Patents

Literature

44results about How to "Guaranteed coaxial accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

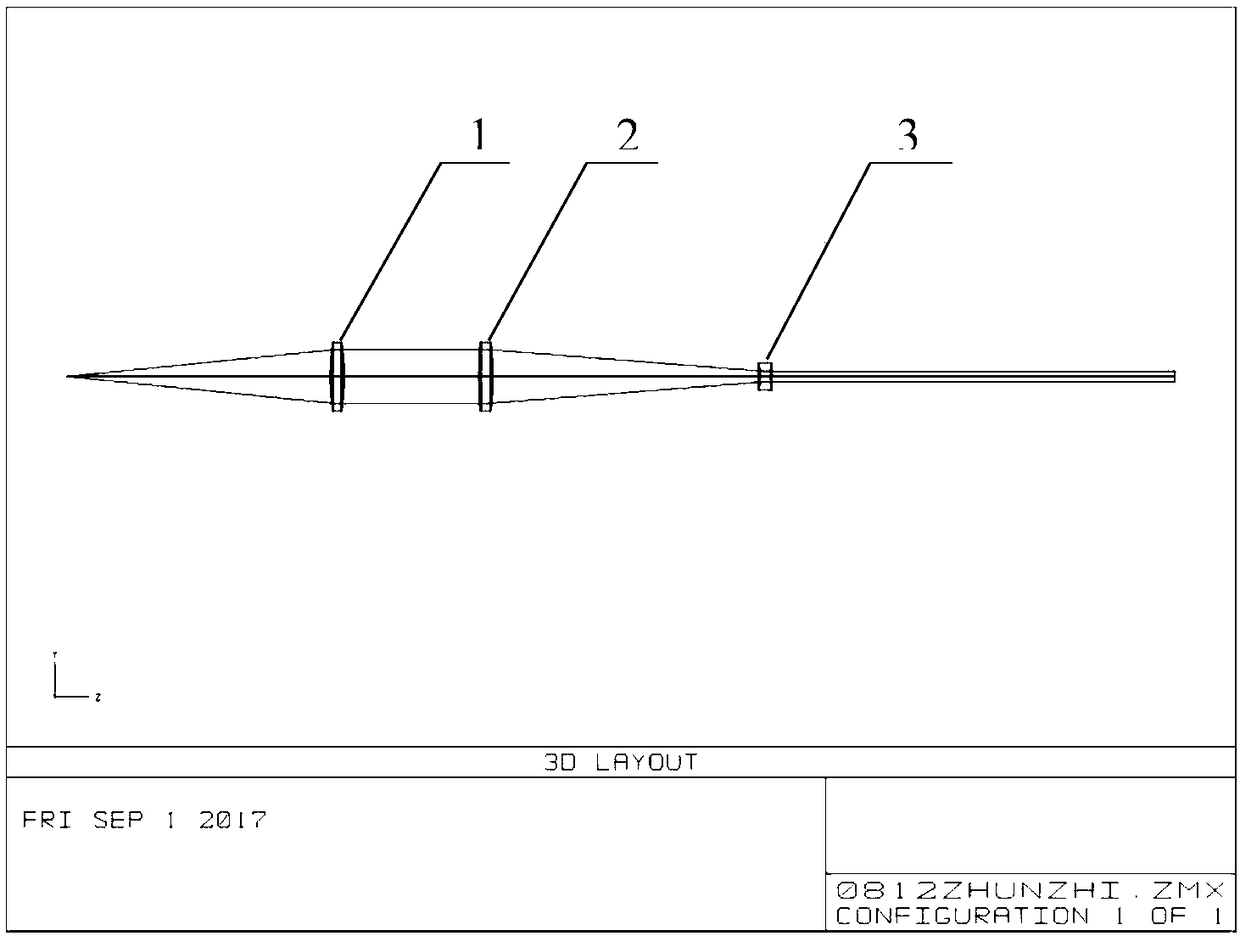

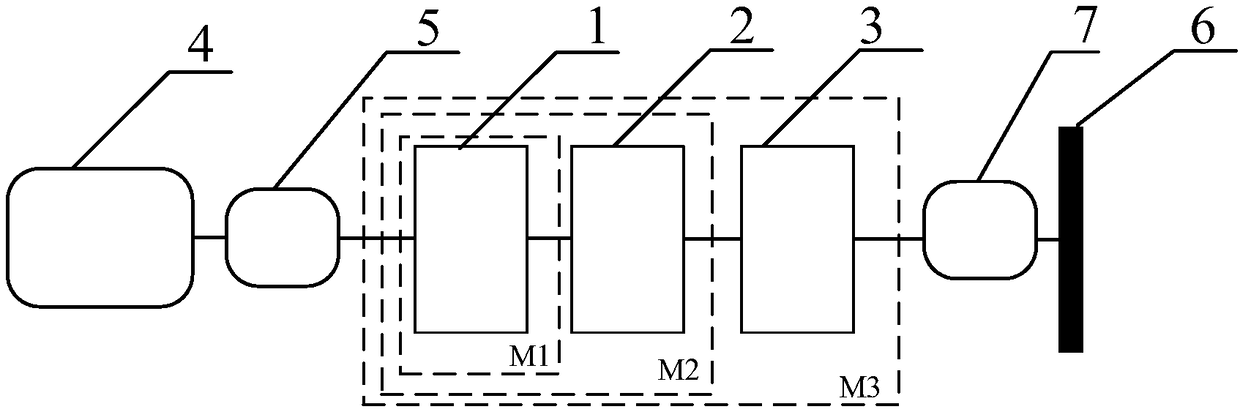

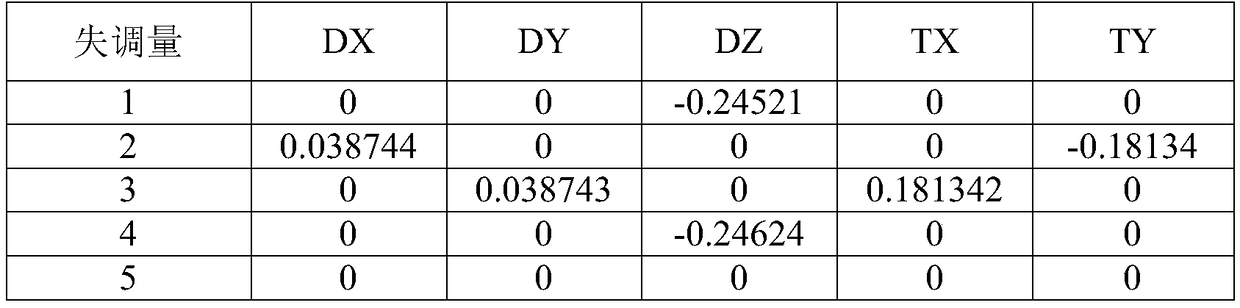

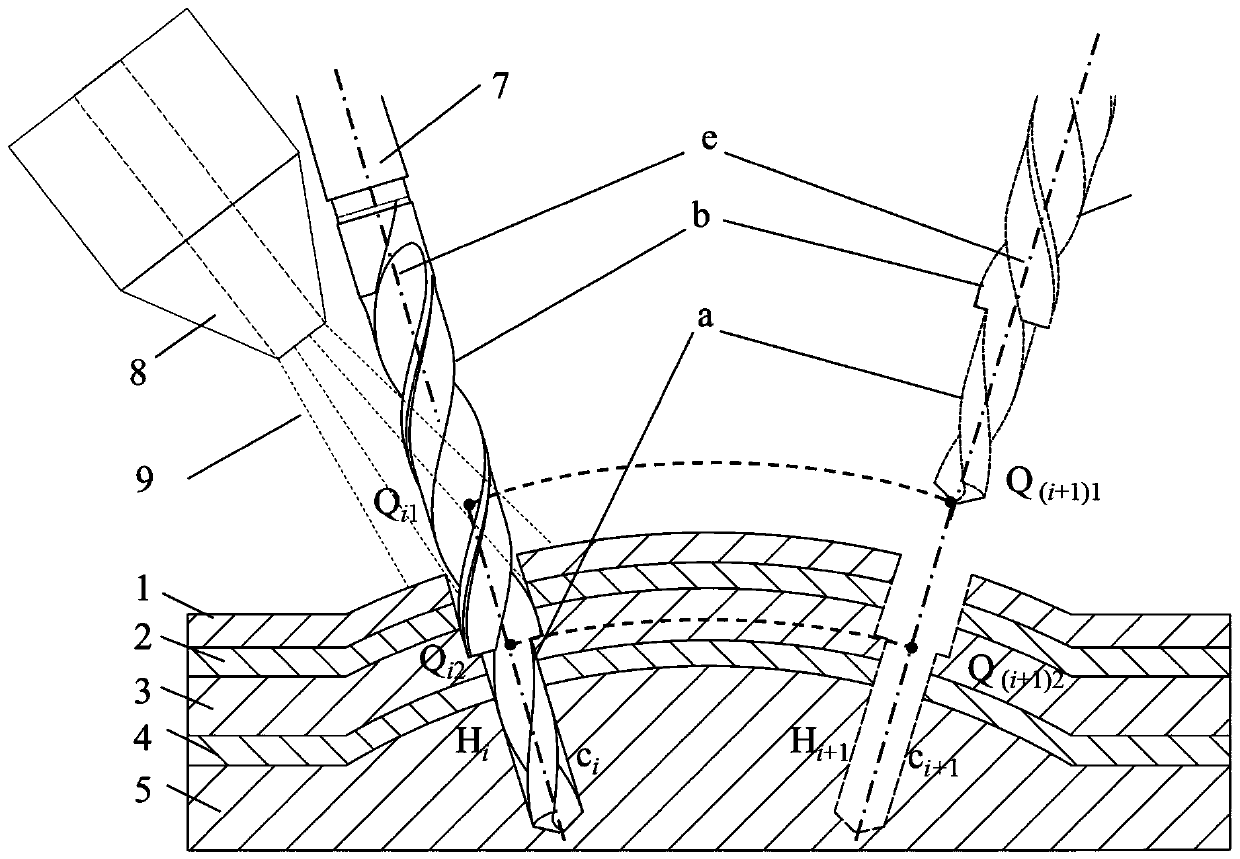

Computer-aided installation and adjustment method of coaxial optical system

ActiveCN109031659AAvoid position mutual compensation problemsSolve the problem that cannot be adjustedDesign optimisation/simulationSpecial data processing applicationsComputer-aidedComputer aid

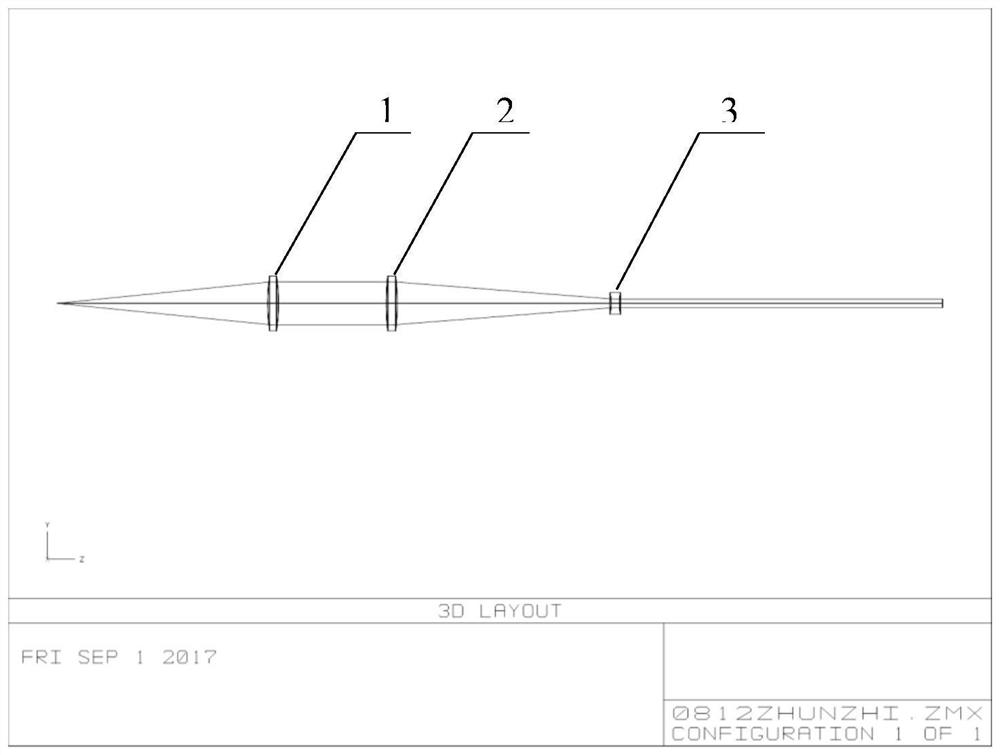

The invention discloses a computer-aided installation and adjustment method of a coaxial optical system. The computer-aided installation and adjustment method comprises the following steps of S1, establishing an optical model of an optical system to be installed and adjusted, and separately establishing n optical sub-systems along the optical path direction, wherein the n optical sub-system comprises optical elements 1-n; S2, selecting the image plane positions of each optical sub-system and obtaining an ideal wavefront aberration through simulation analysis; S3, introducing a position deviation amount to the optical element n in the n optical sub-system to obtain a simulated wavefront aberration; S4, solving a sensitivity matrix corresponding to each optical sub-system by adoptinga sensitivity matrix formula; and S5, solving the actual position deviation of the optical element n in the n optical sub-system by utilizing the sensitivity matrix and the actual wavefront aberration, and adjusting the optical element, so as to successively complete the installation and adjustment of the n optical sub-systems. By adoption of the method, the problem of mutual compensation ofpositions of all the optical elements in the adjusting process can be avoided, so that the convergence speed in the assembling and adjusting process is accelerated, and the assembling and adjusting precision and the assembling and adjusting efficiency are improved.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

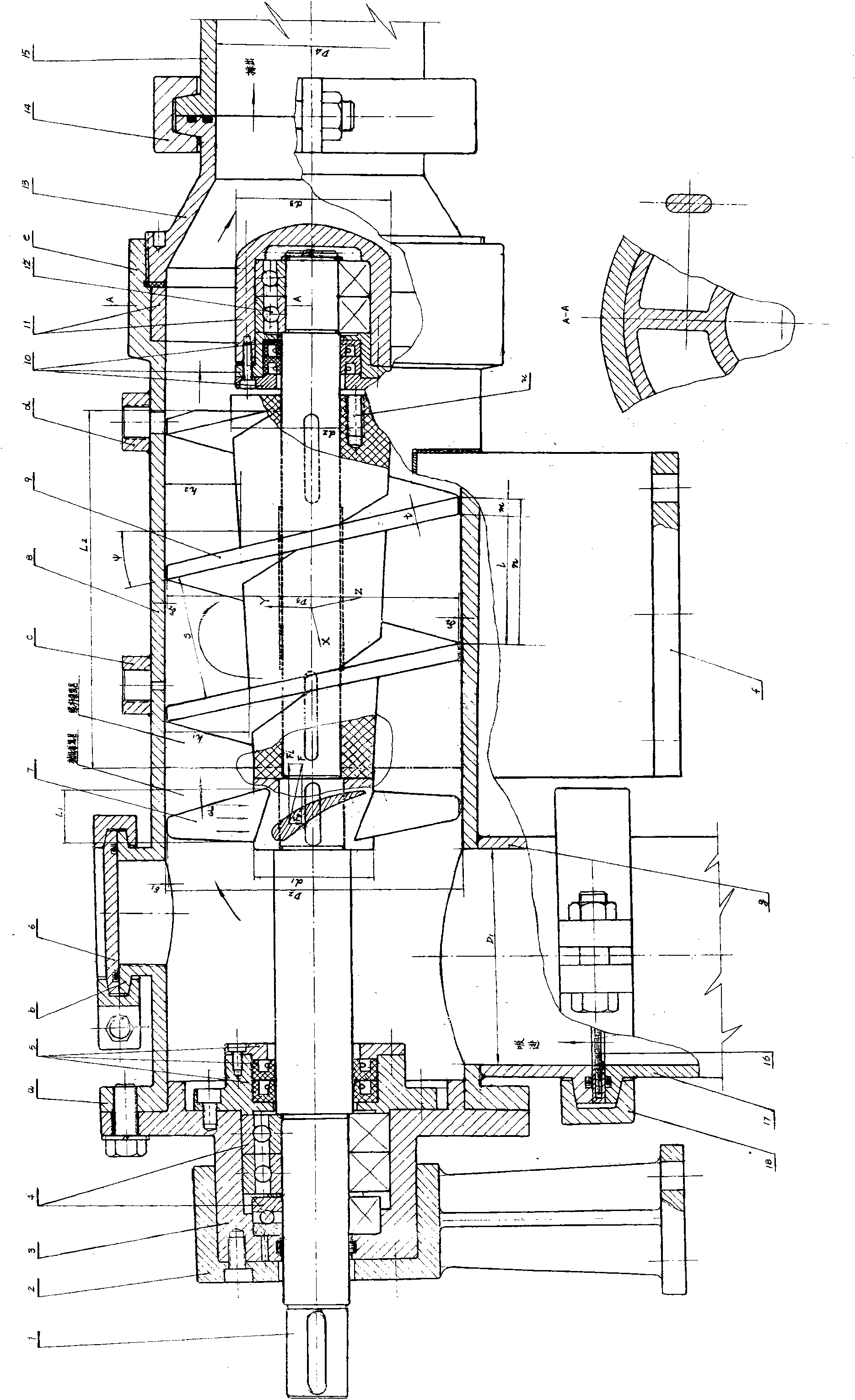

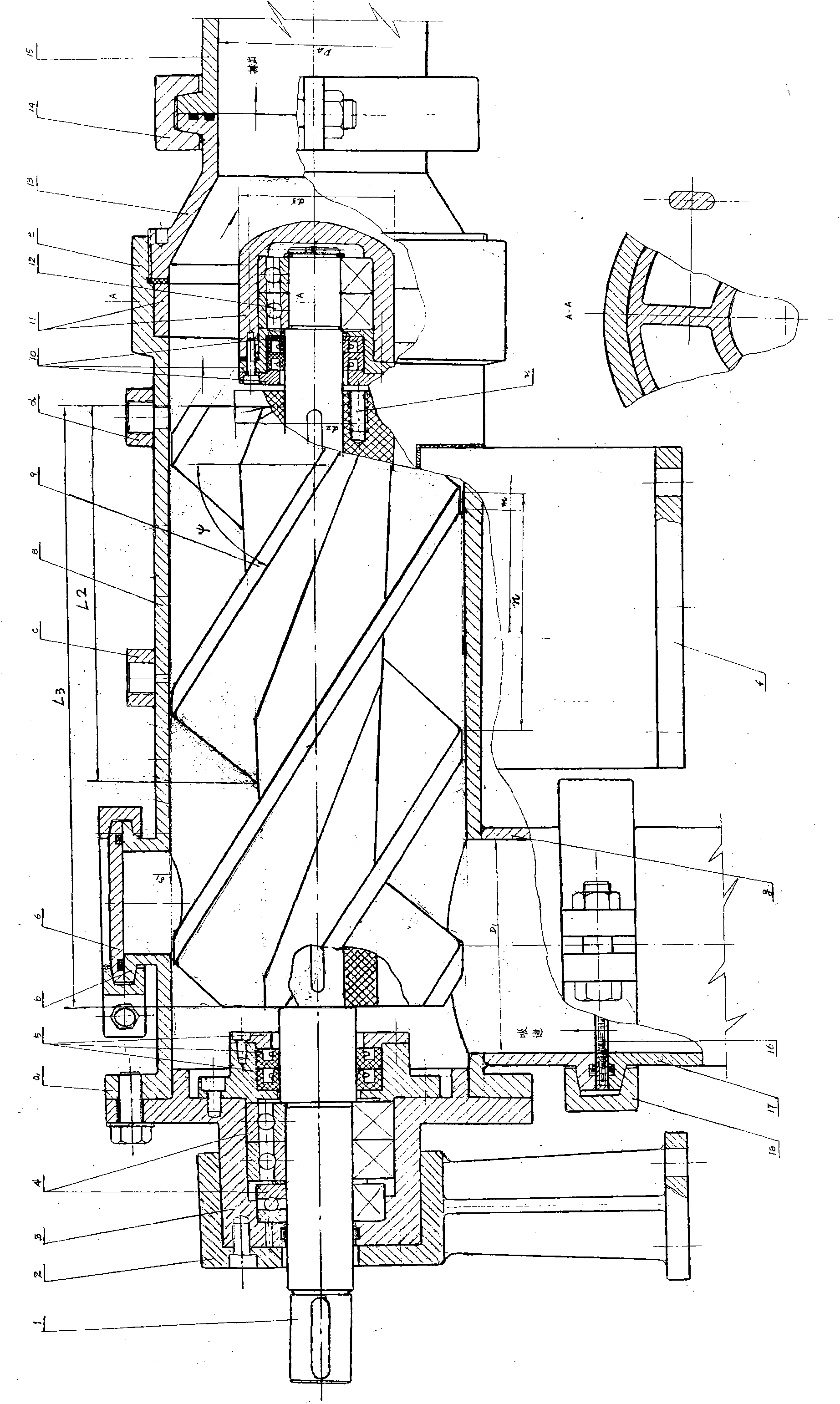

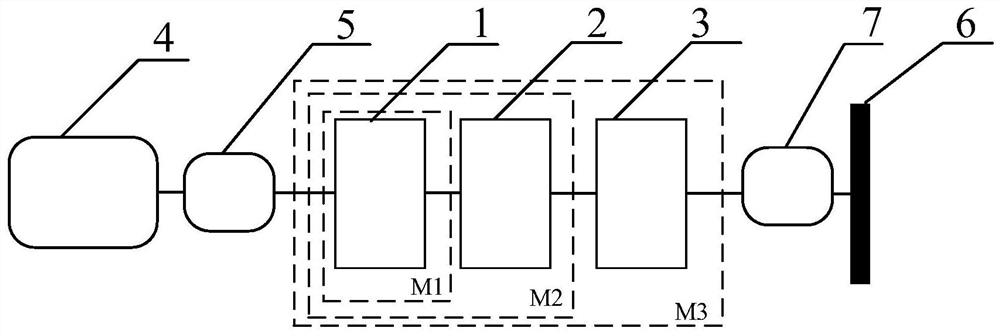

High-efficiency axial flow and screw combined pump for ship

InactiveCN102486169AGuaranteed coaxial accuracyImprove machining accuracyPropulsive elementsPump installationsAxial-flow pumpLow speed

The invention relates to a structure of a high-efficiency axial flow and screw combined pump. A large flow and a high pressure are obtained by high speed rotation. A transmission chain in a ship is greatly simplified. The high-efficiency axial flow and screw combined pump has light weight and is suitable for high-speed sailing. The high-efficiency axial flow and screw combined pump is characterized in that an axial flow pump impeller and a screw of a screw pump which are driven coaxially are arranged in a big sleeve to form a structure of an axial flow pump and the screw pump; if the positions of the axial flow pump and the screw pump are exchanged, a structure of the screw pump and the multi-stage axial pump is formed; and water is sucked from the front of the ship bottom, obtains kinetic energy through the front-mounted pump and then is fed to the rear-mounted pump to be boosted to be sprayed, so that the ship is propelled. One single screw is arranged and is provided with a plurality of heads; screw edges are very narrow and have large screw pitch, so that the depth of a screw thread gradually becomes shallow to achieve the effects of large flow and high pressure; and the axial flow pump is designed by combining excellent aerofoils according to a variable-circulation variable-axis surface. The pump has a very simple structure, has good manufacturability and is easy to manufacture; the high-efficiency axial flow and screw combined pump is convenient to install; the high-efficiency axial flow and screw combined pump rotates at the high speed, has small volume and light weight, is efficient and energy-saving; the high-efficiency axial flow and screw combined pump has the self-adsorption capability and the ship has high sailing speed; the high-efficiency axial flow and screw combined pump can be made to have large power; the high-efficiency axial flow and screw combined pump has double-injection capability, a steering engine is saved and the high-efficiency axial flow and screw combined pump has high performances which cannot be realized by a single low speed axial flow pump or mixed-flow pump injection propeller.

Owner:赵明

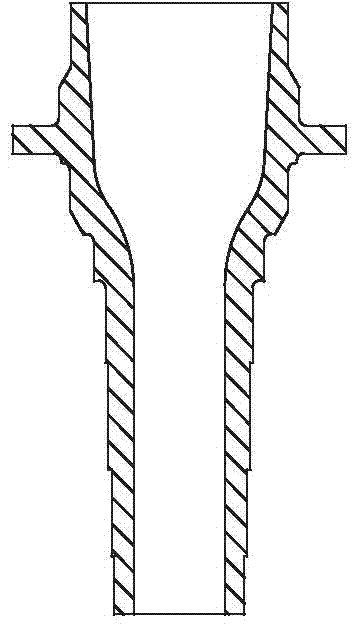

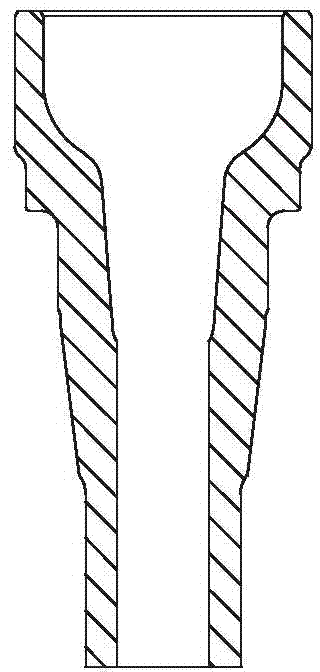

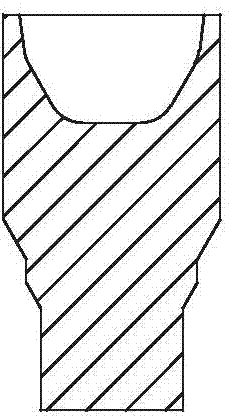

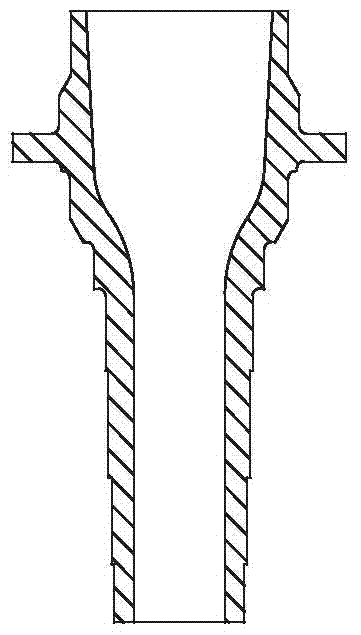

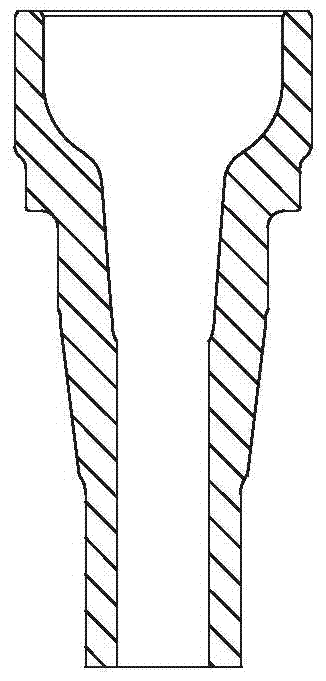

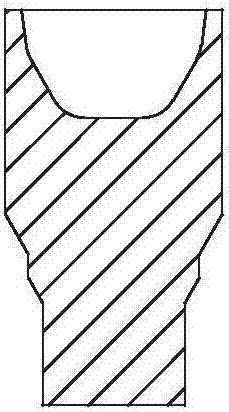

Processing process of axle shaft sleeve

The invention discloses a processing process of an axle shaft sleeve. The processing process is characterized by comprising the following steps that 1, precision forging of the axle shaft sleeve is carried out, wherein precision forging of the axle shaft sleeve comprises extrusion forming and finishing forging of the axle shaft sleeve, and extrusion forming of the axle shaft sleeve comprises a sorting procedure, a first extrusion forming procedure, a second extrusion forming procedure, a third extrusion forming procedure and a fourth extrusion forming procedure; 2, the axle shaft sleeve is installed and welded; 3, finishing turning is carried out on the axle shaft sleeve. Compared with an original process, the weight of an axle shaft sleeve forge piece is reduced, the weight of one axle shaft sleeve forge piece of a light truck series is reduced by about two kilograms, and the weight of one axle shaft sleeve forge piece of a heavy truck series is reduced by about three kilograms; the time spent in processing the one axle shaft sleeve is shortened by about 0.5 hour; the coaxiality and consistency of the central line of an axle housing and axes of inner holes of axle shaft sleeves at the two ends of the axle housing are better.

