Patents

Literature

77results about How to "Guaranteed diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

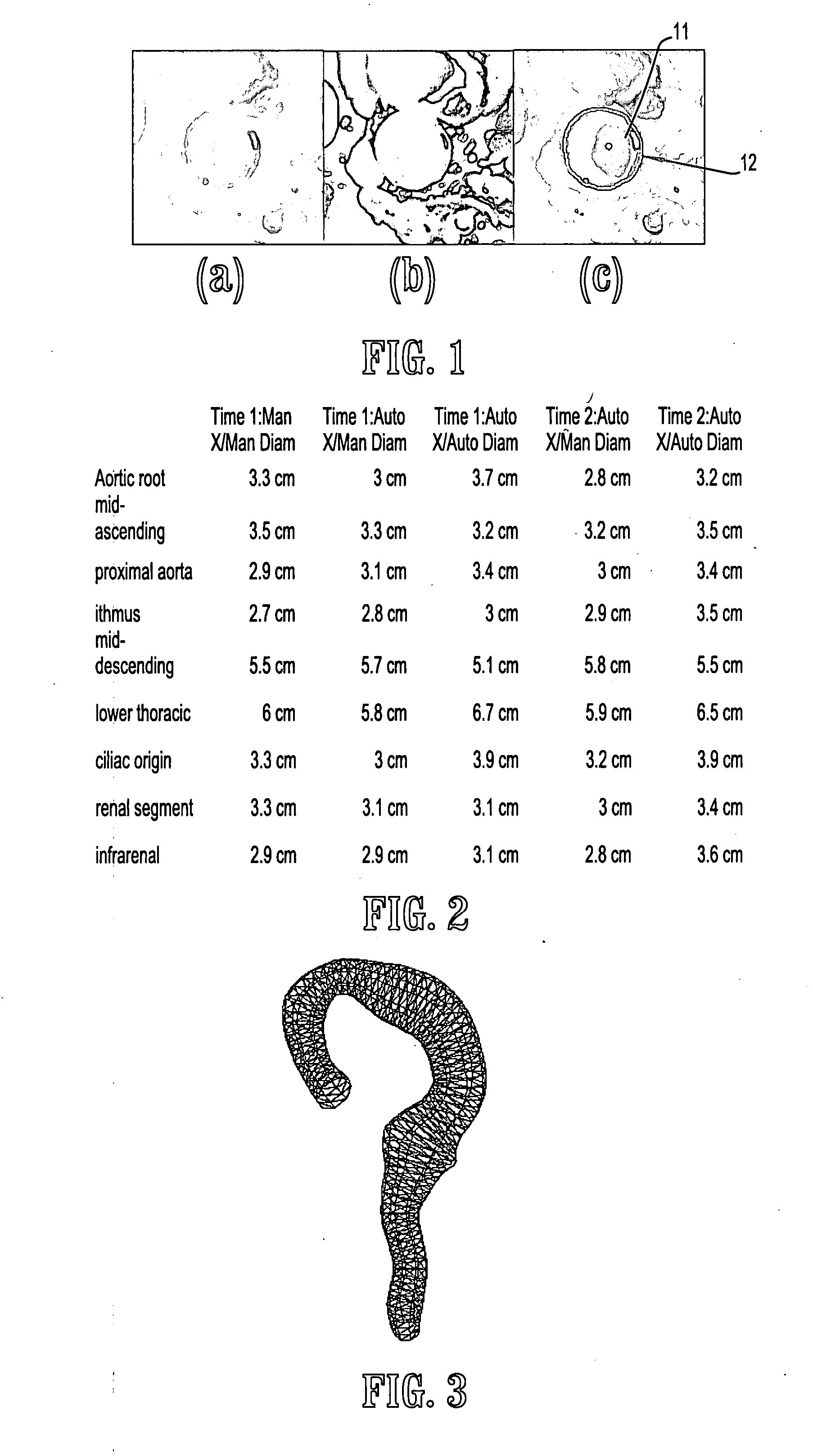

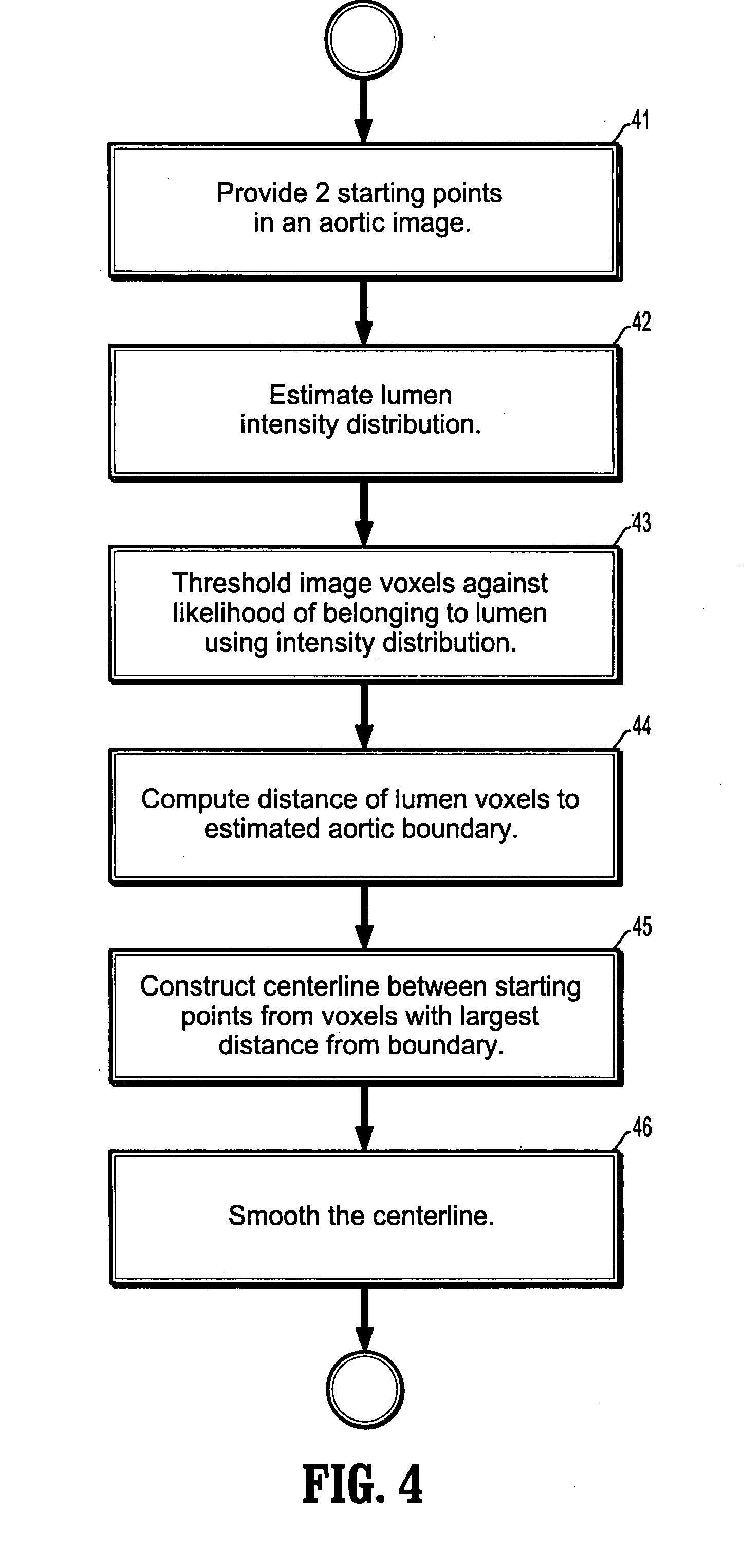

System and method for semi-automatic aortic aneurysm analysis

A method for automatically analyzing an aortic aneurysm includes providing a digitized 3-dimensional image volume of an aorta, determining which voxels in said image are likely to be lumen voxels, determining a distance of said lumen voxels from an aortic boundary, finding a centerline of the aorta in said image volume based on said lumen voxel distances, constructing a series of 2-dimensional multiplanar reformatted (MFR) image planes orthogonal to this centerline, segmenting aortic cross sections in each said MPR image plane wherein an aortic wall is located in each MPR image, and constructing from said aortic wall locations a 3D model of the aorta.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC +1

