Transmission method of a locomotive shaft end speed sensor

A speed sensor, sensor technology, applied in the direction of speed/acceleration/shock measurement, speed/acceleration/shock meter details, instruments, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

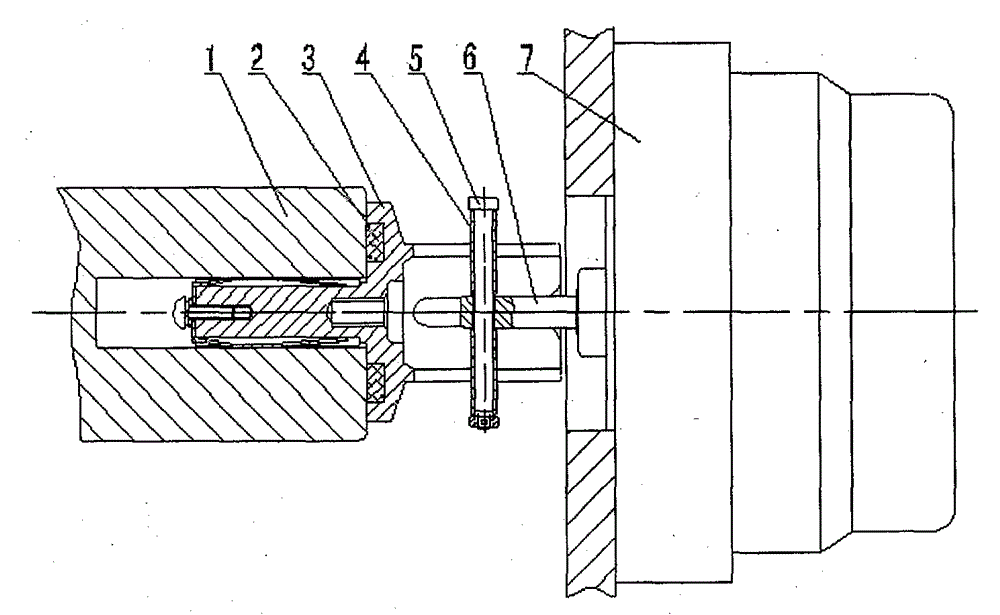

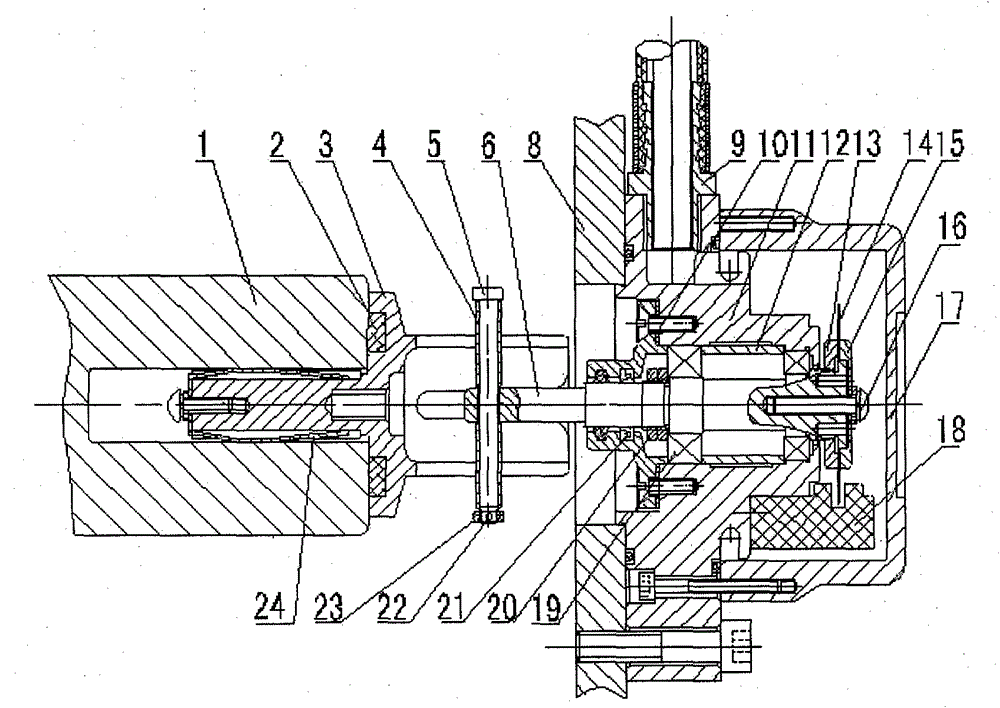

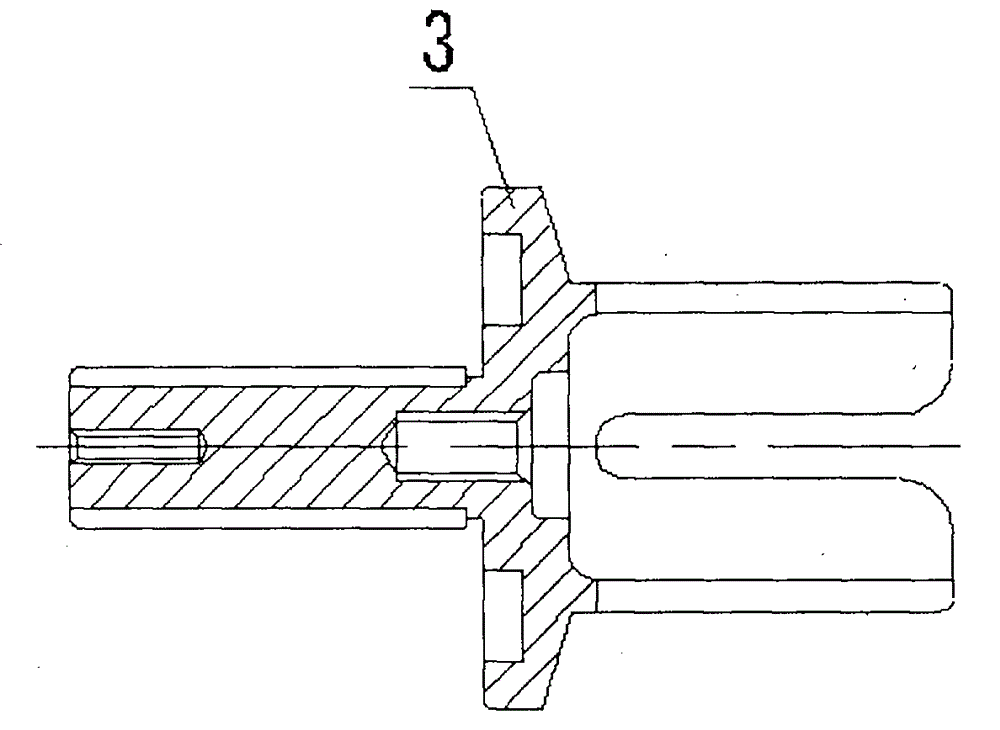

[0010] Referring to the accompanying drawings, an implementation example of a transmission method for a locomotive shaft end speed sensor will be described in detail. The present invention uses the principle of floating transmission to reduce the degree of constraint freedom, adopts rolling contact friction reduction measures, and uses transmission forks, magnetic rings and transmission dials A rod structure, a method and a device for realizing high-reliability transmission under the condition of two degrees of freedom with large floating amount. Including: transmission fork, suction magnetic ring, transmission lever, roller cover, sensor shaft, sensor. drive fork, see figure 2 3 of them, by pulling in the magnetic ring, see figure 2 In 2, connect the transmission fork with the axle end of the locomotive with the drive fork handle, and connect the axle of the locomotive, see figure 2 In 1, the rotation speed is passed through the transmission rod covered with roller sleeves,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com