Owner:ZHUCHENG CITY FURI MACHINERY

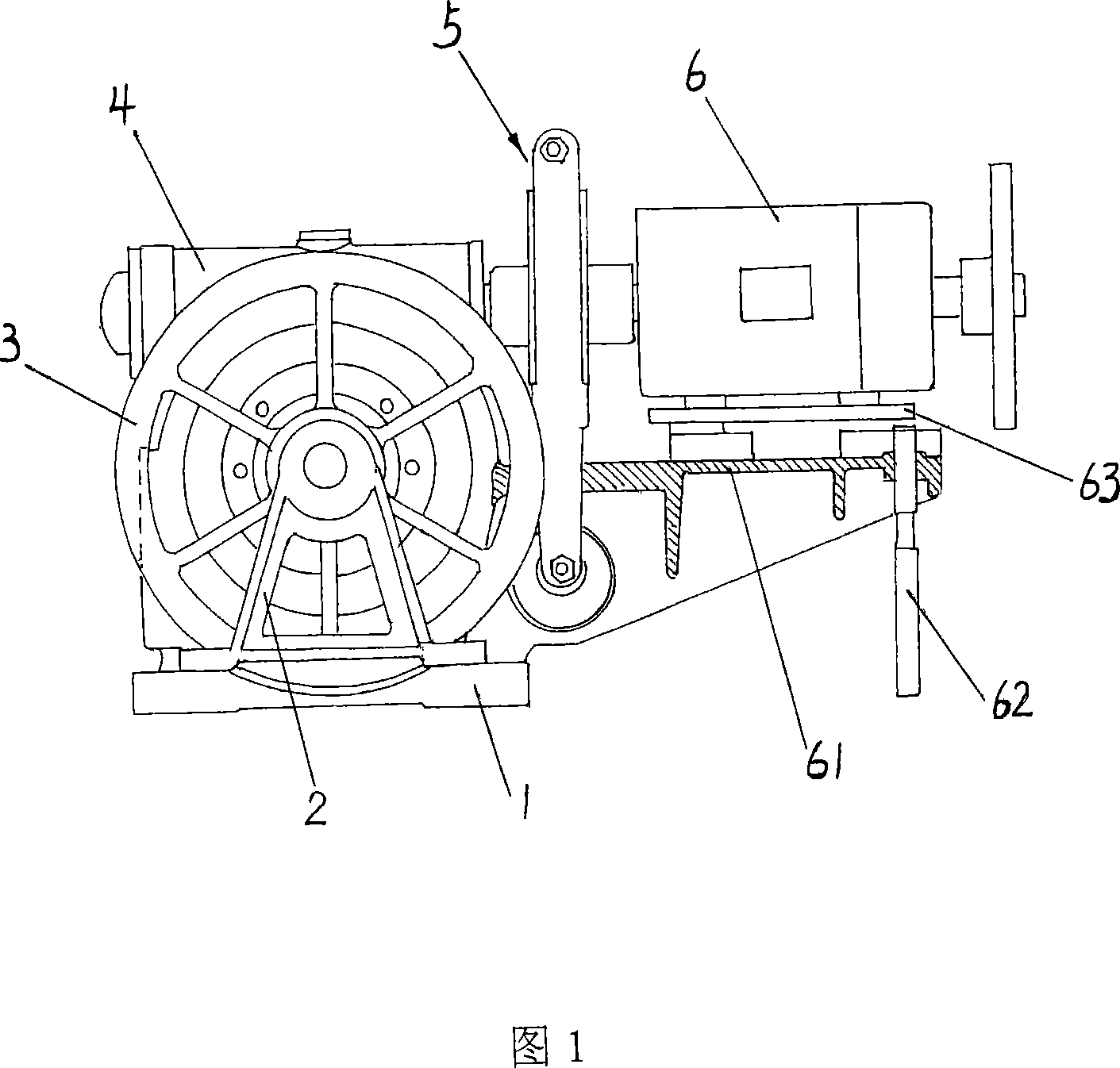

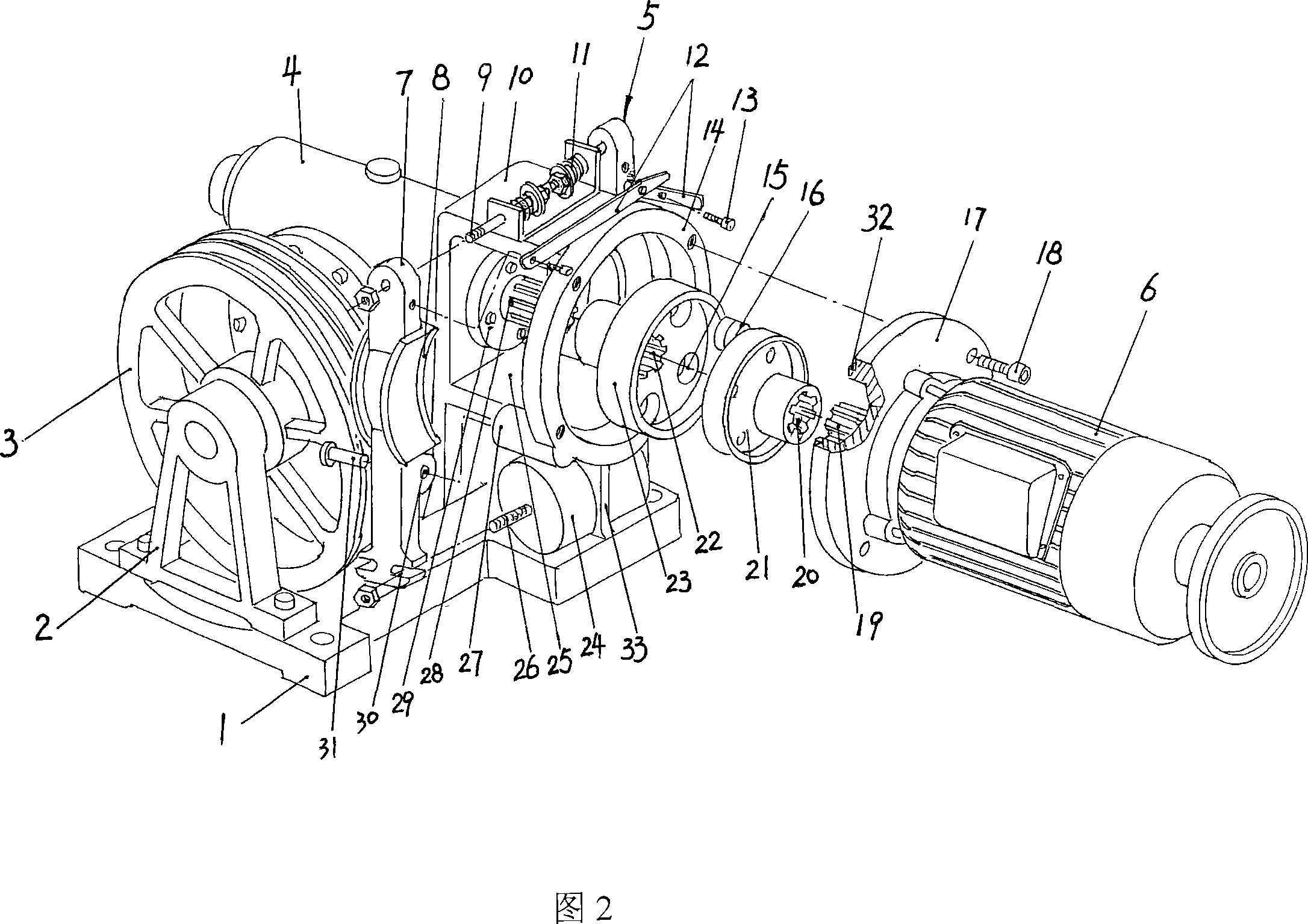

Drag for service elevator

The present invention is one kind of drag for small service elevator, and belongs to the field of elevator driver. The drag for small service elevator includes motor, shaft coupling, speed reducer, brake disc, dragging wheel, jig, pedestal and brake, and features the output shaft of motor with flange, the drag seat of the speed reducer, and the flange seat for the motor to be fixed on through the flange seat. The drag for small service elevator of the present invention has the advantages of simple installation, correct location, high coaxiality between the output shaft of the motor and the worm shaft of the speed reducer, high braking stability and effect, etc.

Owner:CHANGSHU CANON ELEVATOR ACCESSORIES

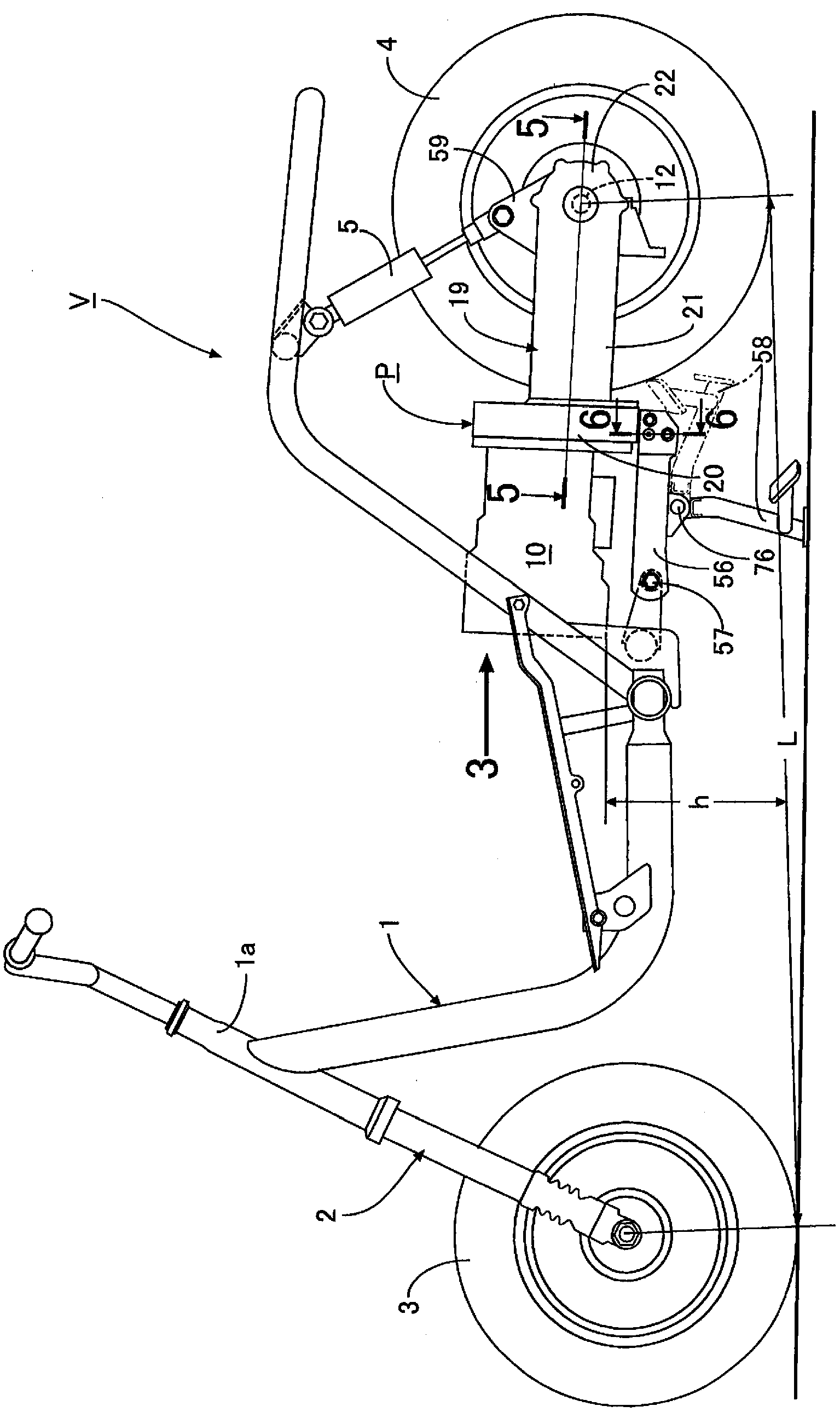

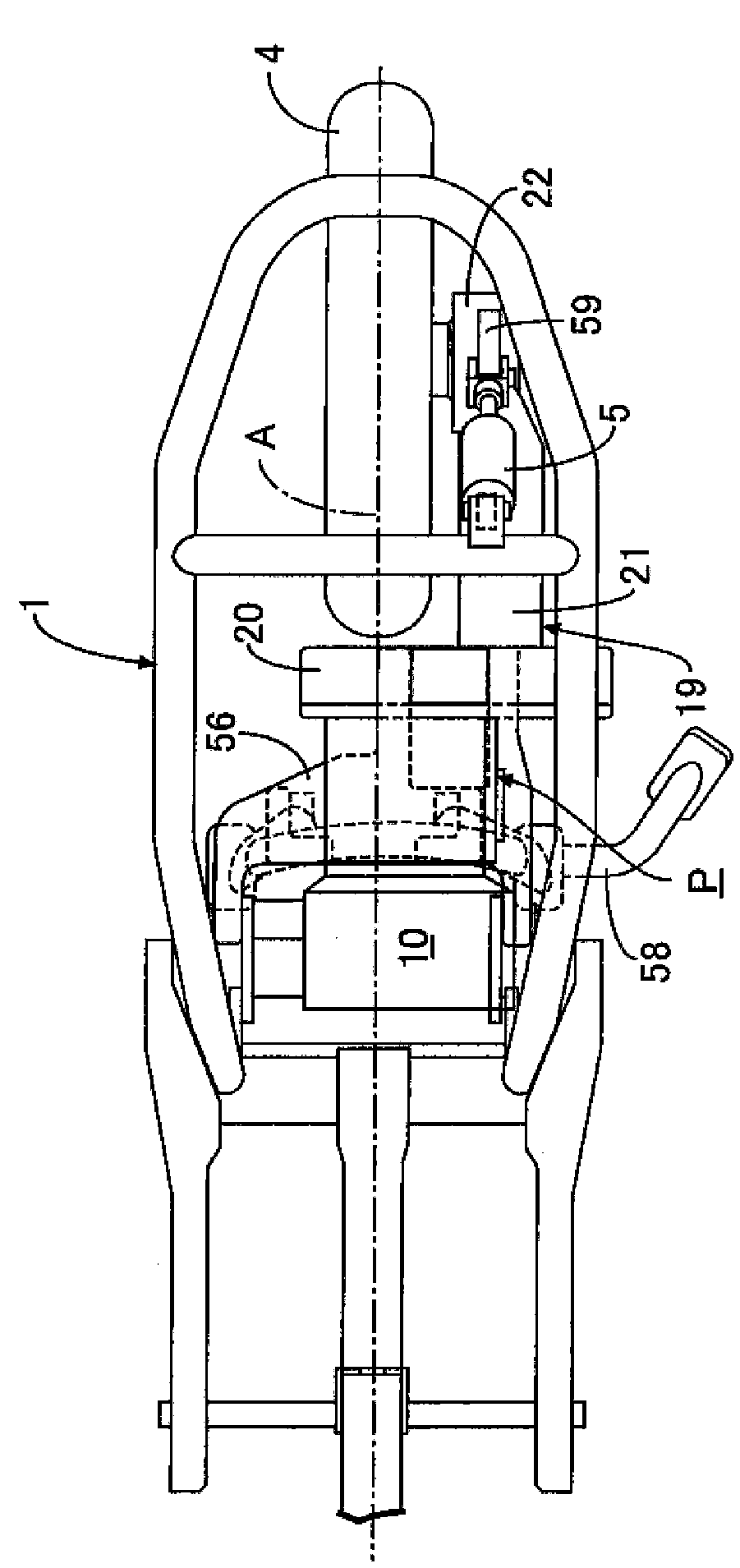

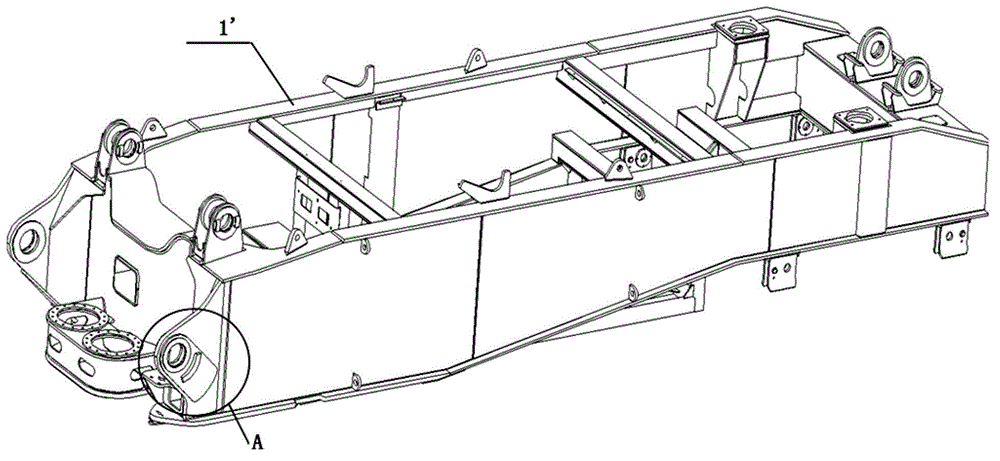

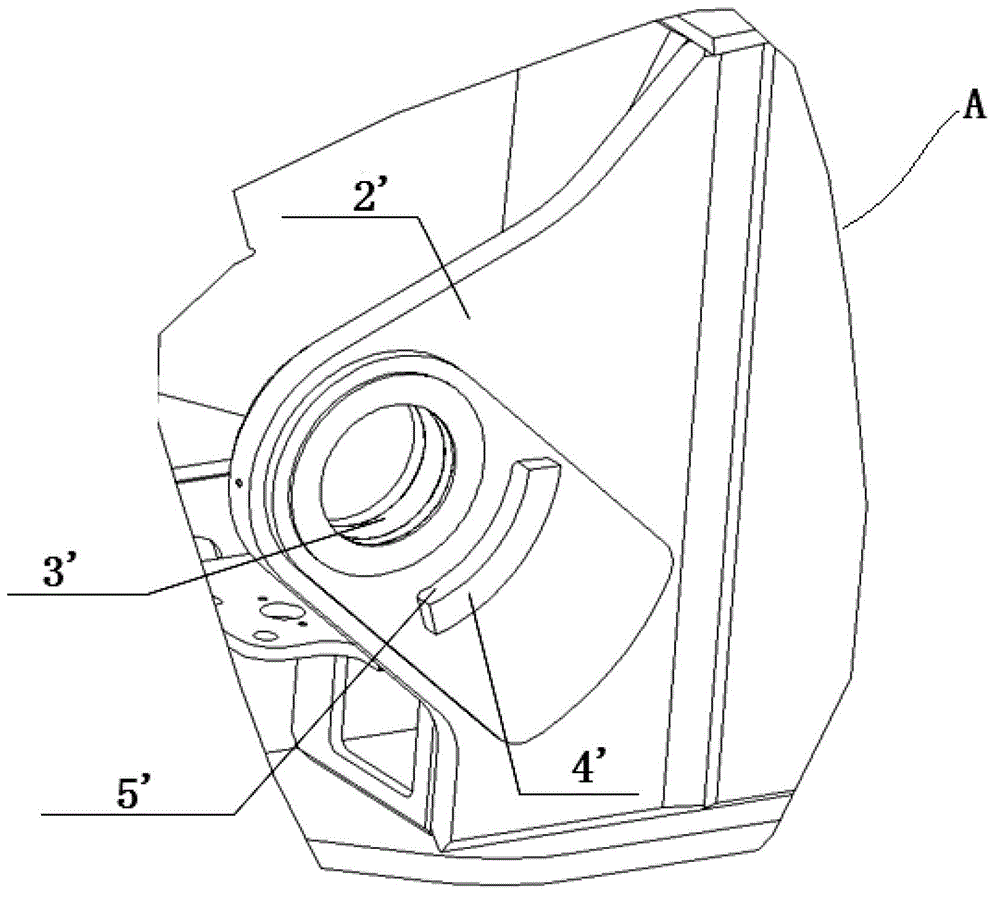

Electric power unit for vehicle

InactiveCN103287536AEasy to assembleGuaranteed coaxial accuracyWheel based transmissionMotorised scootersElectric power systemDrive shaft

The invention provides an electric power unit for a vehicle, which requires small numbers of parts and assembly processes and which is also capable of reducing the weight and securing the stiffness of a transmission case. A second gear case portion (22) housing a secondary reduction gear train (14) is provided integrally continuous to a rear end of a shaft case portion (21) housing a propeller shaft (11). A first opening portion (23) for inserting the propeller shaft (11) and a drive gear (17) of the secondary reduction gear train (14) and for attaching a first bearing (33) supporting a rear portion of the propeller shaft (11) is provided in a front end of the shaft case portion (21). In addition, a second opening portion (24) for inserting a driven gear (18) of the secondary reduction gear train (14) and a rear axle holder (48) holding a bearing (47) supporting a rear axle (12) is provided in one side portion of the second gear case portion (22).