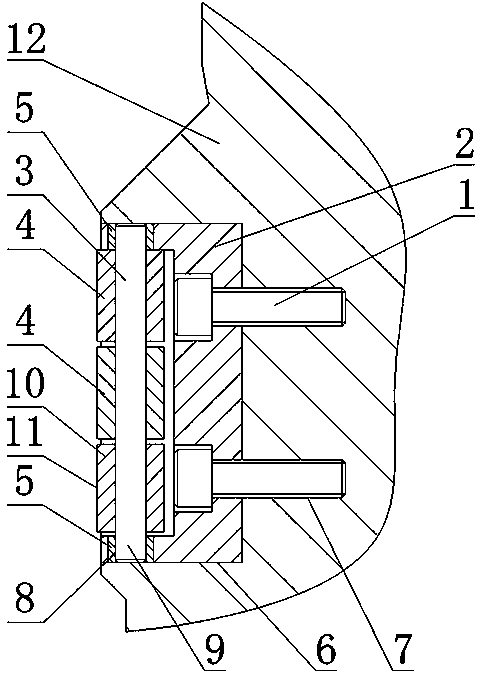

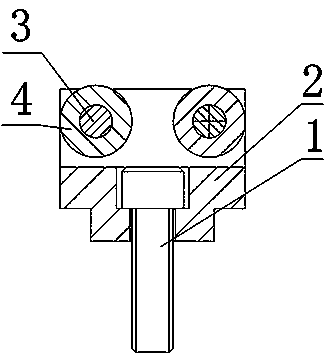

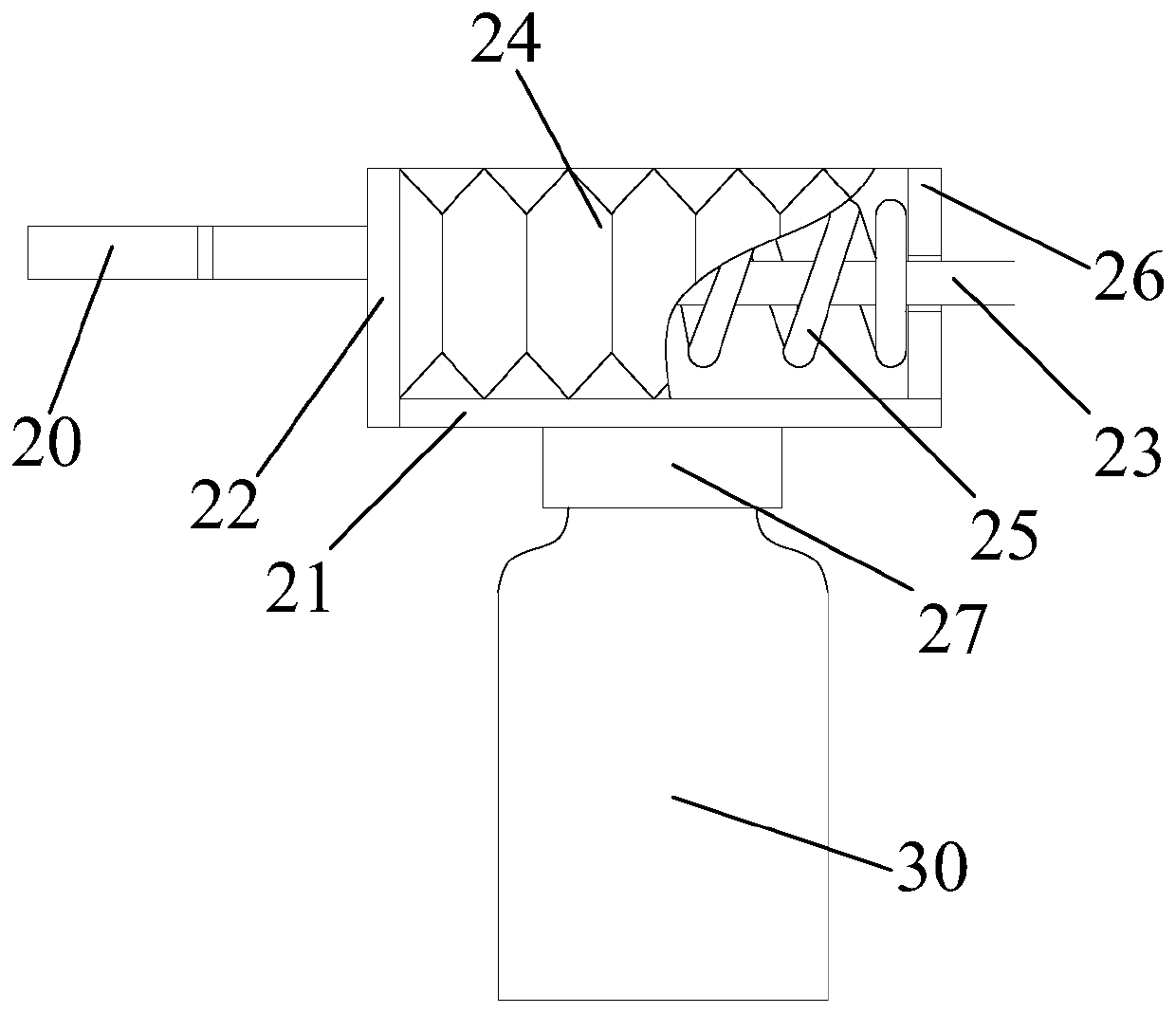

Device for correcting well wall and enhancing drill gauge protection effect through rolling

The invention discloses a device for correcting a well wall and enhancing a drill gauge protection effect through rolling. The device comprises a roller base (2) and a roller (4), wherein the roller base (2) is installed on a gauge-protection cutting surface of a drill (12) through a screw (1), the roller (4) is rotatably installed on the roller base (2) through a pin roll (3), the roller (4) is sleeved on the pin roll (3), and two ends of the pin roll (3) are installed on the roller base (2). The device has the advantages that the well wall is corrected through rolling, the friction between the roller and the well wall is reduced, the effective abrasion volume is increased, and the gauge protection effect is enhanced; simultaneously, a gauge protection unit can roll or roll and slide relative to the well wall and has well reaming and well wall smoothening functions, so that the well quality is improved; the reaction torque during drilling is reduced, and the drill stability is improved; and by the aid of the device, the well track is ordered, the reaction torque during drilling can be reduced in highly-deviated wells and horizontal wells, the drill rotation probability is reduced, the drill service life is prolonged, and the mechanical drilling speed is accelerated.

