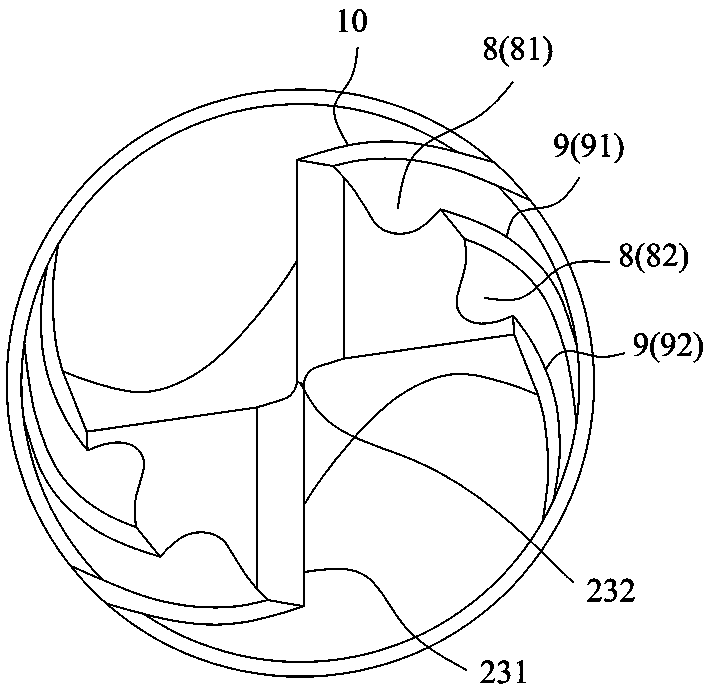

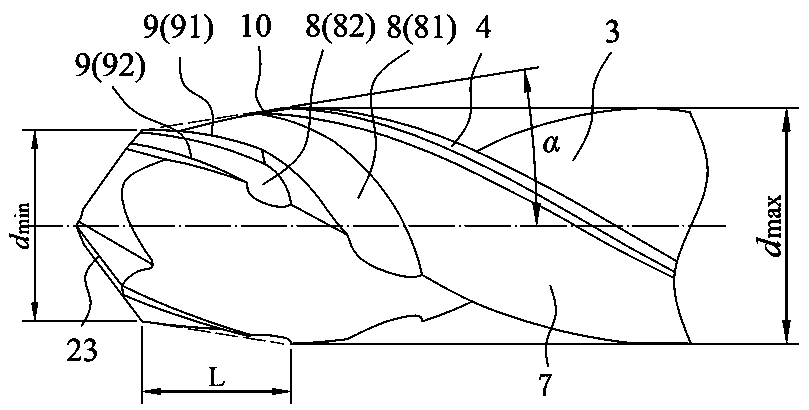

Milling cutter for machining carbon fiber composite material

The invention discloses a milling cutter for machining a carbon fiber composite material. The milling cutter comprises a handle part, a right blade part and a left blade part are sequentially arrangedat the front end of the handle part from left to right, the right blade part comprises a plurality of right-handed teeth spirally arranged rightwards in the circumferential direction, the left bladepart comprises a plurality of left-handed teeth spirally arranged in the direction opposite to the right-handed teeth in the circumferential direction, wherein the right-handed teeth and the left-handed teeth are distributed in a staggered mode, the surfaces of the right-handed teeth and the surfaces of the left-handed teeth are coated with diamond super-wear-resistant coatings correspondingly, the distance between the tail ends of the right-handed teeth and the front ends of the left-handed teeth is 0.6-0.8 mm, right-handed chip discharge grooves a are formed among the right-handed teeth, andleft-handed chip discharge grooves b are formed among the left-handed teeth. According to the milling cutter for machining the carbon fiber composite material, fiber splitting or burrs and the like on the upper edge and the lower edge of a carbon fiber composite plate are restrained at the same time through the opposite axial force of the right blade part and the left blade part, the chip containing space is large, larger milling cutting width can be achieved, the rigidity is good, the machined powdery carbon fiber material can be smoothly discharged, and carbon fiber powder accumulation caused by unsmooth chip discharge is avoided.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