Owner:MUSA PRECISION IND CO LTD

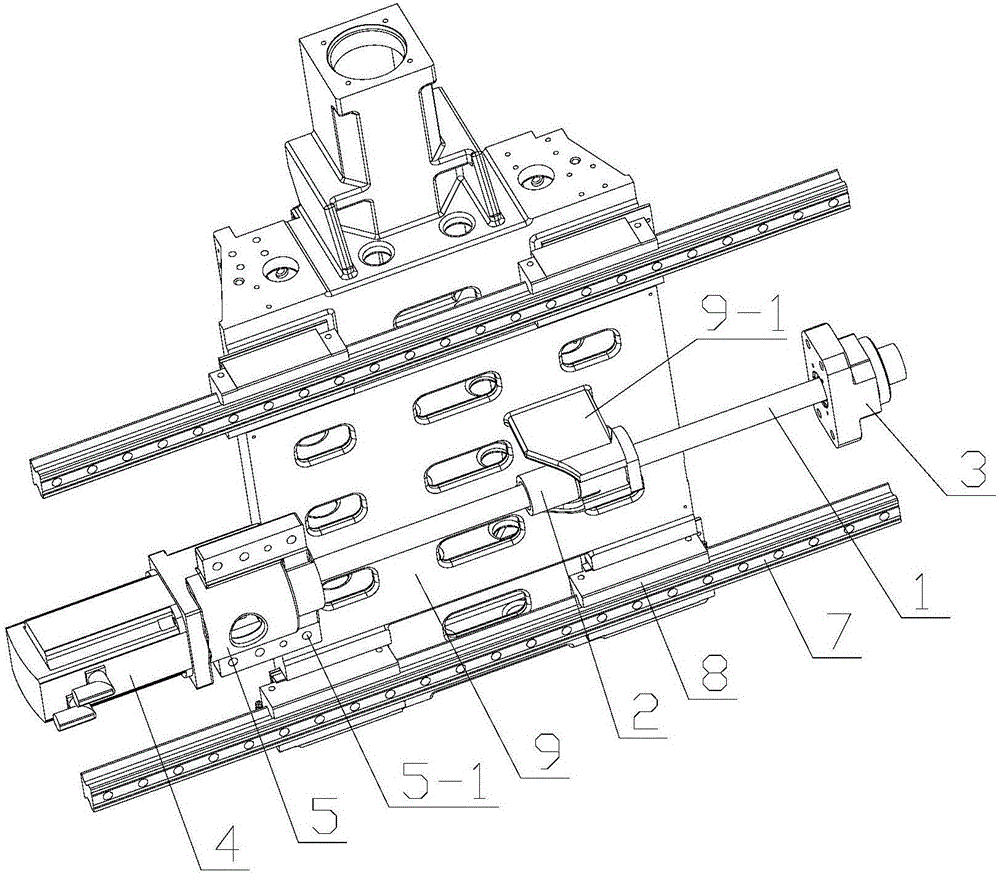

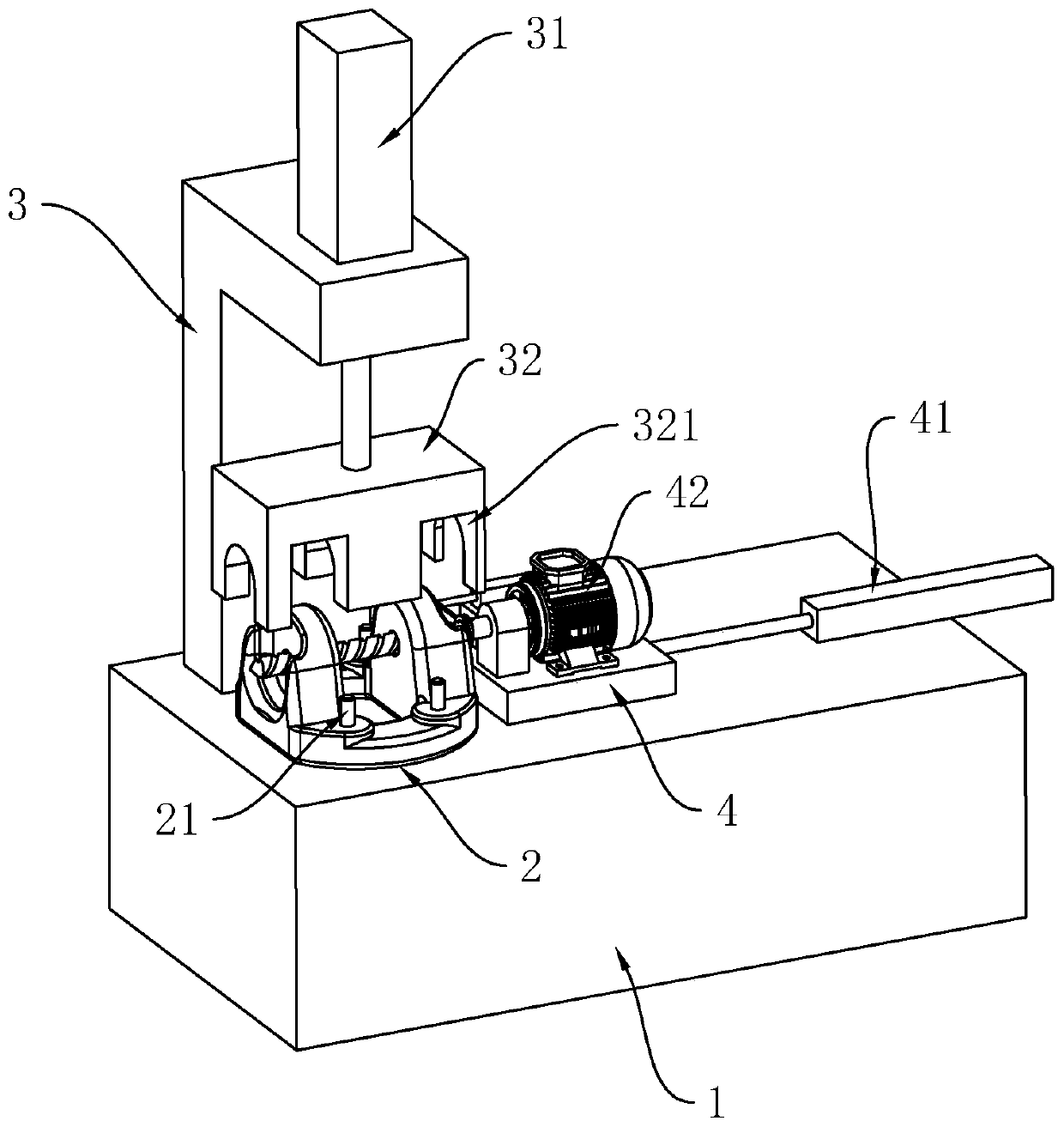

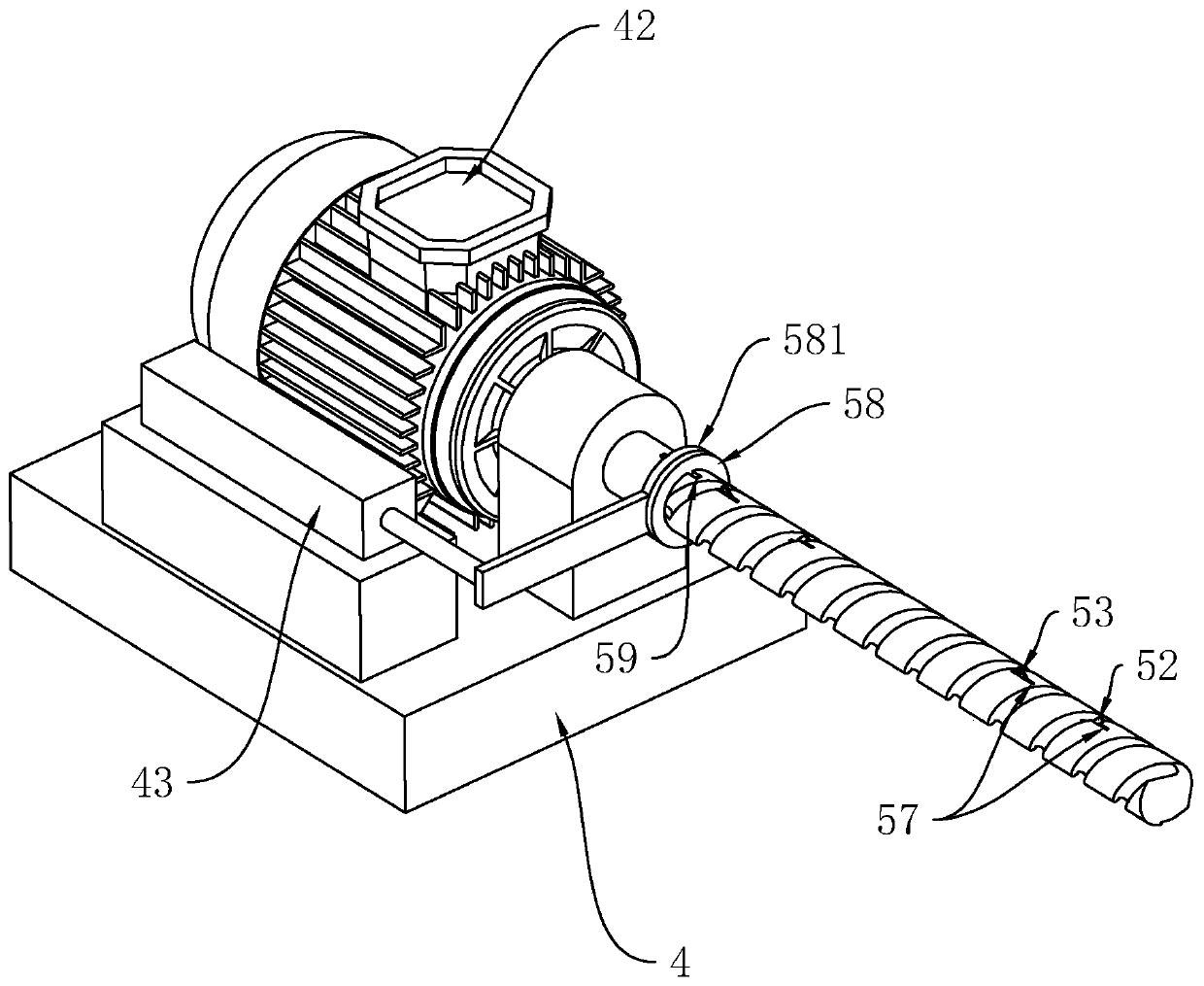

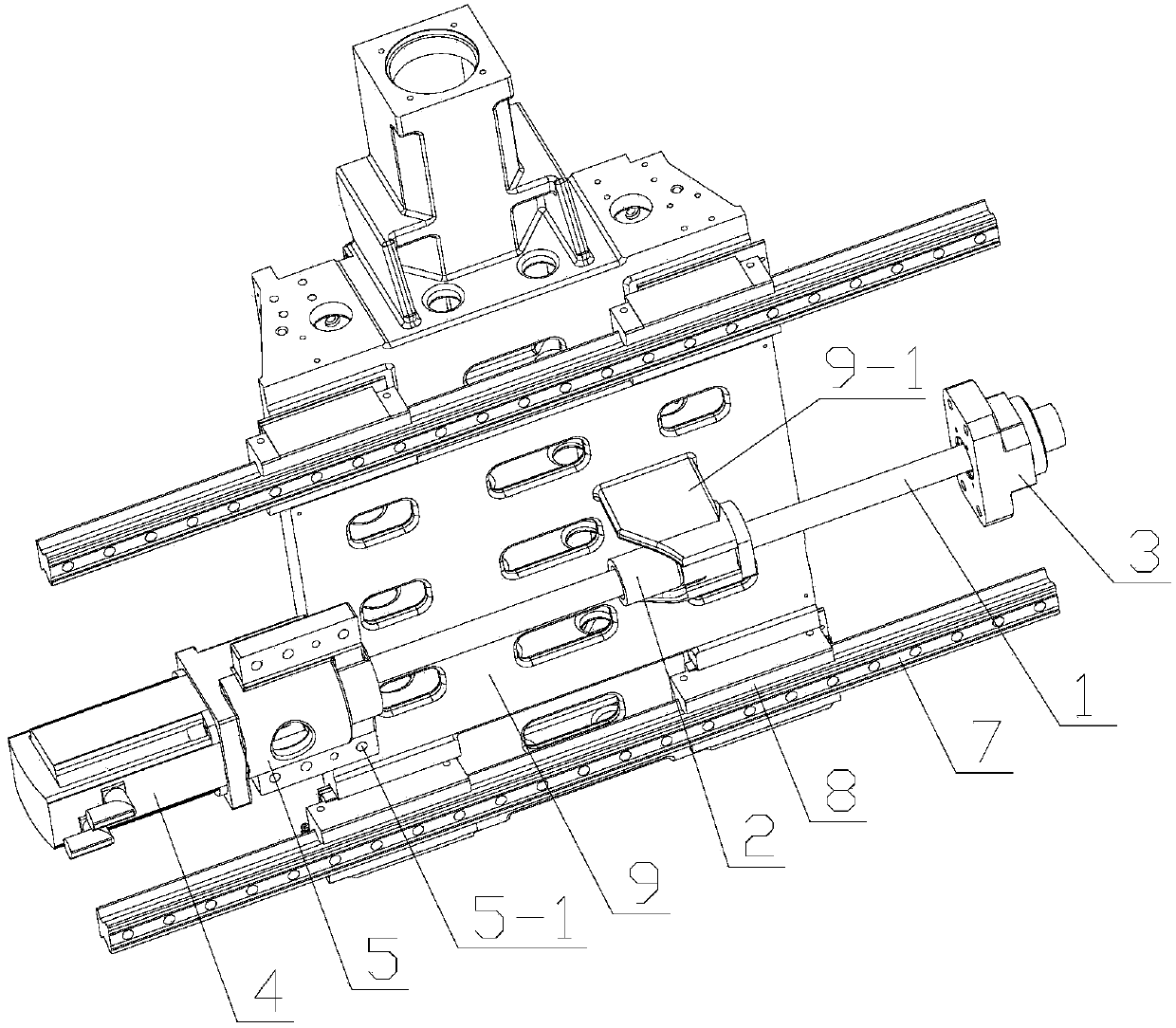

Assembly method of transmission shaft structure

The invention relates to an assembly method of a transmission shaft structure, and a screw tailstock is movably assembled and is self-aligned. A traditional screw tailstock is assembled in a mode that the center height of the screw tailstock is adjusted by adopting an adjusting pad and is fastened radially by using a bolt. Measurement and match grinding are needed, therefore, the skill requirement of assembly personnel is high, and the measurement and match grinding errors exist. According to the assembly method, by utilizing the characteristic that the position of a screw is limited by a screw nut when the screw nut moves to the tail end of the screw, the self alignment of the screw tailstock which is installed on the tail end of the screw is guaranteed, and the screw tailstock is axially fixed at the moment, so that the coaxial precision of the assembly position of the screw tailstock and the screw is guaranteed.

Owner:江苏澋润数控科技有限公司

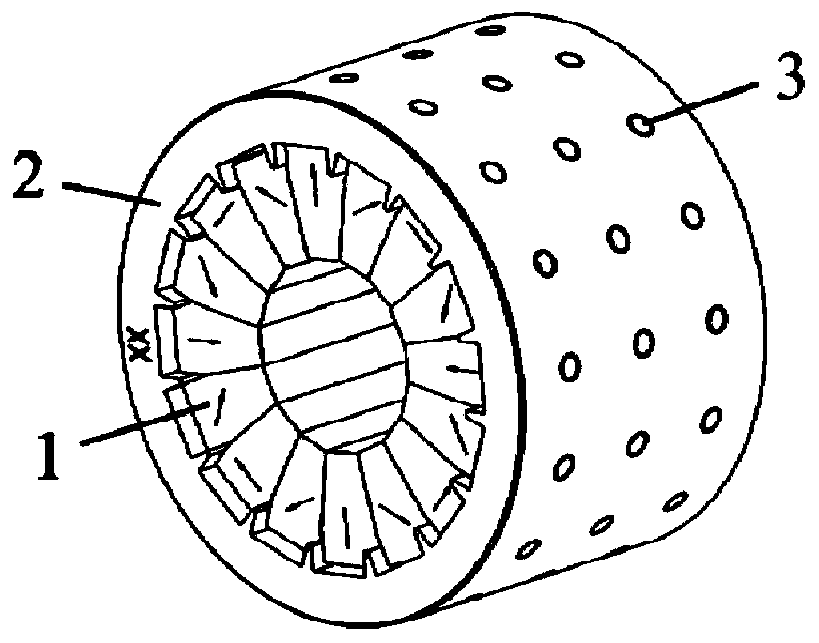

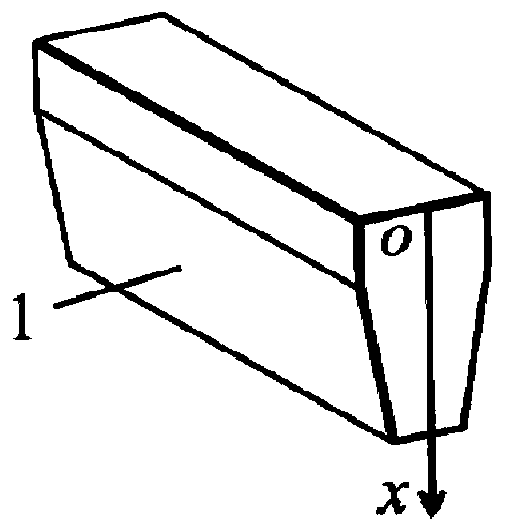

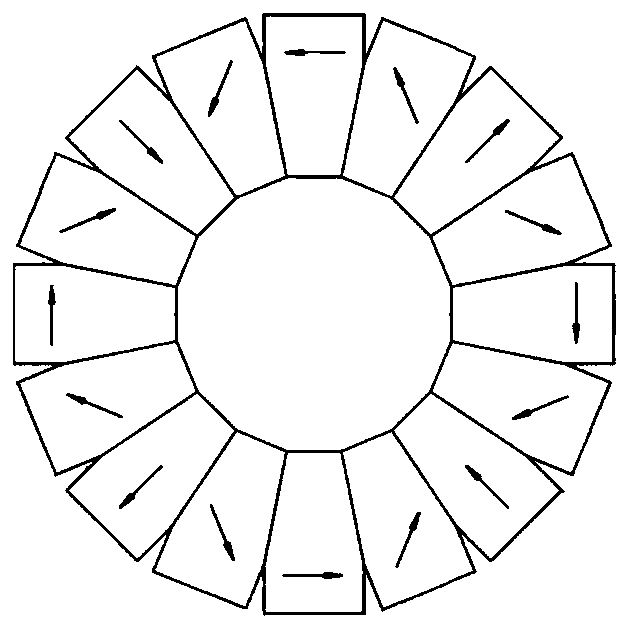

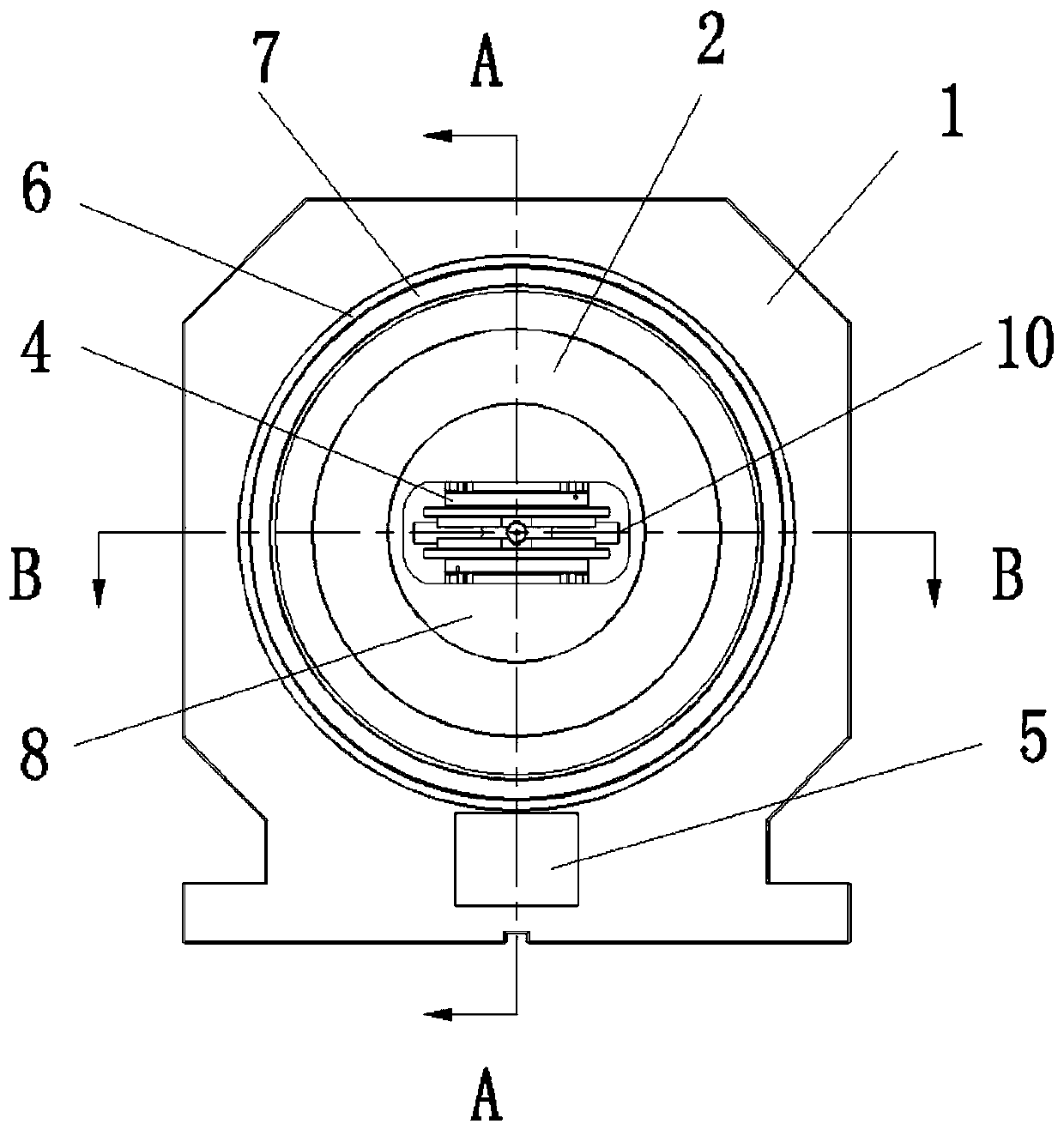

Permanent magnet type quadrupole magnet and assembling method thereof

The invention provides a permanent magnet type quadrupole magnet and an assembling method thereof. The permanent magnet type quadrupole magnet comprises a metal skeleton with a containing cavity, a plurality of magnetic blocks and a plurality of jackscrews, wherein the magnetic blocks and the jackscrews are located in the containing cavity and arranged in a Halbach array mode. The top of each magnetic block is fixed to the inner side of the metal skeleton through the plurality of jackscrews and extrudes towards the center of the metal skeleton, so the side faces of every two adjacent magneticblocks are tightly attached, and the bottoms of the magnetic blocks are sequentially connected end to end to form a circular cavity. The invention further discloses an arrangement mode of the magneticblocks in the metal skeleton so as to improve the rate of finished products. When the permanent magnet type quadrupole magnet is assembled, an auxiliary tool is used, the auxiliary tool is taken outafter the magnetic blocks are fixed in place, then magnetic center measurement is carried out, and mechanical treatment is carried out on the outer circle of the quadrupole magnet skeleton according to the measurement result until the eccentricity of the magnetic center meets the design requirement.