Owner:四川保瑞特钻头有限公司

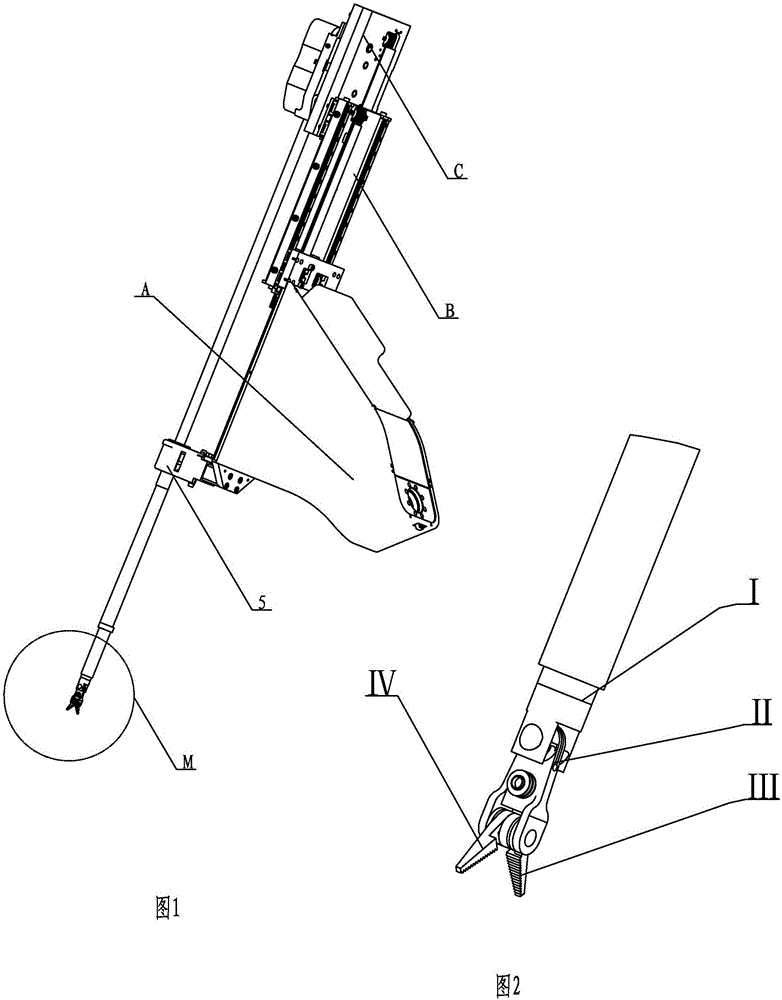

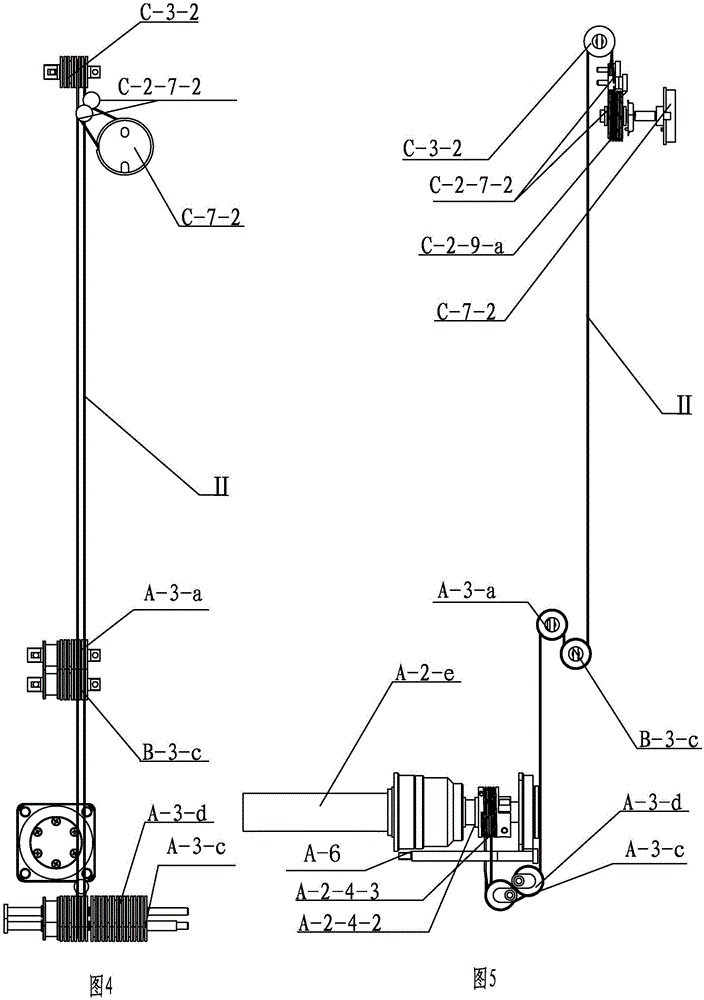

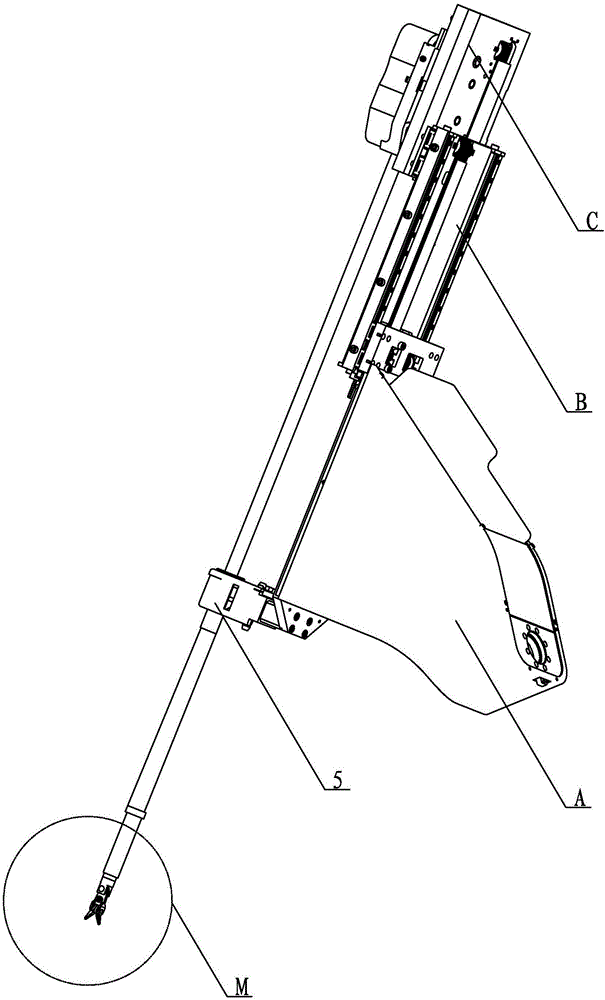

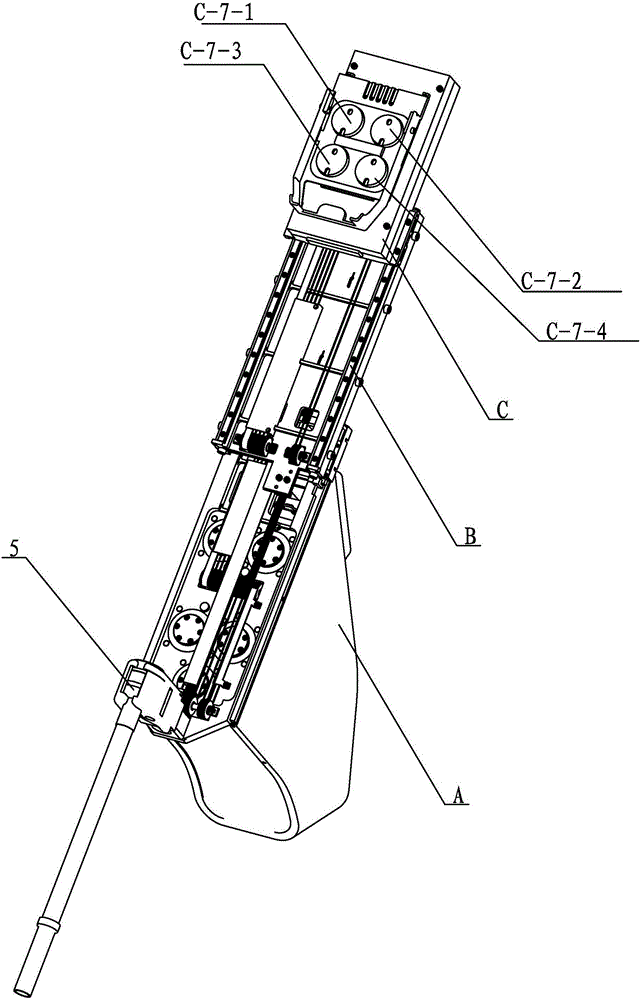

Instrument holding mechanical arm used for minimally-invasive robot

InactiveCN105012023AReduce occupancyEasy to decoupleDiagnosticsSurgeryOperative instrumentTarsal Joint

The invention provides an instrument holding mechanical arm used for a minimally-invasive robot, and relates to the instrument holding mechanical arm. The instrument holding mechanical arm solves the problems that the number of passive joints is large when an existing mechanical arm is arranged in a concentrated mode and the existing mechanical arm is large in overall size and low in rigidity when a passive arm is too long. The instrument holding mechanical arm comprises vertical horizontally-moving safety brake devices, passive joints, first joints, second joints and an integrated operative instrument drive device. One ends of the passive joints are arranged on the upper portions of the vertical horizontally-moving safety brake devices in a rotatable mode. One ends of the first joints are connected to the passive joints in a rotatable mode. One ends of the second joints are connected with the other ends of the first joints in a rotatable mode. The integrated operative instrument drive devices are arranged at the other ends of the second points. The instrument holding mechanical arm is used for operative instrument drive of the micro operative instruments of the robot.

Owner:HARBIN INST OF TECH

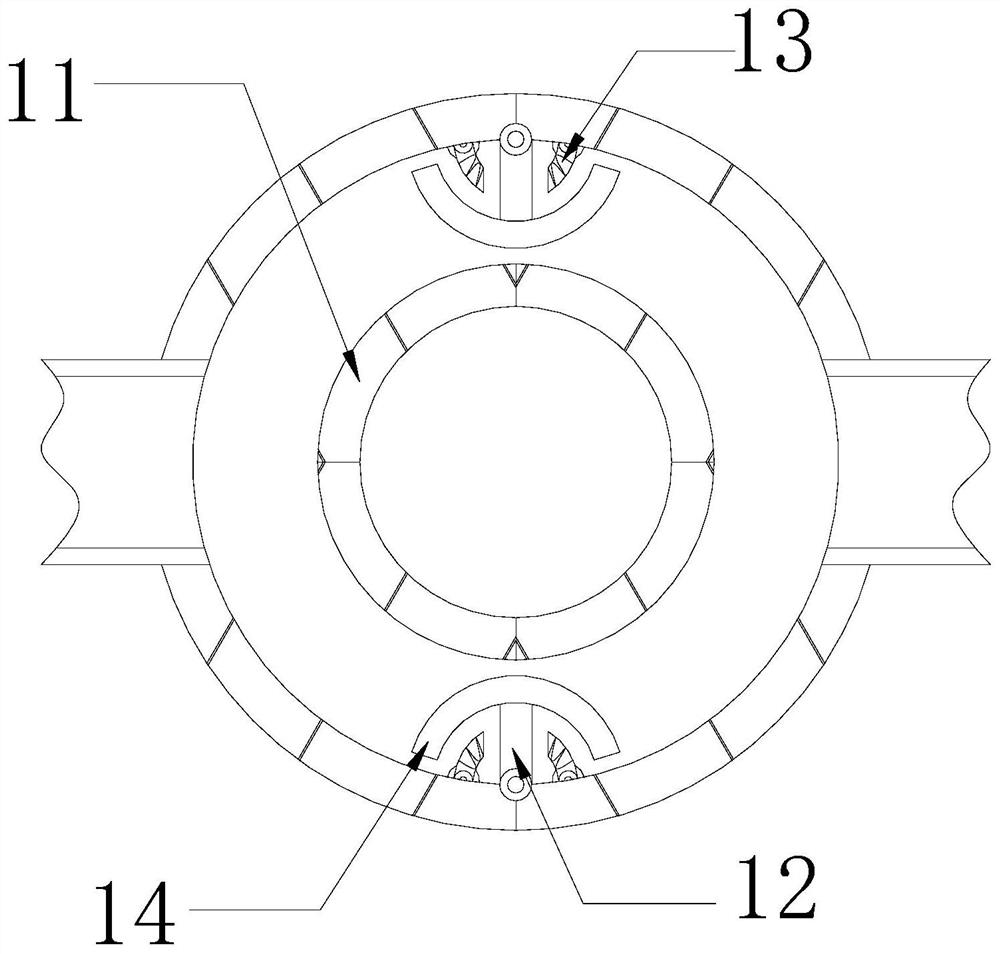

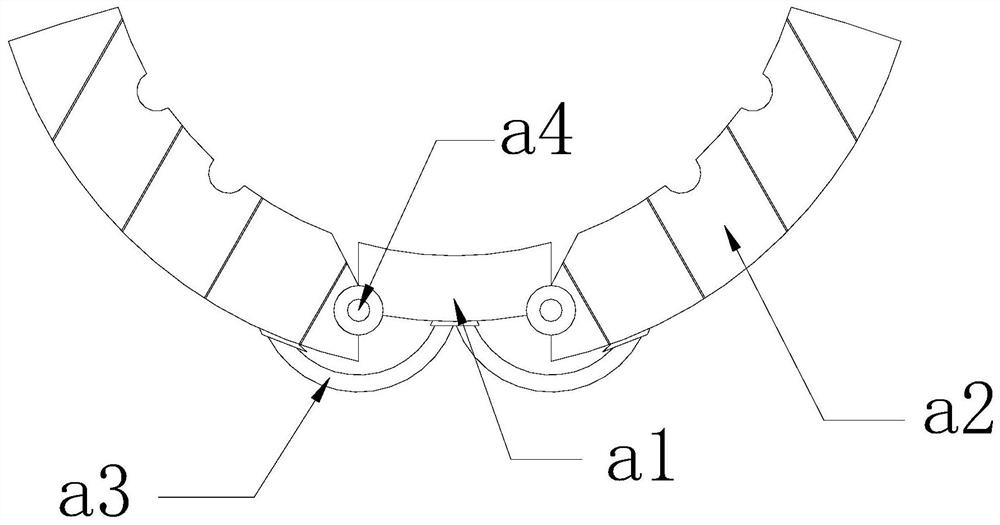

Inertial confinement and induction drilling device with PDC drill bit

ActiveCN107299825ADoes not consume energyPower is not consumed blindlyDrilling rodsBorehole drivesEngineeringSurface pressure

