A method for correcting the deflection of deep and long holes of rotary parts such as pistons

A technology of deep and long holes and parts, which is applied in the field of deep and long hole deflection of rotating body parts, can solve the problems affecting the on-time delivery of products, waste of raw materials, unqualified products, etc., to achieve stable quality, simple operation, guaranteed diameter and coaxiality The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

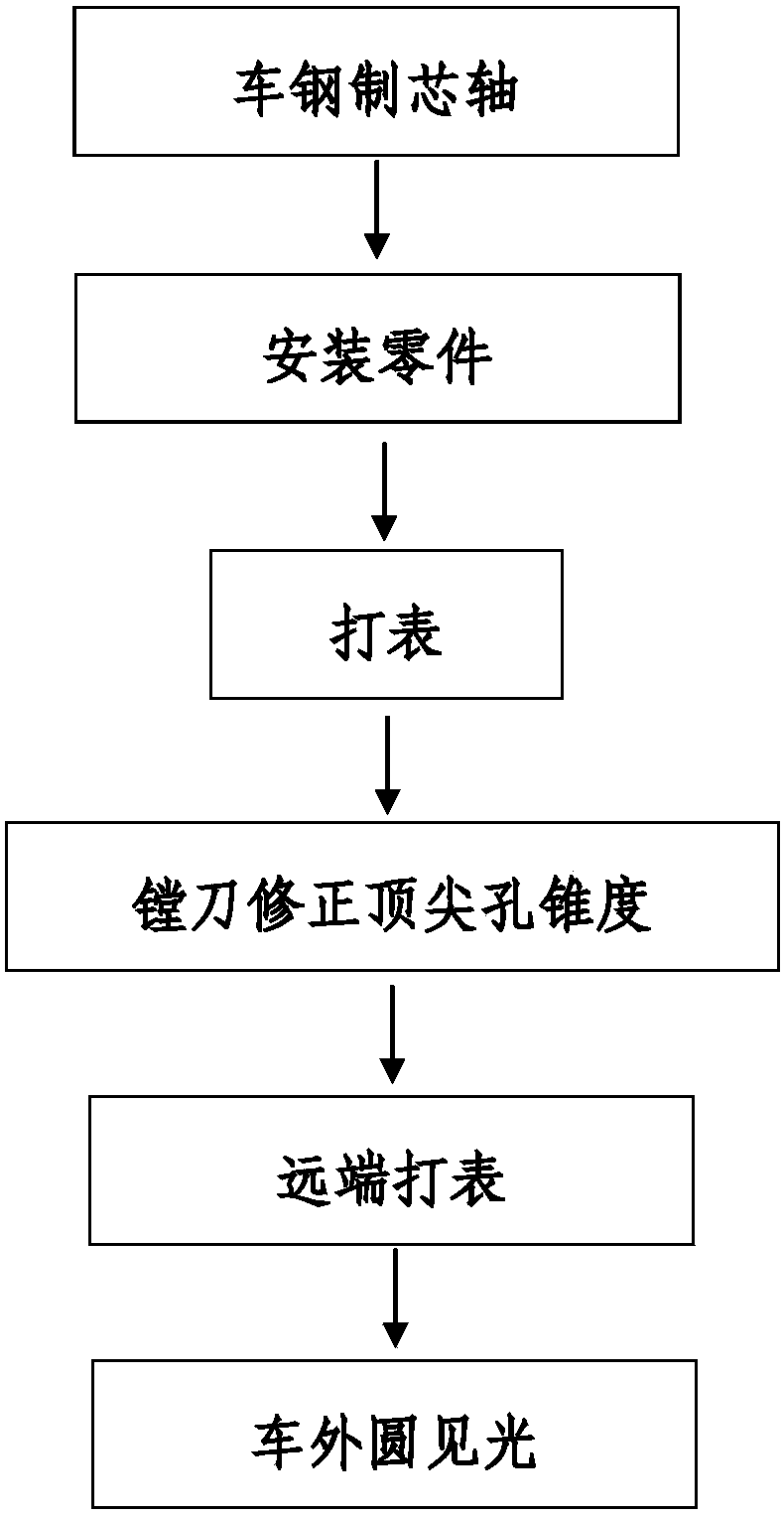

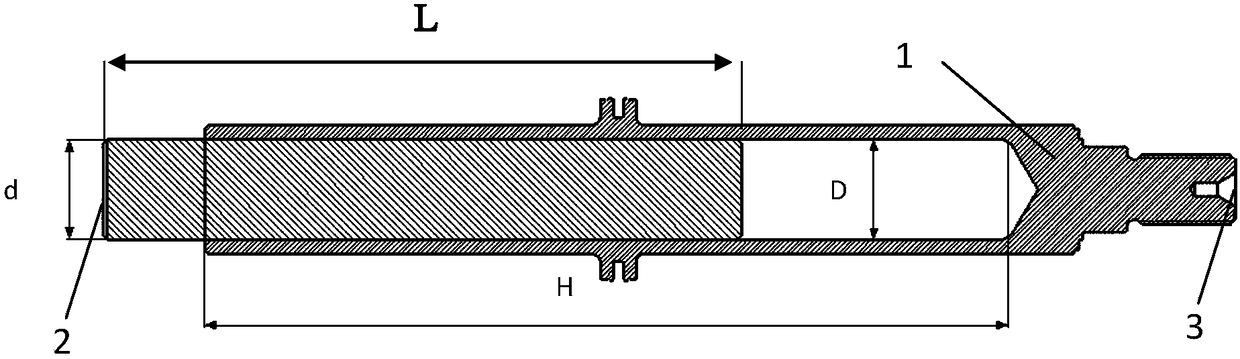

[0032] Example: Take an outer diameter as Inner diameter is Take a piston with a hole depth of 240 and a material of 15-5PH as an example. The design drawing of the piston requires coaxiality Describe the specific implementation of this patent:

[0033] (1) Measuring the diameter of the deep hole of the piston

[0034] (2) According to the measured piston deep hole diameter Calculate the mandrel diameter d:

[0035] Mandrel diameter d=26.05-0.01mm=26.04±0.01mm;

[0036] (3) Calculate the mandrel length L according to the piston inner hole depth H given in the previous process:

[0037] Mandrel length L≥240×2 / 3+30mm=190mm;

[0038] (4) Car steel mandrel according to (2) and (3) dimensions;

[0039] (5) Clamp the mandrel on the main shaft of the lathe, the clamping length is ≥ 20mm, put the piston on the mandrel, the inner hole of the piston is matched with the mandrel, and the piston can rotate freely around the axis of the mandrel;

[0040] (6) Measure the runout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com