Owner:TSINGHUA UNIV +1

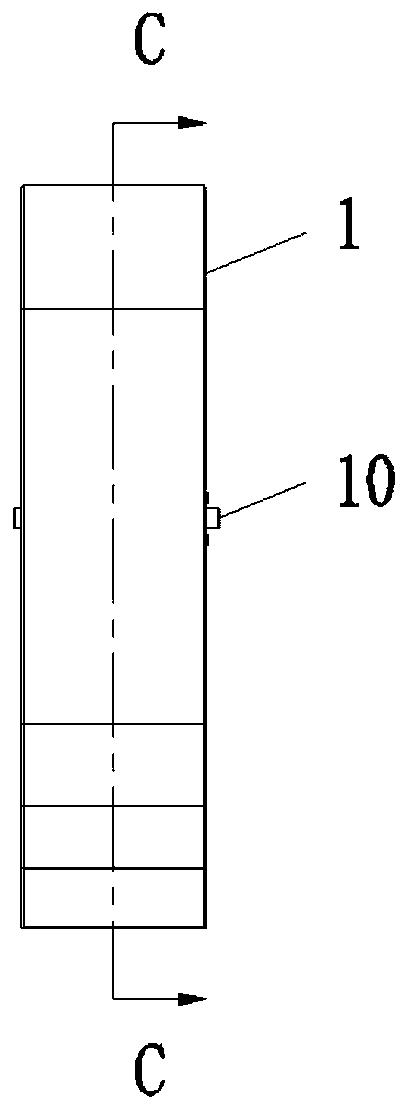

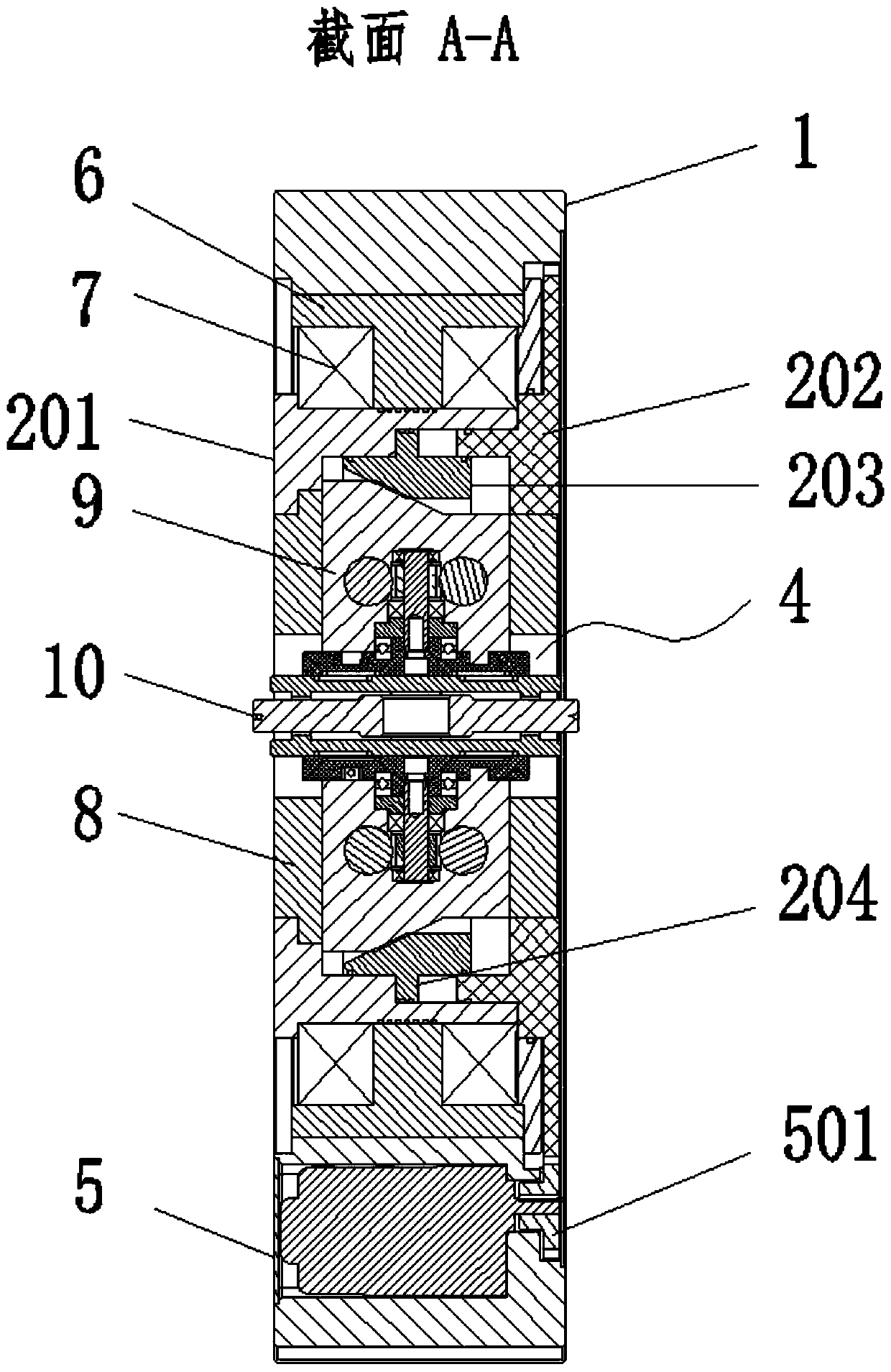

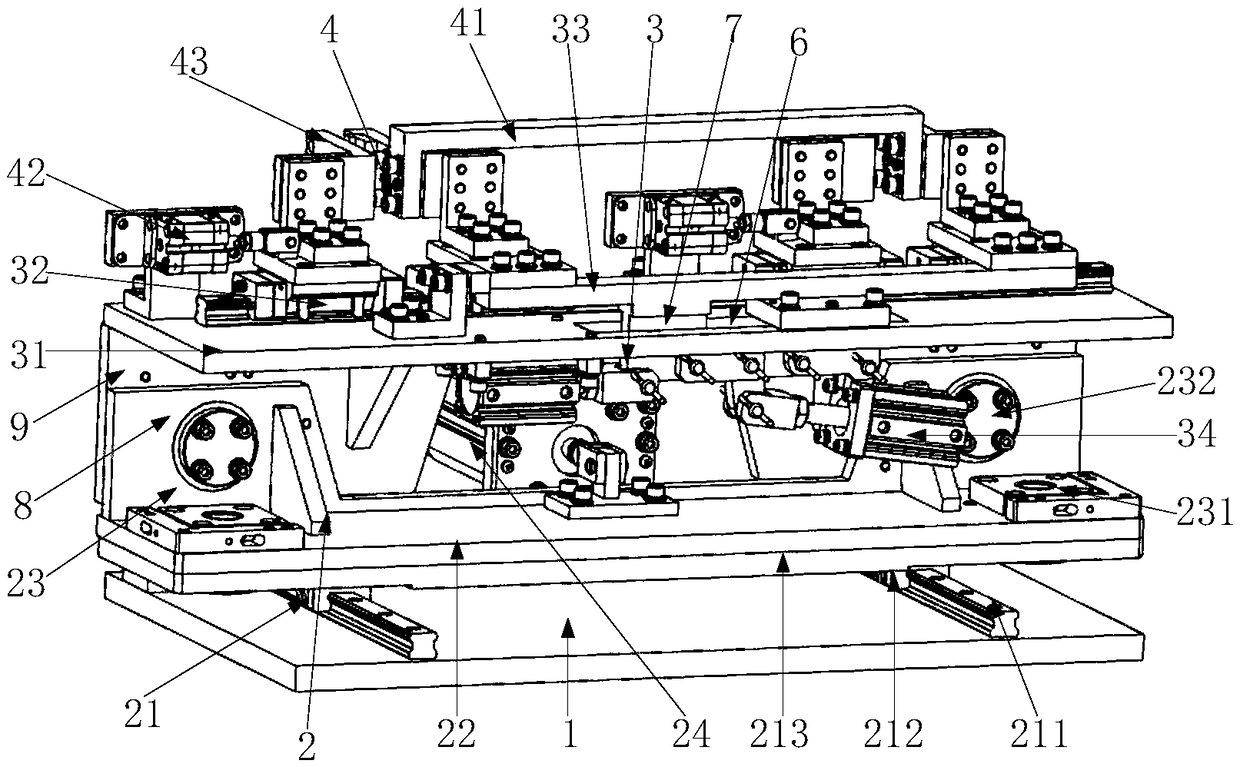

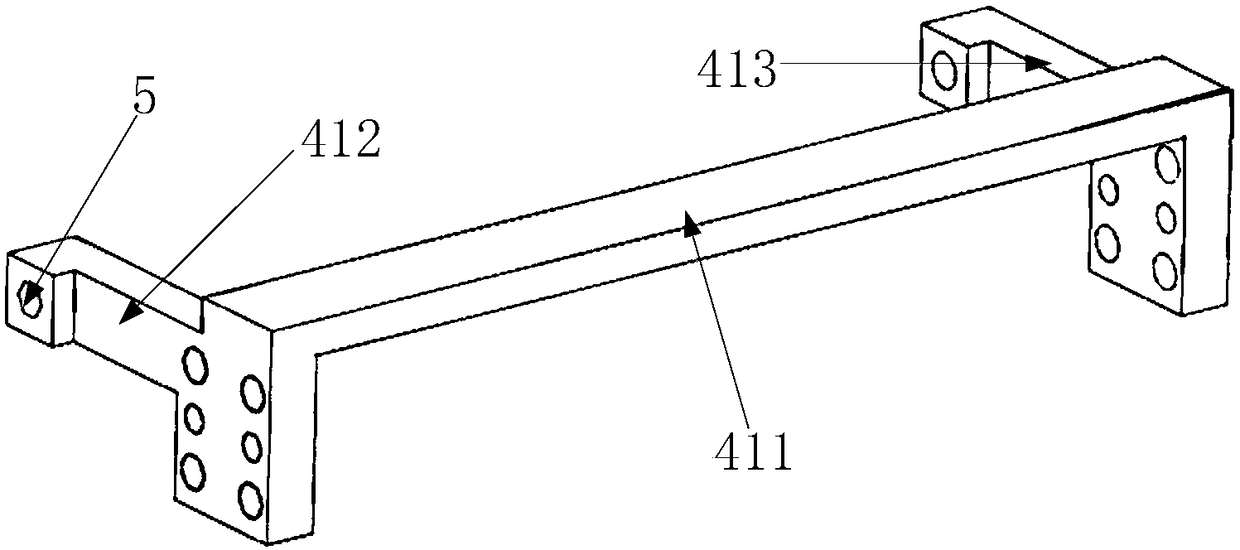

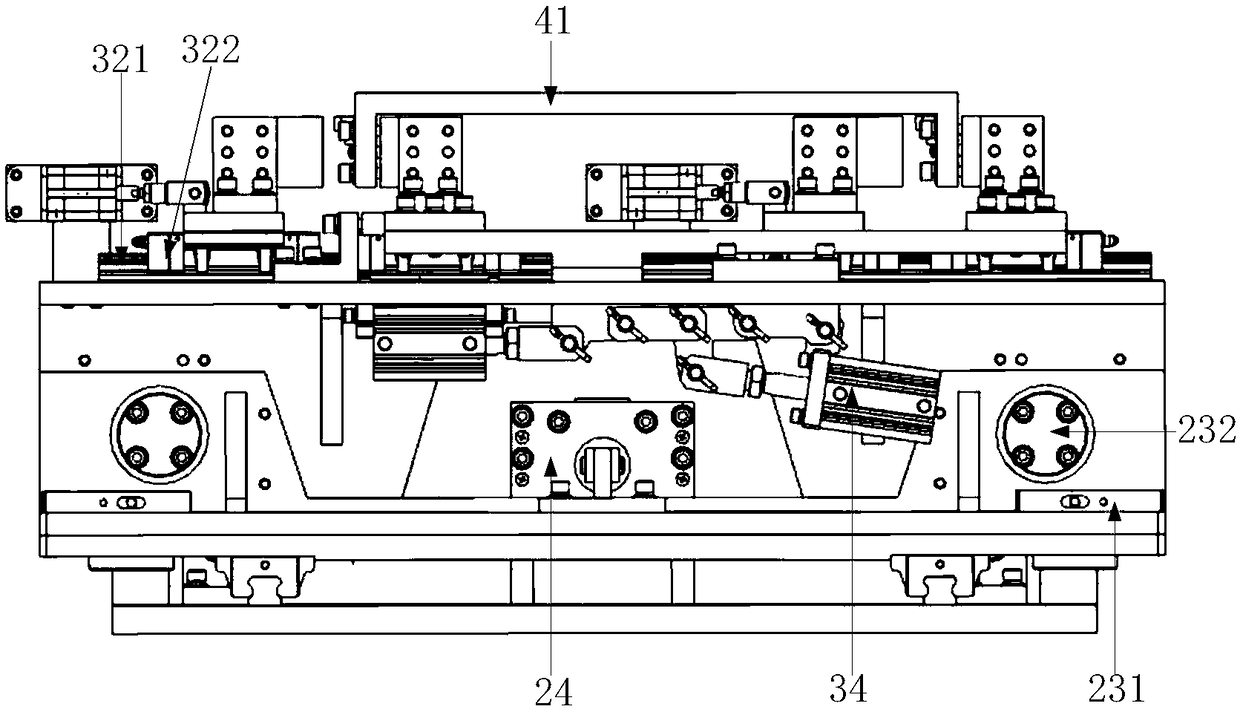

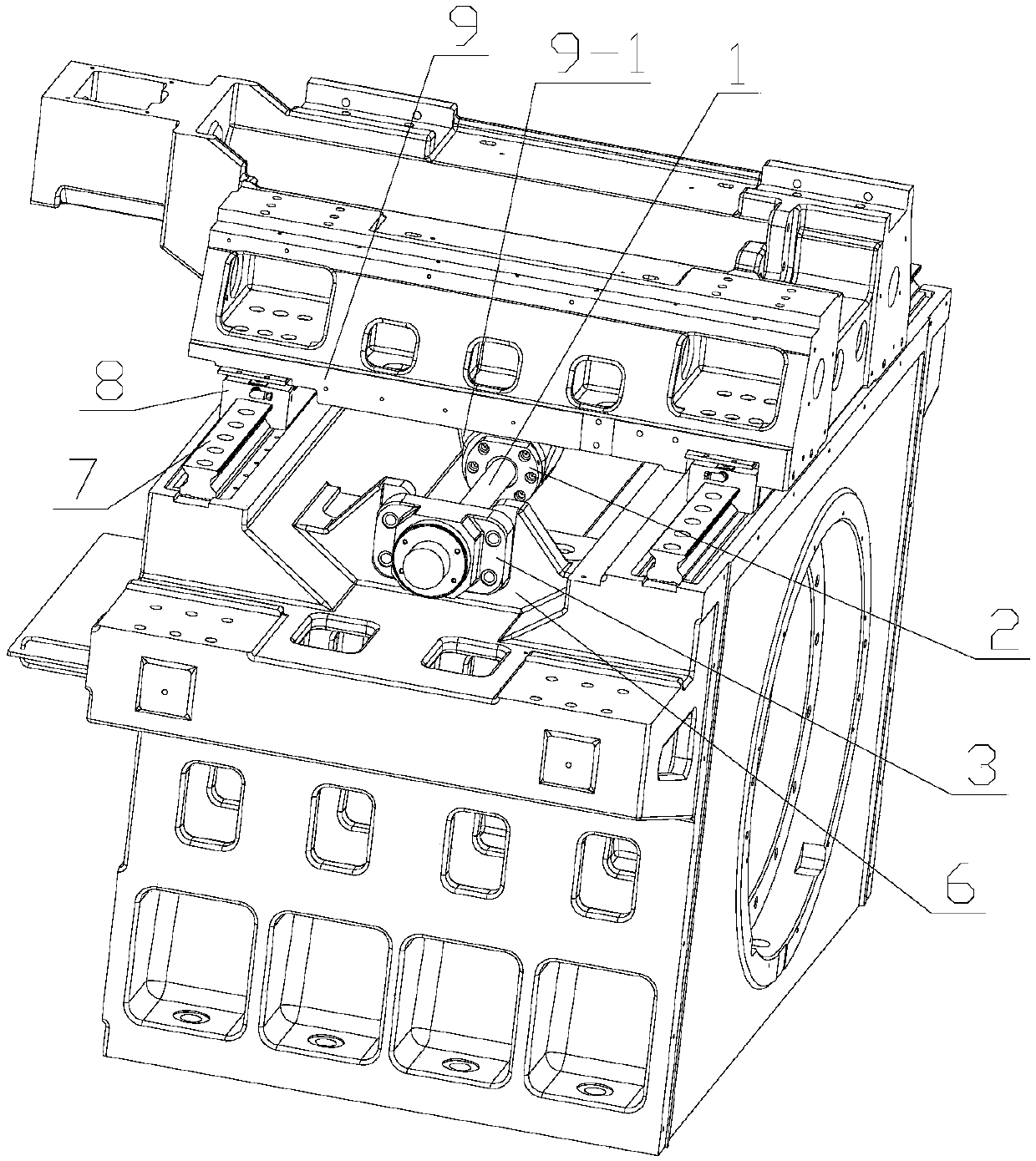

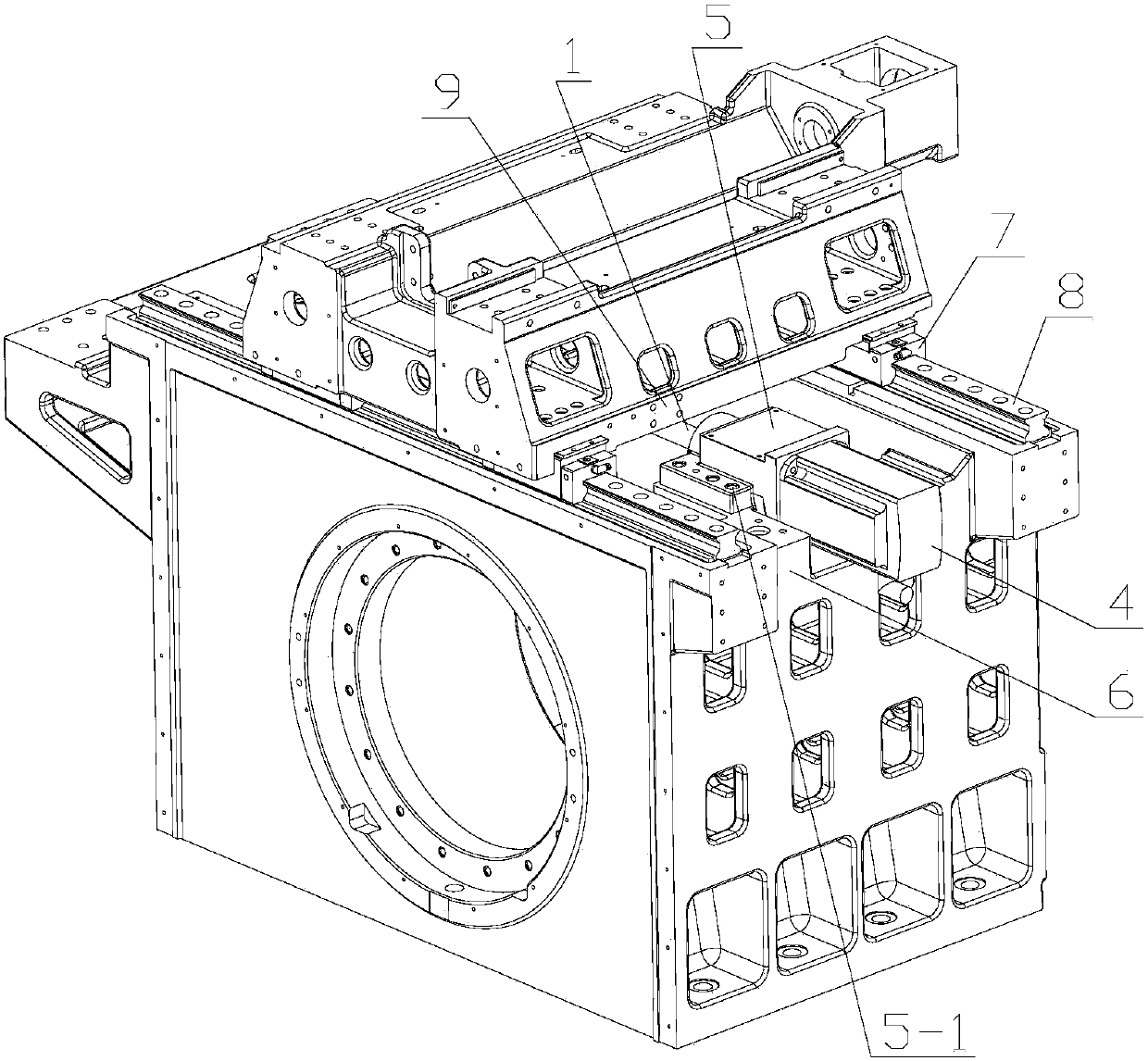

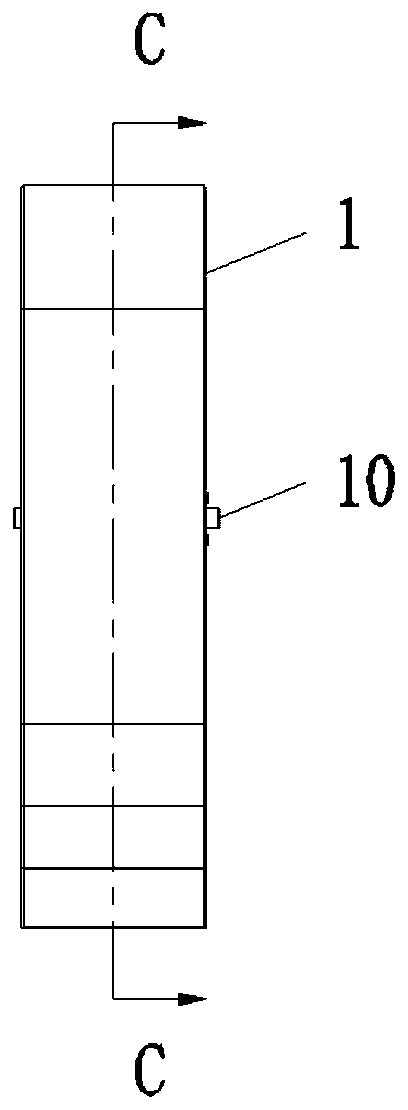

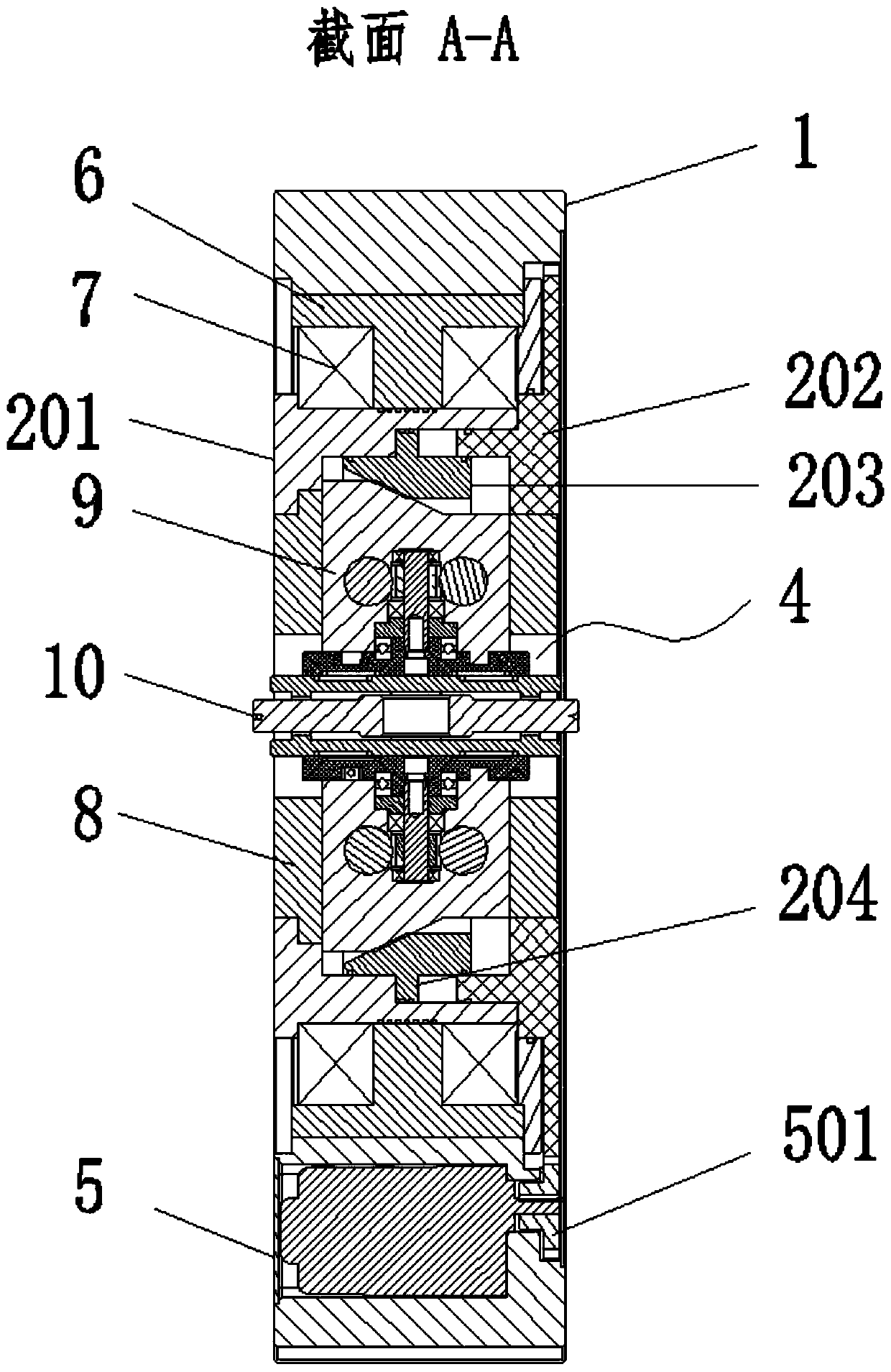

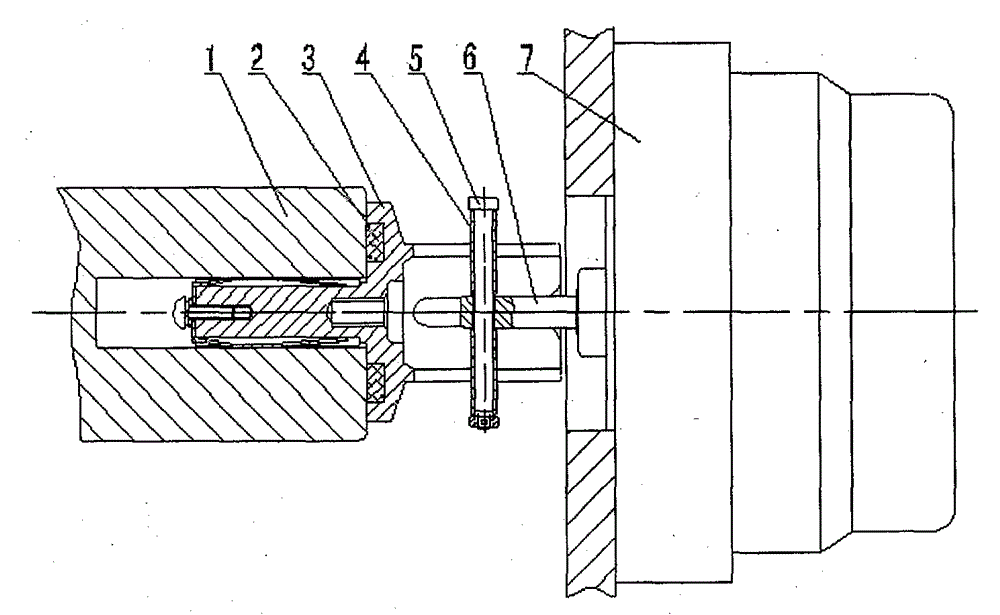

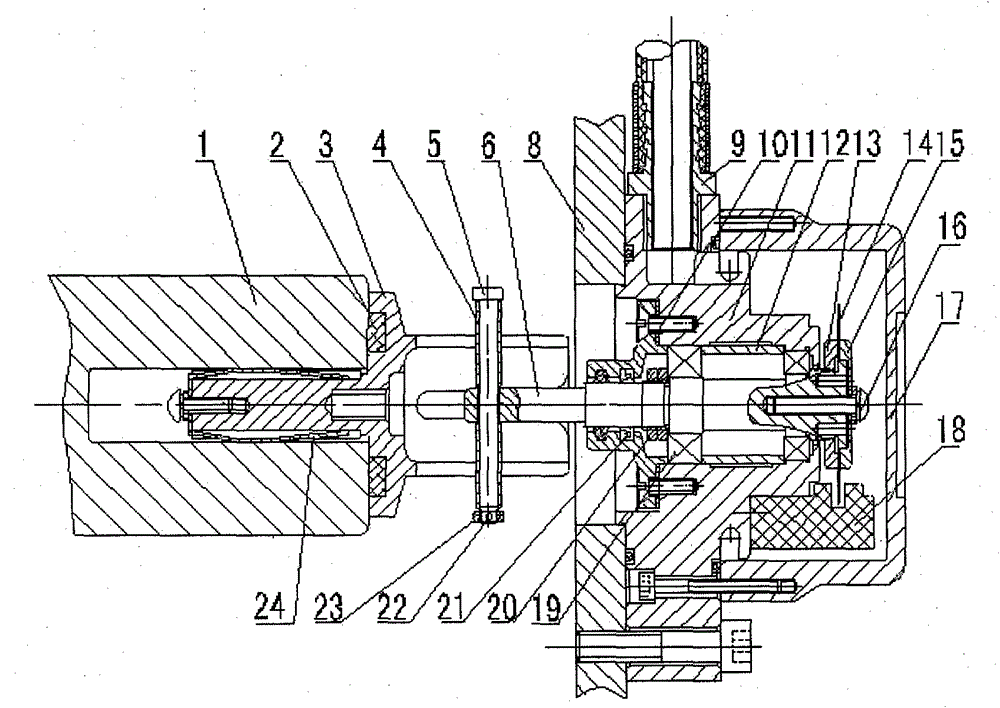

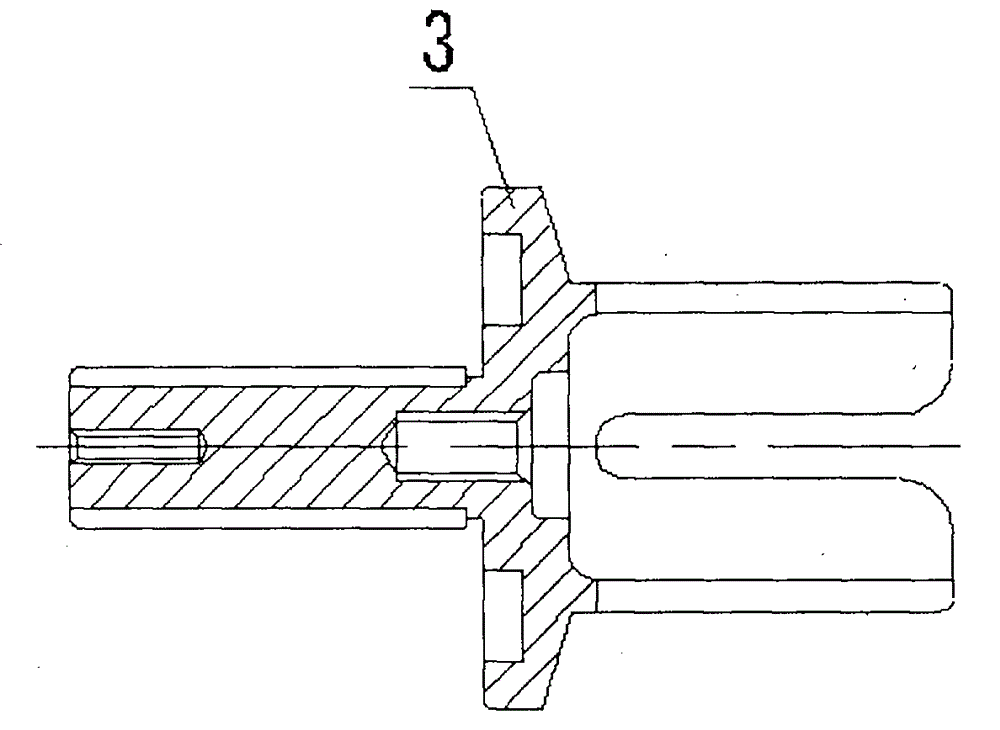

Self-centering bidirectional rotating cross shaft machining main shaft

InactiveCN110102782AQuick loading and unloadingPlay the role of reversing processingLarge fixed membersPositioning apparatusLine shaftEngineering

The invention discloses a self-centering bidirectional rotating cross shaft machining main shaft in the technical field of precision machining equipment. The self-centering bidirectional rotating cross shaft machining main shaft comprises a device shell, a rotating oil cylinder mechanism, a lifting mechanism, clamping reversing mechanisms, positioning mechanisms and a speed reducing motor, whereina bearing fixing sleeve and a pair of angular contact bearings are fixedly attached to an inner cavity of the device shell; the lifting mechanism is arranged in an inner cavity of the rotating oil cylinder mechanism; the lifting mechanism comprises a lifting frame body and two lifting installation blocks; the clamping reversing mechanisms is provided with two groups symmetrical at up and down; the two groups of clamping reversing mechanisms clamp and fix a cross shaft workpiece by mutually approaching; the positioning mechanism is provided with two groups which symmetrical at back and forth and are respectively embedded on the front side and the back side of the lifting frame body and used for positioning two opposite shaft ends in the cross shaft workpiece; and the speed reducing motor is embedded below the device shell and used for driving the rotating oil cylinder mechanism to rotate. The self-centering bidirectional rotating cross shaft machining main shaft is used for machining the cross shaft workpiece.

Owner:福清薛记数控科技有限公司

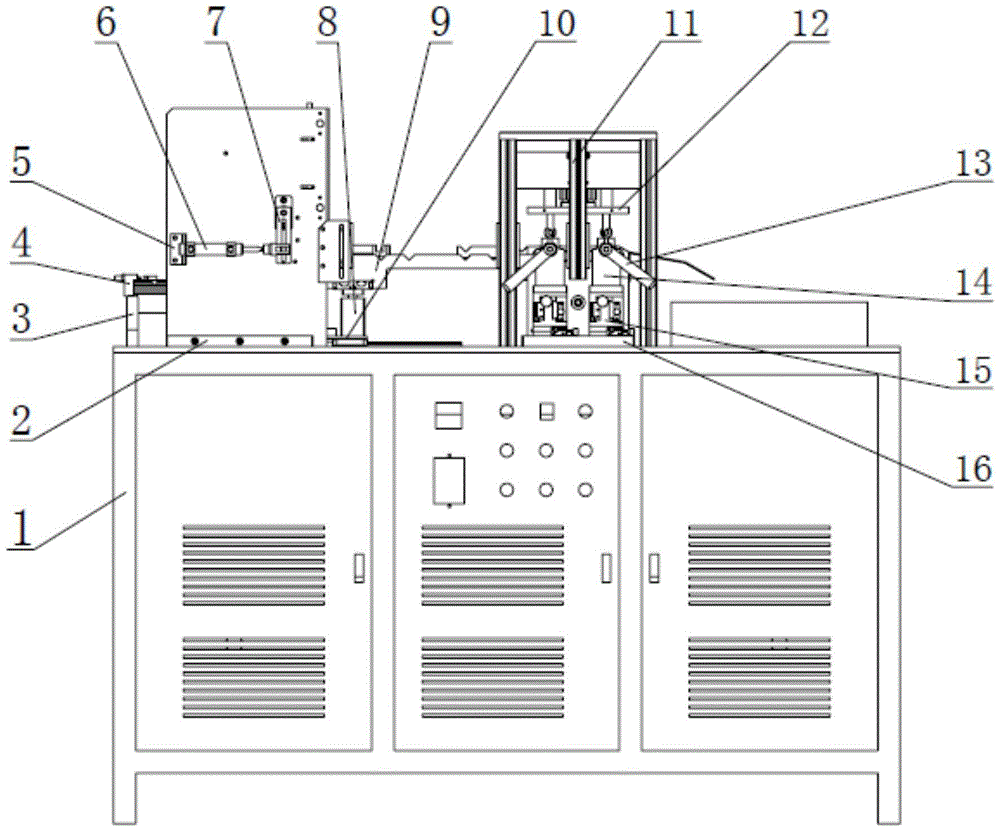

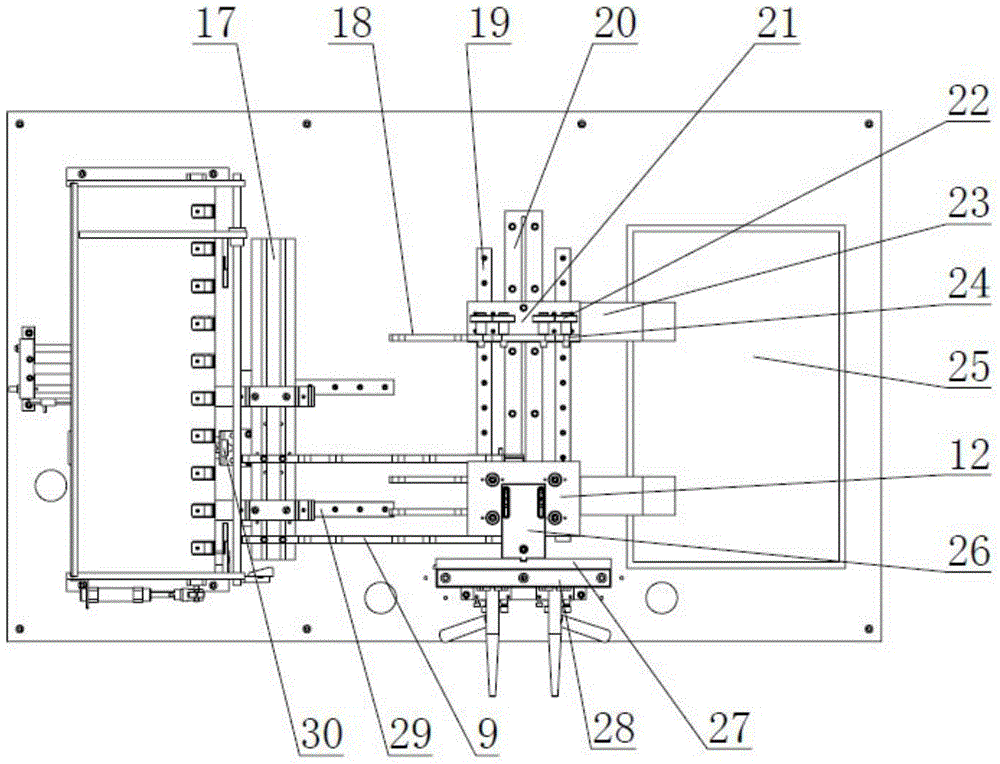

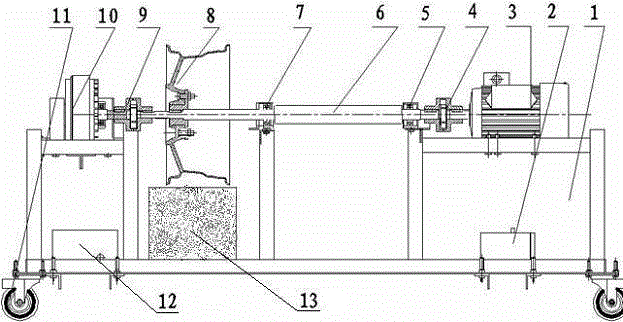

Double welding torch heat pipe automatic welding machine

ActiveCN104842043BEfficient weldingGuaranteed welding requirementsElectrode holder supportersHeat exchange apparatusMain branchDouble tube

The invention discloses a double-welding-gun automatic heat pipe welder. The welder comprises a machine frame, an automatic double-pipe discharging device, an automatic double-pipe feeding device, a double-argon-arc-welding-gun adjusting device, an automatic double-pipe welding device and an automatic double-pipe falling device and a PLC, wherein an outer branch pipe sliding table and a rubber wheel sliding table of the automatic double-pipe feeding device are installed on two linear guide rails through a pair of sliding blocks arranged in parallel respectively, an auxiliary branch pipe fixing plate is arranged on one side of the outer branch pipe sliding table, and two rubber wheel side plates are arranged on the two sides of the rubber wheel sliding table respectively; multiple parallel V-shaped grooves are formed in two main branch pipe plates and three auxiliary branch pipe plates respectively in pairs, and the distance between two V-shaped grooves in each pair is equal to the distance between two material claw block clamping grooves. By the adoption of the welder, two heat pipes are welded at a time, the whole processes include conveying, feeding, welding and falling, two heat pipes are welded at the same time, efficient welding can be achieved, and various welding requirements can be met.

Owner:SOUTH CHINA UNIV OF TECH

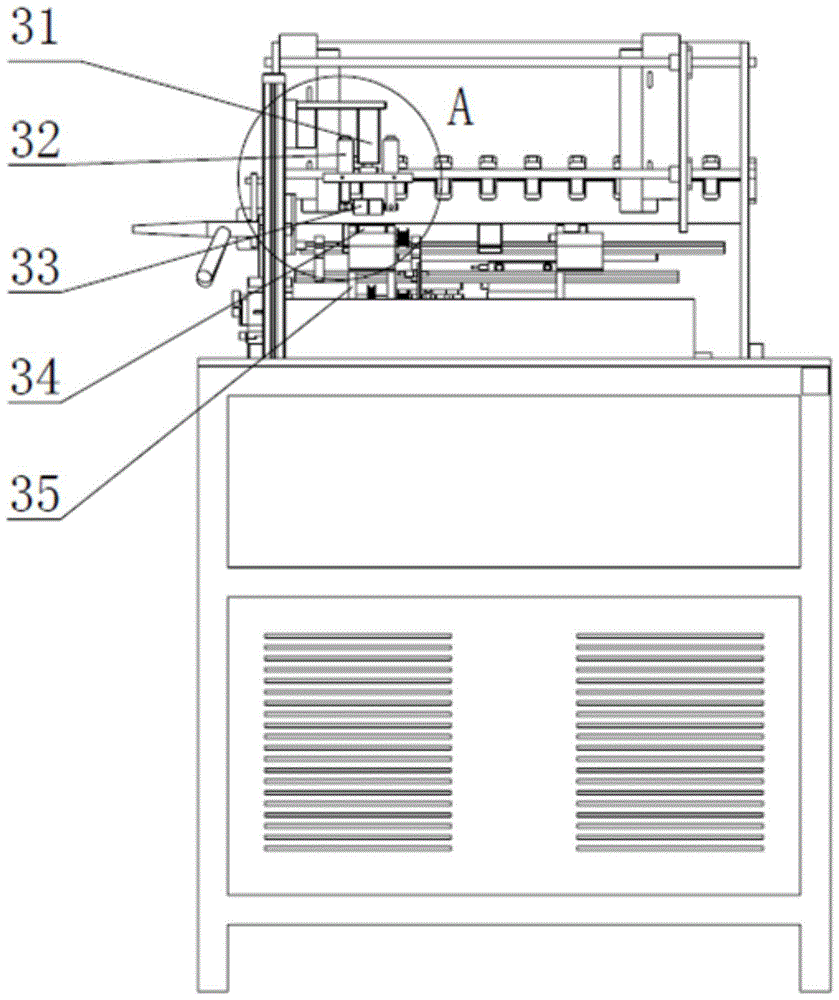

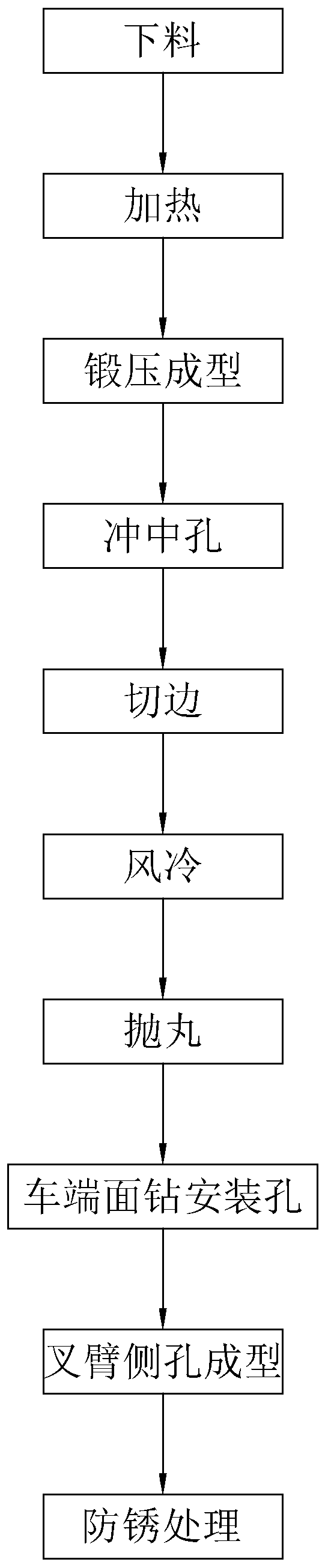

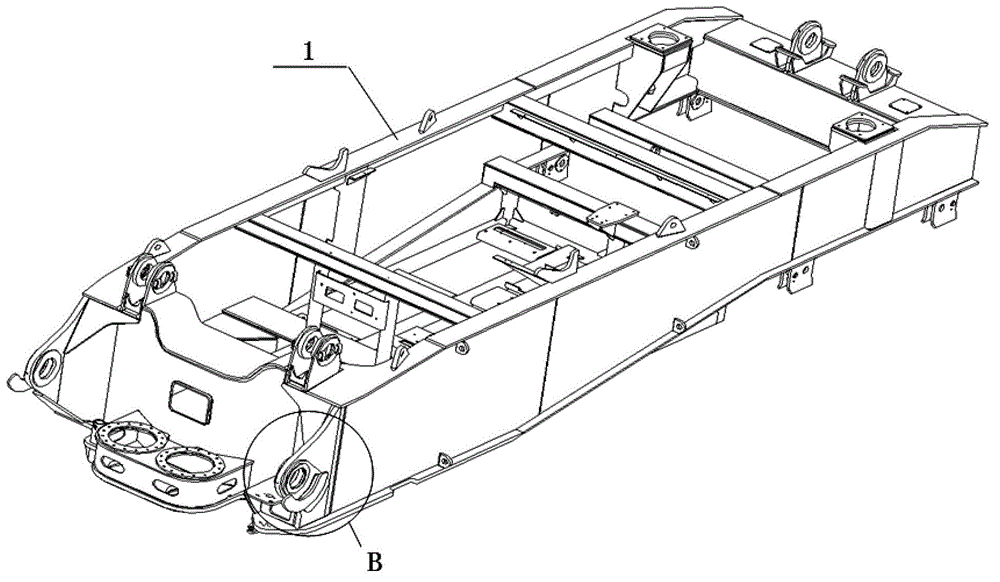

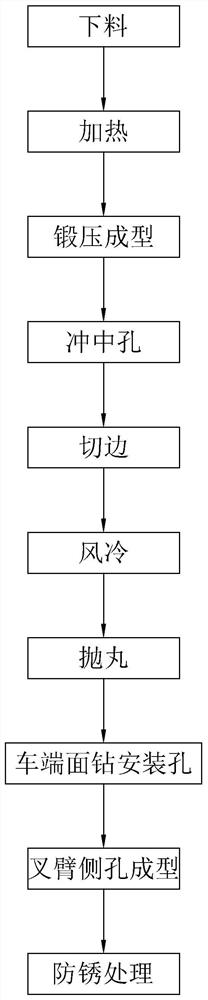

Flange pipe fork forging forming process and flange pipe fork formed by using same

ActiveCN111545696AReduce molding difficultyReduce punching forceYielding couplingMetal-working apparatusForming processesClassical mechanics

The invention relates to a flange pipe fork forging forming process and a flange pipe fork formed by using the same. The flange pipe fork forging forming process comprises the following steps of 1, blanking; 2, heating; 3, forging forming; 4, middle hole punching and edge cutting; 5, air cooling; 6, shot blasting; 7, end face turning and mounting hole drilling; 8, fork arm side hole forming; and 9, rust-proof treatment. The flange pipe fork forging forming process has the effect that the flange pipe fork with high coaxial precision can be formed.