Disclosed is an inertial confinement and induction drilling device with a PDC drill bit. A planetary frame is installed on the outer circumferential surface of an input shaft of the sun wheel in a sleeving mode, and a small sliding bushing is installed on the circumferential surface of the input shaft of the sun wheel in a sleeving mode; four planetary gear shafts are all arranged on the surface of the planetary frame, 8 planetary gears are divided into 2 groups and axially arranged on the planetary gear shafts in a sleeving mode, and one group of planetary gears are close to the drill-collar connecting end of the input shaft of the sun wheel; the end surfaces of the first group of planetary gears are fitted with the inner end surfaces of steps at one end of the input shaft of the sun wheel through end-surface pressure bearings. An output shaft of the planetary frame is installed on the outer circumferential surface of the input shaft of the sun wheel, so that the inner end surface of the output shaft of the planetary frame is fitted with the outer end surface of the planetary frame. The inertial confinement and induction drilling device with the PDC drill bit is completed on the basis of a planetary-wheel reducer structure, and has the advantages that the impact is stable and continuous, the durability is guaranteed, the quality of drilling holes is ensured, and the energy consumption is low.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

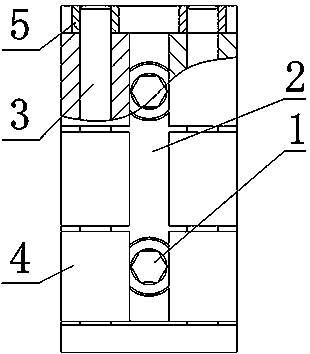

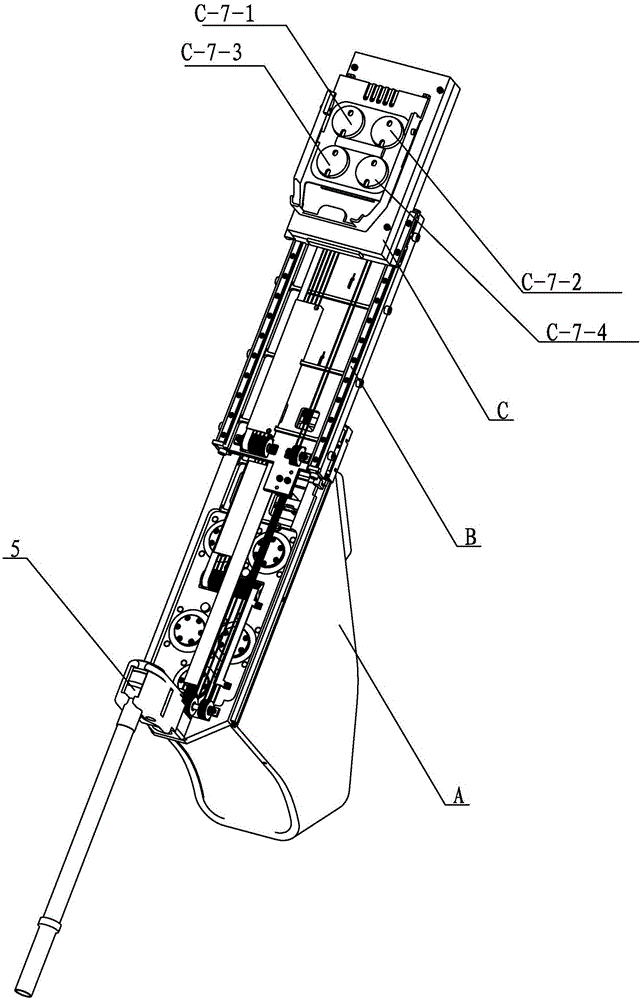

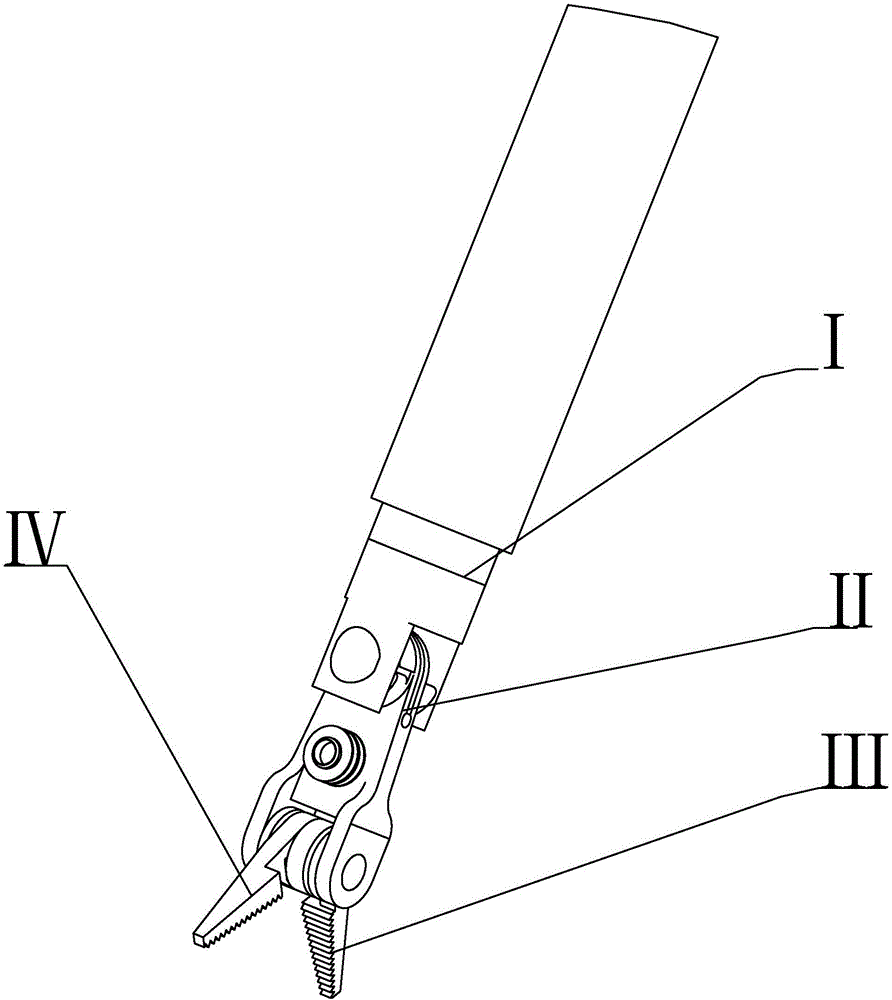

Integrated surgical instrument drive device with decoupling function

ActiveCN105012022AReduce occupancyEasy to decoupleSuture equipmentsInternal osteosythesisElectric machineEngineering

The invention relates to an integrated surgical instrument drive device, in particular to an integrated surgical instrument drive device with a decoupling function so as to solve the problems that due to the arrangement mode of a drive motor of an existing surgical instrument, drive torque of joints is increased, a system shakes easily, and meanwhile translational motion of the surgical instrument is generally driven in a nut lead screw mode, which is unbeneficial for adjusting the position of the surgical instrument before an operation. The drive device comprises a power source assembly (A), a decoupling transition assembly (B), a connector assembly (C) and a plurality of winding wires (D). The power source assembly (A), the decoupling transition assembly (B) and the connector assembly (C) are sequentially staggered and stacked in a sliding mode from bottom to top, and connected through the winding wires (D) in a decoupling winding mode. The drive device is used for driving a surgical instrument of a robot surgical micro-instrument.