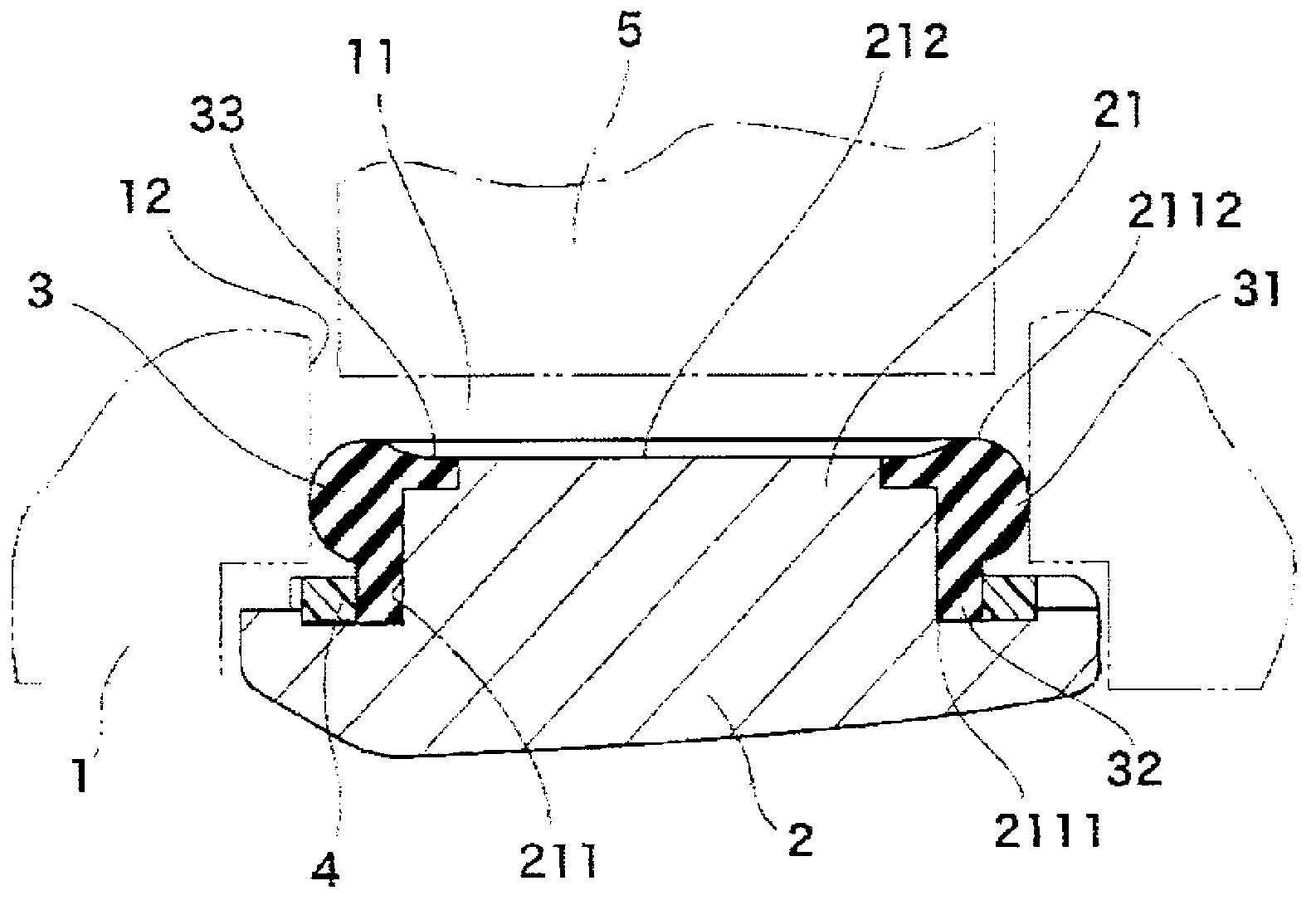

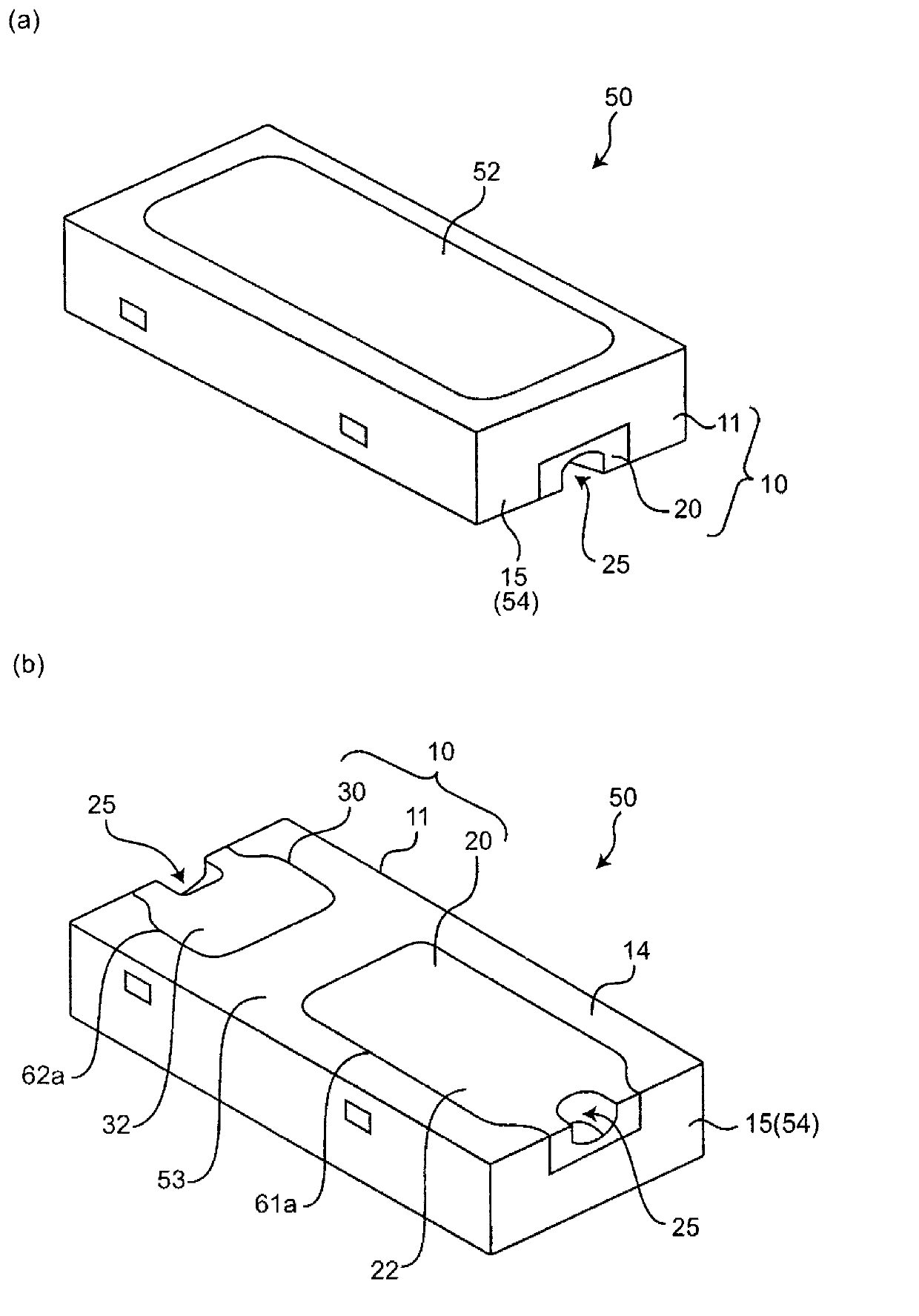

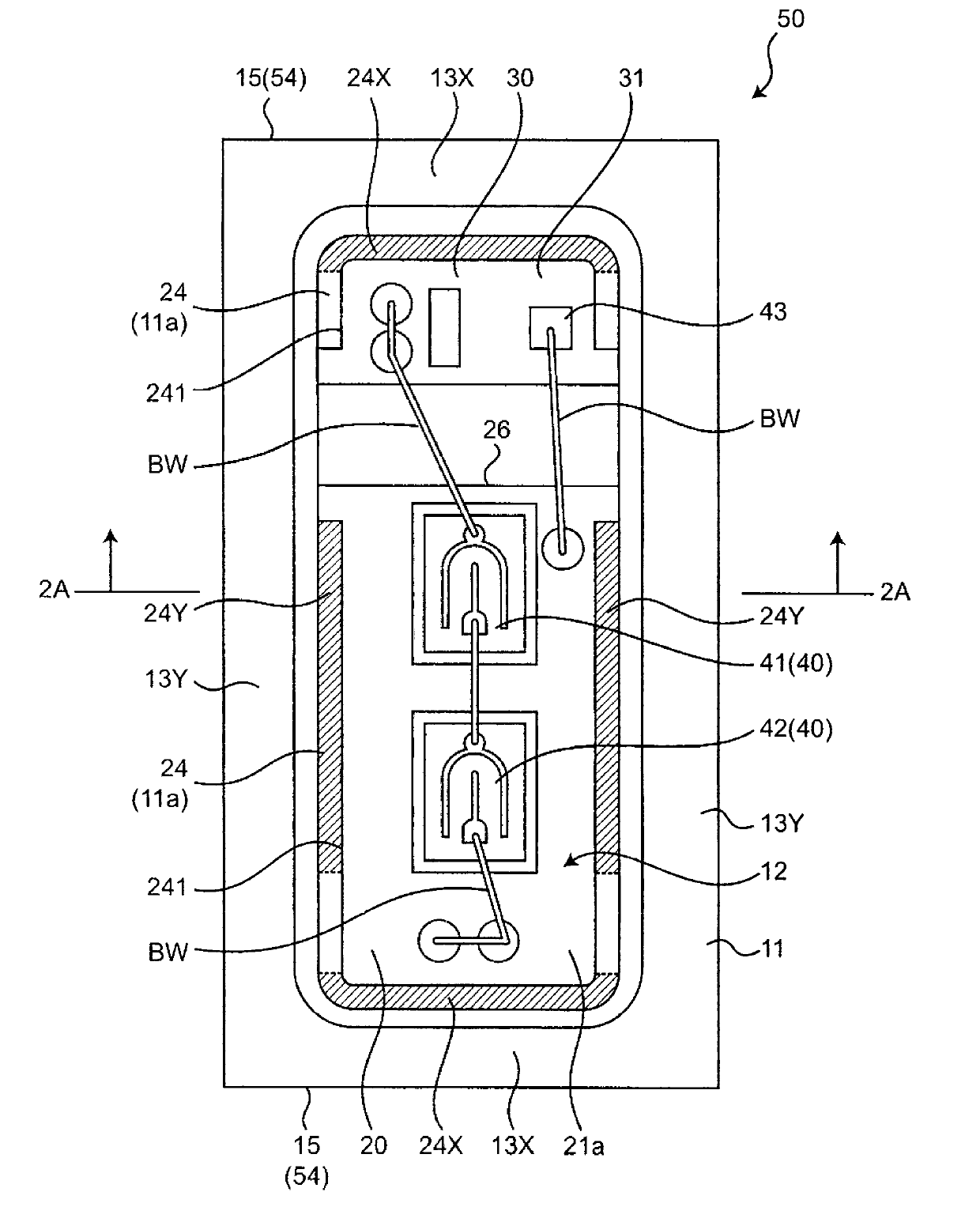

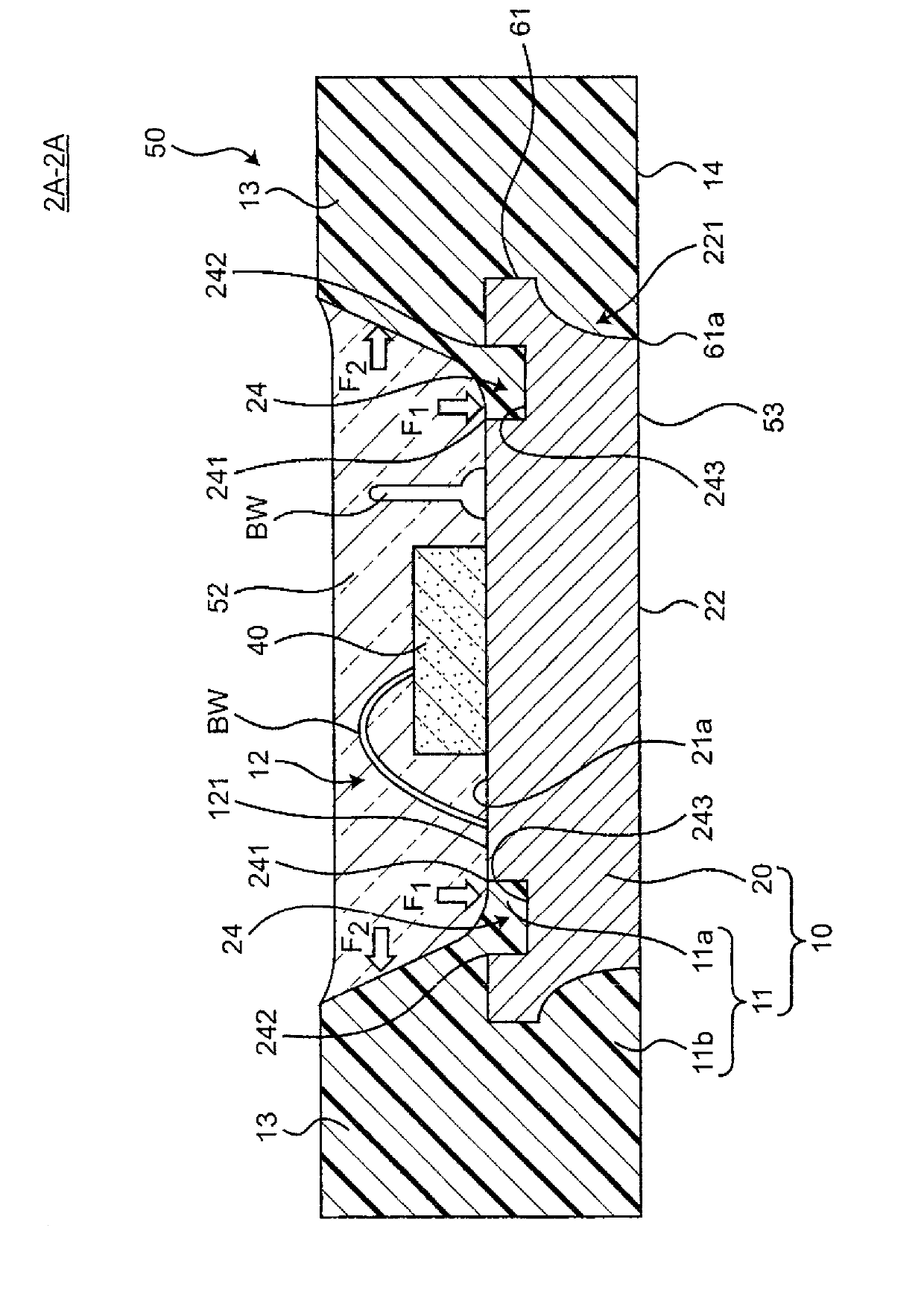

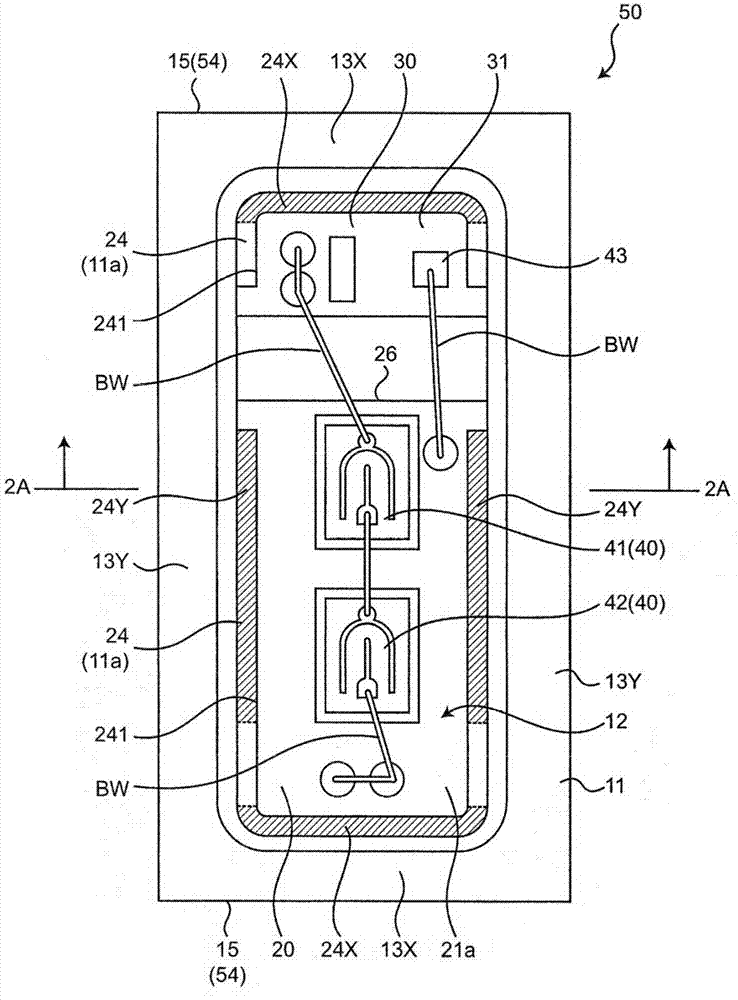

Molded package and light emitting device

ActiveCN103219446AInhibition of exudationPrevent intrusionSolid-state devicesPrinted circuitsEngineeringLight emitting device

A molded package includes a molded resin and a lead. The molded resin has a recess portion provided on an upper surface of the molded resin to accommodate a light emitting component. The lead is partially exposed from a bottom surface of the recess portion of the molded resin to be electrically connected to the light emitting component and extends below a side wall of the recess portion. The lead has a groove formed on a surface of the lead at least partially along the side wall. The groove has an inside upper edge and an outside upper edge and is filled with the molded resin so that the inside upper edge is exposed from the bottom surface of the recess portion and the outside upper edge is embedded within the molded resin.