Owner:上海长特锻造有限公司

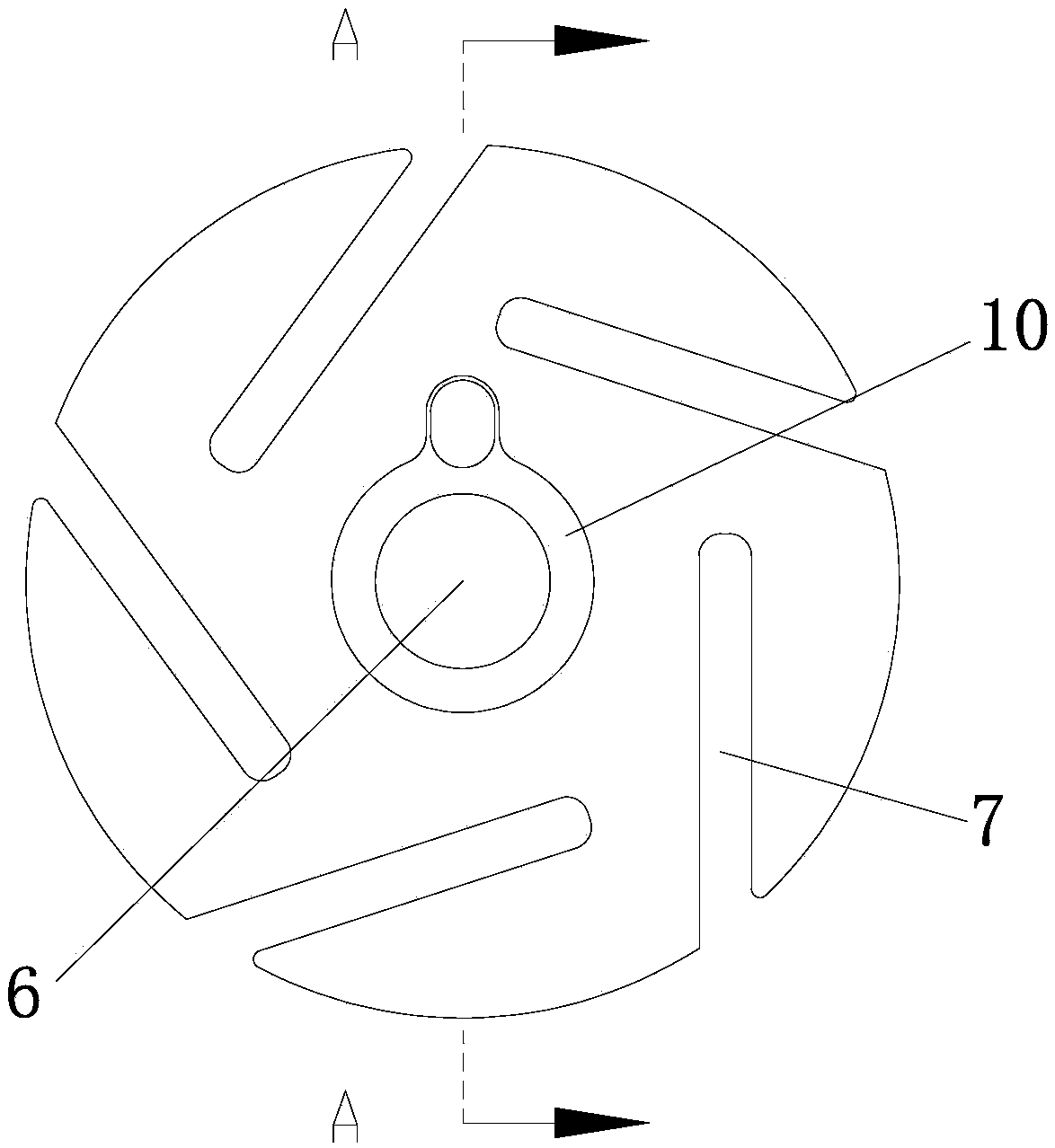

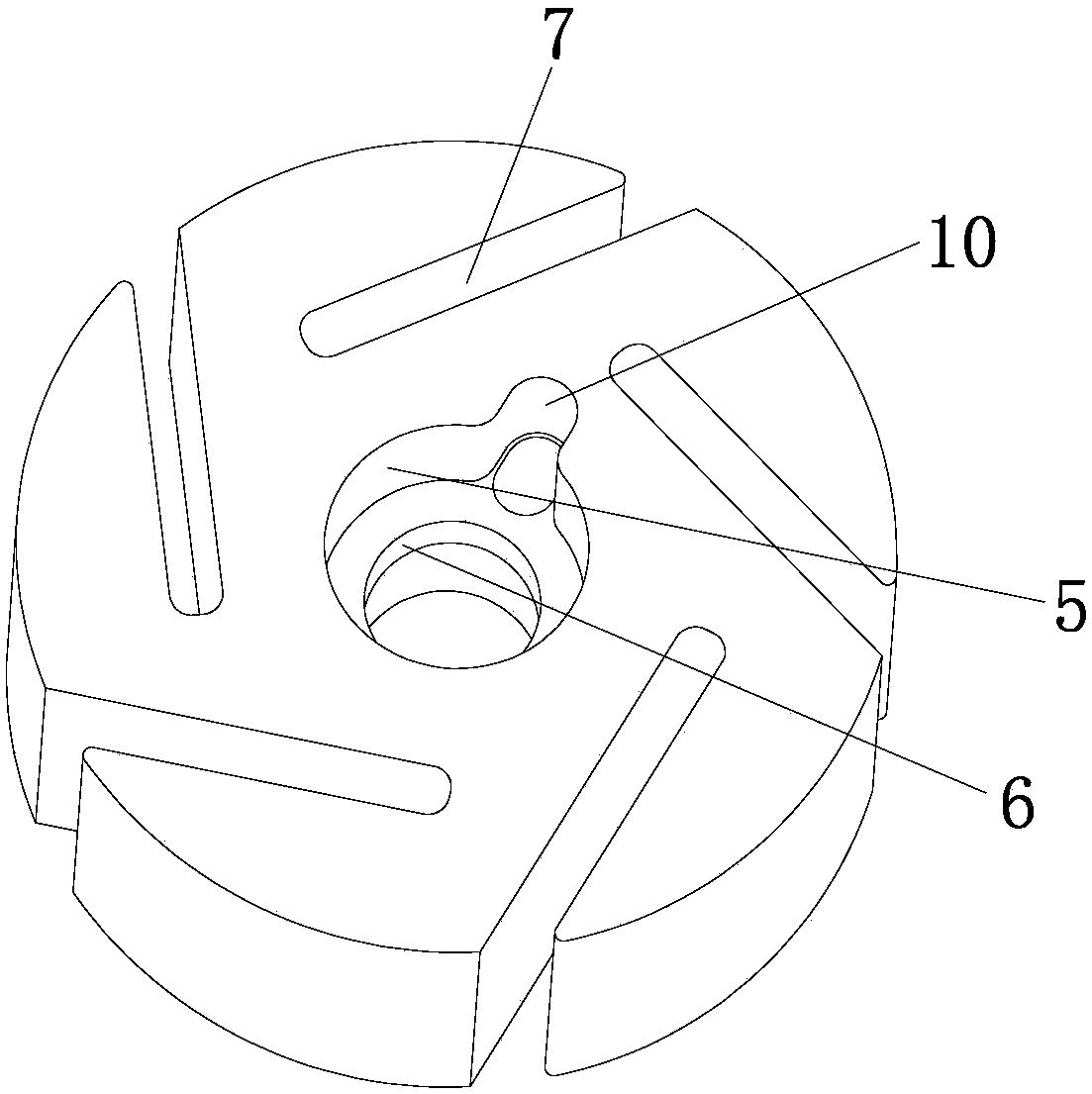

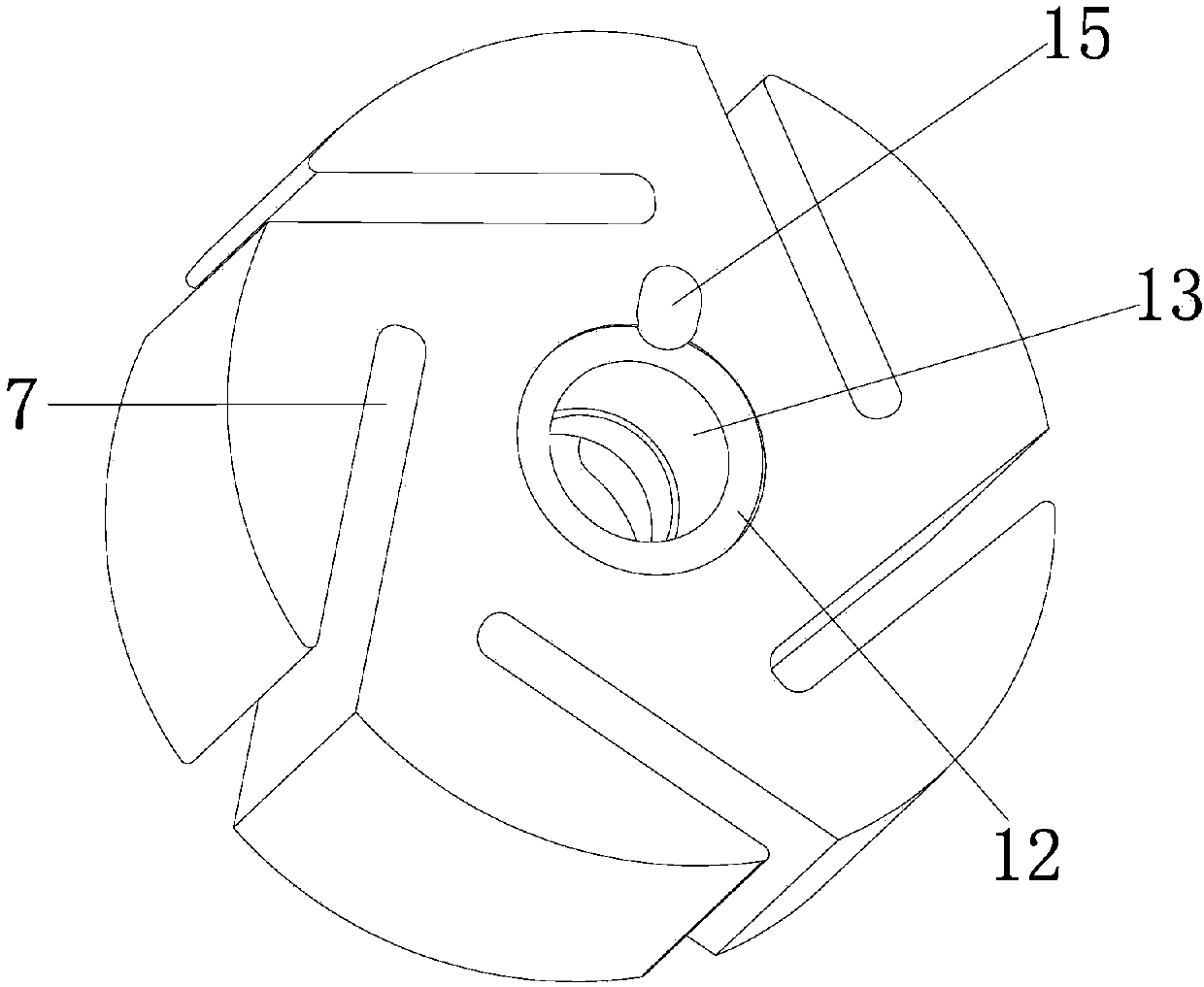

Machining method for graphite blade pump rotor and special clamps thereof

ActiveCN107654369AImprove efficiencySmall difference in accuracyRotary piston pumpsRotary piston liquid enginesGraphiteEngineering

The invention discloses a machining method for a graphite blade pump rotor and further discloses a first special clamp and a second special clamp which are used in the machining method. The machiningmethod comprises the following steps of (1) end face milling; (2) positioning hole drilling; (3) roughening; (4) assembly hole drilling; (5) rotary vane groove rough milling; (6) connecting plate positioning face finish milling; (7) first outer circle finish milling; (8) finish drilling; (9) secondary roughening; (10) second outer circle finish milling; (11) rotary vane groove finish milling; (12)breaking-milling; (13) outer circle grinding; and (14) plane grinding. According to the machining method, the coaxiality of the rotor and damage avoidance of the edges and corners of a rotary vane groove in the rotor can be ensured, and the machining accuracy and efficiency are improved. An air groove is formed in the first special clamp so that a workpiece can be tightly sucked, it is ensured that the workpiece cannot move in the machining process accordingly, and thus the machining accuracy of the workpiece is ensured; and an air draft hole is formed in the second special clamp so that therotor can be tightly sucked and fixed, and the machining accuracy of the rotor is improved.

Owner:深圳市石金科技股份有限公司

Cooling wheel testing device

InactiveCN104535340ASolve the cooling effectSimple structureVehicle wheel testingCouplingVariable-frequency drive

The invention relates to a cooling wheel testing device. The cooling wheel testing device comprises a support, a frequency converter, a motor, couplers, bearings, a stepped shaft, a torque meter and wheels, wherein the frequency converter is fixedly mounted below the support; the motor and the torque meter are horizontally opposite to each other, fixedly mounted at the left end and the right end of the support respectively and located in the same axis; the stepped shaft is supported by the two bearings mounted on the support, the two ends of the stepped shaft are connected with an output shaft of the motor and an input shaft of the torque meter through the couplers respectively, and a cooling wheel is mounted on the small-diameter shaft section of the stepped shaft for testing; the wheels are fixedly mounted at the lower ends of the four corners of the support respectively, the support can be moved through the wheels, and meanwhile a locking structure is arranged on each wheel; a base of the support can be stretched to adapt to stepped shafts with different lengths. The cooling wheel testing device is reasonable in structural design, low in manufacturing cost and good in detection effect.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