Owner:杭州唯精医疗机器人有限公司

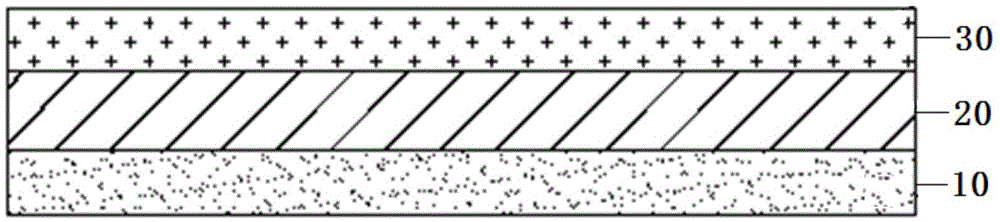

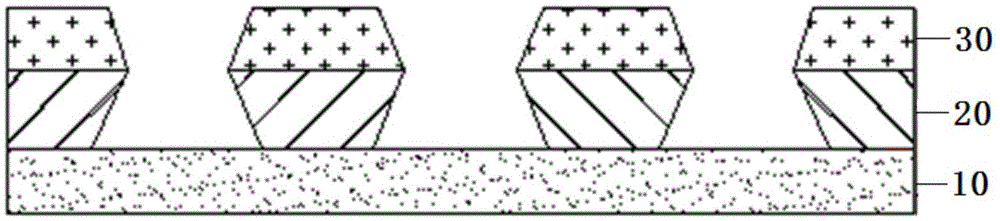

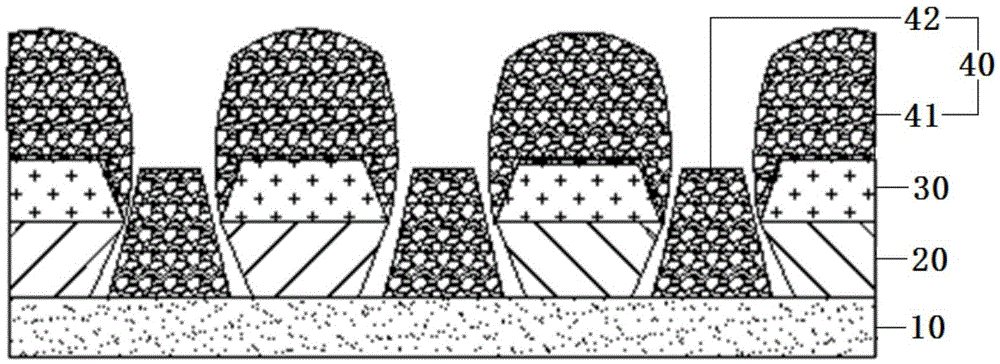

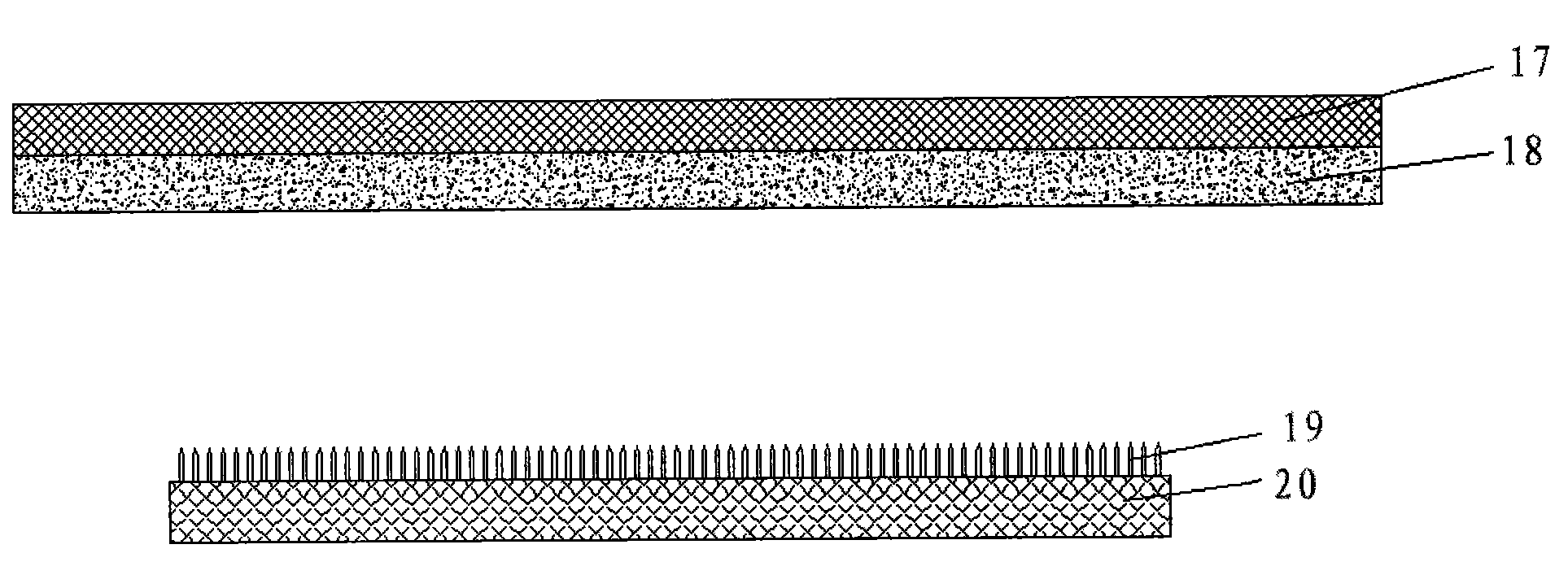

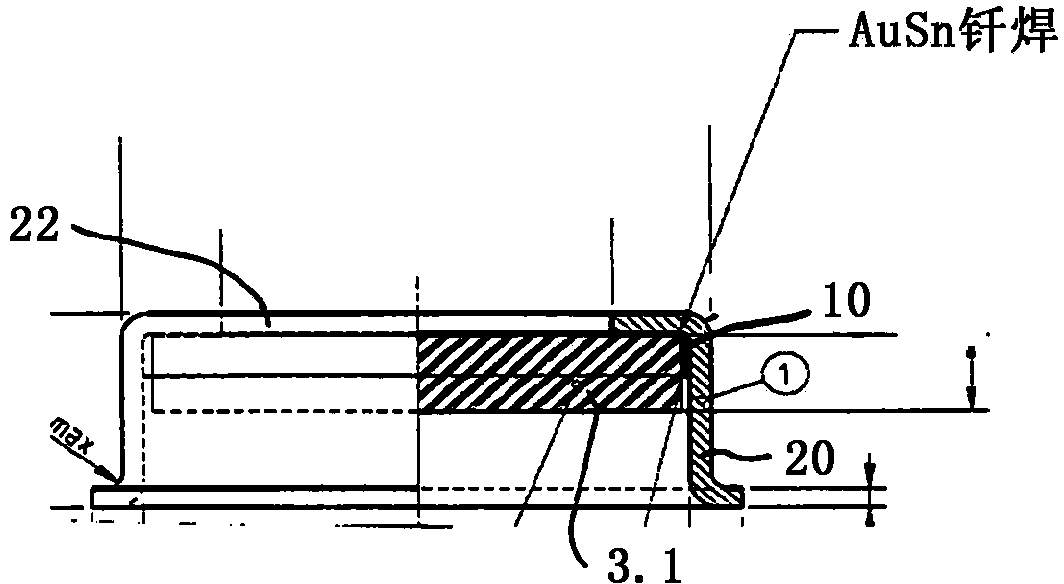

Technical method of infrared detector indium bump

ActiveCN105575892AEasy to makeCheap manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingIndium bumpPhotoresist

The invention provides a technical method of an infrared detector indium bump. The method comprises spin-coating two layers of photoresist on a chip in a superposing manner, and further comprises the following steps: firstly, spin-coating a layer of negative photoresist on the chip, and then spin-coating a layer of inversion photoresist on the negative photoresist; through a masking plate exposure and masking plate-free exposure, enabling the contours of the sections of the upper half portions of the two layers of photoresist on the chip to be trapezoidal and the contours of the sections of the lower half portions to be inverted-trapezoidal; and performing indium membrane precipitation, wherein an indium precipitation window is not obviously reduced and an indium bump is platform-shaped so that subsequent preparation is facilitated. By means of the method provided by the invention, the technical problem of preparing a flat-top indium bump on the chip is solved, and good effects of easy preparation, low cost and facilitated combination with external equipment are achieved.

Owner:WUHAN GAOXIN TECH

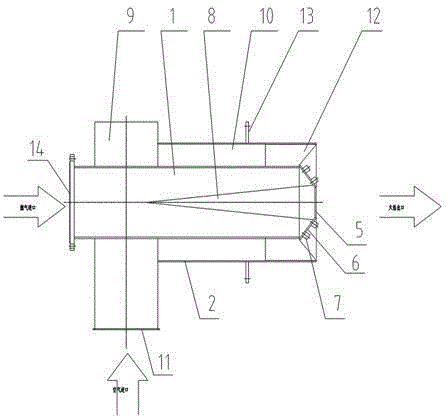

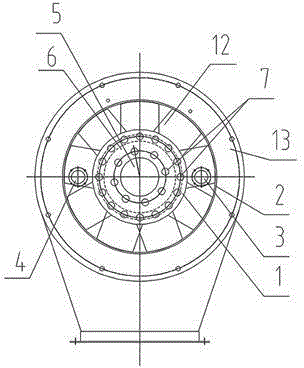

Biomass gas burner

The invention discloses a biomass gas burner. The biomass gas burner comprises a gas pipe (1) located at the axial center, an air pipe (2) arranged outside the gas pipe (1) in a sleeving mode, an ignition device (3) and a flame detection device (4), wherein a round sealing plate (5) with the front diameter smaller than the gas pipe (1) and a conical surface (6) connecting the front end edge of a pipe body with the round sealing plate (5) are arranged on the front end face of the gas pipe (1), and two circles of gas distribution nozzles (7) perpendicular to the conical surface (6) are arranged on the conical surface (6); a pressurization cylinder (8) is arranged in the gas pipe (1), and the ignition device (3) and the flame detection device (4) penetrate through the air pipe (2) and extend to the front end of the air pipe (2). The biomass gas burner has the beneficial effects that biomass gas is separated through the nozzles after being pressurized primarily, the pressure head of biogas gas is stable, flow balancing is achieved, and the diameter and length of a flame are guaranteed; burning is complete and sufficient, and heat efficiency is high.

Owner:广东宝杰环保科技有限公司

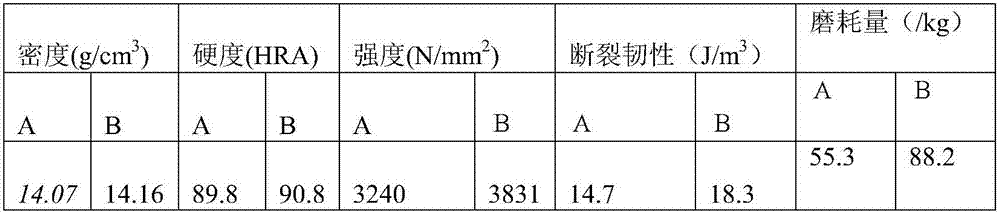

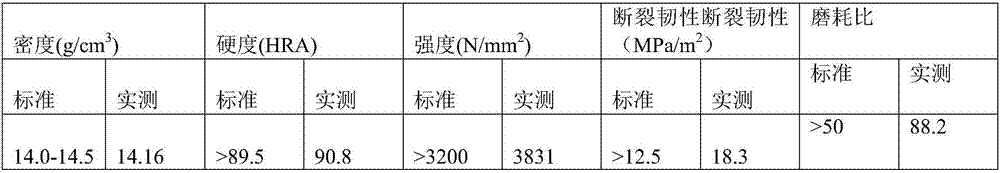

Bicrystal cemented carbide and preparation method thereof

The invention relates to the technical field of cemented carbide. A bicrystal cemented carbide comprises, by weight, 25-35% of mixtures A of tungsten carbide and tungsten metal with the diameter of 1.5-2.0 [mu]m, 50-60% of mixtures B of the tungsten carbide and the tungsten metal with the diameter of 3.2-3.7 [mu]m, 10-13% of cobalt powder, 0.8-1.5% of chromium carbide powder and 0.15-0.5% of rare earth oxide powder. The invention also provides a preparation method of the bicrystal cemented carbide. The preparation method comprises the steps of mixing excessive tungsten powder and carbon black to obtain the mixtures of the tungsten carbide and the tungsten metal after carbonization; screening the mixtures of the tungsten carbide and the tungsten metal, and then compounding and ball-milling the mixtures to obtain ball-milled products after drying; compression molding of the ball-milled products to obtain blanks; and sintering the blanks to obtain products after cooling. The bicrystal cemented carbide provided by the invention is high in toughness, strength, abrasion resistance and corrosion resistance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