Owner:NICHIA CORP

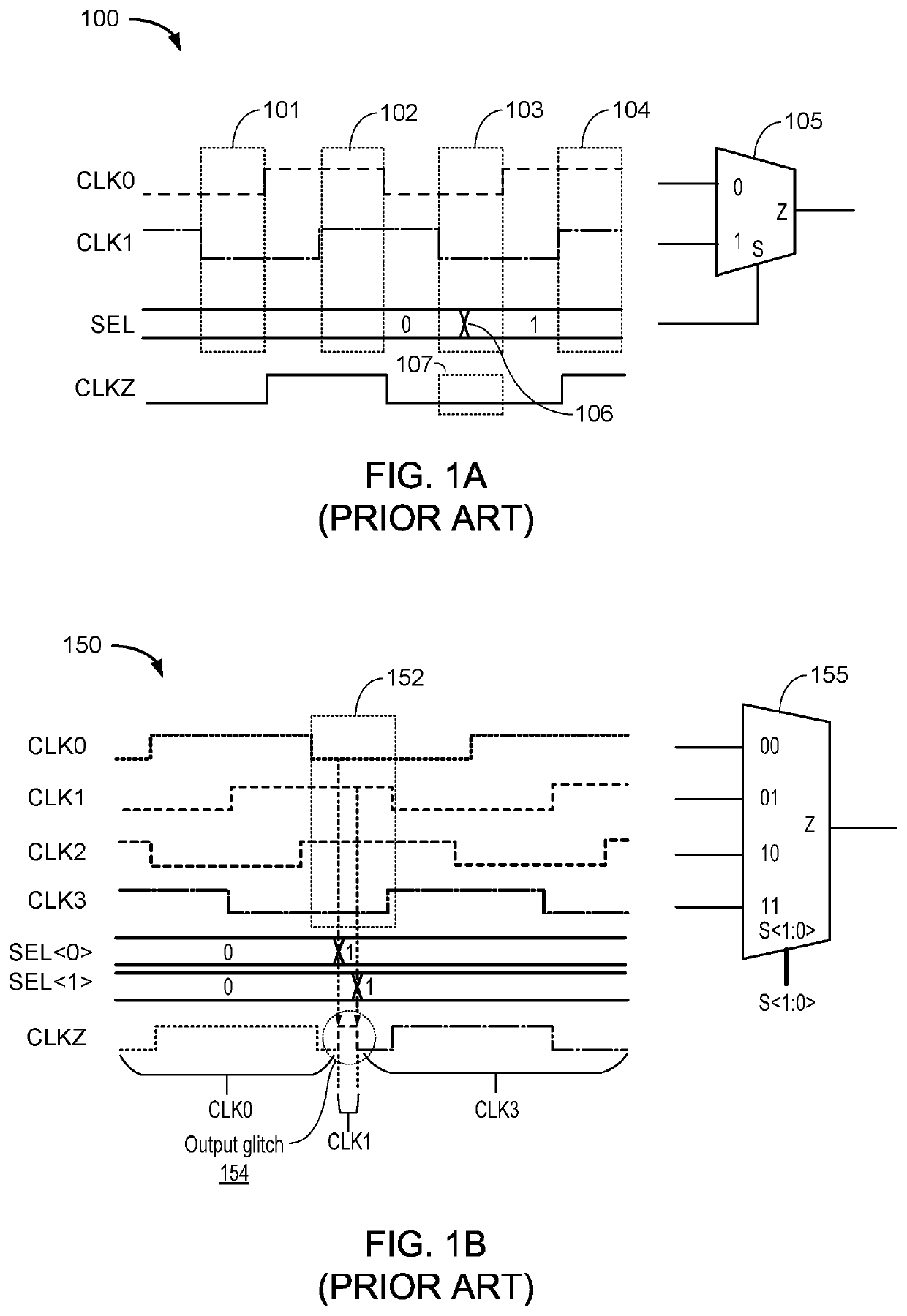

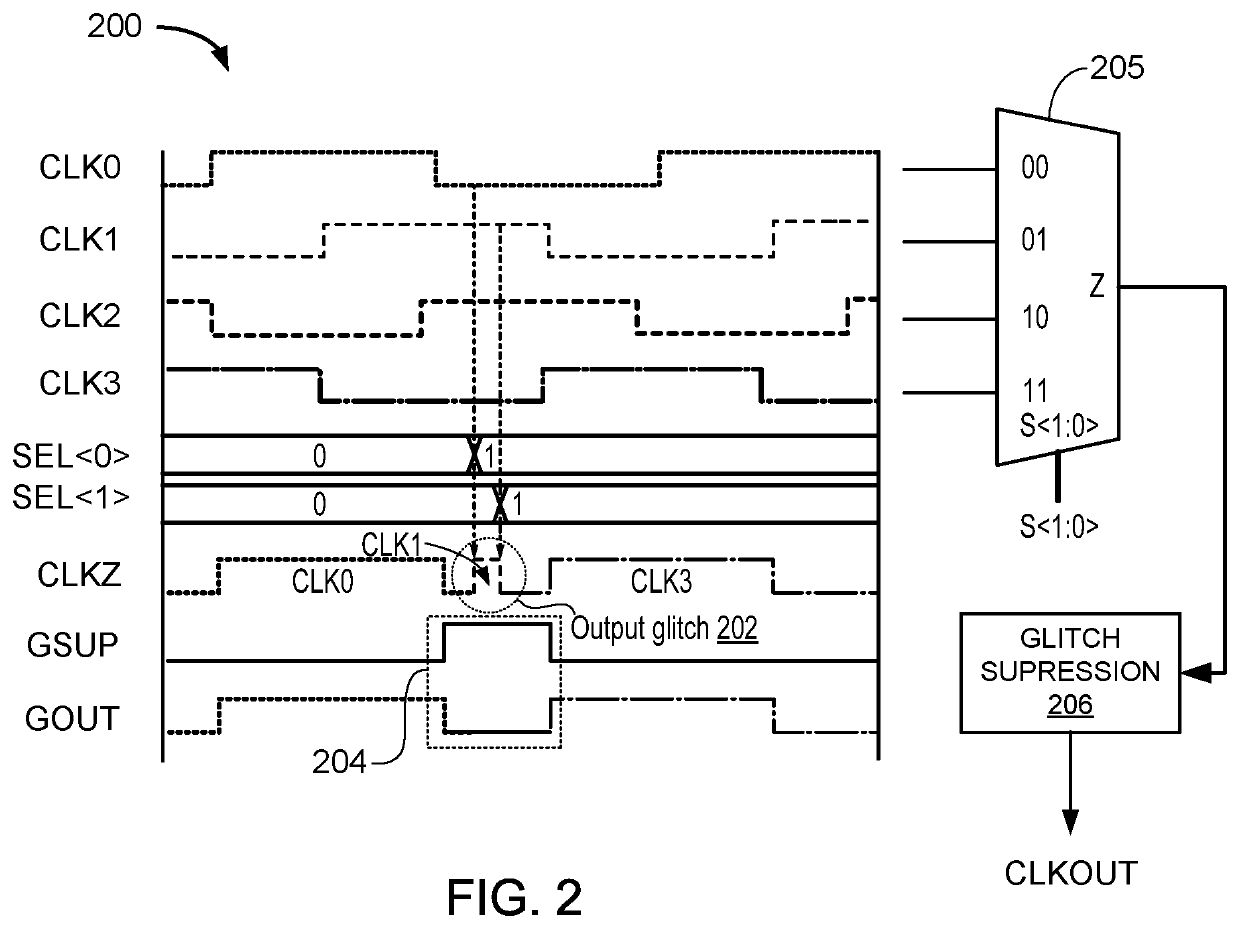

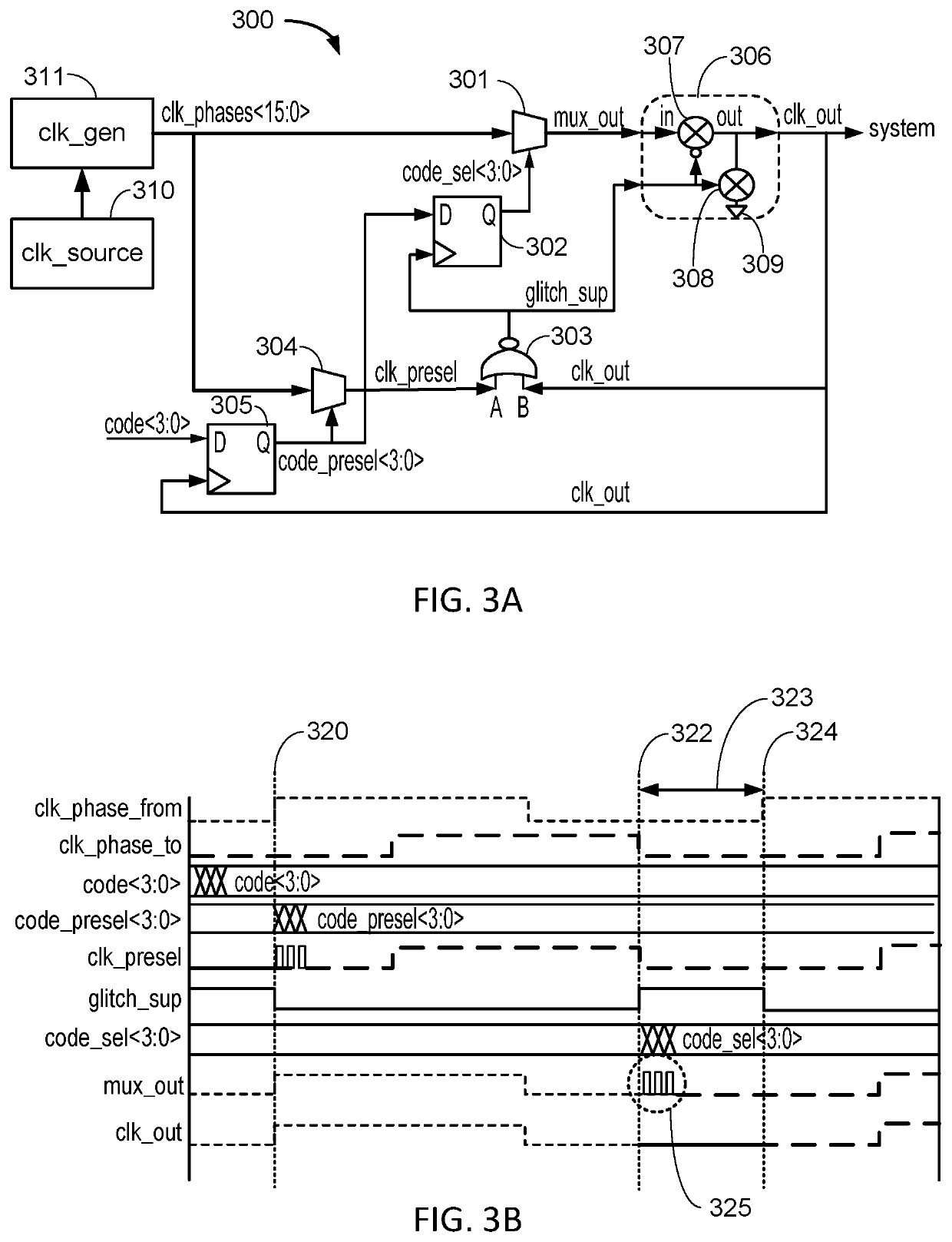

Apparatuses and methods for avoiding glitches when switching clock sources

ActiveUS10705558B2Avoid failureSuppress glitchLogic circuits characterised by logic functionGenerating/distributing signalsMultiplexerHemt circuits

Certain aspects of the present disclosure provide an input clock switching system, including: a clock source configured to output a reference clock signal; a clock generator circuit connected to the clock source and configured to output a plurality of input clock signals based on the reference clock signal; an output clock multiplexer, configured to: receive the plurality of input clock signals; receive an output clock selection signal; and output a first clock signal, wherein the first clock signal is one of the input clock signals; and a glitch suppression circuit, configured to: receive the first clock signal; receive a glitch suppression signal; output a clock output signal, wherein the clock output signal is: the first clock signal when the glitch suppression signal is in a first state; and a logic low signal when the glitch suppression signal is in a second state.

Owner:QUALCOMM INC

Robotic hole making end effector

InactiveCN103639471BImprove hole qualityImprove hole making efficiencyMeasurement/indication equipmentsFeeding apparatusEngineeringActuator

The invention discloses a drilling end actuator suitable for an industrial robot. The drilling end actuator comprises a cutting unit, a connecting unit, a feeding unit, a pressing unit and a measuring unit. The cutting unit mainly comprises a motorized spindle, a cutter handle, a cutter, a servo motor and a cutting transmission assembly and is used for achieving planetary drilling and cutting; the connecting unit mainly comprises a connecting plate and tool fast-switching devices and is used for achieving three installation modes and fast switching between the different installation modes; the feeding unit mainly comprises a lead screw nut pair, a feed motor and a feed transmission assembly and is used for achieving feed movement of planetary drilling and cutting; the pressing unit mainly comprises an air cylinder, a pressing plate, a pressing pipe and a pressing head and is used for pressing a workpiece; the measuring unit comprises a photoelectricity distance sensor and a force sensor and is used for detecting the perpendicularity of the cutter before and after pressing and monitoring the state of the cutter during the drilling process in real time. The drilling end actuator can form a flexible drilling system when used in cooperation with the industrial robot, and precise drilling of stacked materials can be achieved.

Owner:ZHENGZHOU UNIV

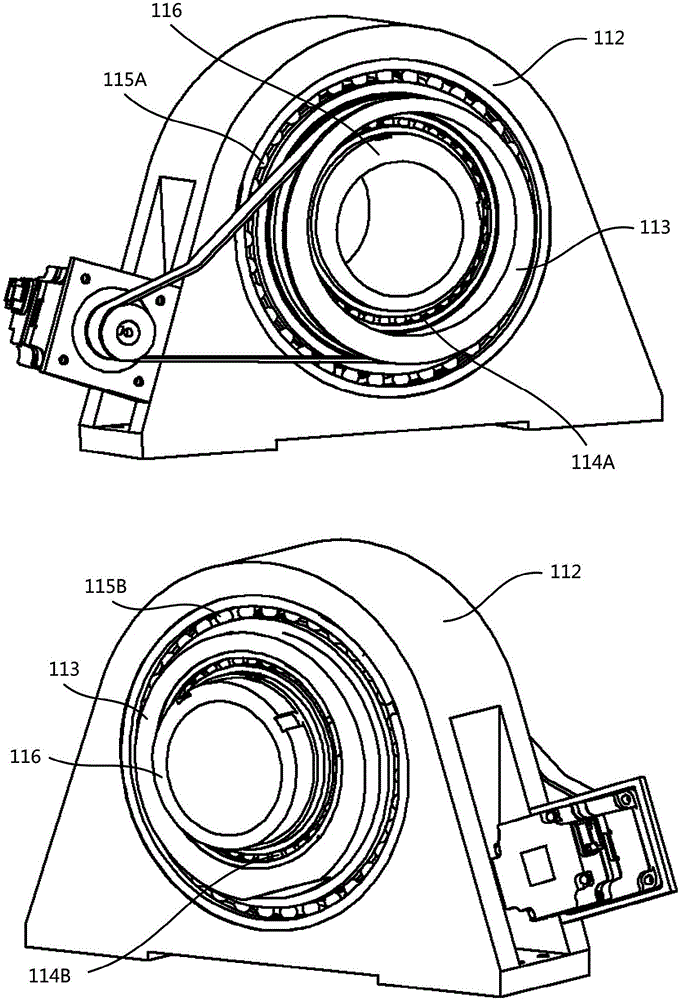

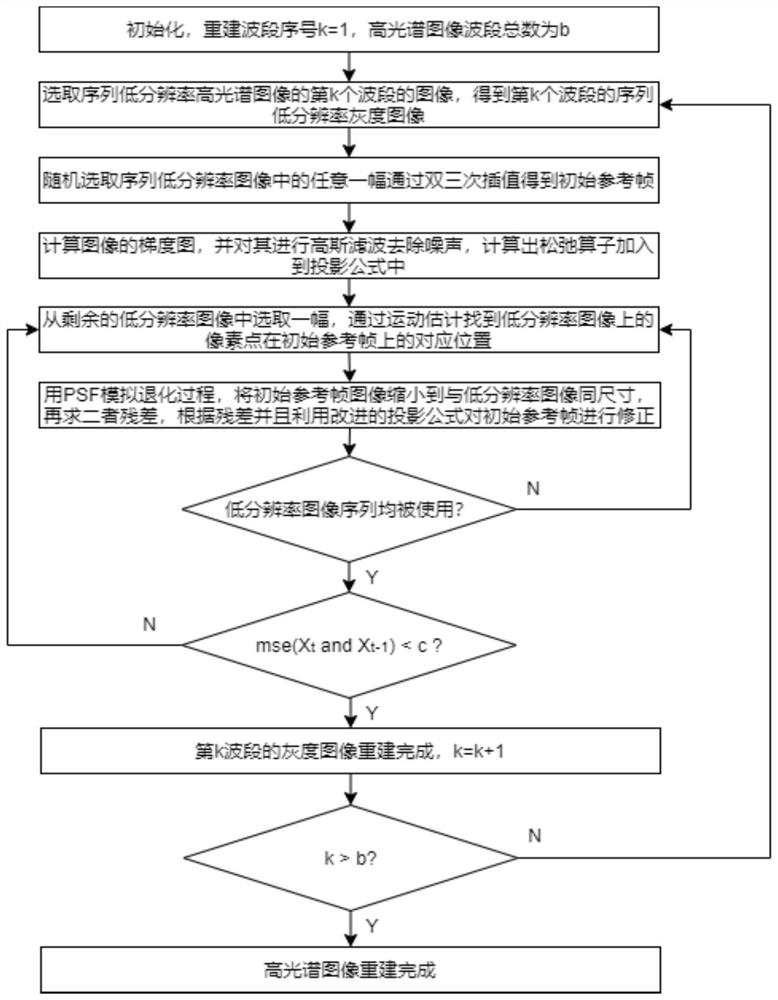

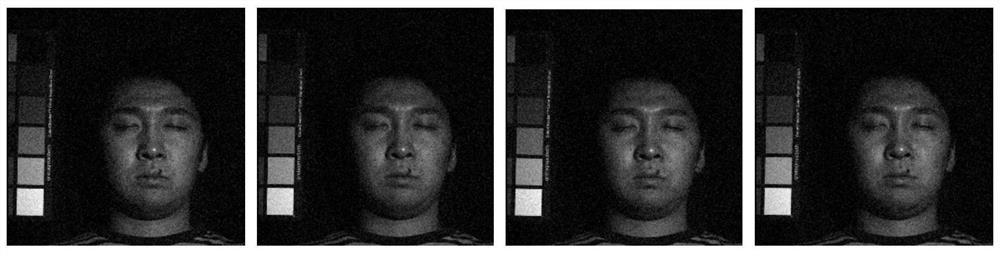

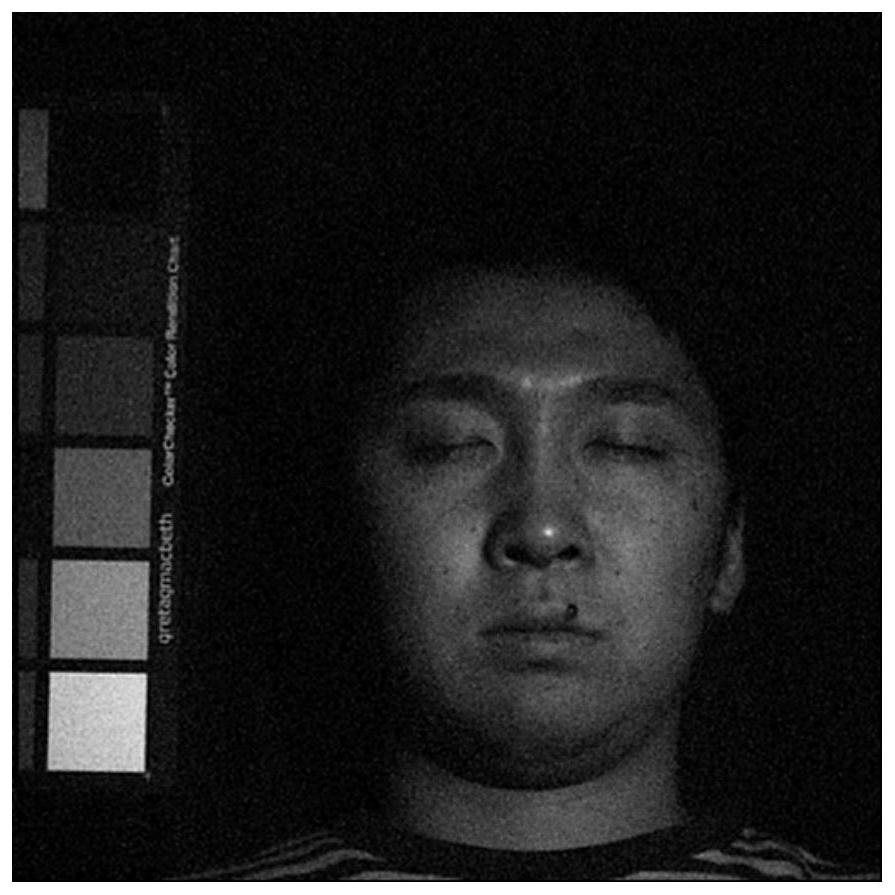

Improved hyperspectral image super-resolution reconstruction method based on POCS

ActiveCN113506212AAlleviate the blur problemImprove spatial resolutionImage enhancementImage analysisImage resolutionGradation

The invention discloses an improved hyperspectral image super-resolution reconstruction method based on POCS, and the method comprises the steps: firstly, randomly selecting one from gray images of a first wave band of a sequence low-resolution hyperspectral image, obtaining an initial reference frame through bicubic interpolation, and relieving the problem of edge blurring of a reconstructed image to a certain degree; correcting the residual grayscale image of the first wave band according to a projection formula into which a relaxation operator is introduced, so that burrs of a smooth region of the reconstructed image are inhibited; after more than two iterations, indicating that the iteration process is self-adaptive according to the condition whether the mean square error between the reconstructed images of the two iterations is smaller than a certain threshold value or not, so that the subjectivity of manually setting the number of iterations is avoided; and finally, repeating the above process on the grayscale image of each wave band of the hyperspectral image to obtain the hyperspectral image with improved spatial resolution. The method can be used as an effective means for improving the spatial resolution of the hyperspectral image.