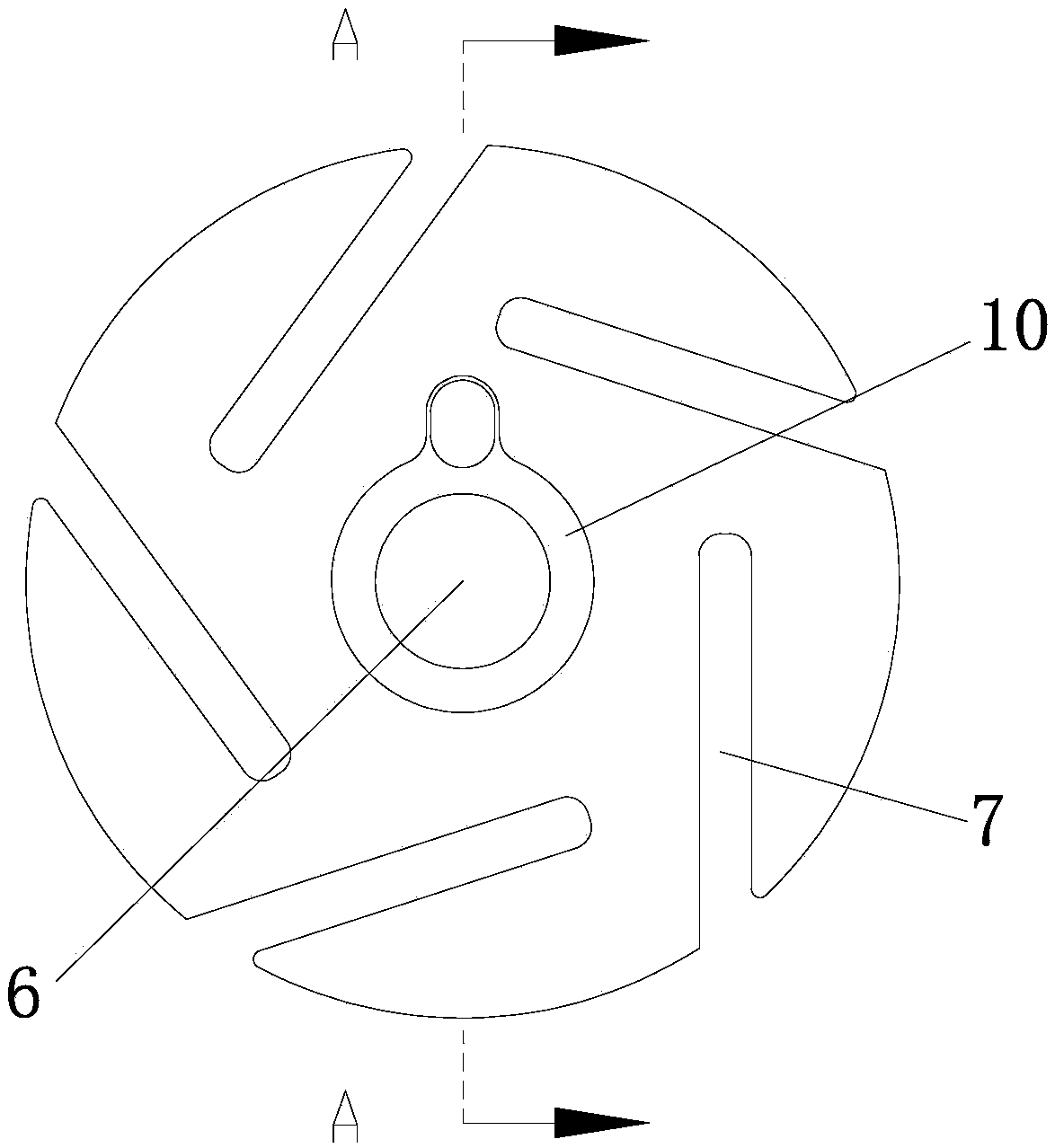

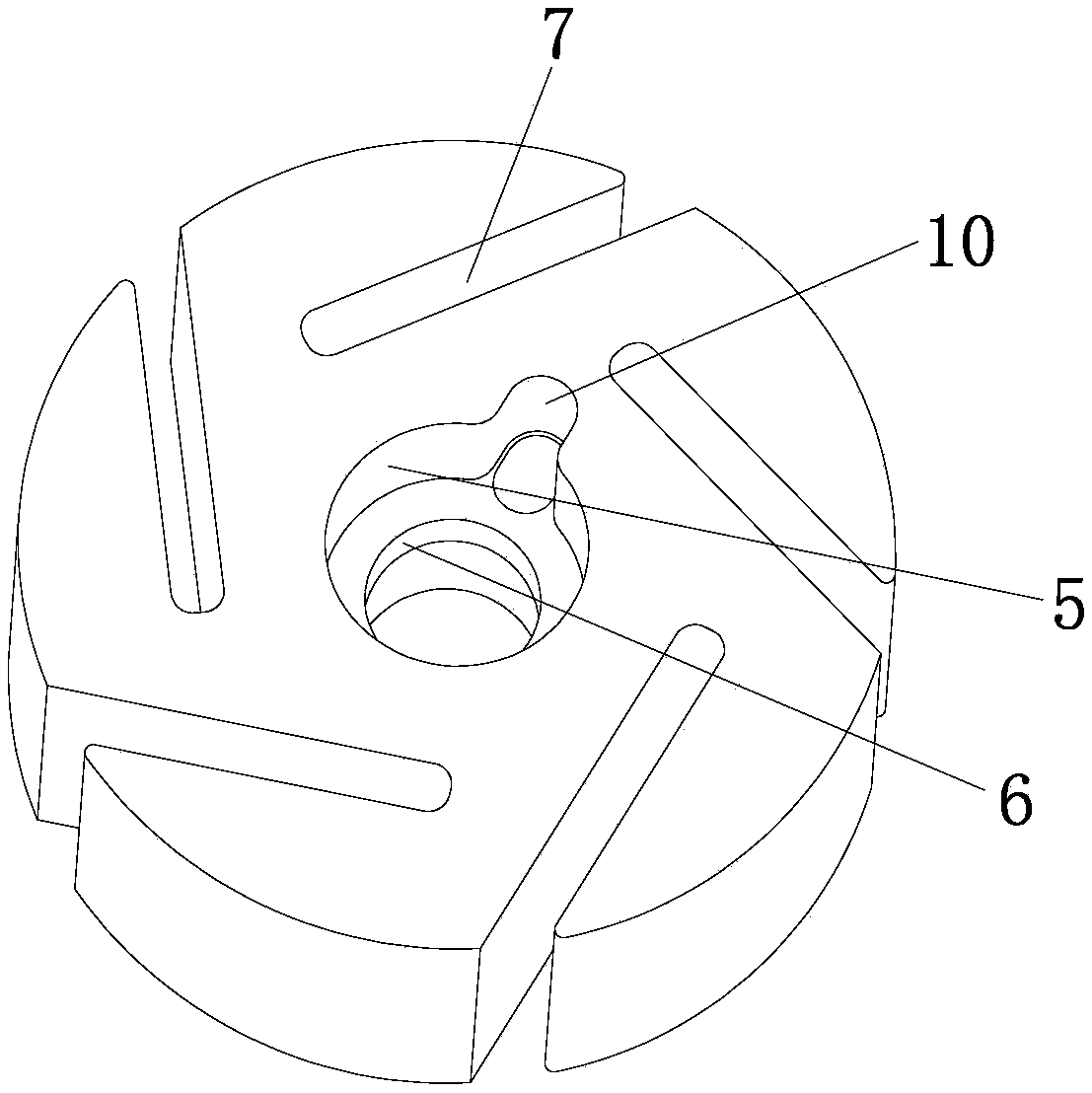

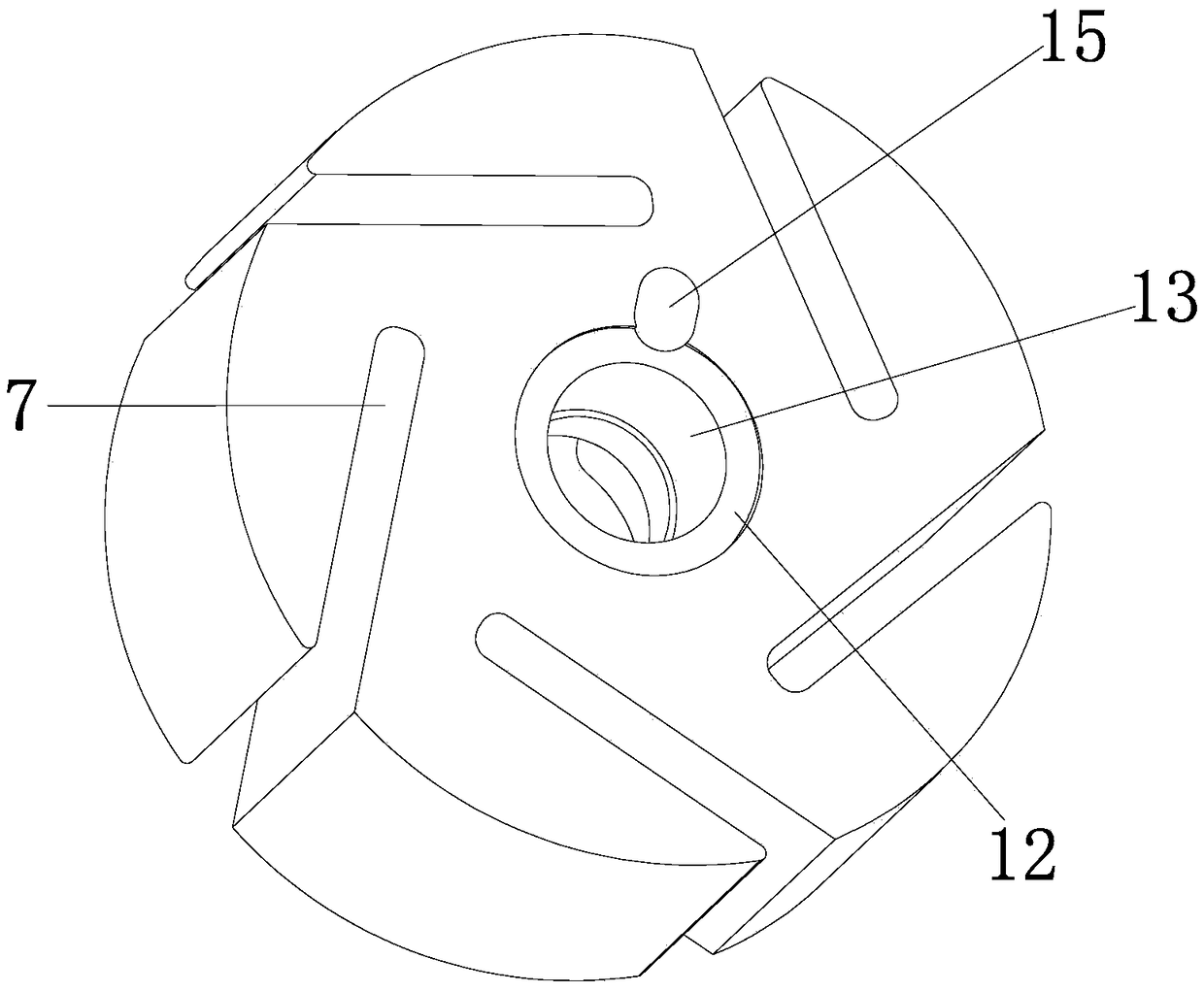

Grinding device

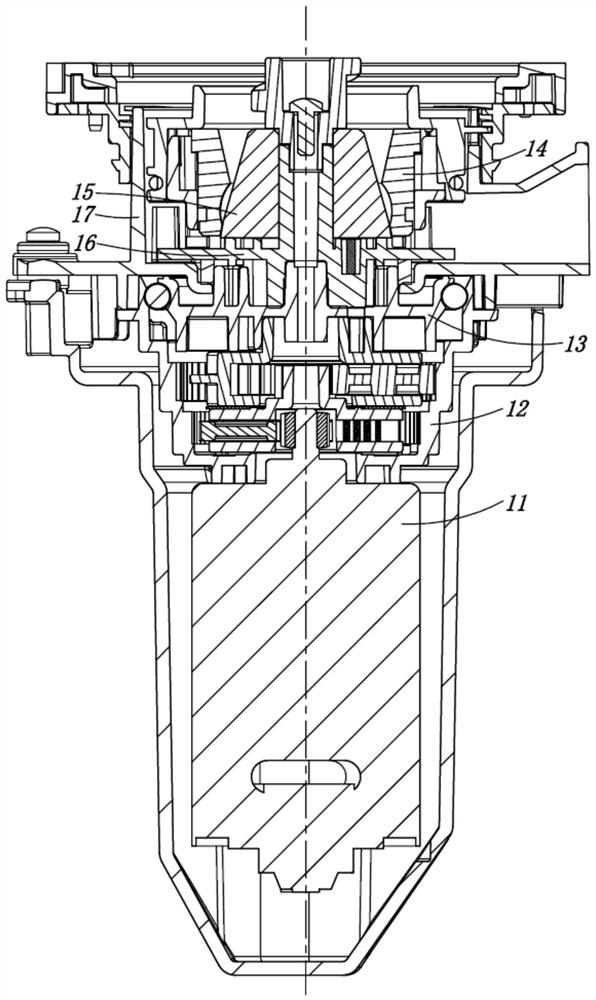

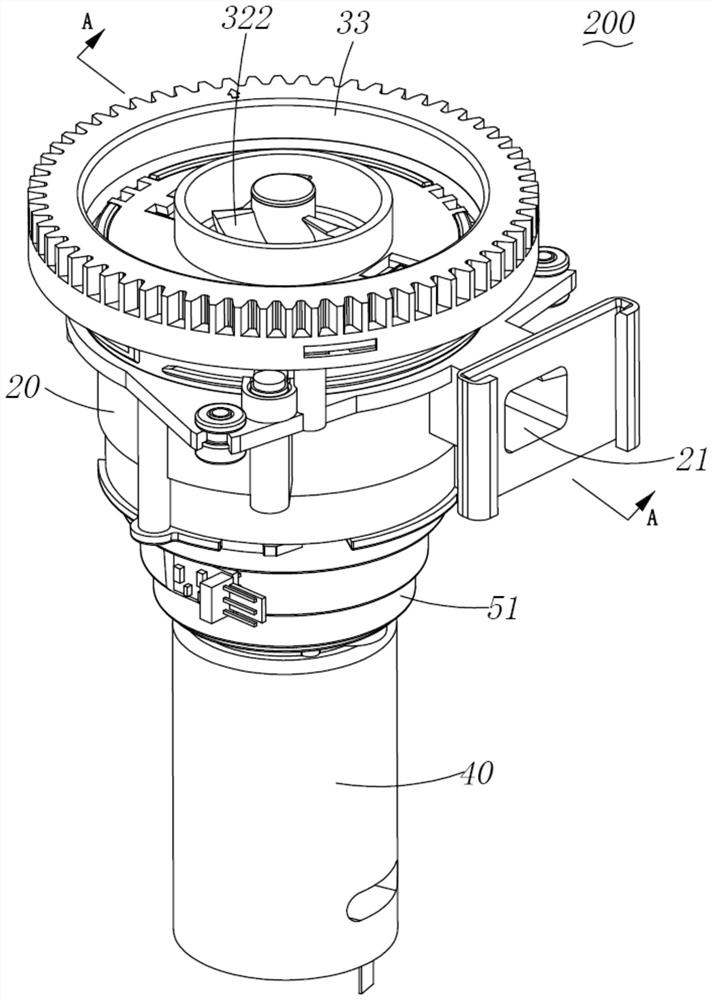

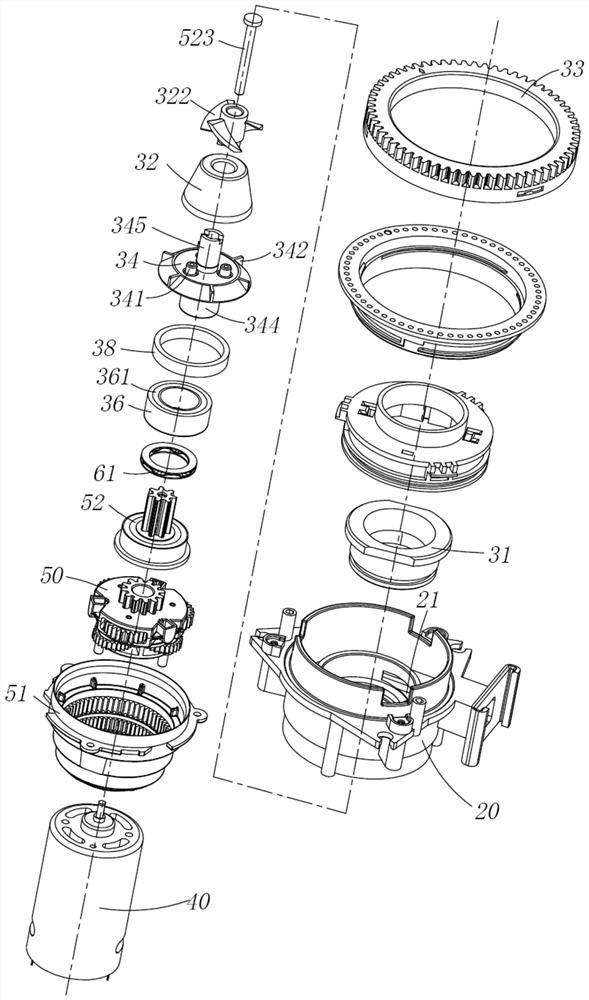

ActiveCN113558498AImprove the problem of force creepGuaranteed coaxial accuracyCoffee millsSpice millsTorque transmissionPhysics

The invention provides a grinding device which comprises a grinding shell, a discharging opening is formed in one side of the grinding shell. a first grinding element and a second grinding element are coaxially arranged in the grinding shell, a grinding gap is formed between the first grinding element and the second grinding element, and the second grinding element rotates relative to the first grinding element so as to grind the raw materials to be ground in the grinding gap; a propelling wheel is connected to the lower portion of the second grinding element so as to drive the second grinding element to rotate, and the rotation of the propelling wheel can push the ground raw materials from the grinding gap to the discharging opening; a driving assembly is arranged below the grinding shell, and the driving assembly is connected with the propelling wheel in a torque transmission manner; the propelling wheel and the driving assembly comprise a torque connecting part, the grinding shell is provided with a through hole for the torque connecting part to penetrate through, the torque connecting part is radially supported on the grinding shell through a fixed supporting piece, a rolling supporting piece is arranged between the propelling wheel and the grinding shell, and the rolling supporting piece provides at least axial support for the propelling wheel.

Owner:SUZHOU KALERM COFFEE MASCH TECH CO LTD

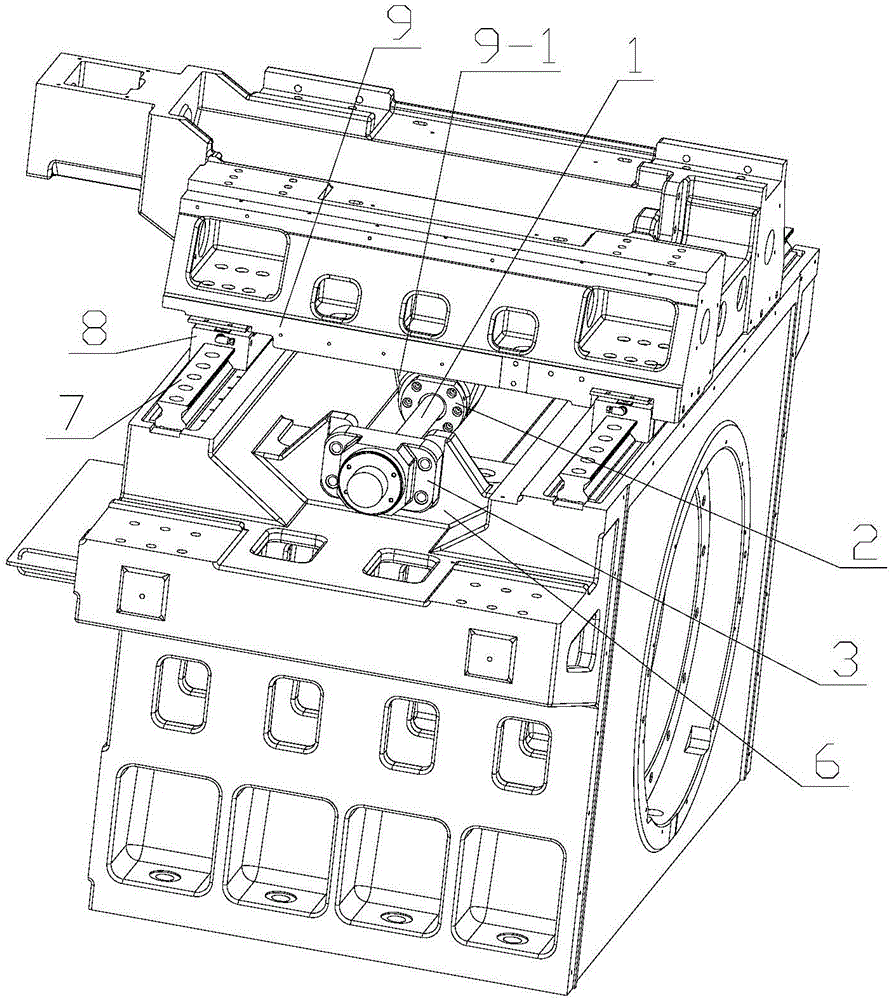

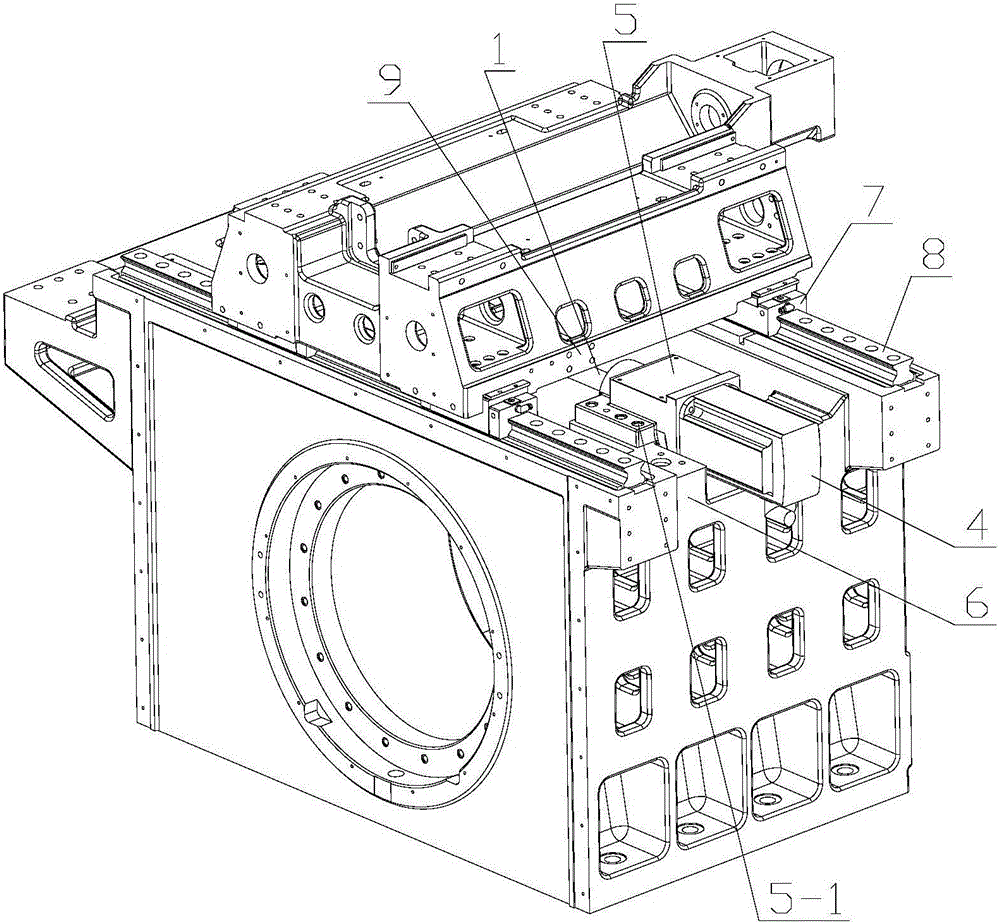

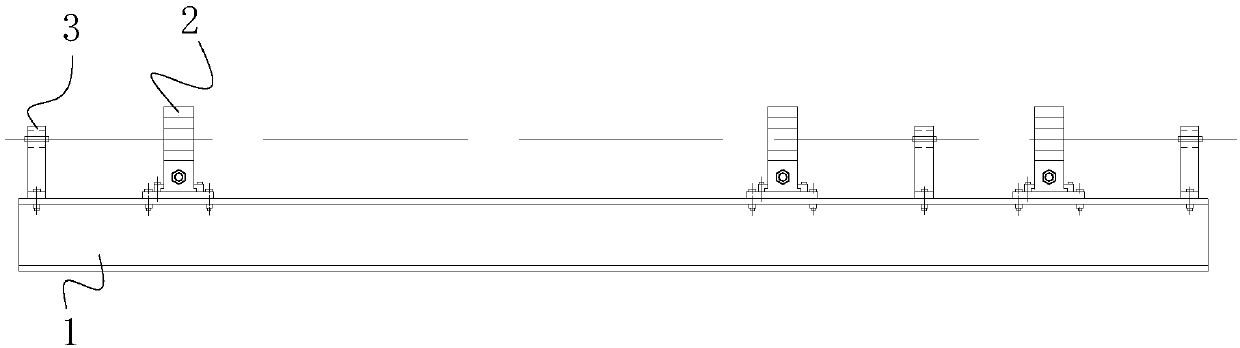

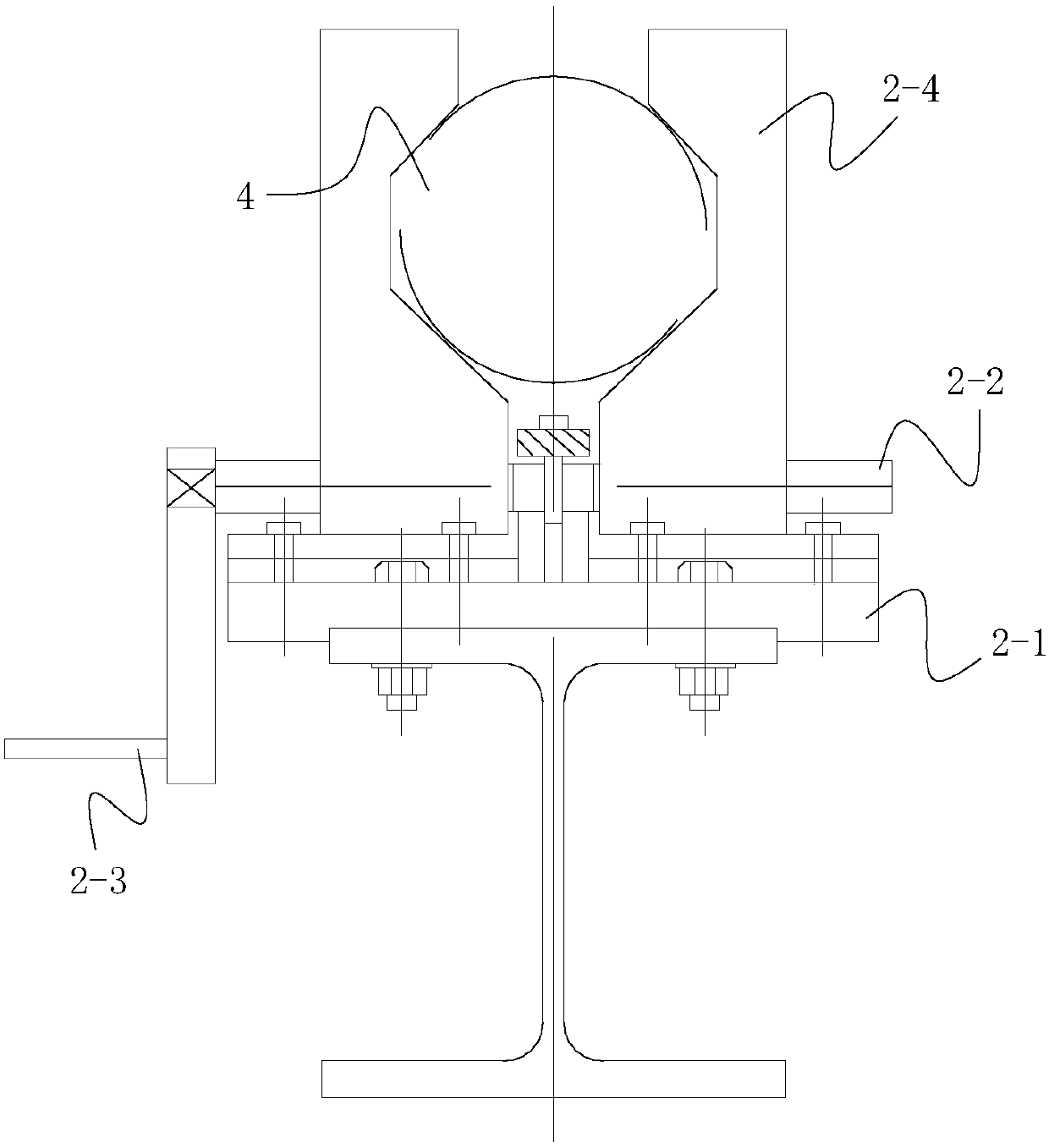

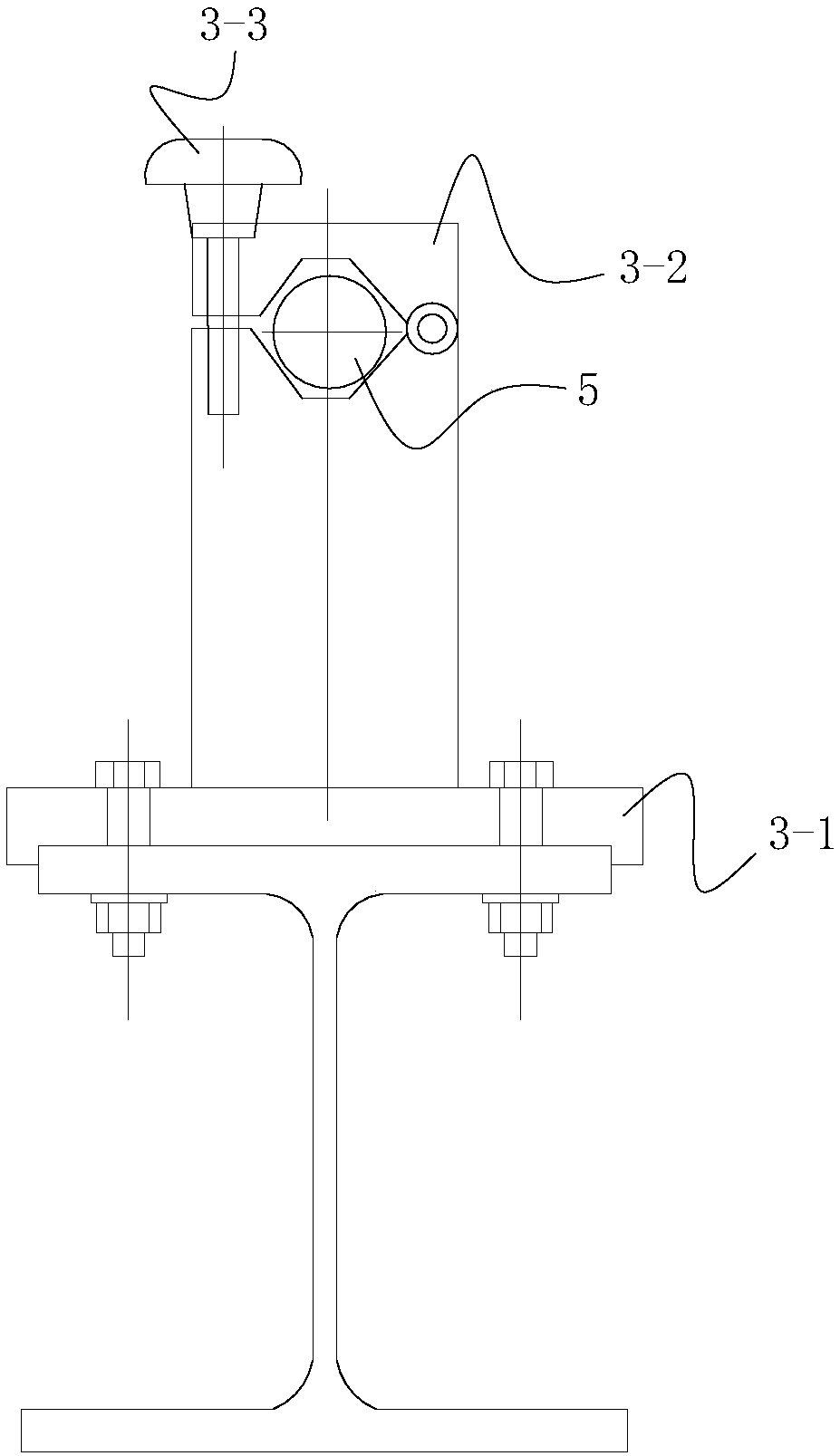

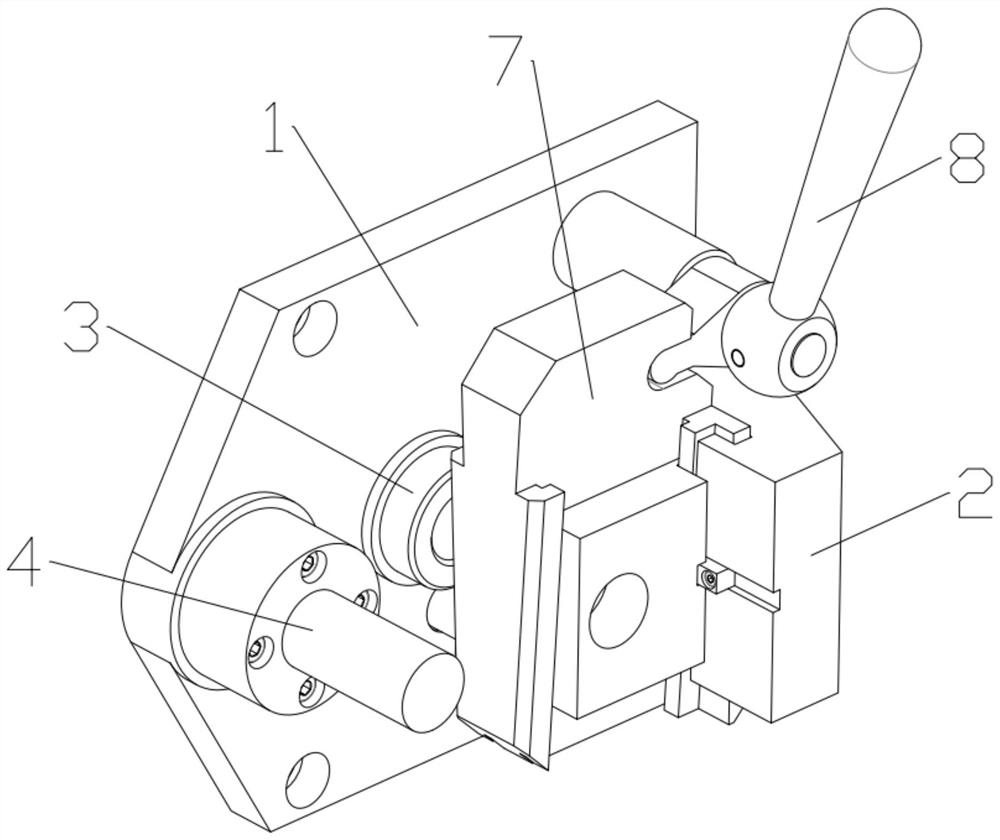

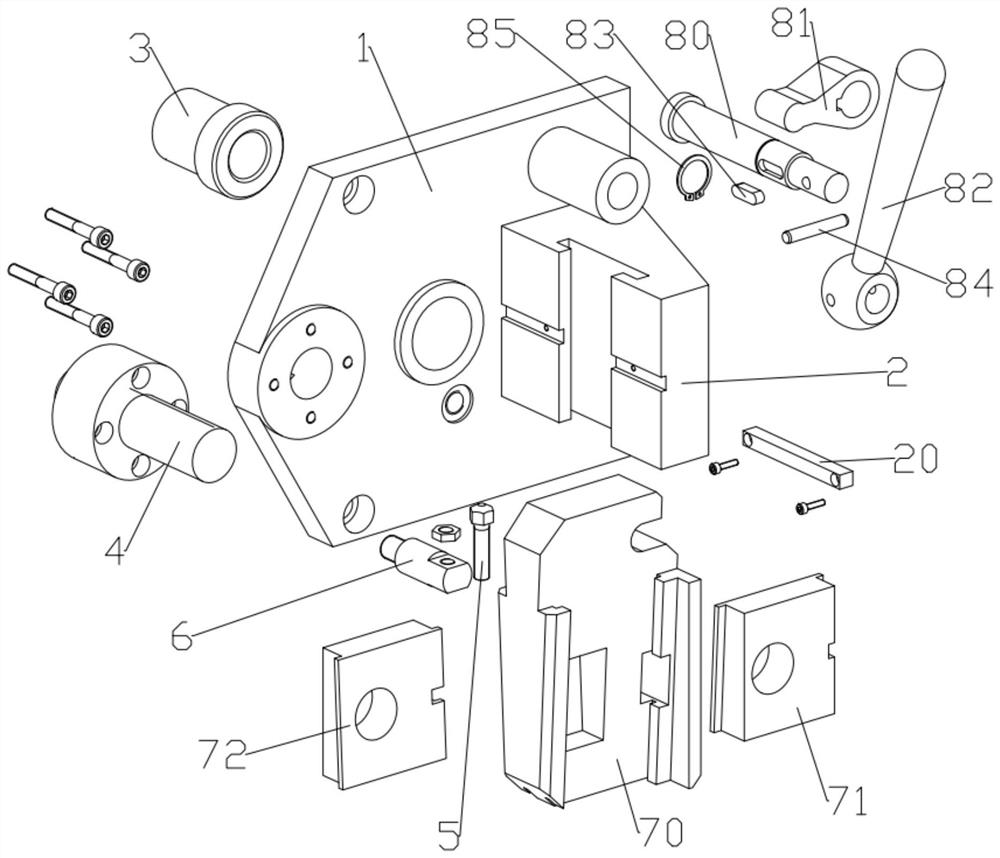

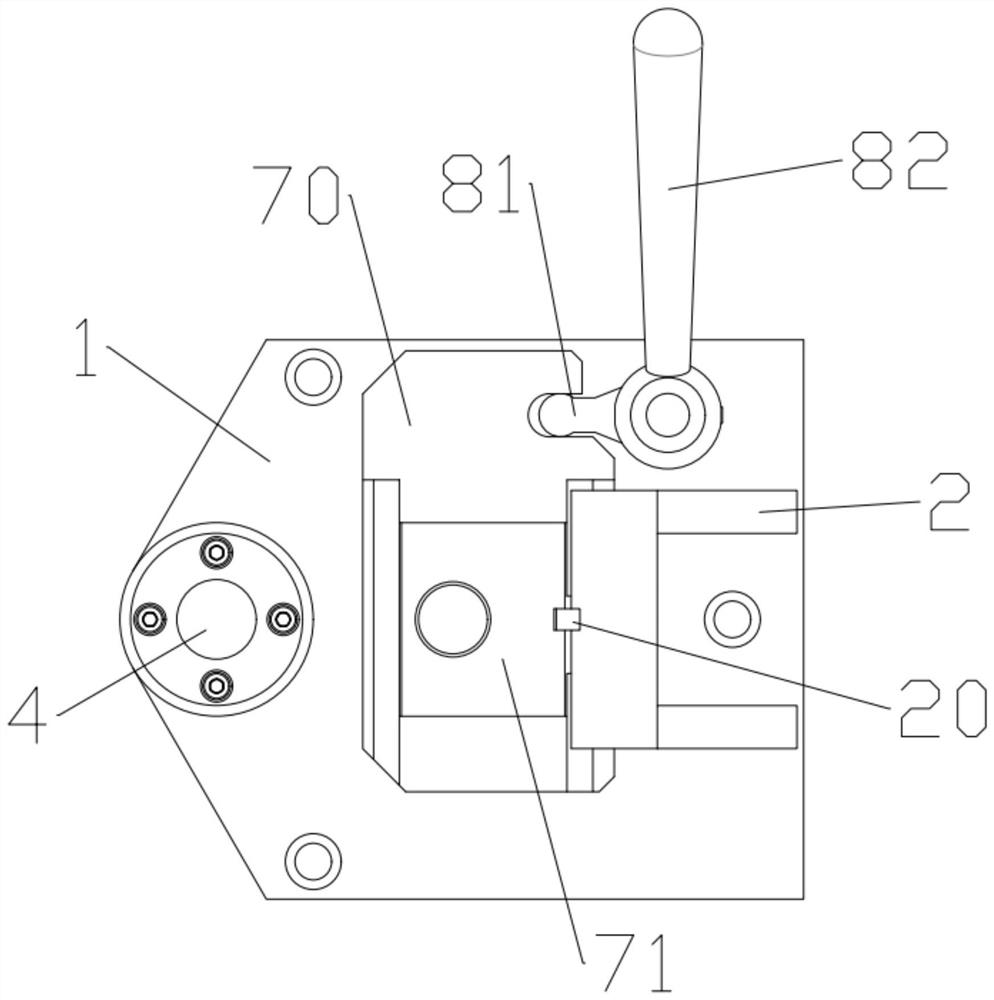

Assembling and welding tool for air transportation roller

InactiveCN107775260AQuality improvementGuaranteed coaxial accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSteel tube

The invention relates to a butt welding tool for airport transportation rollers, which is characterized in that it includes a base, a steel pipe support device and a shaft head clamping device; the steel pipe support device includes a bottom plate, a screw, a hand wheel and two C-shaped seats , the bottom plate is fixed on the base through fasteners, two C-shaped seats are installed on the bottom plate through horizontal slideways, the screw is fitted on the two C-shaped seats through threads, and the hand wheel is installed on the screw; the shaft head is clamped The device includes a base, the base is installed on the base through fasteners, the upper end of the base is connected to the upper cover through a pin shaft, the upper cover is equipped with locking bolts, and the lower part of the upper cover and the upper part of the base are provided with V-shaped grooves mouth. The invention can ensure the coaxial precision of the steel pipe body and the shaft head, solve the problem that it is difficult to meet the coaxiality requirements and low production efficiency only by manual marking and alignment, and finally realize the high-quality and high-efficiency production of airport transport rollers .