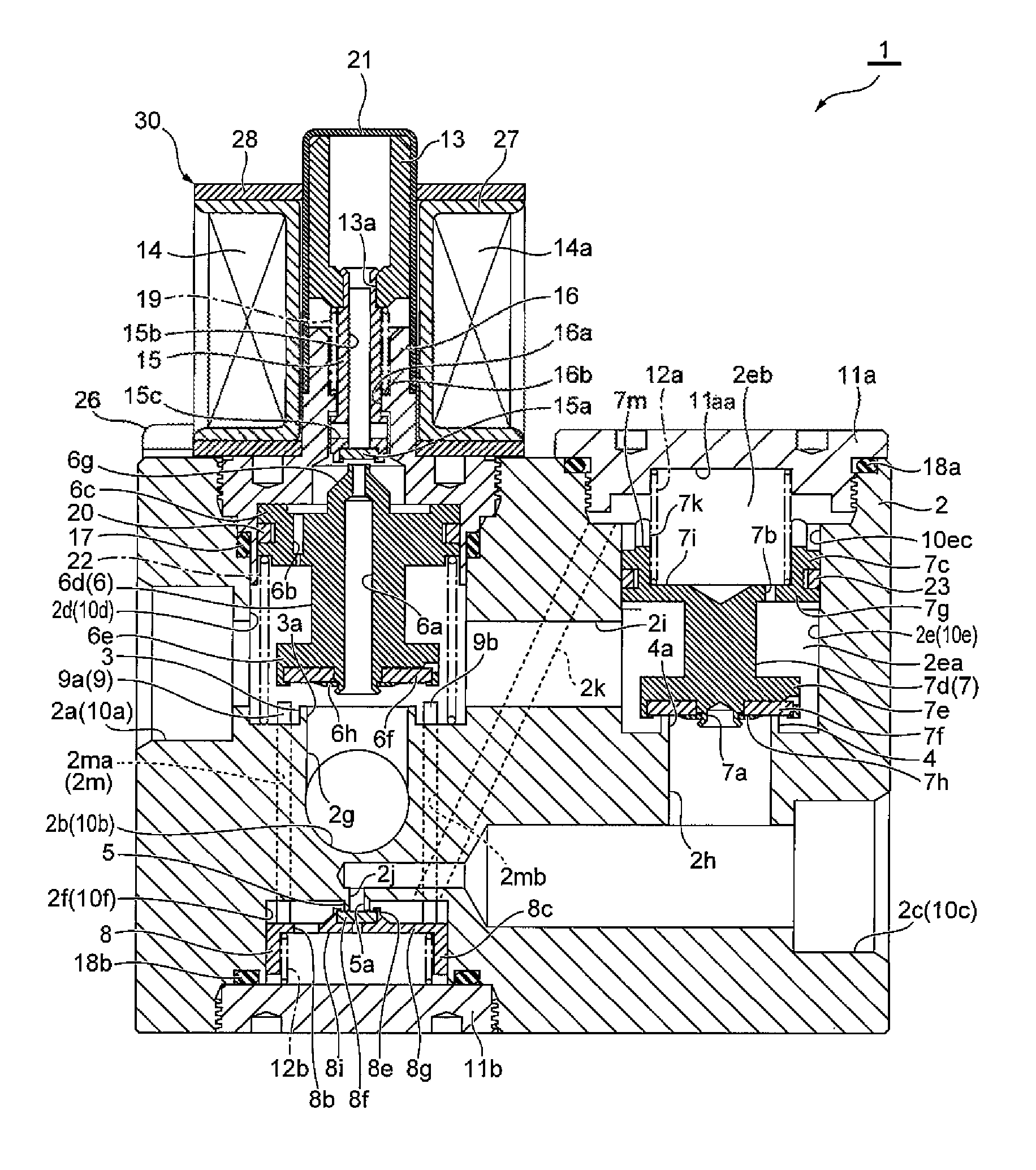

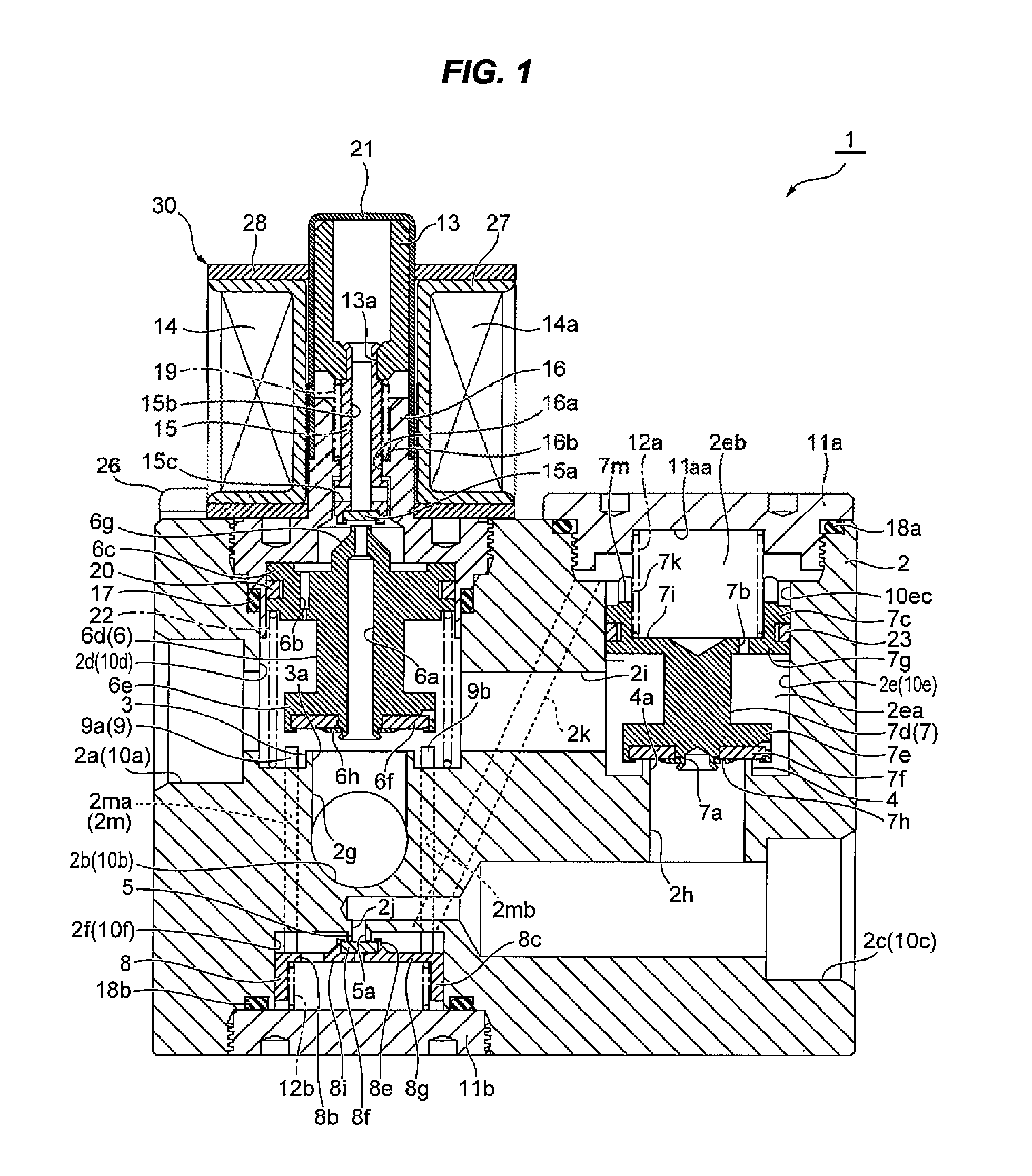

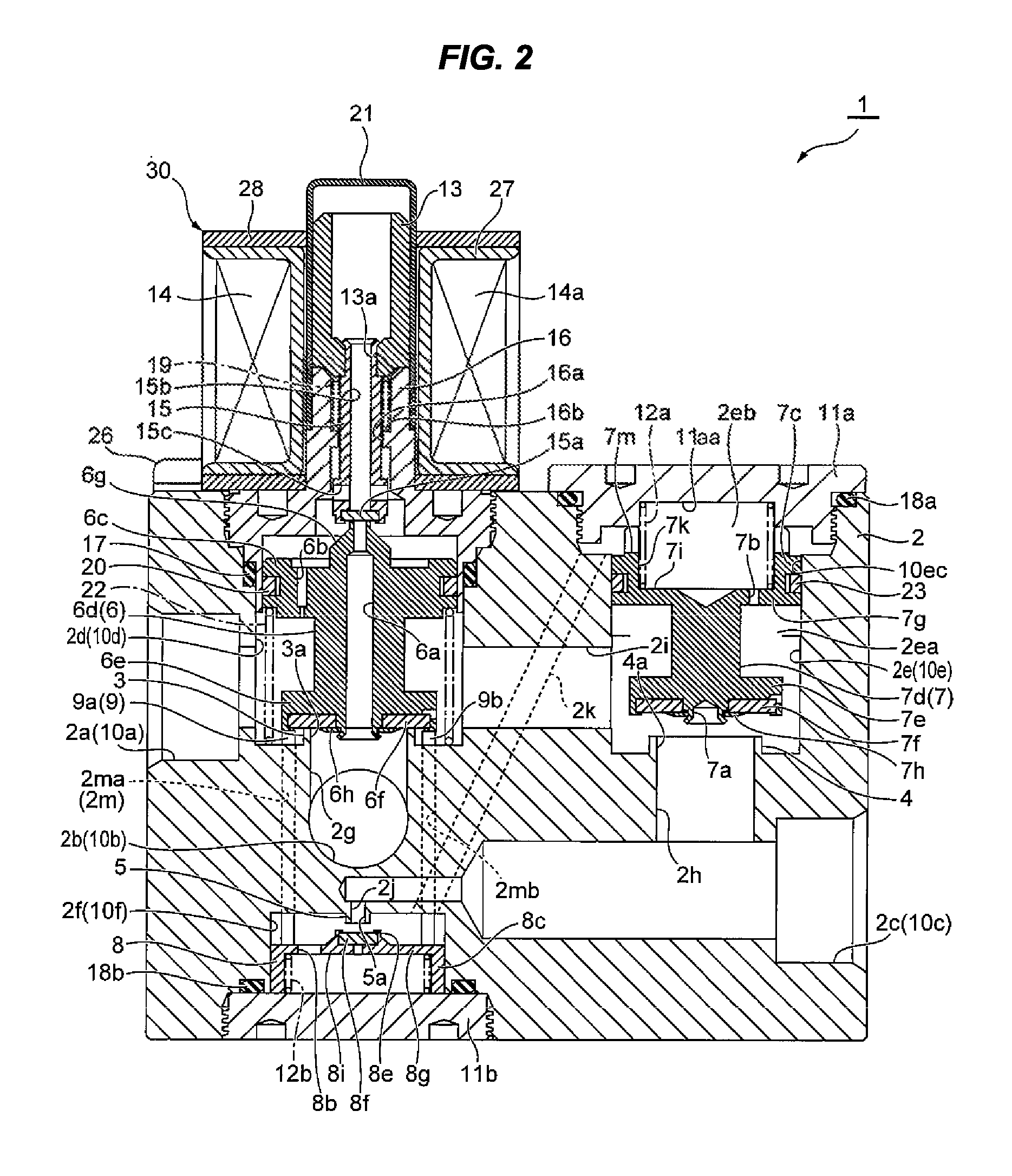

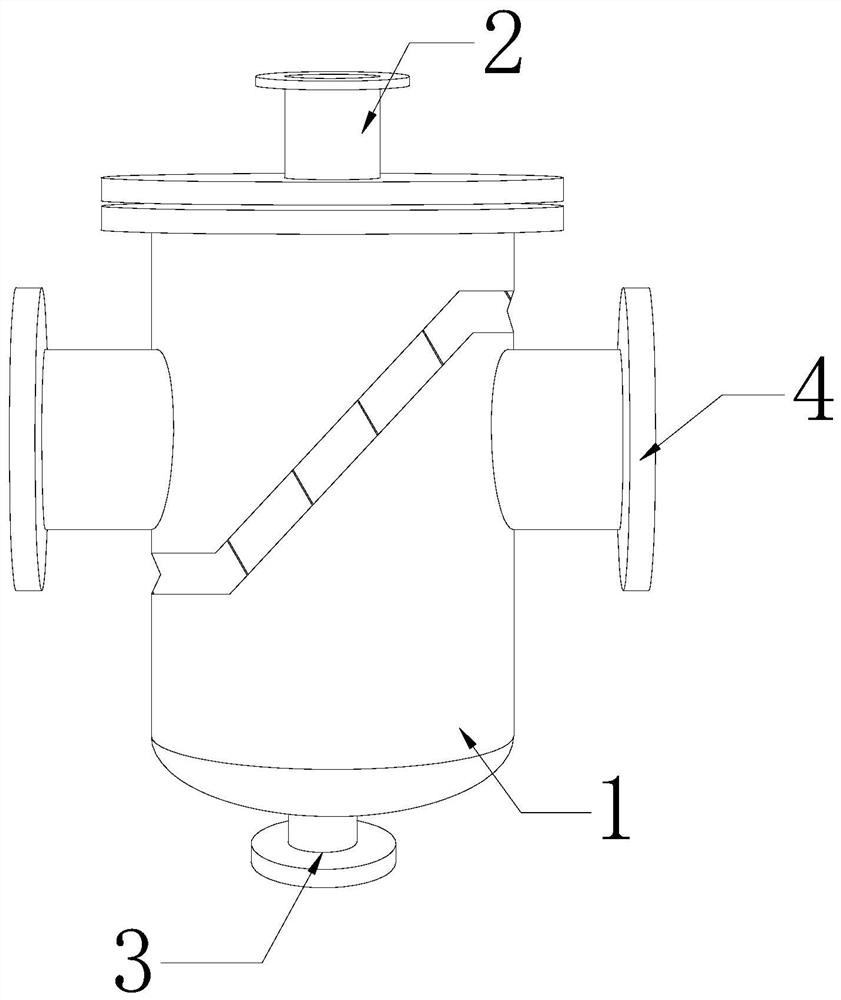

Three-way solenoid valve

ActiveUS9404600B2Increase in sizeReliable switchingOperating means/releasing devices for valvesMultiple way valvesDifferential pressureSolenoid valve

Owner:FUJIKOKI CORP

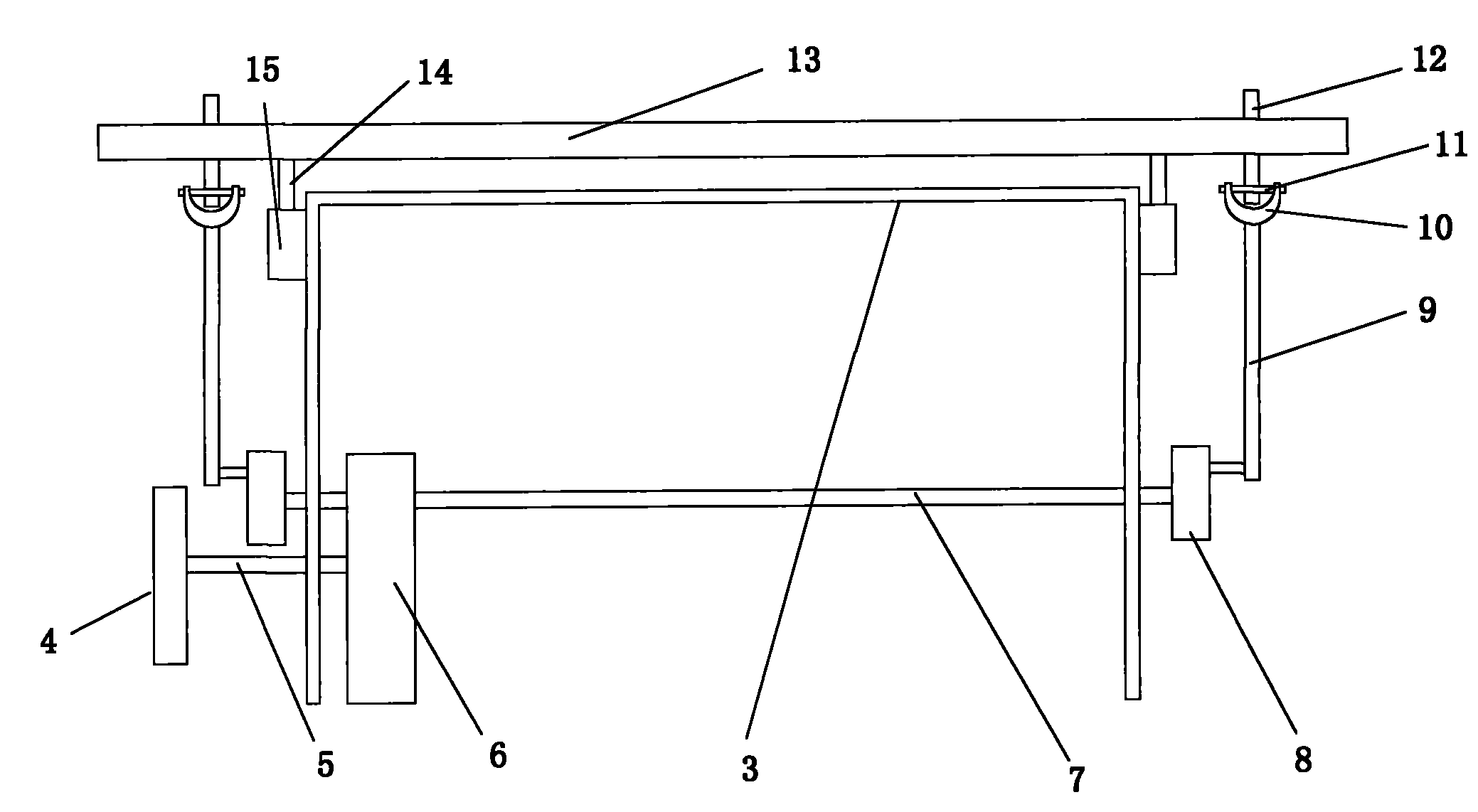

Device for manufacturing porous release film

InactiveCN101817185AGuaranteed diameterGuaranteed PenetrationMetal working apparatusAgricultural engineeringEngineering

The invention discloses a device for manufacturing a porous release film, which comprises a workbench, a motor, a reduction box, side frames, a press plate and a pin plate, wherein the pin plate is arranged on the workbench; the pin plate is uniformly provided with a plurality of pins; the output shaft of the motor is connected with a belt pulley through a belt; the belt pulley is connected with the reduction box below the workbench through the main shaft; the auxiliary shaft of the reduction box is connected with rotating wheels on both sides below the workbench; the outer side of each rotating wheel is provided with a connecting rod which is eccentrically connected with the rotating wheel, and the connecting plate is arranged on the connecting rod; and both ends of the press plate are respectively connected with the upper end of the connecting plate. The invention solves the problems that high purchase cost of the porous release film, high enterprise load and environmental pollution of waste bag films in the prior art. The invention reutilizes the waste by recycling the vacuum bag films in the system, thereby saving the enterprise cost and increasing the waste utilization ratio.