Owner:DALIAN MARITIME UNIVERSITY

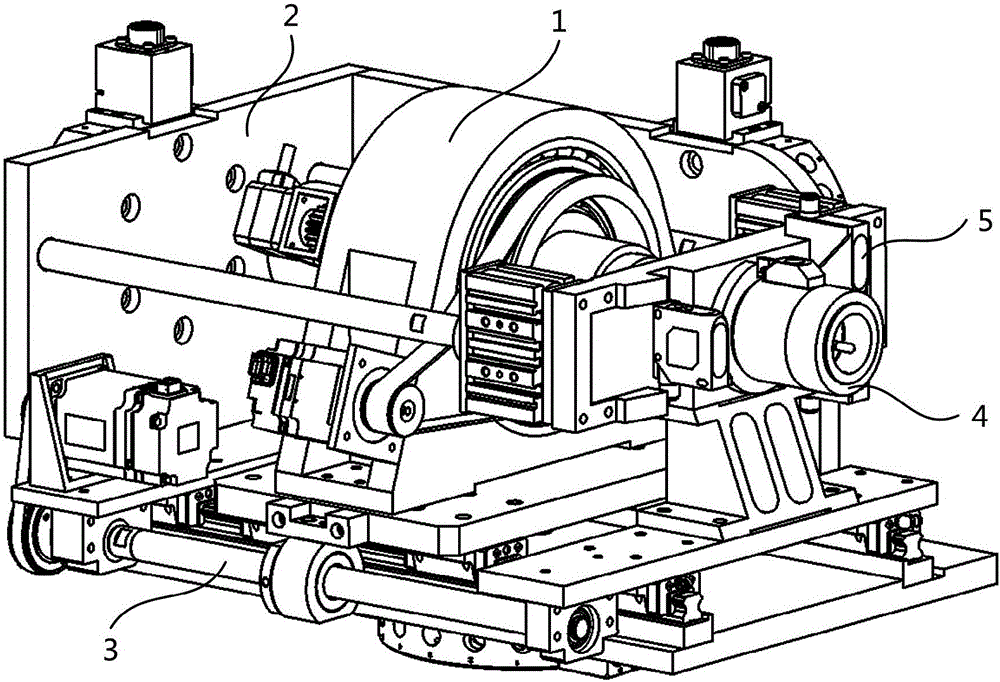

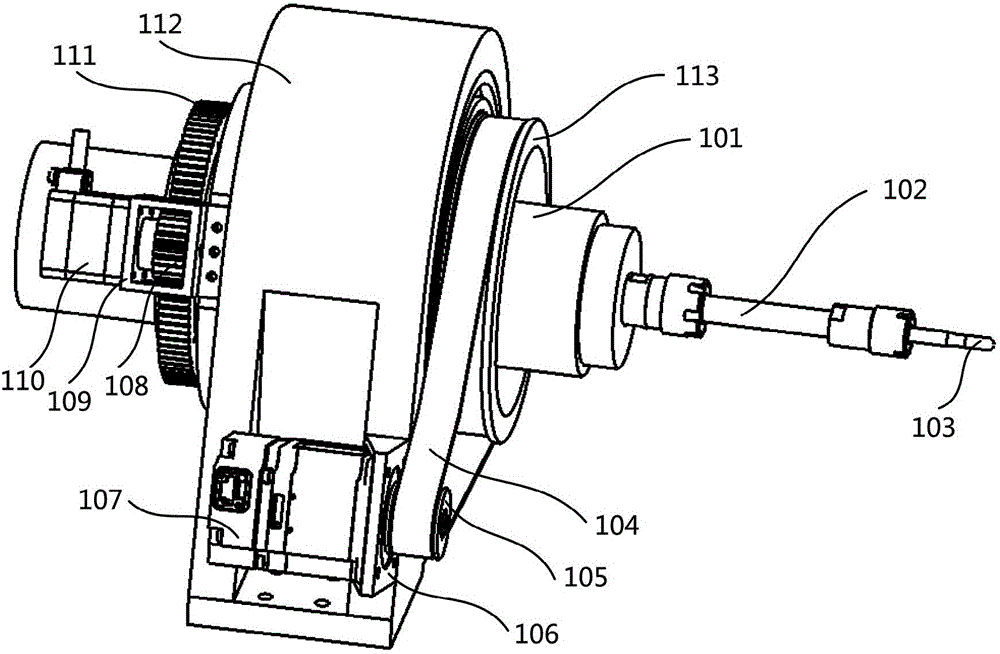

Non-resonant three-dimensional elliptical diamond fly-cutting optical free curved surface method and special device

The invention discloses a non-resonant three-dimensional elliptical diamond fly-cutting optical free curved surface method and a special device, belonging to the field of cutting technology of free curved surface of hard-processing materials. In the invention, a non-resonant driving mode is used to enable a diamond cutter to generate medium-high frequency or ultrahigh frequency three-dimensional elliptical movement in order to form high-speed or ultrahigh-speed diamond fly-cutting main movement; a cutter edge motion track is projected as reciprocating rectilinear movement on an x-z plane and is respectively projected as elliptical movement on an x-y plane and a y-z plane; the optical free curved surface is created on the basis of the combination of the movements of three-dimensional elliptical diamond fly cutting, X-axis feeding, Z-axis reciprocating feeding, worepiece rotary feeding, and the like. The invention also discloses a diamond cutter three-dimensional elliptical movement track generating device which are directly driven by four piezoelectric stacks, the three-dimensional elliptical movement parameters can be independently controlled, which is beneficial to the obtaining of optimal cutting performance, and the follow-up control of the three-dimensional elliptical movement avoids distortion in a real cutting process.

Owner:CHANGCHUN UNIV OF TECH

A hole-making method for ion propulsion carbon grid assembly

ActiveCN109227740BGuaranteed coaxial accuracyGuaranteed positioning accuracyMetal working apparatusMachine toolMachining

Owner:DALIAN UNIV OF TECH

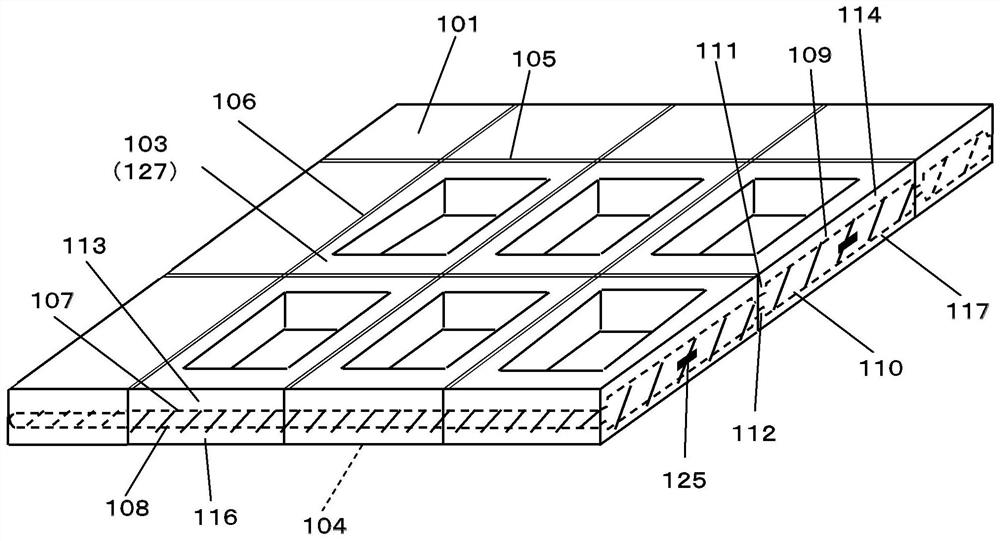

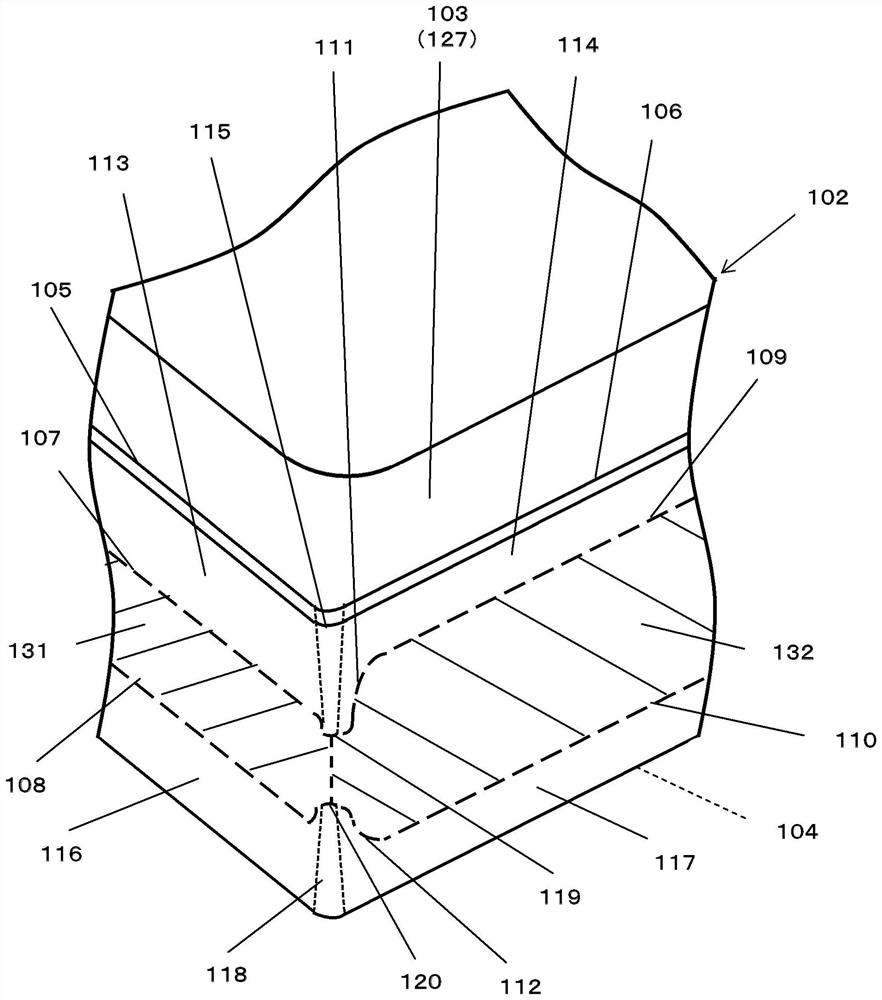

Multi-chip wiring substrate, wiring substrate

ActiveCN108781502BLess susceptible to positional driftSuppress glitch3D rigid printed circuitsImpedence networksStructural engineeringMechanical engineering

Owner:KYOCERA CORP

Glass fiber reinforced polyamide resin composition

InactiveCN101508839BHigh mechanical strengthExcellent surface appearanceElectrical apparatus casings/cabinets/drawersGlass fiberElastomer

The invention provides a glass fiber reinforced daiamid resin composition, which has excellent thin-wall forming property and surface appearance, and is applied to thin-wall portable electronic appliance components or computer frame components. The glass fiber reinforced daiamid resin composition is formed in combined with 50 to 150 parts of glass fiber by weight relative to 100 parts of daiamid resin composition by weight containing 90% to 99% of daiamid resin by weight and 1% to 10% of acid modified styrene elastomer by weight, the daiamid resin is combined with 20% to 60% of daiamid 66 resin by weight, 20% to 40% of daiamid 12 resin and 20% to 50% of amorphous daiamid resin by weight, and the total dose is 100% by weight.

Owner:UNITIKA LTD

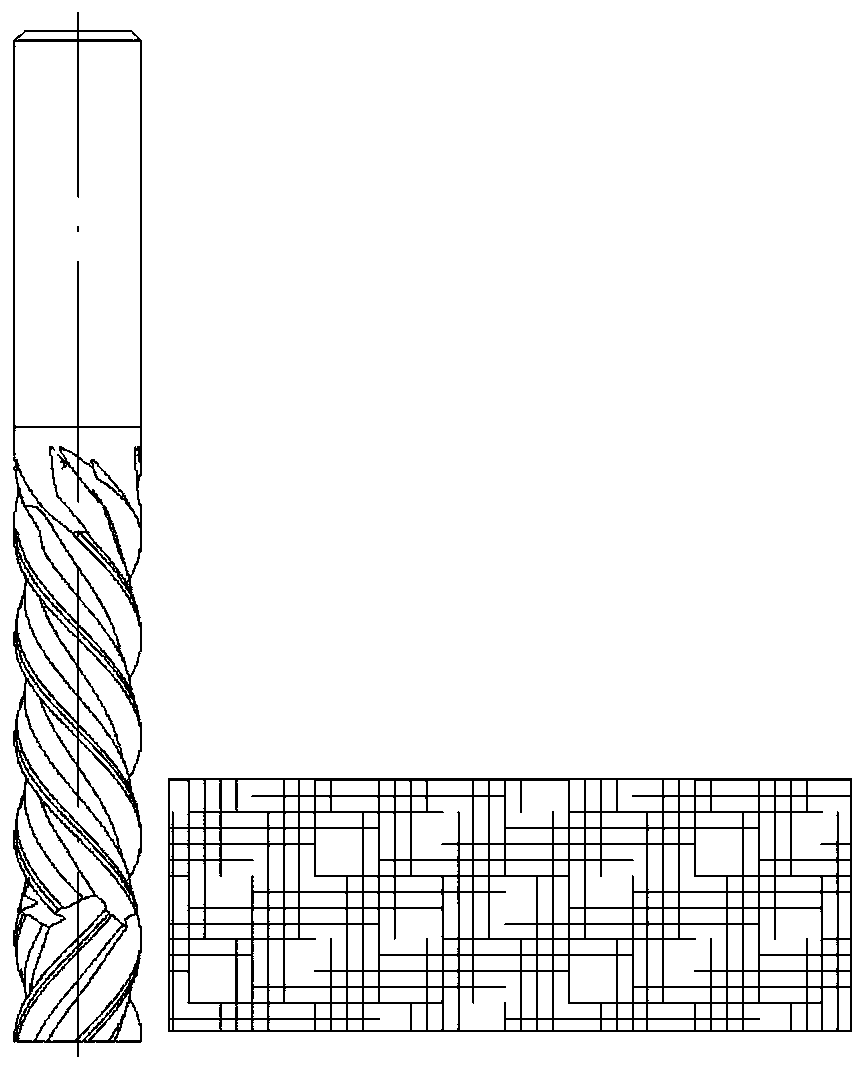

End mill for cutting optical film and method for manufacturing optical film using same

PendingCN114786851ASuppress glitchMilling cuttersPolarising elementsEngineeringMechanical engineering

The present invention provides an end mill capable of suppressing burrs during cutting of an optical thin film. This end mill for cutting an optical thin film is provided with a main body that rotates about a rotation axis, and n cutting blades that protrude from the main body and constitute the outermost diameter, and satisfies any one of the following conditions (1)-(3): (1) n is 1; (2) n is 2 or more, and the maximum value of the difference between the cutting edge lengths of all the cutting edges is 0.12% or less with respect to the reference cutting edge length; or (3) n is 2 or more, and the minimum value of the difference between the edge length of the longest cutting edge and the edge length of the other cutting edges is 0.60% or more with respect to the reference edge length.