Owner:TIANJIN SERI MACHINERY EQUIP

Steel hinge positioning device

ActiveCN108818361AGuaranteed coaxial accuracyReduce workloadWork holdersPhotovoltaic energy generationEngineeringMechanical engineering

The invention is applicable to the technical field of automobile positioning tools, and provides a steel hinge positioning device. The device comprises a base, an adjusting mechanism, a pressing mechanism and a positioning mechanism, wherein the adjusting mechanism is arranged on the base, the pressing mechanism comprises an upper mounting plate arranged above the adjusting mechanism, a first sliding mechanism arranged on the upper mounting plate, a connecting piece arranged on the first sliding mechanism and a pressing air cylinder connected with the connecting piece, the positioning mechanism comprises a positioning workpiece arranged on the connecting piece and pressing blocks arranged at the two ends of the upper mounting plate correspondingly, pin shaft positioning holes are formed inthe two ends of the positioning workpiece, and the pressing blocks are opposite to the pin shaft positioning holes. According to the device, two hinges are positioned through the positioning workpiece and then adjusted through the adjusting mechanism, the coaxiality precision of the two hinge pin shafts is guaranteed, the workload of adjustment is reduced, and the working efficiency is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

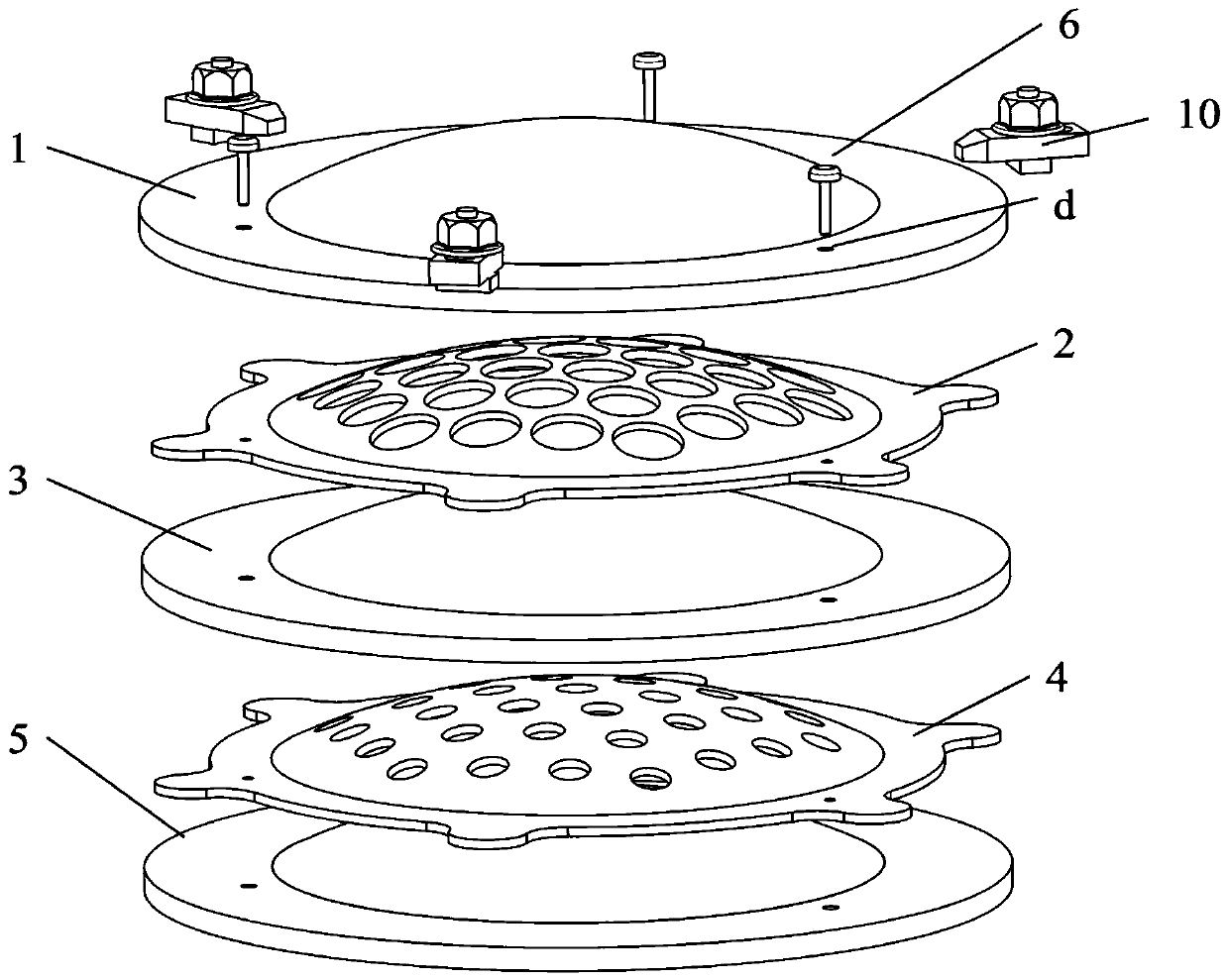

A hole-making method for ion propulsion carbon grid assembly

ActiveCN109227740BGuaranteed coaxial accuracyGuaranteed positioning accuracyMetal working apparatusMachine toolMachining

Owner:DALIAN UNIV OF TECH

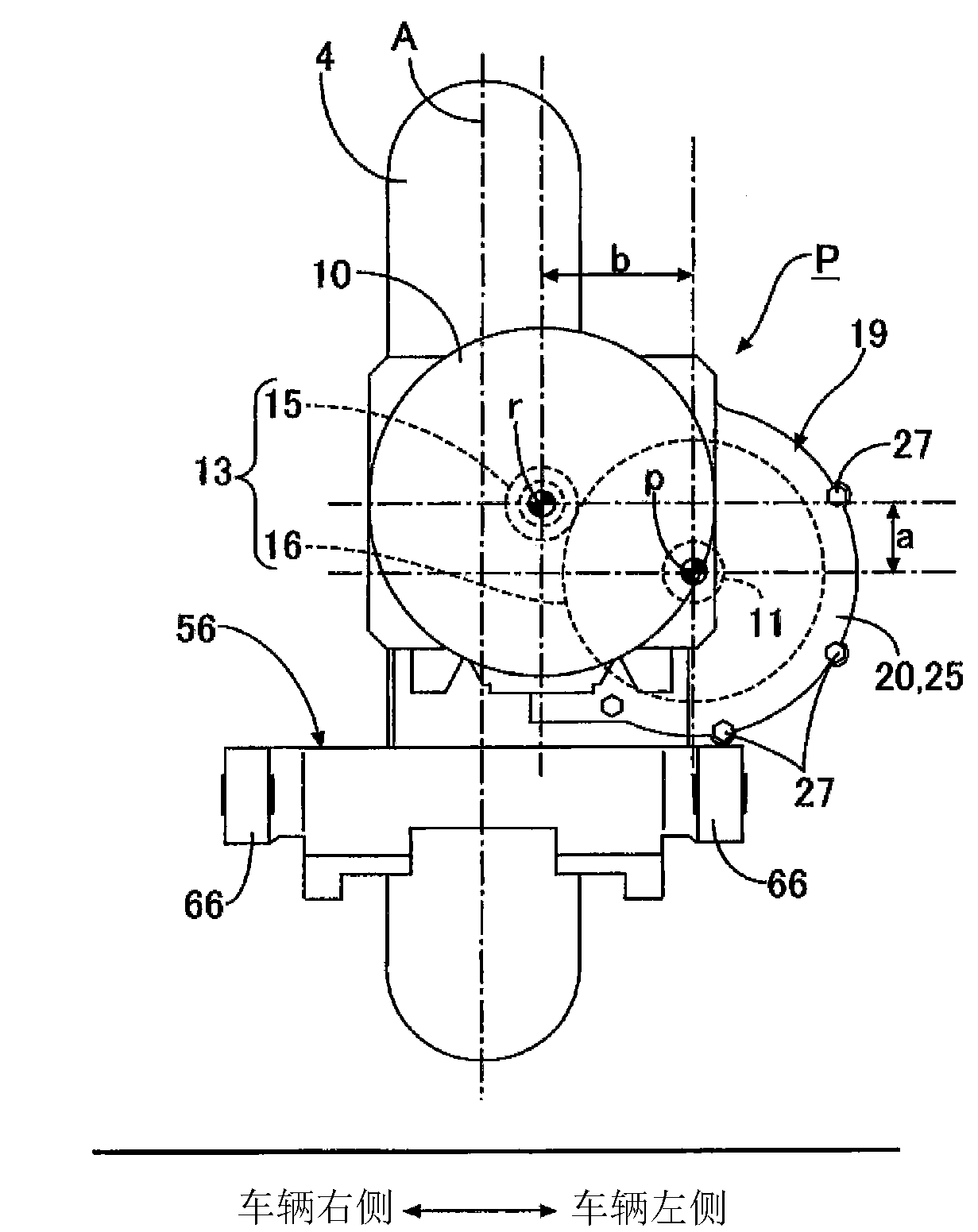

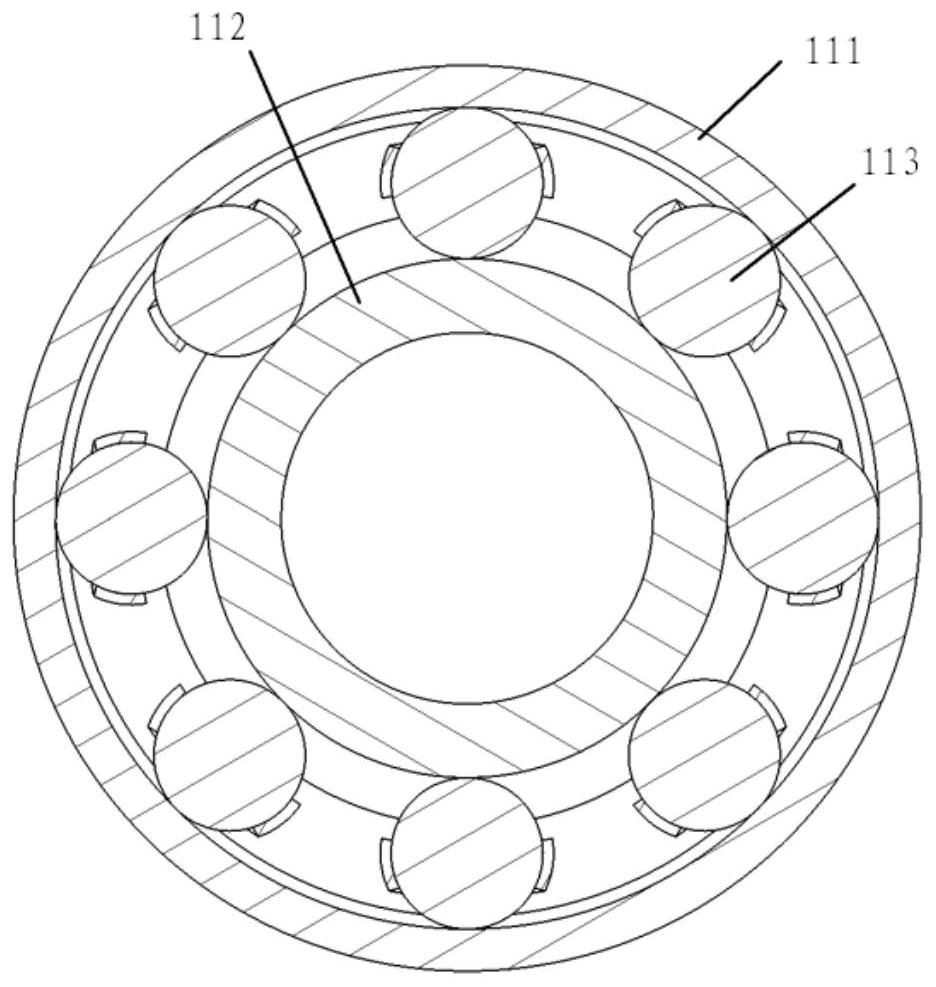

A rotating assembly and steering gear connection mechanism

ActiveCN109515691BEliminate free gapsHigh running precisionWith power amplificationBall bearingsTorque transmissionMechanical engineering

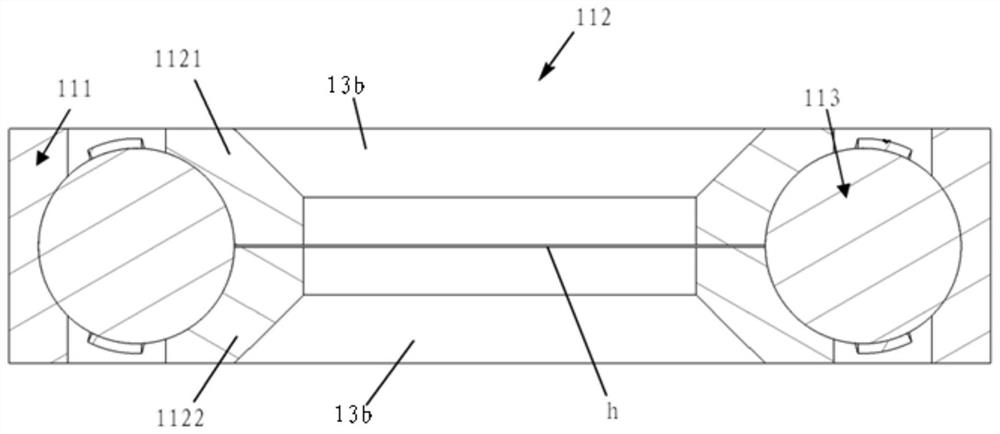

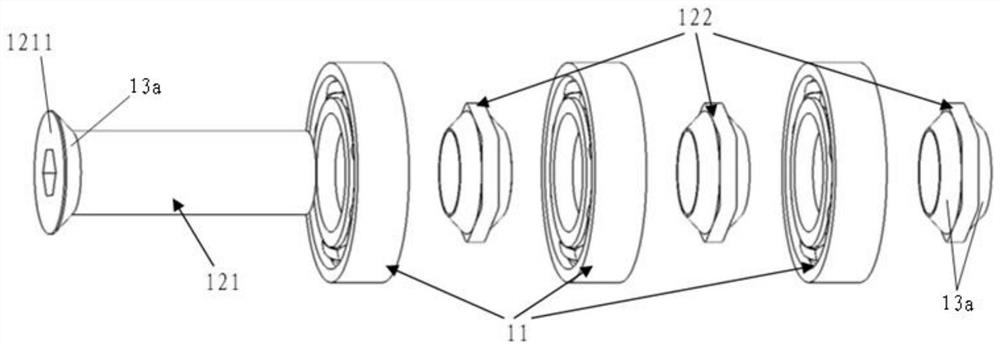

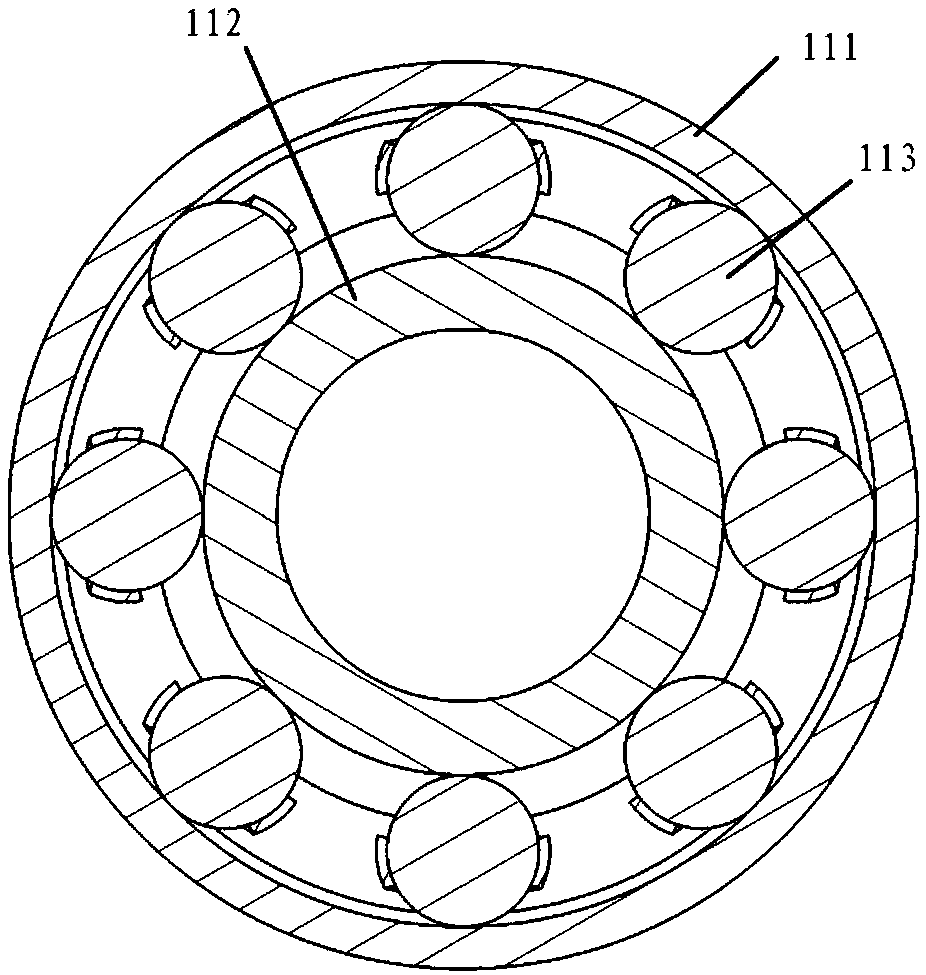

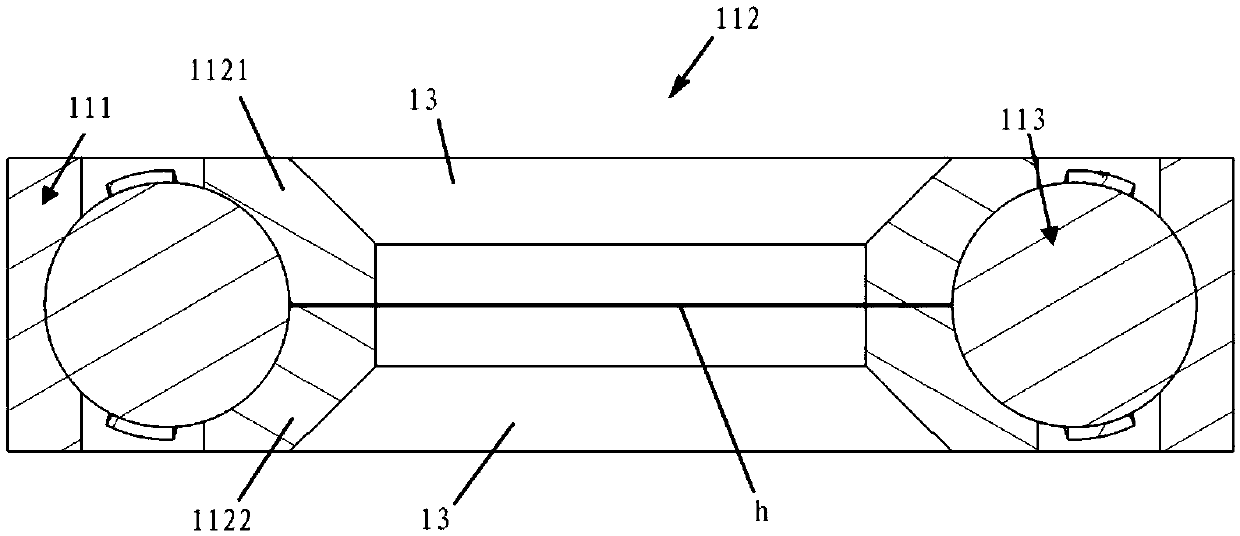

The invention relates to a rotating component and a steering gear connecting mechanism. The rotating component comprises a bearing (11) and a locking component (12), wherein the bearing (11) comprisesa rotating outer ring (111), a rotating inner ring (112), and a rolling component (113) located between the rotating outer ring (111) and the rotating inner ring (112); the rotating inner ring (112)comprises a first inner ring portion (1121) and a second inner ring portion (1122); and the locking component (12) is coaxial with the rotating inner ring (112) and is used for locking the first innerring portion (1121) and the second inner ring portion ( 1122). By adopting the rotating component, the rotating inner ring of the rotating component can eliminate the free gap of the mechanism underthe locking action of the locking component, so that when the torque of the steering gear connecting mechanism is transmitted to a rudder shaft end, the torque is not delayed and not lost, and meanwhile, the steering gear connecting mechanism has good later-period maintainability and curing property.

Owner:BEIJING SPACE TECH RES & TEST CENT

Rotating component and steering engine connecting mechanism

ActiveCN109515691AEliminate free gapsHigh running precisionWith power amplificationBall bearingsEngineeringRudder

The invention relates to a rotating component and a steering gear connecting mechanism. The rotating component comprises a bearing (11) and a locking component (12), wherein the bearing (11) comprisesa rotating outer ring (111), a rotating inner ring (112), and a rolling component (113) located between the rotating outer ring (111) and the rotating inner ring (112); the rotating inner ring (112)comprises a first inner ring portion (1121) and a second inner ring portion (1122); and the locking component (12) is coaxial with the rotating inner ring (112) and is used for locking the first innerring portion (1121) and the second inner ring portion ( 1122). By adopting the rotating component, the rotating inner ring of the rotating component can eliminate the free gap of the mechanism underthe locking action of the locking component, so that when the torque of the steering gear connecting mechanism is transmitted to a rudder shaft end, the torque is not delayed and not lost, and meanwhile, the steering gear connecting mechanism has good later-period maintainability and curing property.

