A hole-making method for ion propulsion carbon grid assembly

A technology of ion propulsion and components, which is applied in metal processing and other directions, can solve the problems such as the inability to apply carbon grid porous manufacturing applications, the inability to apply spherical crown carbon grid component processing, and the large measurement error of spherical crown shape workpieces, etc., to achieve the suppression of burrs And delamination defects, improve the rigidity, good effect of precision consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

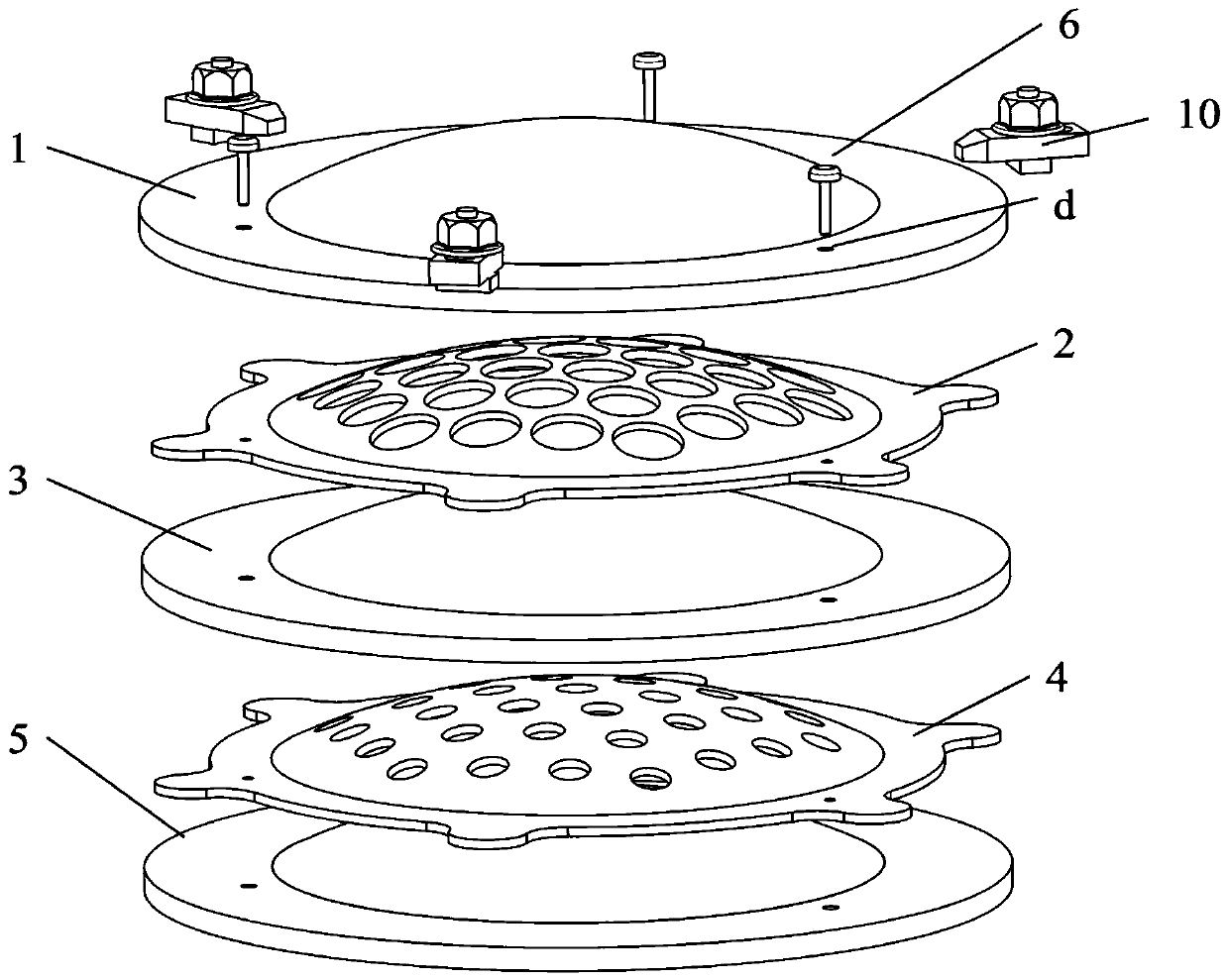

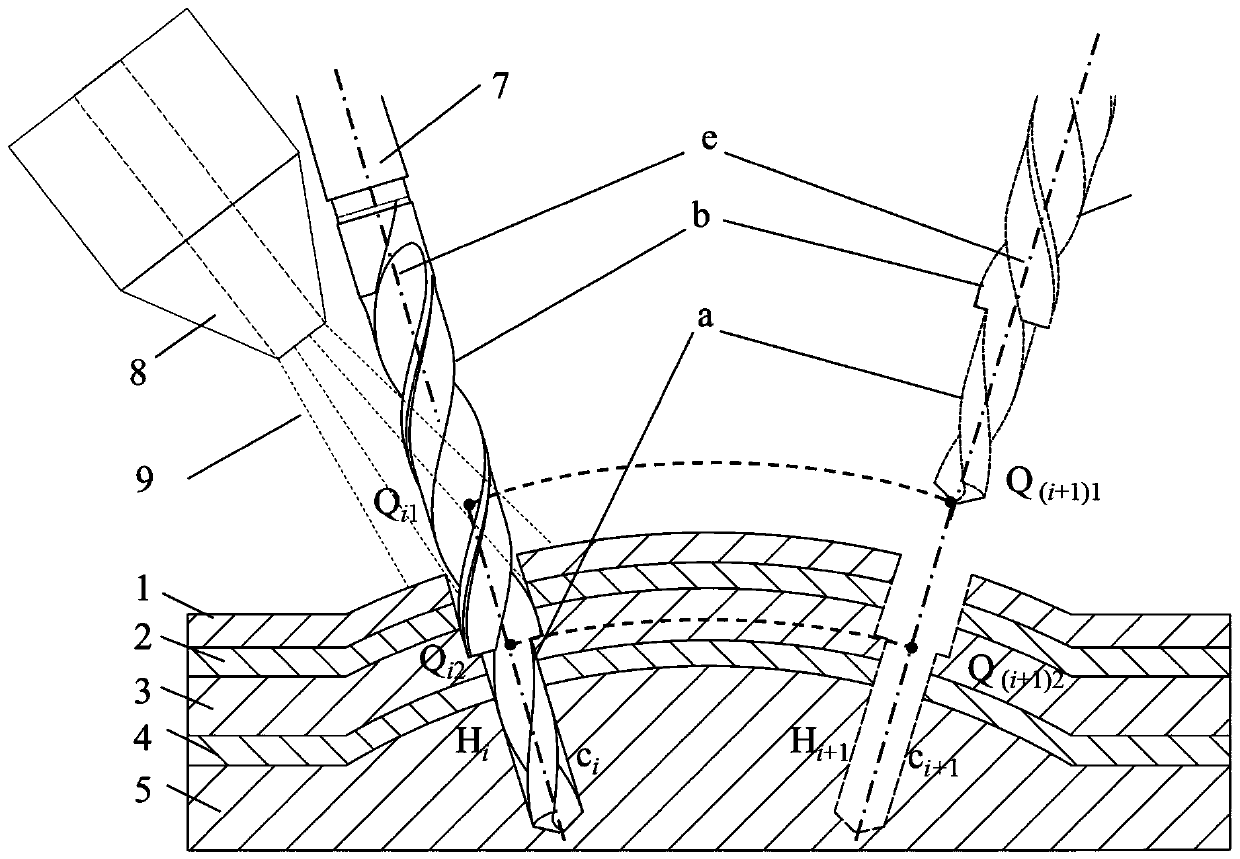

[0018] figure 1 It is a schematic diagram of the positioning and clamping of the carbon grid assembly. In this embodiment, the screen grid 2 has a diameter of 110 mm and a thickness of 0.5 mm, and the acceleration grid 4 has a diameter of 110 mm and a thickness of 0.7 mm. The diameter of the front end of the stepped drill bit 7 is 1.1 mm, and the diameter of the rear end is 1.9 mm.

[0019] The specific steps of the method are as follows:

[0020] The first step is "sandwich" clamping

[0021] The spherical crown-shaped carbon grid assembly is composed of screen grid 2 and acceleration grid 4; the surface shape of the aluminum alloy backing plate is consistent with the surface shape of the matching surface of the corresponding grid; the aluminum alloy lower backing plate 5, the acceleration grid 4, The aluminum alloy intermediate backing plate 3, the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com