Owner:NITTO DENKO CORP

Ultrasonic elliptically vibrating boring process

The ultrasonic elliptically vibrating boring process in the field of precise machining technology includes the following steps: 1) adhering two piezoelectric ceramic chips onto two orthogonal surfaces of elliptically vibrating amplitude-varying rod; 2) applying sinusoidal voltage across the chips to make the chips to stretch and contract and the rod to bend and vibrate; 3) strengthening the bending and vibration of the rod; 4) making the boring cutter fixed to the tip of the rod obtain maximum elliptic vibration; 5) synthesizing the horizontal and vertical bending vibrations to obtain the elliptic vibration track in the edge of the boring cutter; and 6) fixing the elliptically vibrating amplitude-varying rod onto the boring rod via the vibration node. The present invention has greatly reduced boring force, reduced boring rod deformation, raised stability of the boring system and raised boring precision and surface smoothness.

Owner:SHANGHAI JIAOTONG UNIV

A milling and drilling compound processing tool

ActiveCN107030319BReduce thicknessChange distribution statusTransportation and packagingMilling cuttersPetalEngineering

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

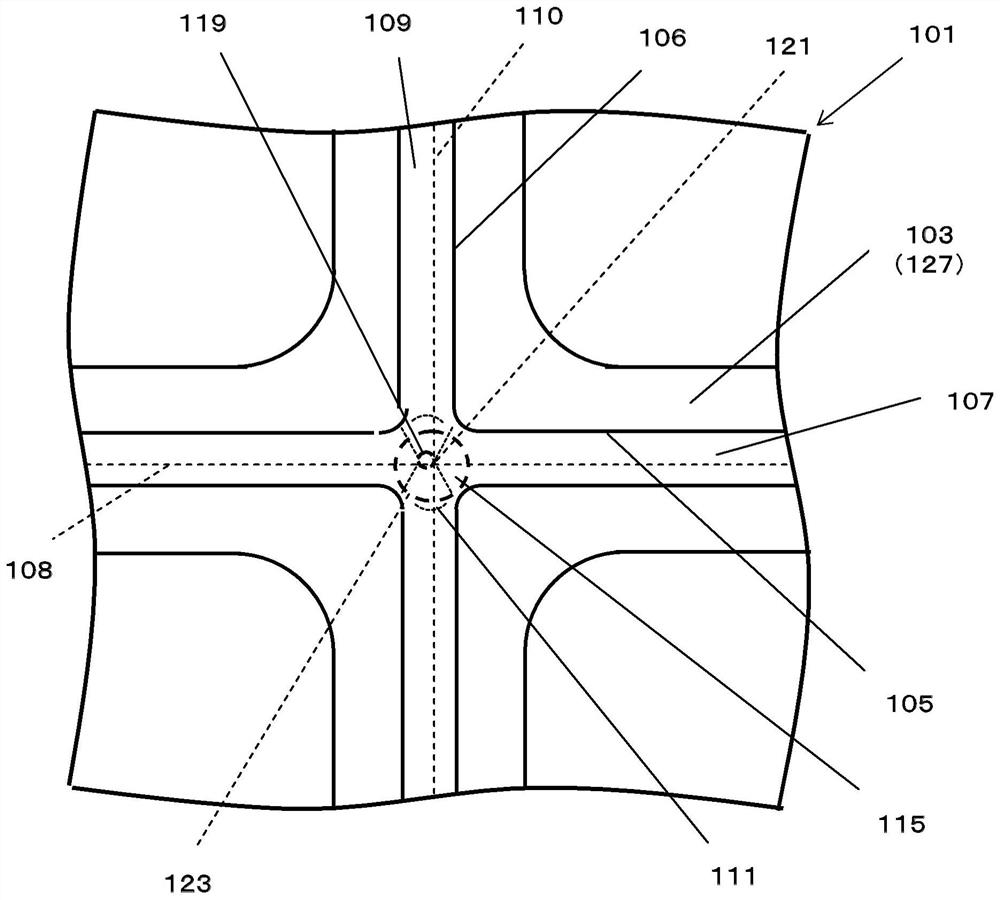

A double-sided groove cutting insert

The invention relates to the technical field of metal cutting, and discloses a double-face groove profile cutting blade. A blade body is of a geometric structure, wherein the geometric structure is provided with a polygon and is symmetric up and down. A positioning hole is formed in the geometric center. The blade body is composed of an upper end face, a lower end face, a plurality of side surfaces and an arc side face located between every two adjacent side surfaces, and the upper end face and the lower end face are provided with supporting surfaces between the edges of scrap cutting tables and the positioning hole. The top corner of the blade is provided with no fewer than one cutting unit part, and each cutting unit part is composed of a cutting edge, the corresponding scrap cutting table and a scrap cutting guiding protruding part, wherein the scrap cutting table is composed of a front blade face and a plurality of cutting guiding faces, the scrap cutting guiding protruding part isarranged at the top corner of the cutting unit part, and the cutting edge is composed of an arc cutting edge body, a main cutting edge body, a transition cutting edge body and an auxiliary cutting edge body. Through the blade, the sharpness and stability of the cutting edges are improved, scrap cutting and discharging are smooth, blade abrasion is reduced, and the phenomenon of built-up edges iseffectively restrained.