Owner:BEIJING SPACE TECH RES & TEST CENT

A Processing Technology of Half-shaft Sleeve

Owner:ZHUCHENG CITY FURI MACHINERY

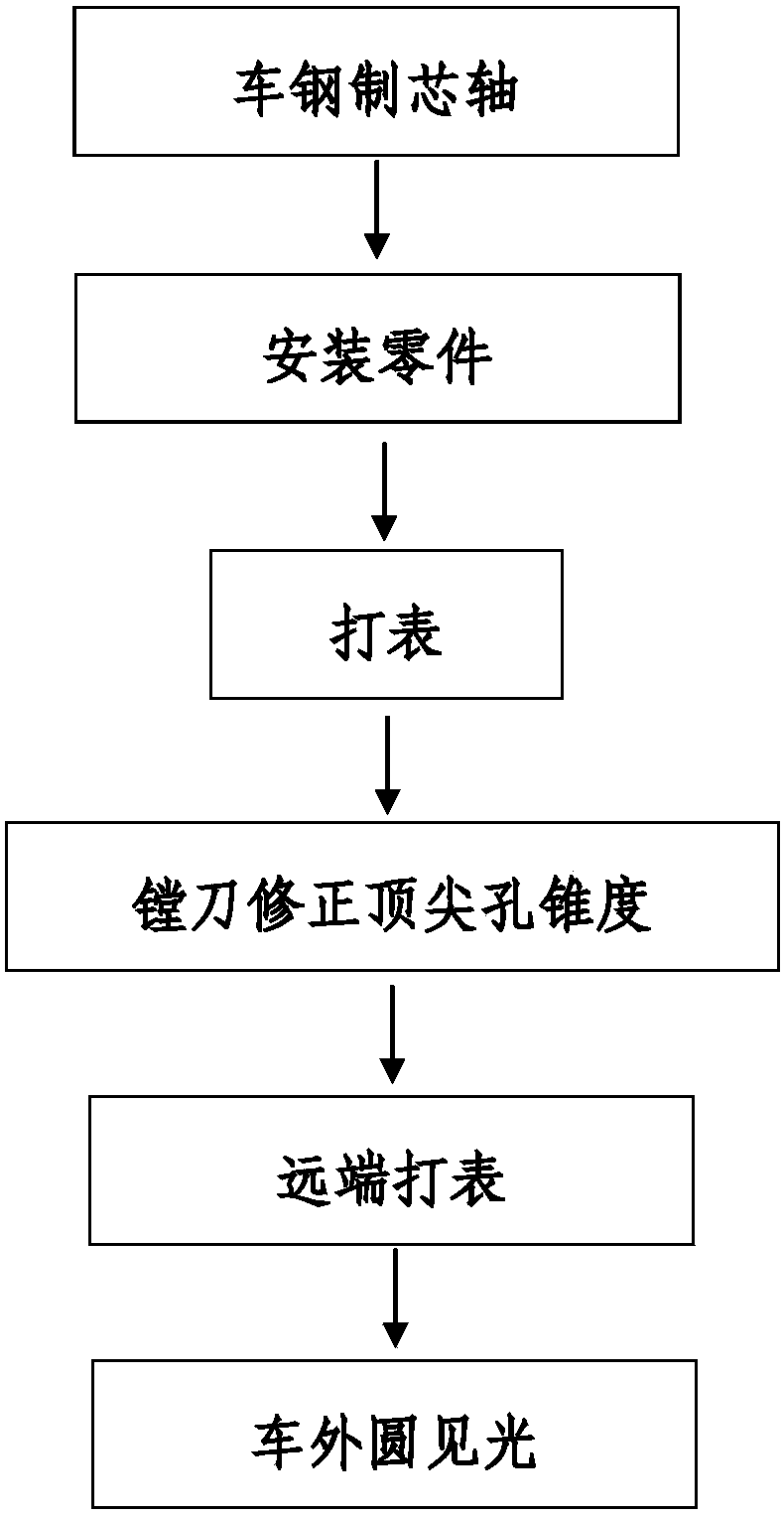

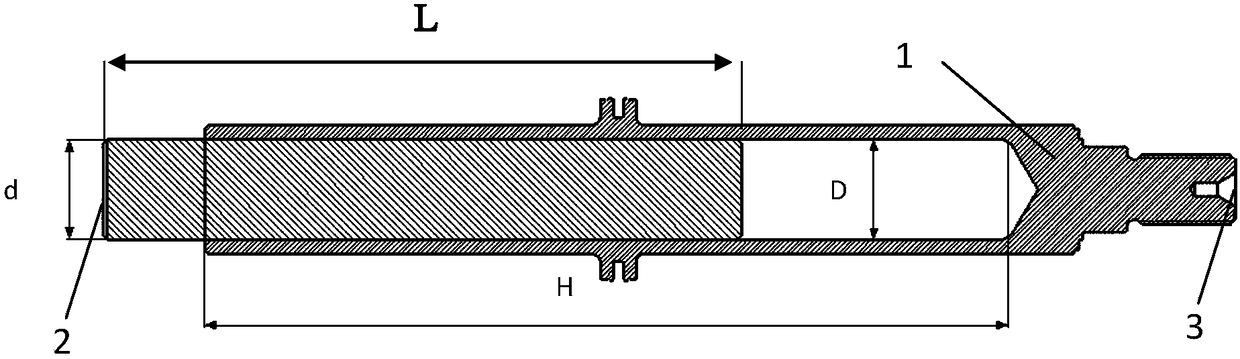

Large-diameter counter bit machining method

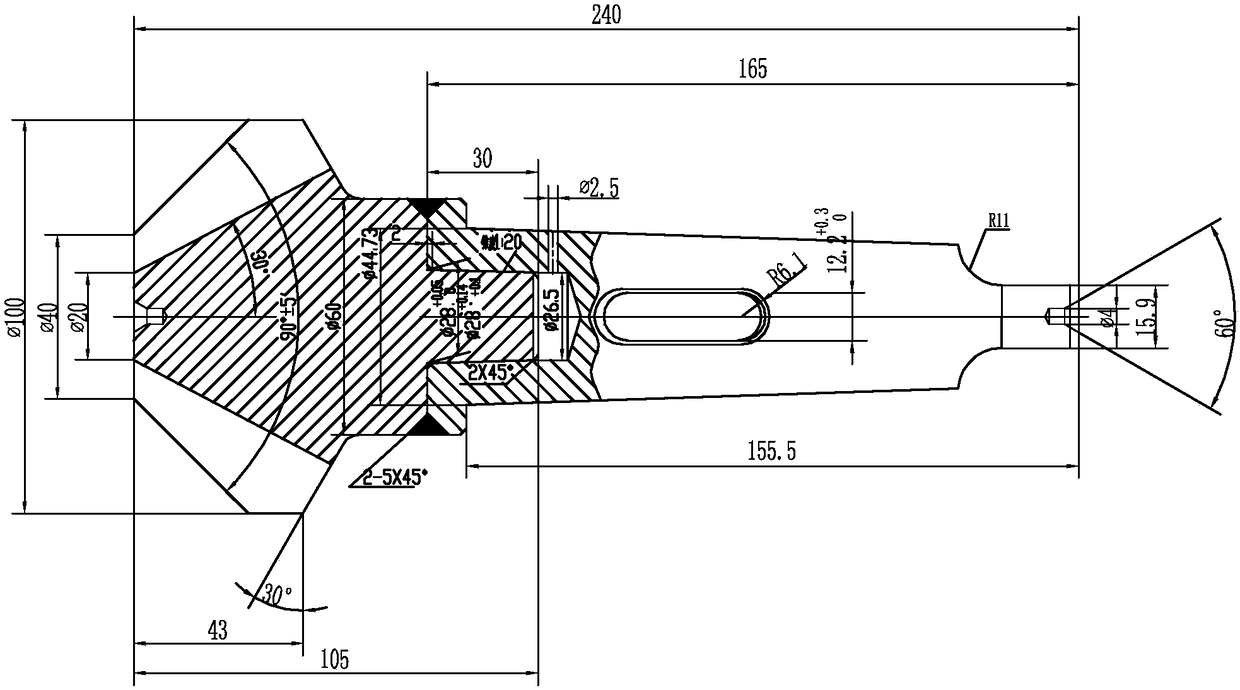

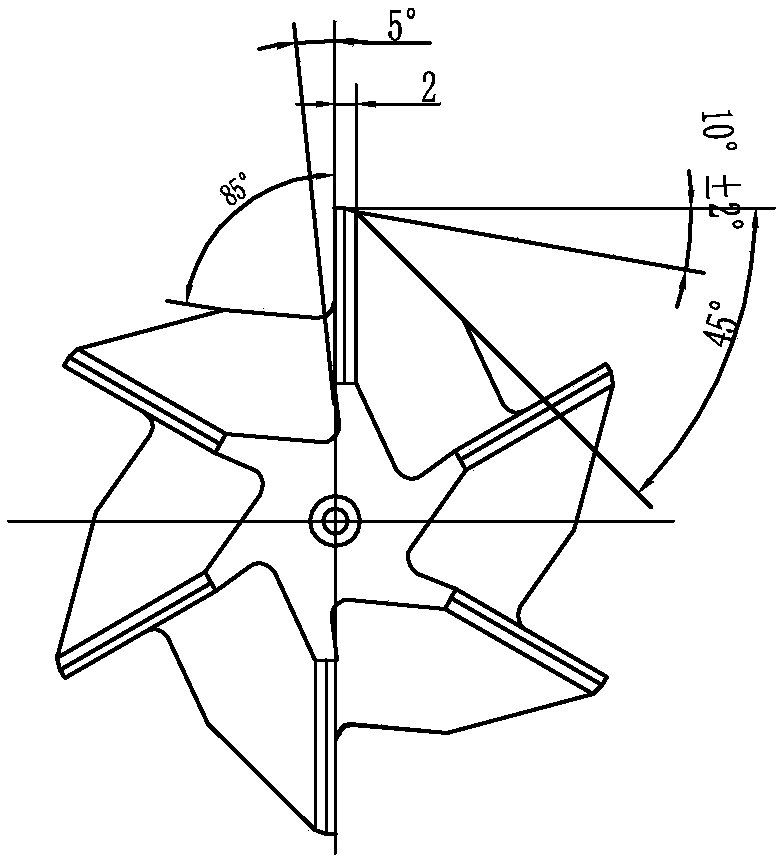

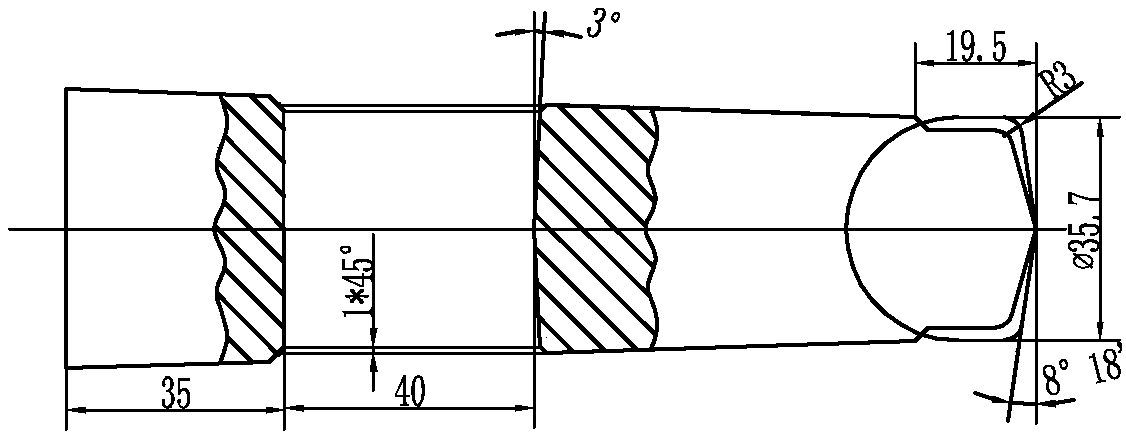

The invention discloses a large-diameter counter bit machining method and relates to a counter bit machining method. By means of the large-diameter counter bit machining method, the problems that by means of an existing large-diameter counter bit machining method, tool materials are wasted, the machining allowance is extremely large, and machining time is wasted are solved. The large-diameter counter bit machining method comprises the steps that 1, a counter bit and a tool bar are turned through a lathe; 2, a counter bit groove, a front corner and a rear corner are milled through a horizontalmilling machine; 3, a tool bar flat tail is milled through the horizontal milling machine, and a tool bar kidney-shaped hole is milled; 4, a bench worker drills a vent hole communicating with a conical hole in the tool bar; 5, the counter bit and the tool bar are welded into a whole through electrowelding, and after welding, the welding stress is removed; 6, heat treatment is conducted on a 90-degree cutting conical surface, machined in step 1, of the counter bit till HRC66-68 is reached; 7, central holes in the two ends of the counter bit are ground; 8, the 5-degree front corner of the counter bit is ground through a tool grinding machine; 9, the central holes in the two ends of the counter bit are jacked through two jacking tips, the 90-degree cutting conical surface of the counter bit is ground, and a Mohs 5 taper-shank is ground; and 10, the 10-degree counter bit rear corner is ground through the tool grinding machine.

Owner:HARBIN TURBINE

A computer-aided adjustment method for coaxial optical system

ActiveCN109031659BAvoid position mutual compensation problemsSolve the problem that cannot be adjustedDesign optimisation/simulationSpecial data processing applicationsEngineeringComputer-aided

The invention discloses a computer-aided installation and adjustment method of a coaxial optical system. The computer-aided installation and adjustment method comprises the following steps of S1, establishing an optical model of an optical system to be installed and adjusted, and separately establishing n optical sub-systems along the optical path direction, wherein the n optical sub-system comprises optical elements 1-n; S2, selecting the image plane positions of each optical sub-system and obtaining an ideal wavefront aberration through simulation analysis; S3, introducing a position deviation amount to the optical element n in the n optical sub-system to obtain a simulated wavefront aberration; S4, solving a sensitivity matrix corresponding to each optical sub-system by adoptinga sensitivity matrix formula; and S5, solving the actual position deviation of the optical element n in the n optical sub-system by utilizing the sensitivity matrix and the actual wavefront aberration, and adjusting the optical element, so as to successively complete the installation and adjustment of the n optical sub-systems. By adoption of the method, the problem of mutual compensation ofpositions of all the optical elements in the adjusting process can be avoided, so that the convergence speed in the assembling and adjusting process is accelerated, and the assembling and adjusting precision and the assembling and adjusting efficiency are improved.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

A processing method of graphite vane pump rotor and its special fixture

ActiveCN107654369BImprove efficiencySmall difference in accuracyRotary piston pumpsWorking accessoriesGraphiteMachining process

The invention discloses a machining method for a graphite blade pump rotor and further discloses a first special clamp and a second special clamp which are used in the machining method. The machiningmethod comprises the following steps of (1) end face milling; (2) positioning hole drilling; (3) roughening; (4) assembly hole drilling; (5) rotary vane groove rough milling; (6) connecting plate positioning face finish milling; (7) first outer circle finish milling; (8) finish drilling; (9) secondary roughening; (10) second outer circle finish milling; (11) rotary vane groove finish milling; (12)breaking-milling; (13) outer circle grinding; and (14) plane grinding. According to the machining method, the coaxiality of the rotor and damage avoidance of the edges and corners of a rotary vane groove in the rotor can be ensured, and the machining accuracy and efficiency are improved. An air groove is formed in the first special clamp so that a workpiece can be tightly sucked, it is ensured that the workpiece cannot move in the machining process accordingly, and thus the machining accuracy of the workpiece is ensured; and an air draft hole is formed in the second special clamp so that therotor can be tightly sucked and fixed, and the machining accuracy of the rotor is improved.

Owner:深圳市石金科技股份有限公司

A method for correcting the deflection of deep and long holes of rotary parts such as pistons

ActiveCN106625026BAccurate realizationGuaranteed diameterMeasurement/indication equipmentsEngineeringMachining

Owner:FLIGHT AUTOMATIC CONTROL RES INST

A jig for broaching two small holes of a lifting lug

ActiveCN112894410BAvoid deformationGuaranteed working accuracyWork clamping meansPositioning apparatusClassical mechanicsStructural engineering

The invention discloses a clamp for broaching two small holes of a lifting lug, which comprises a clamp body, a trapezoidal support block, a positioning sleeve, a pre-positioning device, a wedge block combination mechanism and a manual adjustment mechanism; the trapezoidal support block is arranged on the clamp body The positioning sleeve is a central through hole structure and is arranged at the center of the clamping body; the pre-positioning device includes a pre-positioning pin for positioning the large hole end of the workpiece, a lifting lug for the workpiece The pre-positioned support screws and supports positioned on the bottom end face; the wedge block combination mechanism is arranged on the trapezoidal support block, and the wedge block combination mechanism is a central through hole structure; the wedge block combination mechanism The inner side faces are expanded so as to be close to the two inner side end faces of the lifting lug of the workpiece; the manual adjustment mechanism is used to control the expansion and contraction of the wedge block combination mechanism. The invention can prevent the deformation of the workpiece when two small holes are broached in an automobile lifting ear part, and can well ensure the dimensional accuracy and coaxiality accuracy of the two small holes.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

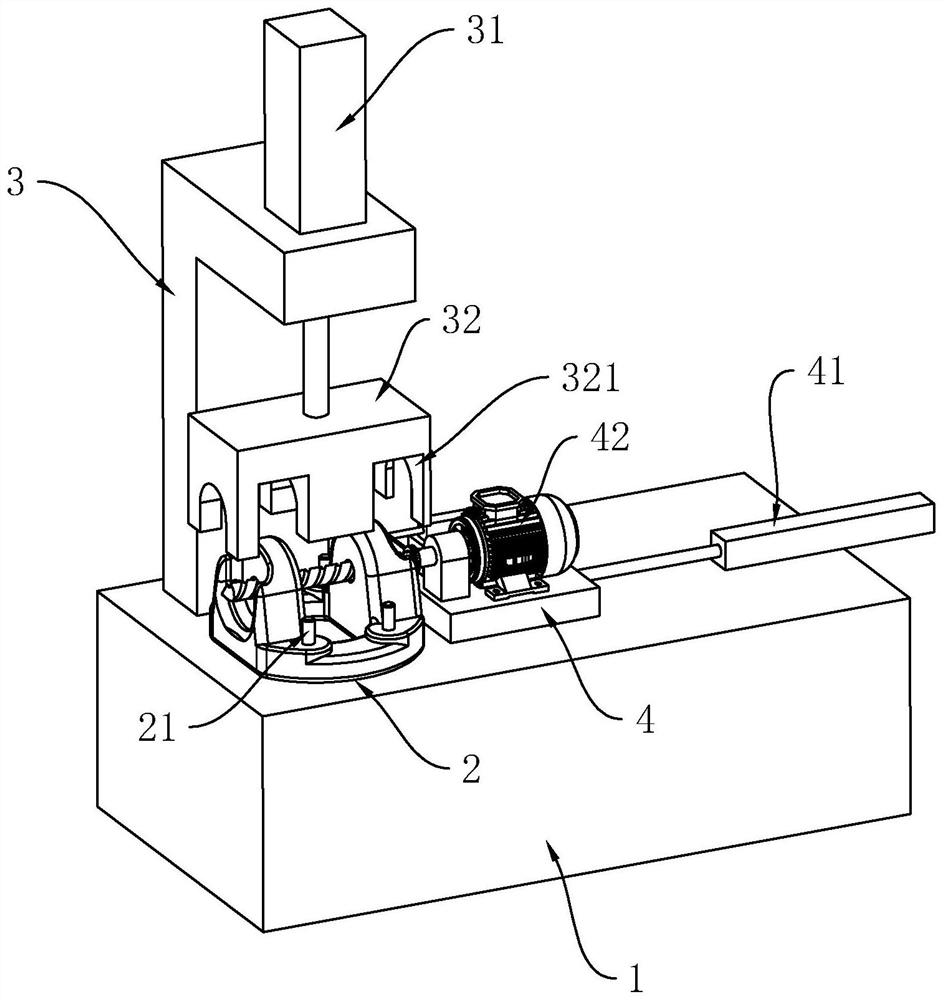

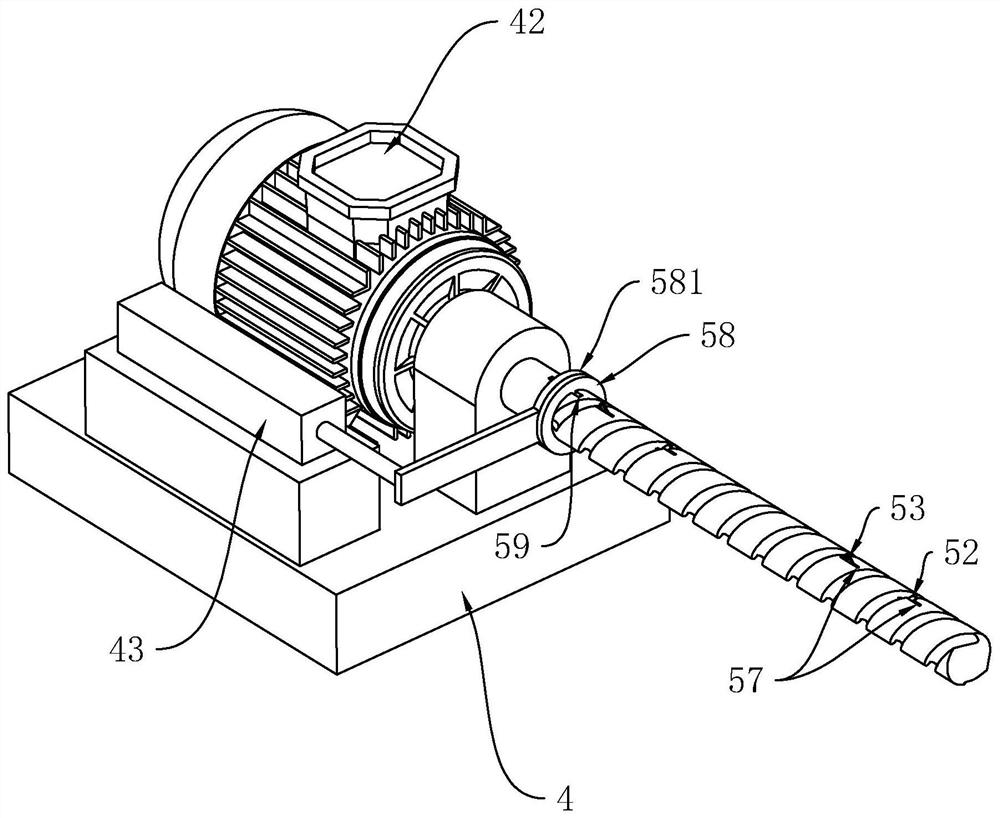

Assembly method of transmission shaft structure

The invention relates to an assembly method of a transmission shaft structure, and a screw tailstock is movably assembled and is self-aligned. A traditional screw tailstock is assembled in a mode that the center height of the screw tailstock is adjusted by adopting an adjusting pad and is fastened radially by using a bolt. Measurement and match grinding are needed, therefore, the skill requirement of assembly personnel is high, and the measurement and match grinding errors exist. According to the assembly method, by utilizing the characteristic that the position of a screw is limited by a screw nut when the screw nut moves to the tail end of the screw, the self alignment of the screw tailstock which is installed on the tail end of the screw is guaranteed, and the screw tailstock is axially fixed at the moment, so that the coaxial precision of the assembly position of the screw tailstock and the screw is guaranteed.

Owner:江苏澋润数控科技有限公司

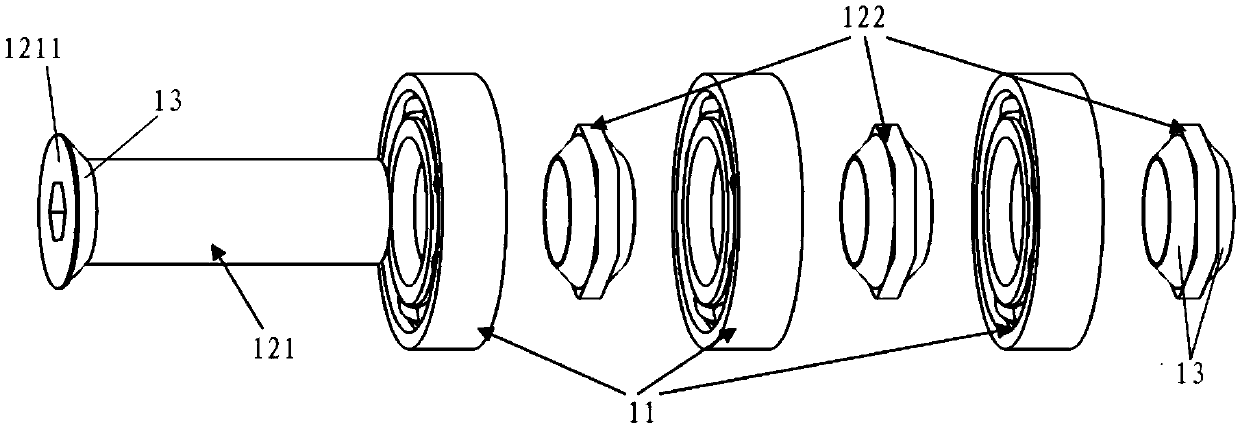

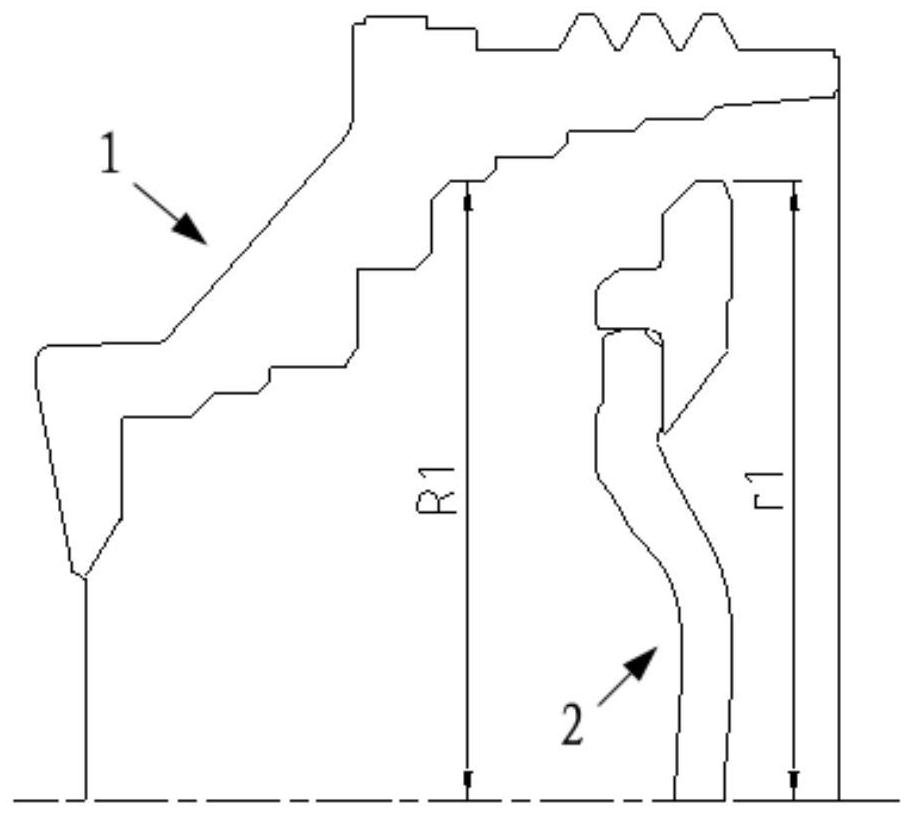

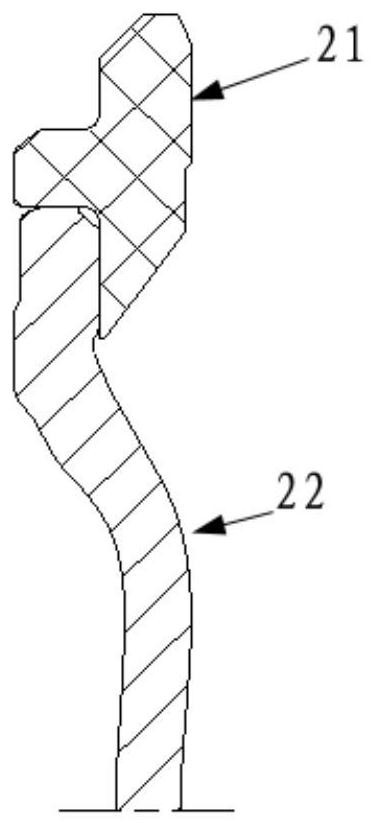

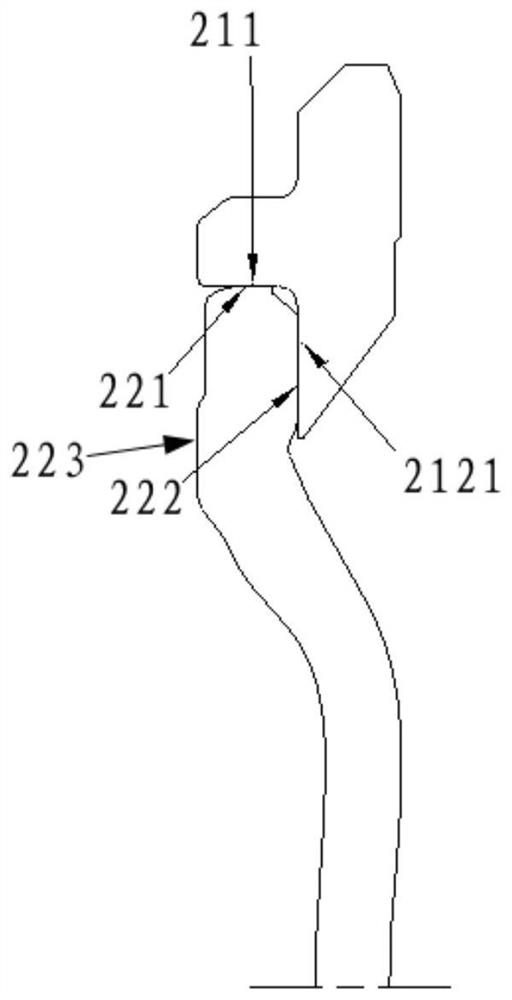

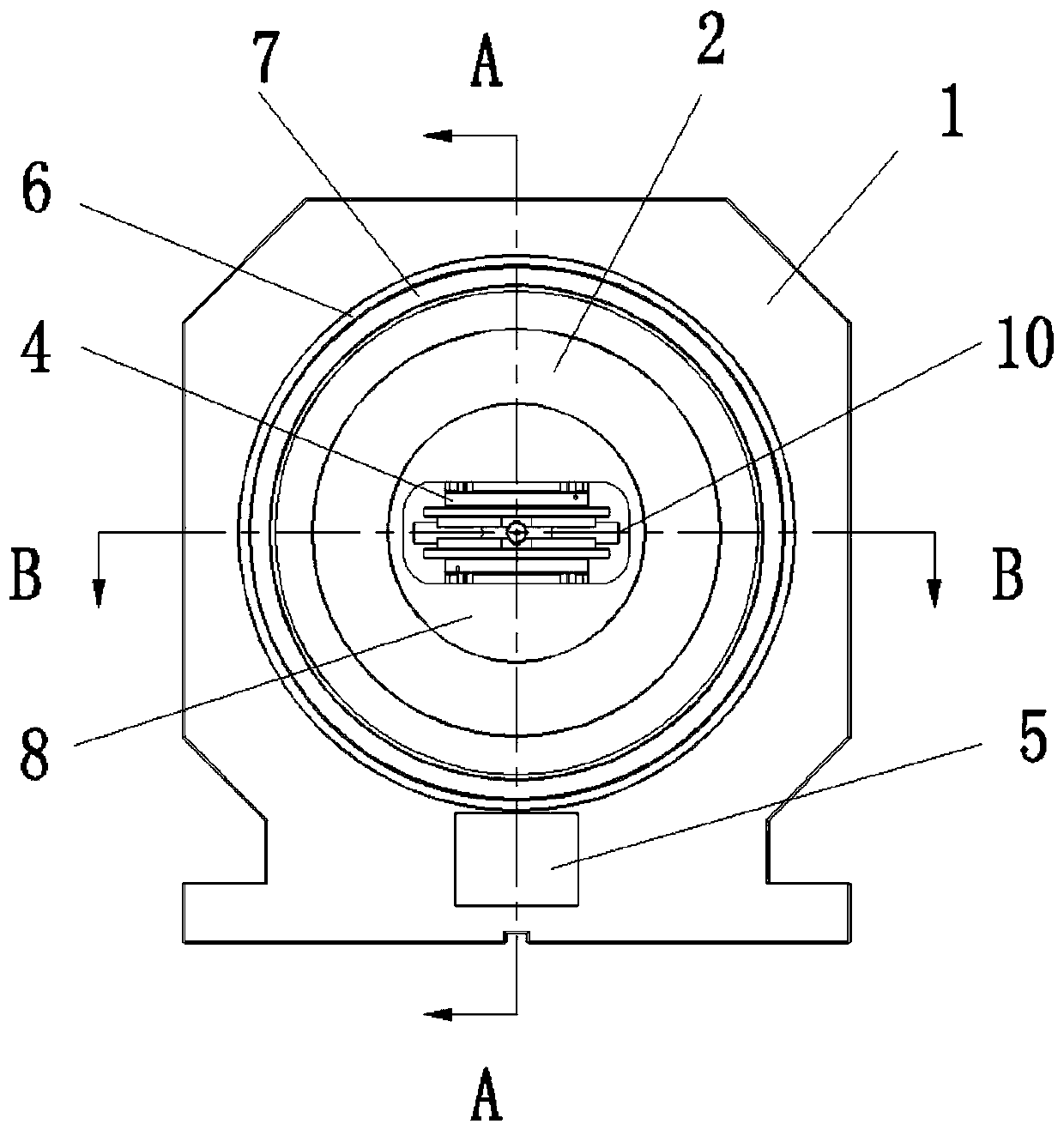

Imaging lens

PendingCN113296219AImprove assembly stabilityImprove service performanceMountingsInterference fitOphthalmology

The invention relates to an imaging lens which comprises a lens barrel (1) and at least one lens assembly (2) arranged in the lens barrel (1). The lens assembly (2) comprises a supporting space ring (21) and a lens (22) which is coaxially arranged with the supporting space ring (21); and a first lens matching surface (221) on the outer side of the lens (22) in the circumferential direction is attached to or in interference fit with a first space ring matching surface (211) on the inner side of the supporting space ring (21) in the circumferential direction. According to the imaging lens, the lens assembly comprising the lens and the supporting space ring is designed; and the lens assembly, the lens barrel and other components are arranged in a matched mode, so that the assembling stability of the imaging lens and the service performance in a special environment are remarkably improved.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

A self-centering two-way rotating cross-axis machining spindle

InactiveCN110102782BQuick loading and unloadingPlay the role of reversing processingLarge fixed membersPositioning apparatusElectric machineryStructural engineering

The invention discloses a self-centering bidirectional rotating cross shaft machining main shaft in the technical field of precision machining equipment. The self-centering bidirectional rotating cross shaft machining main shaft comprises a device shell, a rotating oil cylinder mechanism, a lifting mechanism, clamping reversing mechanisms, positioning mechanisms and a speed reducing motor, whereina bearing fixing sleeve and a pair of angular contact bearings are fixedly attached to an inner cavity of the device shell; the lifting mechanism is arranged in an inner cavity of the rotating oil cylinder mechanism; the lifting mechanism comprises a lifting frame body and two lifting installation blocks; the clamping reversing mechanisms is provided with two groups symmetrical at up and down; the two groups of clamping reversing mechanisms clamp and fix a cross shaft workpiece by mutually approaching; the positioning mechanism is provided with two groups which symmetrical at back and forth and are respectively embedded on the front side and the back side of the lifting frame body and used for positioning two opposite shaft ends in the cross shaft workpiece; and the speed reducing motor is embedded below the device shell and used for driving the rotating oil cylinder mechanism to rotate. The self-centering bidirectional rotating cross shaft machining main shaft is used for machining the cross shaft workpiece.

Owner:福清薛记数控科技有限公司

Main lug structure and crawler hoisting rotary table with same

Owner:XCMG CONSTR MACHINERY

Forging forming process of flange pipe yoke and flange pipe yoke formed by this process

ActiveCN111545696BHigh strengthReduce molding difficultyYielding couplingMetal-working apparatusFlangeAir cooling

Owner:上海长特锻造有限公司

Transmission method of a locomotive shaft end speed sensor

InactiveCN103163313BReliable transmission methodHigh rotation accuracySpeed/acceleration/shock instrument detailsReliable transmissionMechanical engineering

The invention provides a novel transmission method and a device applied to a speed sensor at a shaft end of a locomotive. A floating transmission principle capable of reducing restraint freedom degrees is used, a rolling contact antifriction measurement is adopted, by means of the structure of a transmission fork, a pull-in magnetic ring and a roller transmission lifting lever, the reliable transmission method and the device under conditions of floating amount with two large freedom degrees are achieved. The device comprises the transmission fork, the pull-in magnetic ring, the transmission lifting lever, a transmission lifting lever roller sleeve, a sensor shaft and a sensor. The transmission fork is connected with the shaft end of the locomotive through a fork handle and the pull-in magnetic ring and moves with a shaft of the locomotive, the roller transmission lifting lever is installed at the end portion of the sensor shaft and embedded in a sleeve-shaped fork segment of the transmission fork, and the transmission fork drives the shaft of the locomotive to rotate. Therefore, on the condition that axial bouncing and radial bouncing occur to the shaft of the large-power locomotive relative to a locomotive body, the rotating speed of the shaft of the locomotive is reliably transferred to the sensor shaft. Meanwhile, a three-segment coaxial structure is adopted in the sensor, and rotating precision is effectively improved.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com