Owner:OKE PRECISION CUTTING TOOLS CO LTD

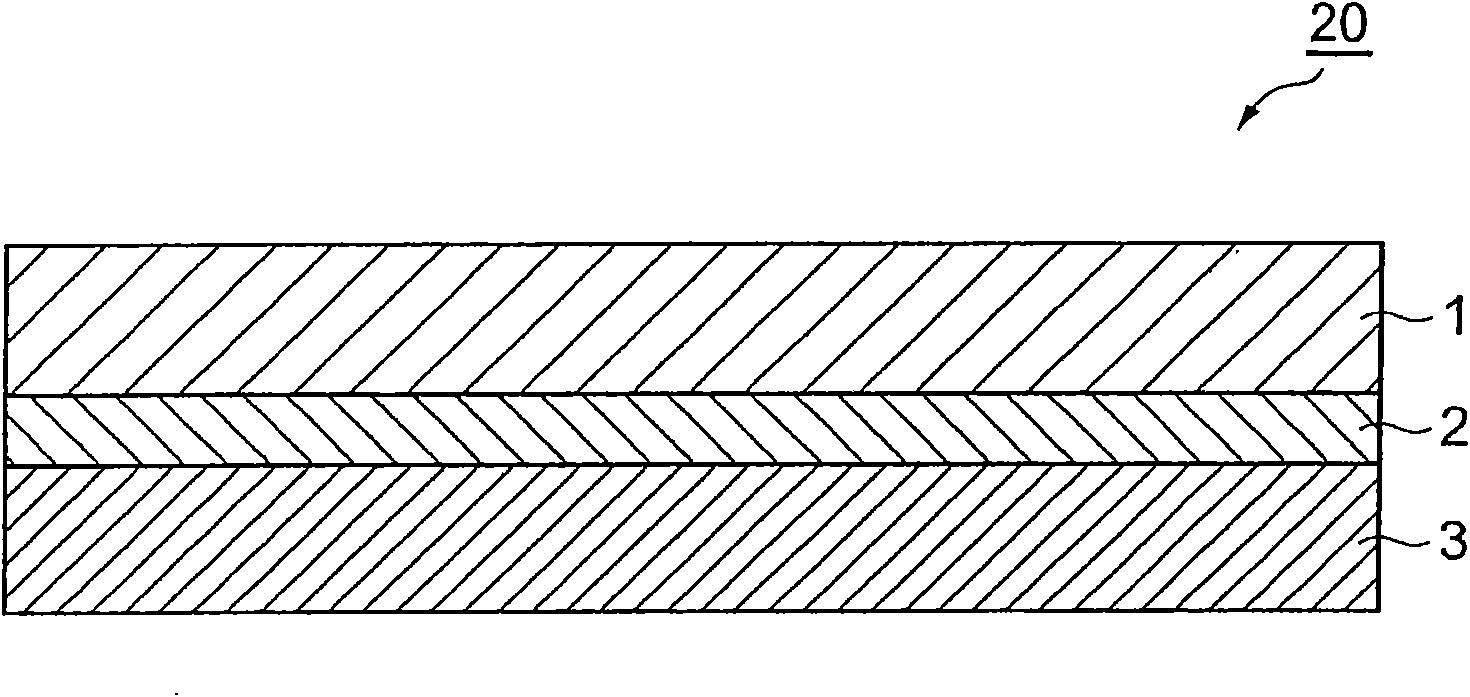

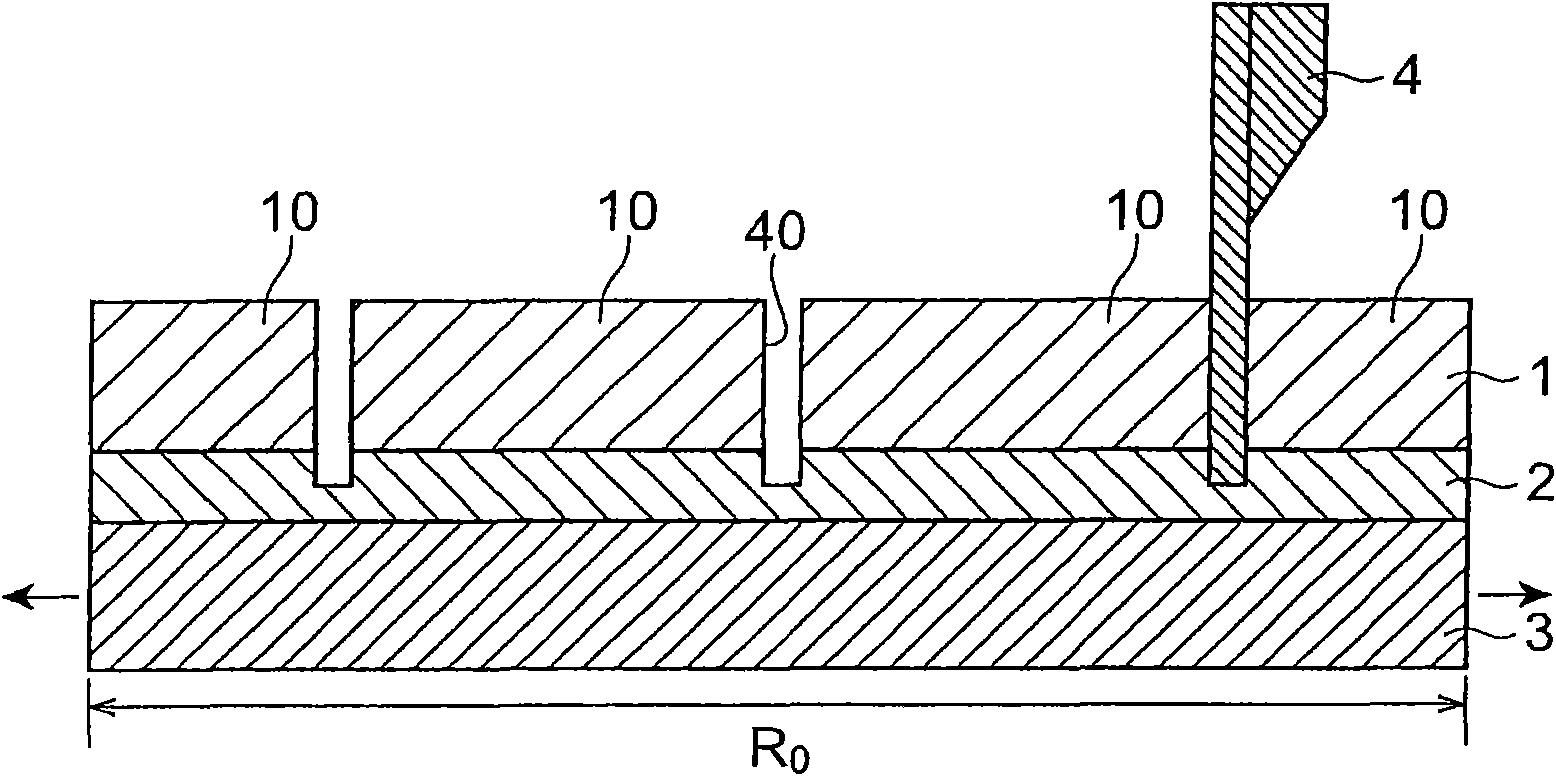

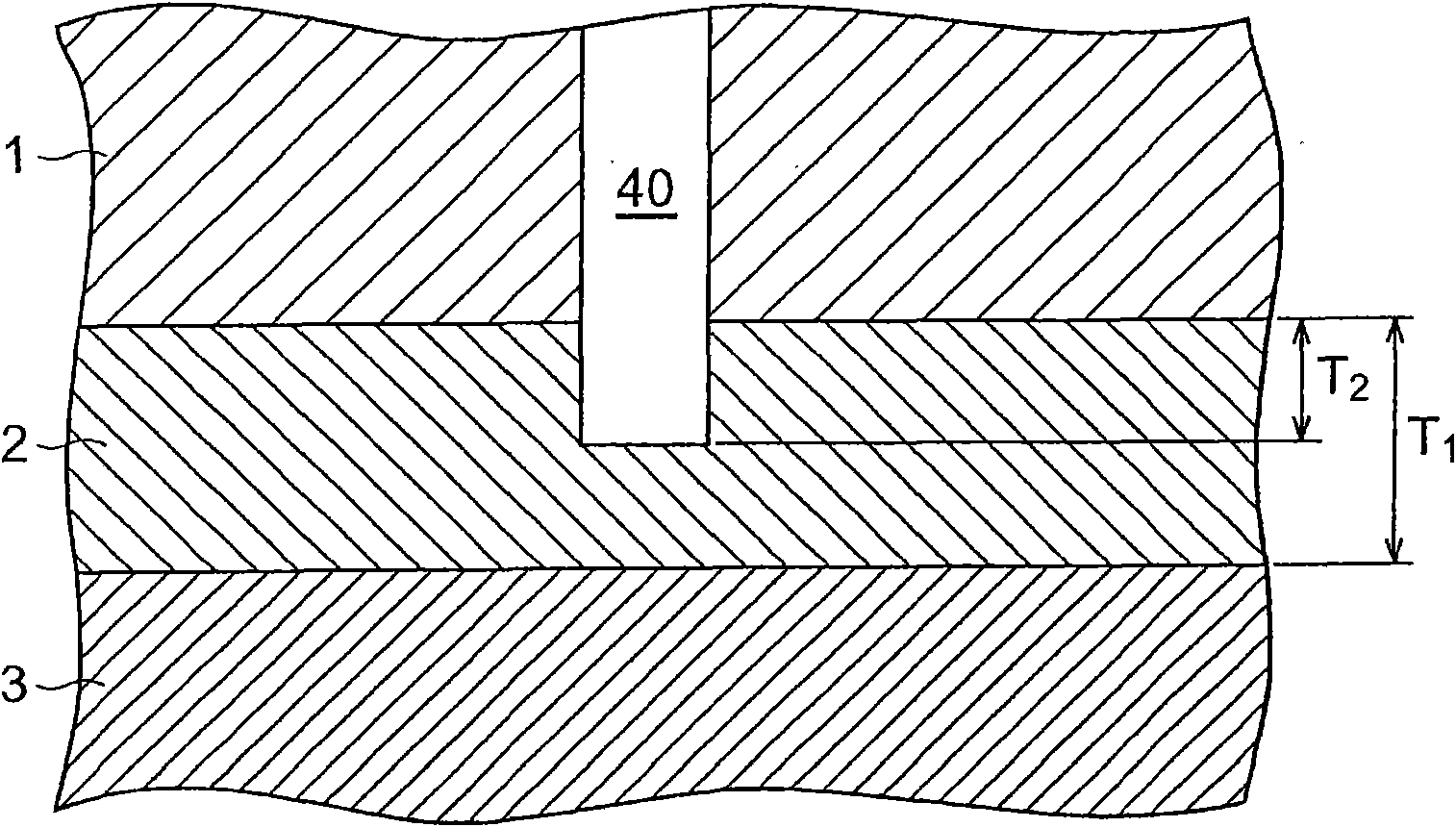

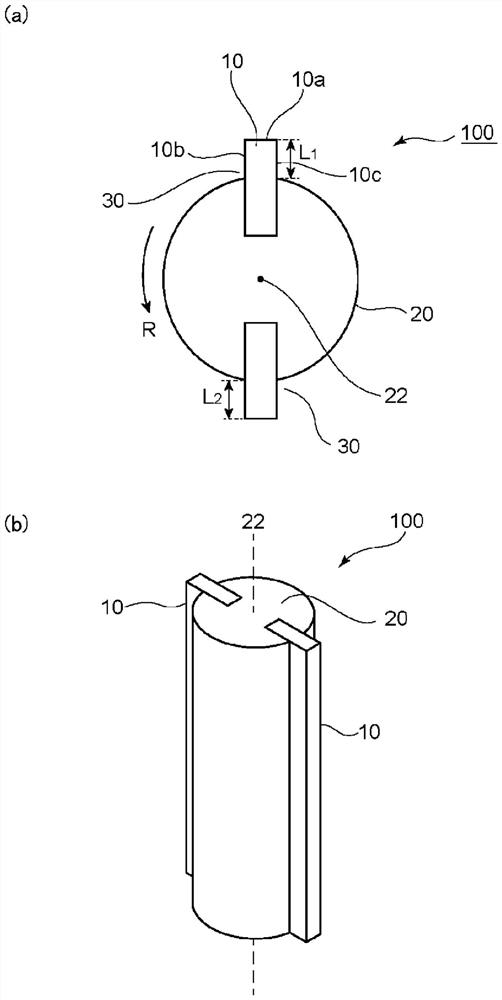

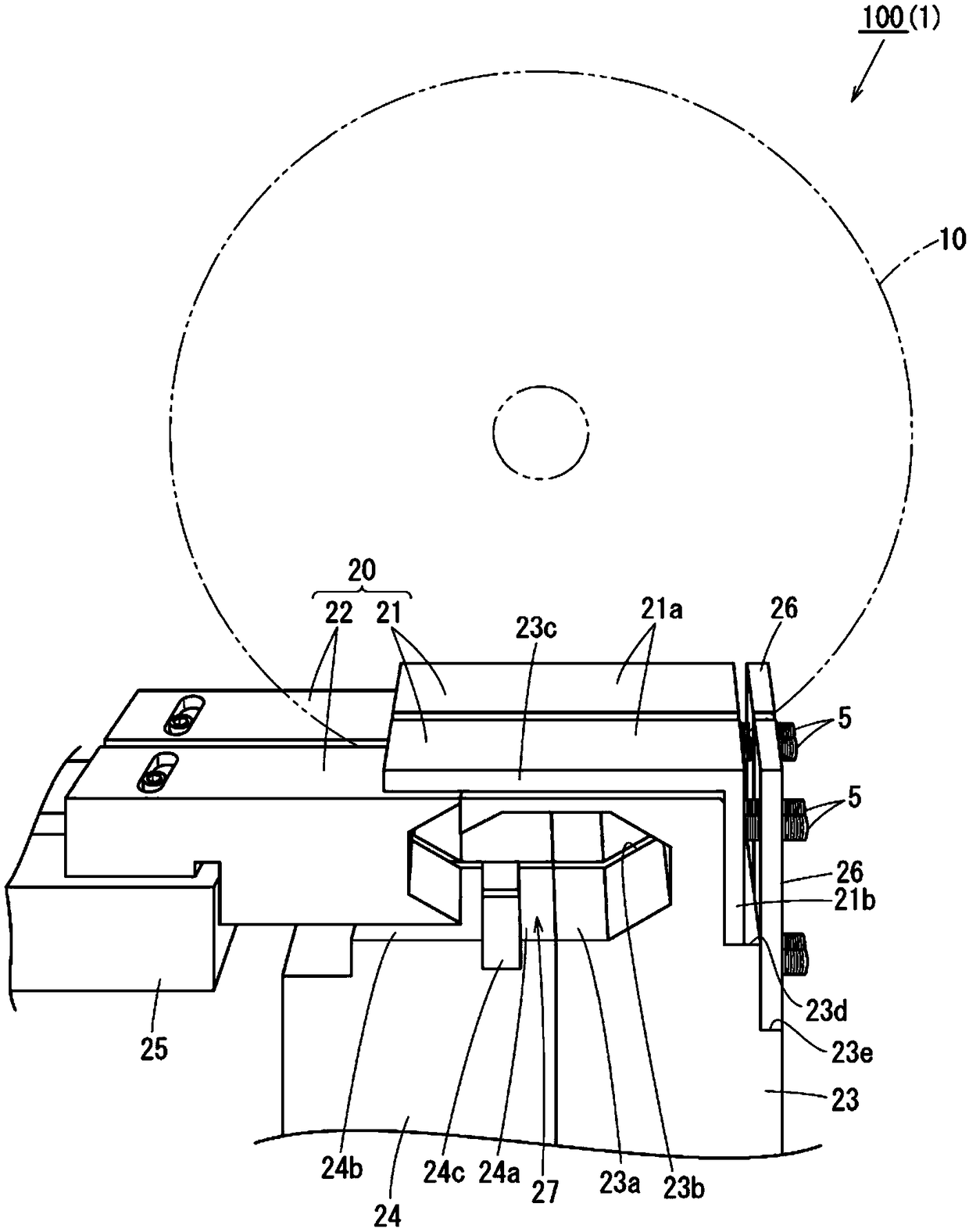

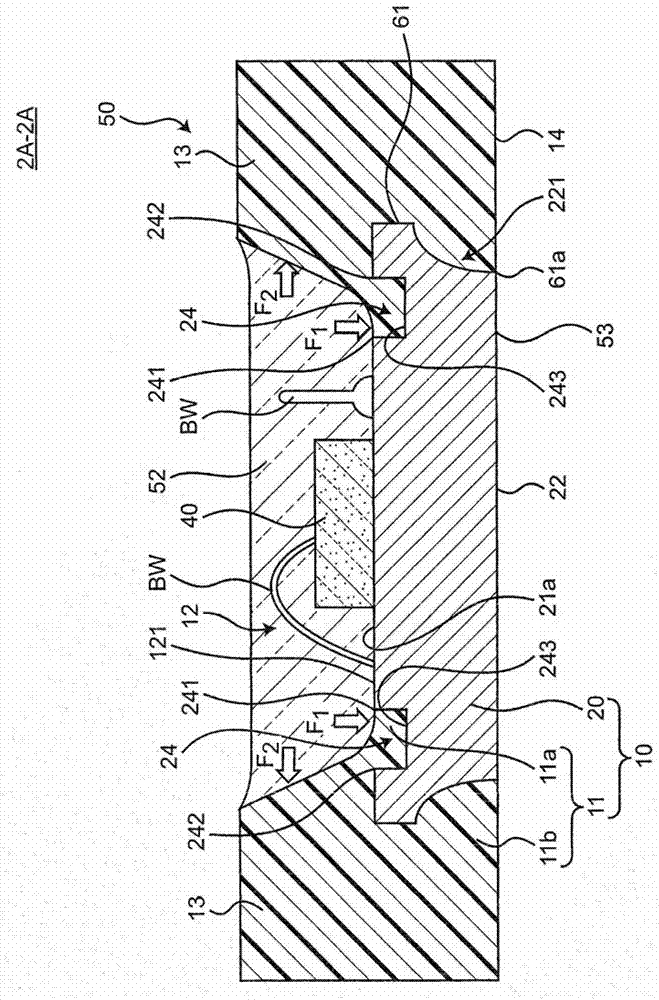

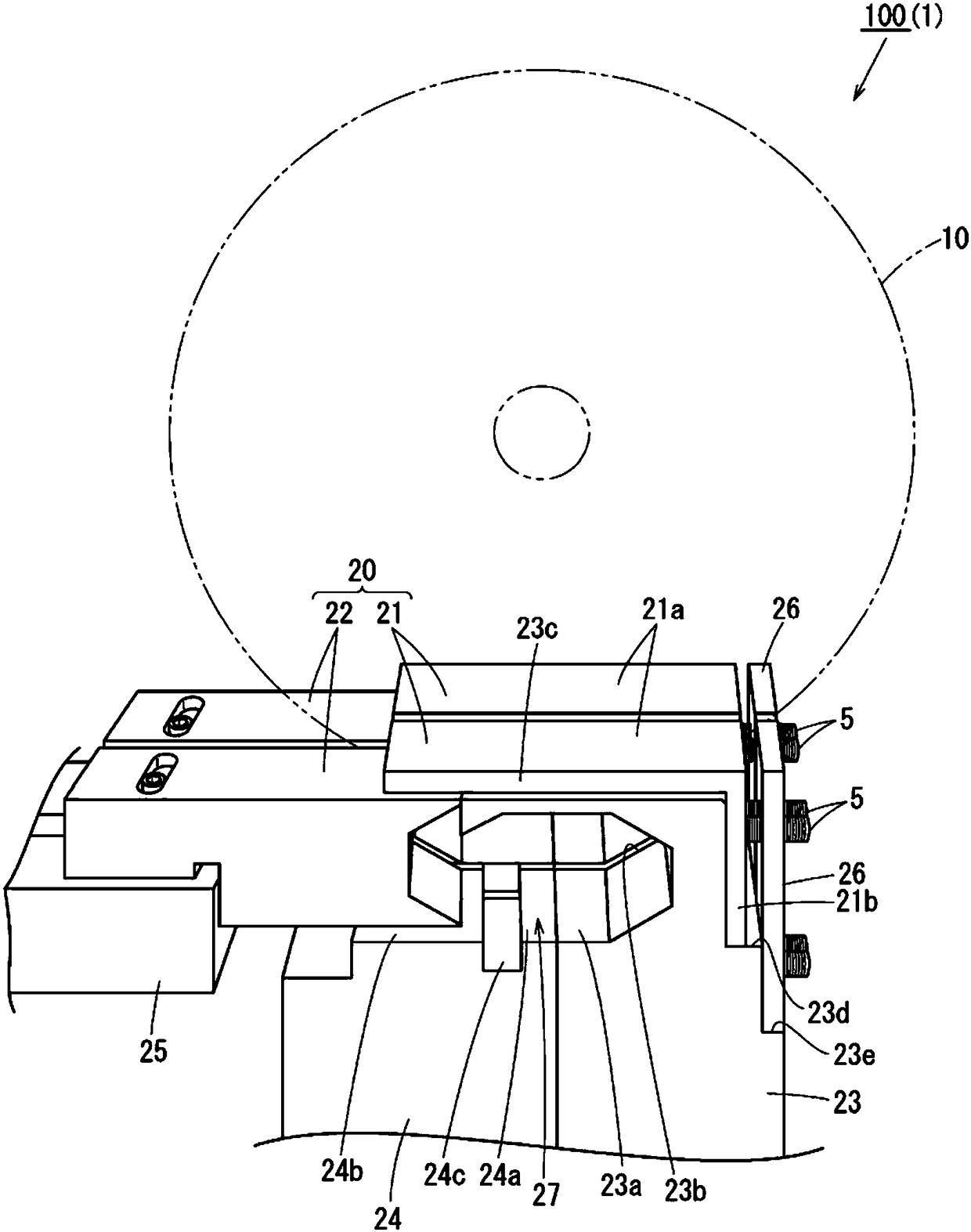

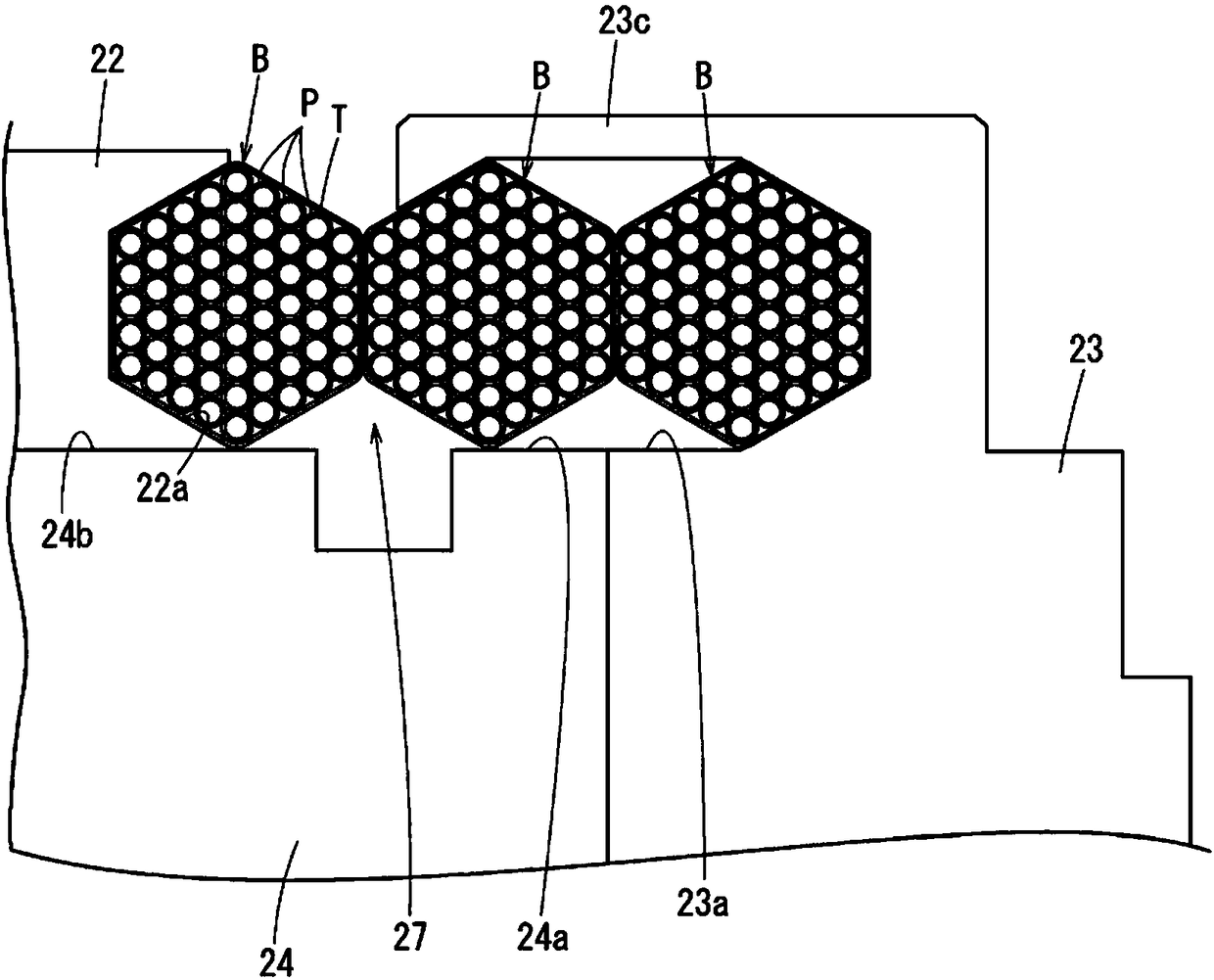

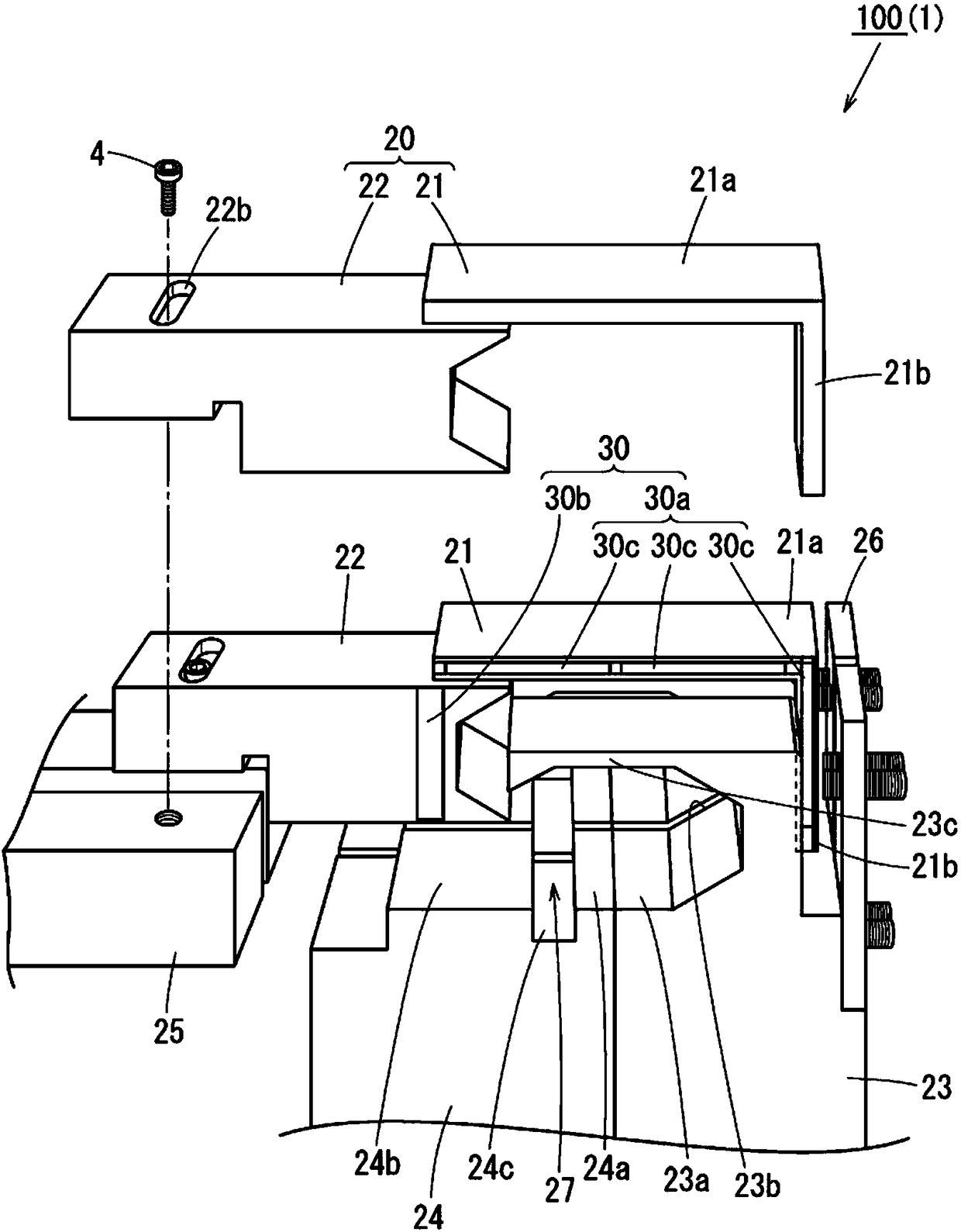

Grinding wheel guide, production line, and manufacturing method involved in manufacturing central core of secondary battery

ActiveCN108472784BSuppress glitchAvoid damageMetal sawing devicesFinal product manufactureProduction lineAlloy

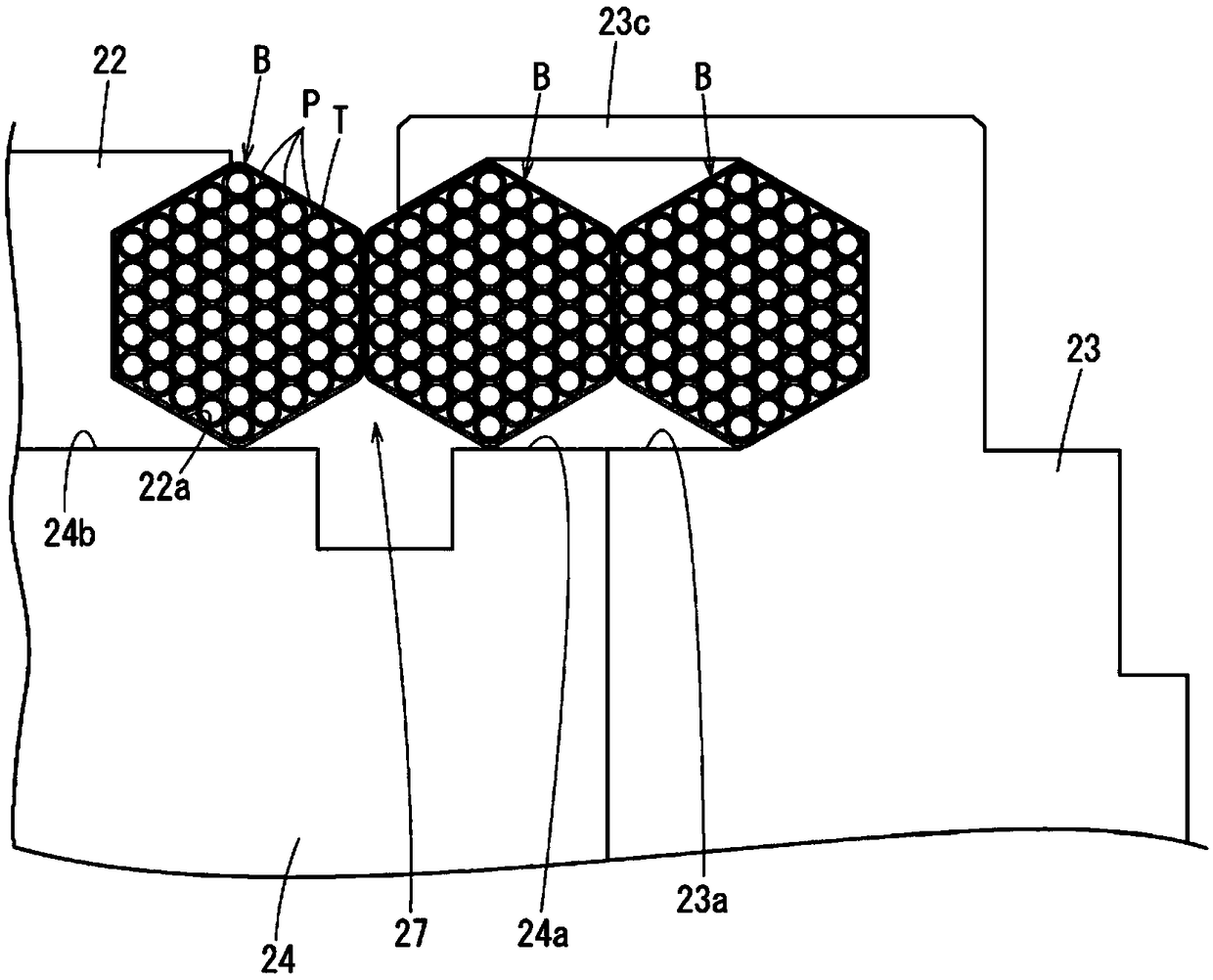

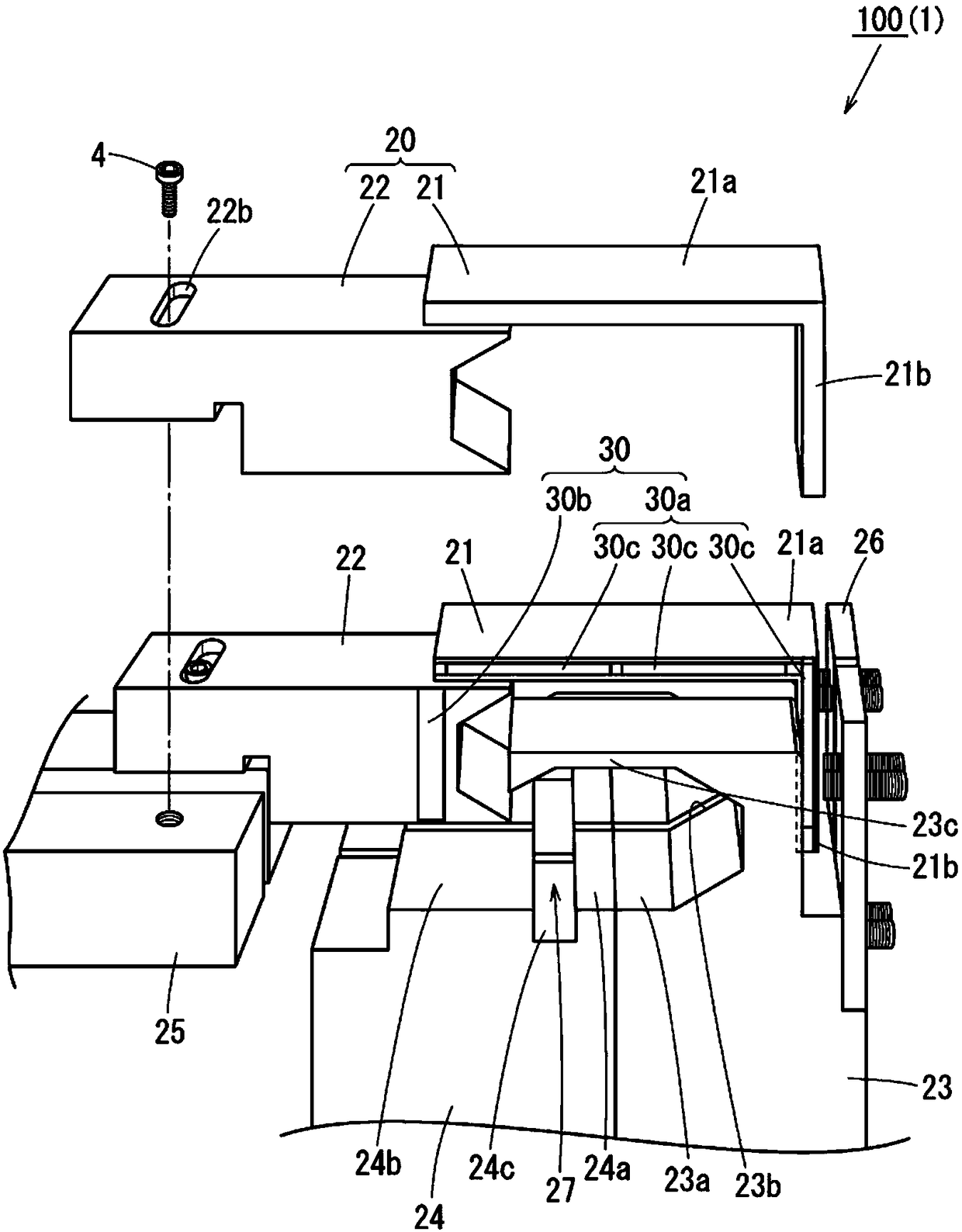

An object of the present invention is to suppress generation of burrs or damages at both ends of a tubular center core for a secondary battery. The grinding wheel guide (20) of the present invention is used to guide a cutting grinding wheel (10) for cutting a tube when manufacturing a tubular central core for a secondary battery, and the grinding wheel guide (20) includes: a tube bundle support ( 22, 23, 24), which hold the tube bundle in a state where one or more bundles of material tubes are arranged; Guide, the guide member (22, 23) has a pair of guide surfaces (30) that abut against the side surfaces of the cut-off grinding wheel (10), and the guide surfaces (30) are formed of sintered diamond or cemented carbide. Preferably, the tube bundle support (22, 23, 24) has a holding frame (27) for a plurality of tube bundles to be fixed side by side on the inside, and the guide surface (30) is arranged so as to surround the holding frame (27) toward the cutting wheel (10). U-shaped with the opposite side open.

Owner:KOTOBUKI PRECISION CO LTD

Molded package for light-emitting device and light-emitting device using the same

ActiveCN103219446BInhibition of exudationPrevent intrusionSolid-state devicesPrinted circuitsEngineeringLight emitting device

The present invention provides a molded package capable of effectively suppressing the intrusion of flux into the recessed portion of the molded package when used in a light-emitting device, and capable of suppressing the occurrence of burrs in the molded resin body in the recessed portion. The package molding of the present invention includes: a resin molding having a concave portion for accommodating a light-emitting component on its upper surface; a bottom surface of the concave portion of the resin molding is partially exposed and extending to a side constituting the concave portion The lead wire is below the wall and is electrically connected to the light emitting part, and in the package molding body, the lead wire has a groove portion formed on the surface of the lead wire along at least a part of the side wall, the groove portion It has an inner upper end edge and an outer upper end edge, and is filled with the resin molded body so that the inner upper end edge is exposed on the bottom surface of the concave portion and the outer upper end edge is embedded in the resin molded body.

Owner:NICHIA CORP

Grindstone guide, production line and production method pertaining to rechargeable battery core production

ActiveCN108472784ASuppress glitchAvoid damageMetal sawing devicesFinal product manufactureProduction lineElectrical battery

The present invention limits the occurrence of burrs and scratches on the two ends of a pipe-type core for a rechargeable battery. This grindstone guide (20) is for guiding a cutting grindstone (10) for cutting pipes when manufacturing pipe-type cores for rechargeable batteries and is provided with: pipe bundle supports (22, 23, 24) for holding one or multiple pipe bundles, in which material pipeshave been bundled, side by side; and guiding members (22, 23) for guiding the cutting grindstone (10). The guiding members (22, 23) have a pair of guiding surfaces (30) that contact the side surfacesof the cutting grindstone (10) and the guiding surfaces (30) are formed with sintered diamond or cemented carbide. The pipe bundle supports (22, 23, 24) have a holding frame (27) for juxtaposing themultiple pipe bundles in parallel therein and immobilizing same. The guiding surfaces (30) are preferably disposed in a U-shape so as to surround the holding frame (27) and opens towards the side opposite to the cutting grindstone (10).

Owner:KOTOBUKI PRECISION CO LTD

Devices and methods for calibrating and operating a snapback clamp circuit

ActiveUS9182767B2Fast response timeSuppress glitchParameter calibration/settingTransistorControl signalIntegrated circuit

A device includes a snapback clamp circuit configured to clamp a supply voltage in response to the supply voltage exceeding a trigger voltage level. In at least one embodiment, the snapback clamp circuit includes a clamp transistor and a programmable resistance portion that is responsive to a control signal to calibrate the trigger voltage level. Alternatively or in addition, the snapback clamp circuit may include a programmable bias device configured to calibrate the trigger voltage level by biasing a gate terminal of the clamp transistor. In another particular embodiment, a method of calibrating a snapback clamp circuit is disclosed. In another particular embodiment, a method of operating an integrated circuit is disclosed.

Owner:QUALCOMM INC

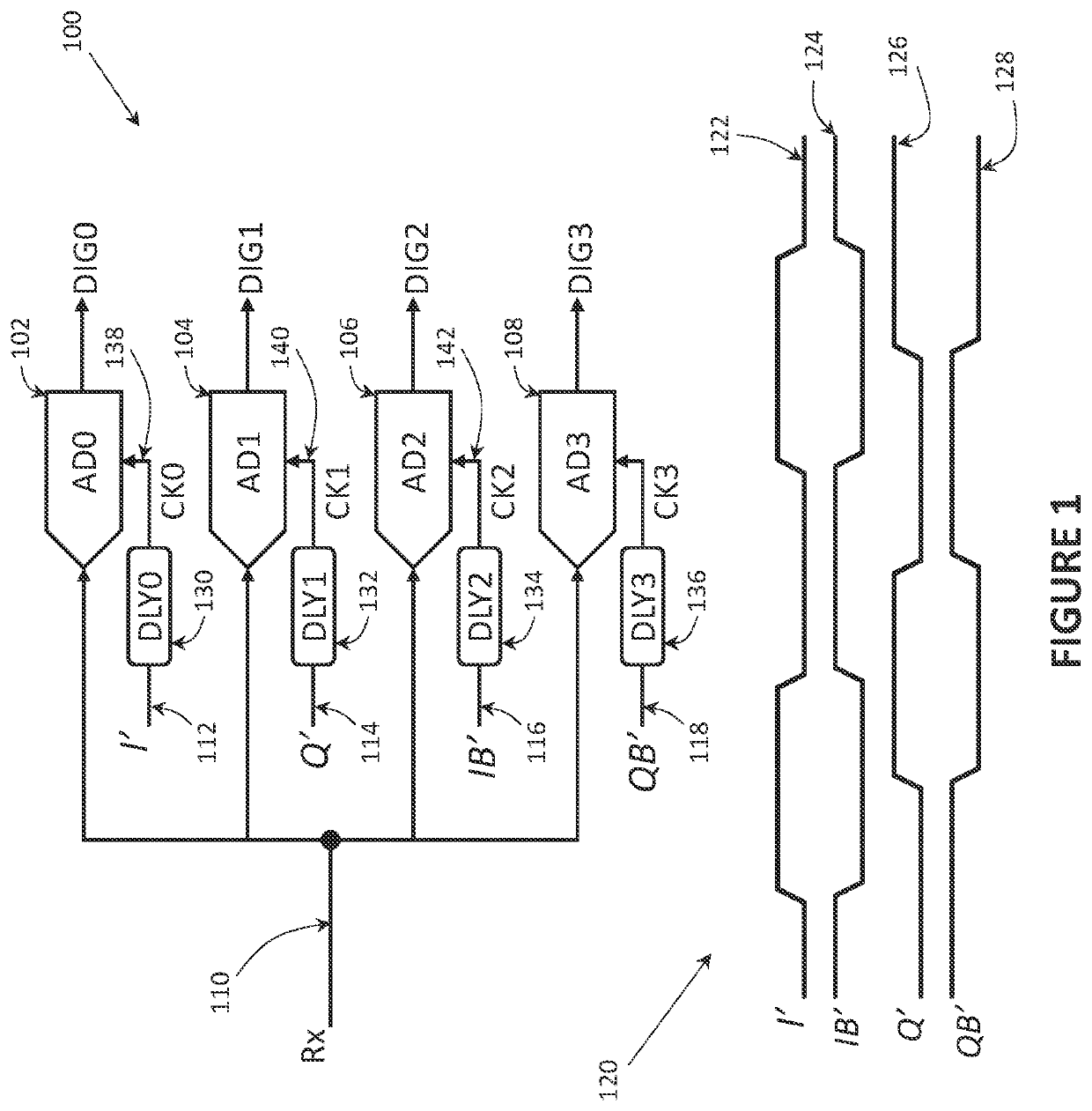

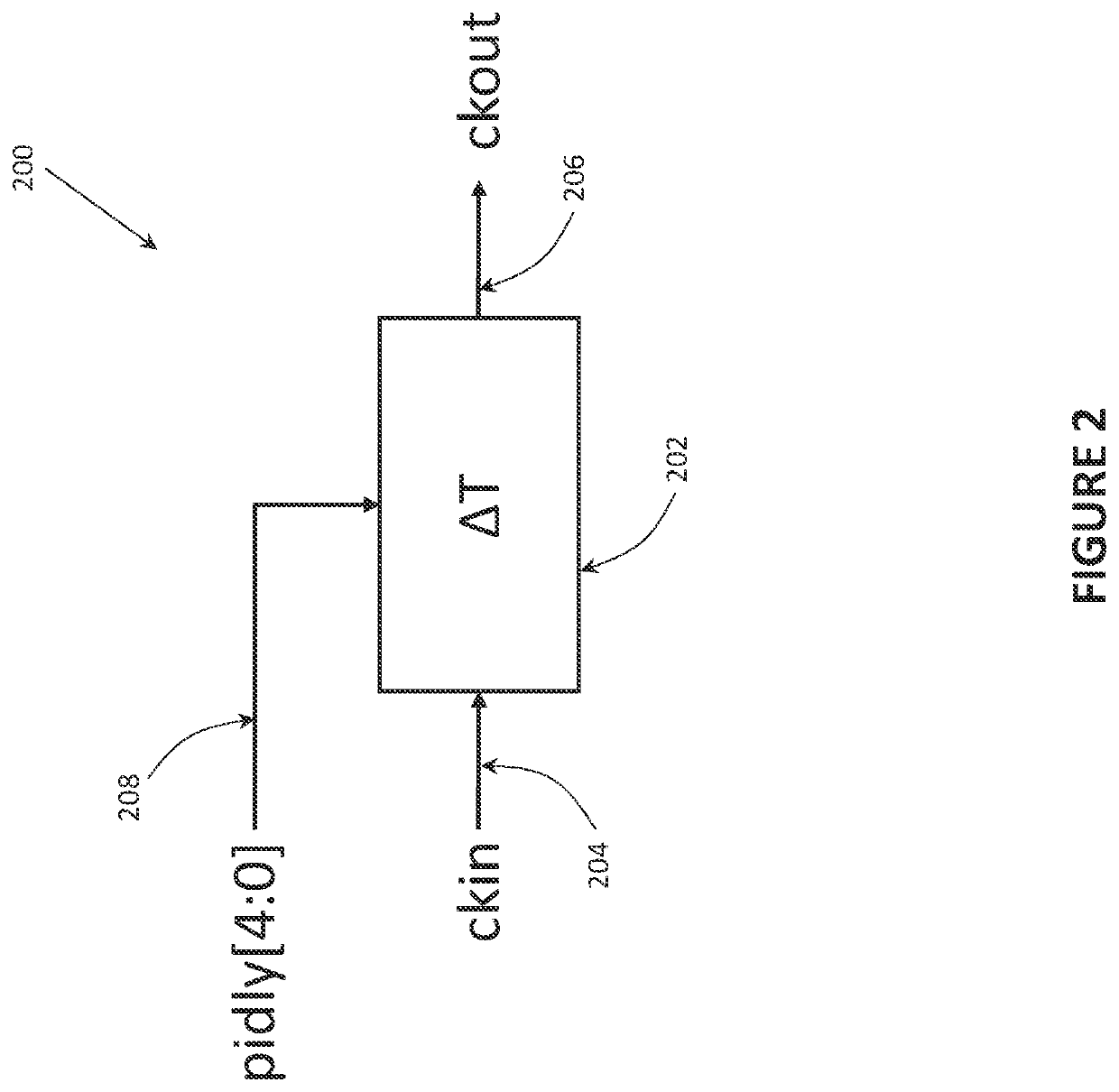

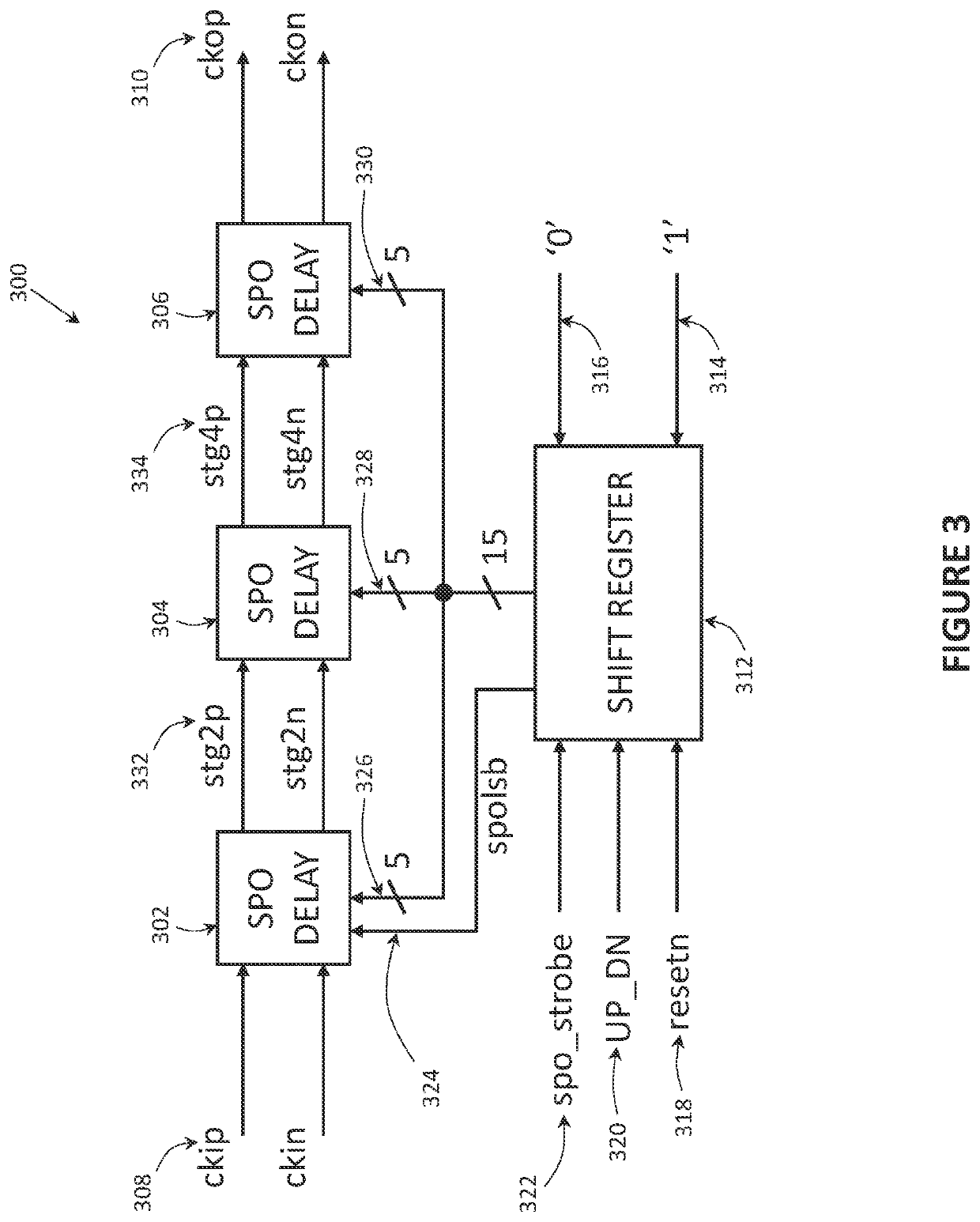

Programmable delay line with glitch suppression

ActiveUS20220147017A1Suppress glitchProgramme controlComputer controlSoftware engineeringMechanical engineering

There is disclosed herein programmable delay lines and control methods having glitch suppression. In particular, the programmable delay lines may include latches that are triggered based on a trigger event of an input signal (which is often an edge of the input signal). The programmable delay lines may include one or more latches coupled between capacitor and transistor subassemblies and the latches, where the latches cause a delay between the time the trigger event arrives at the capacitor and transistor subassemblies and the latches. The delay can prevent the latches from updating at the same time that the edge of the input signal arrives at the capacitor and transistor subassemblies, which can suppress glitches that can causes errors in operation.

Owner:ANALOG DEVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com