Owner:昆山华风风电科技有限公司

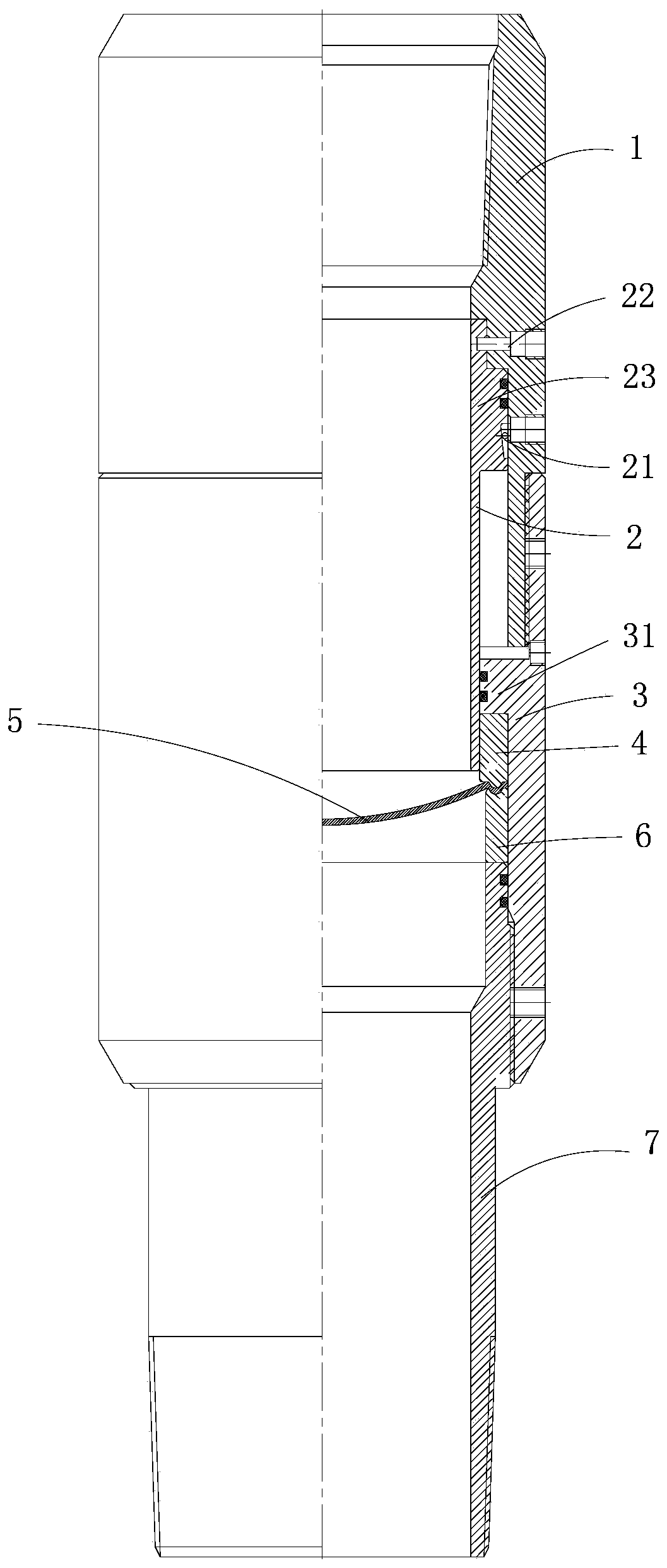

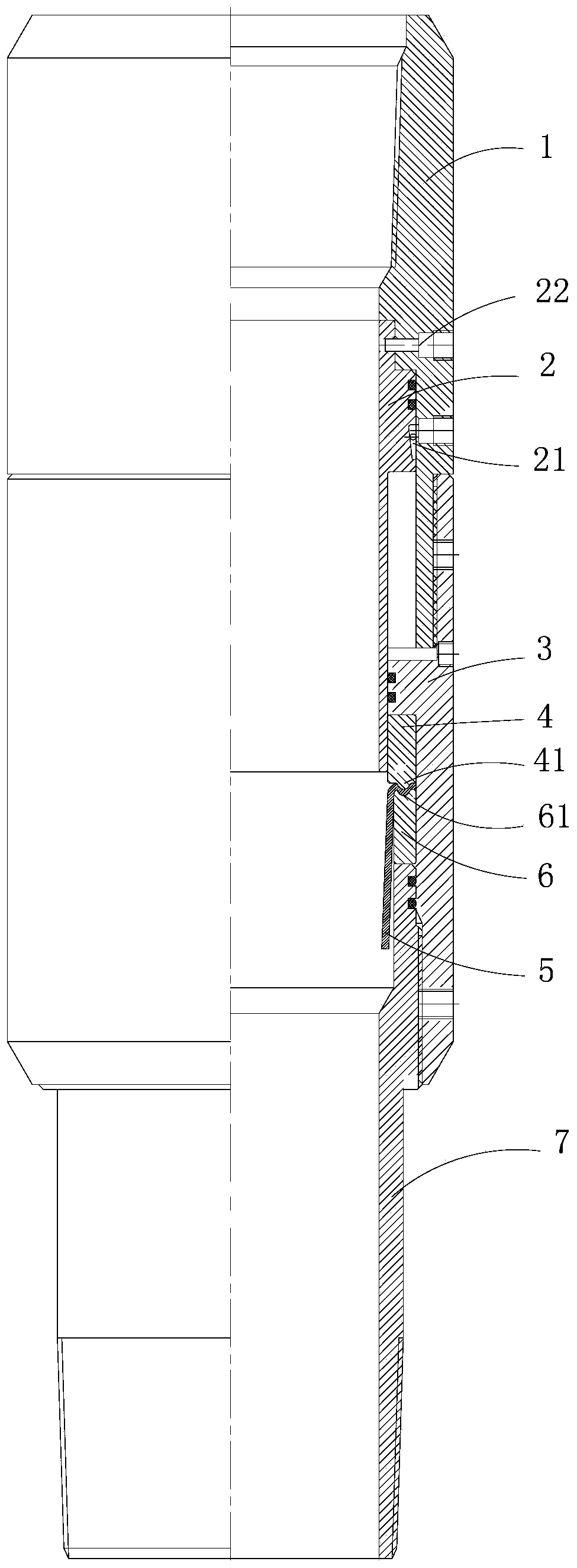

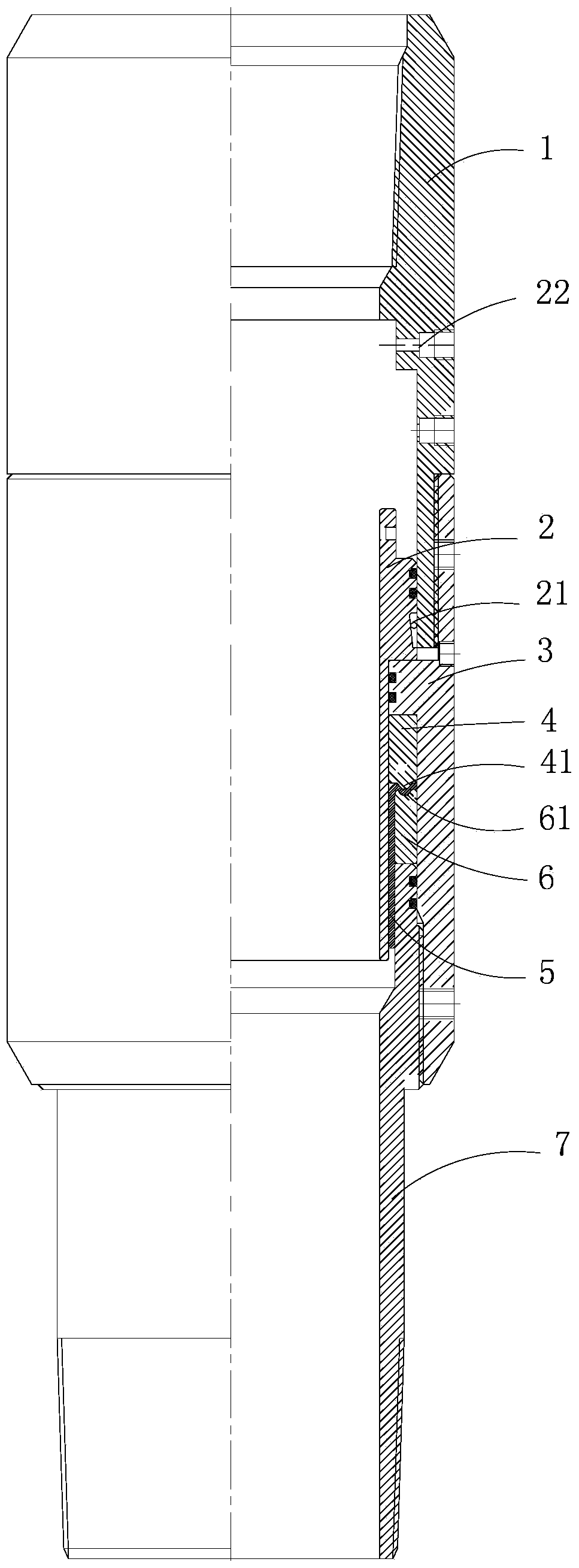

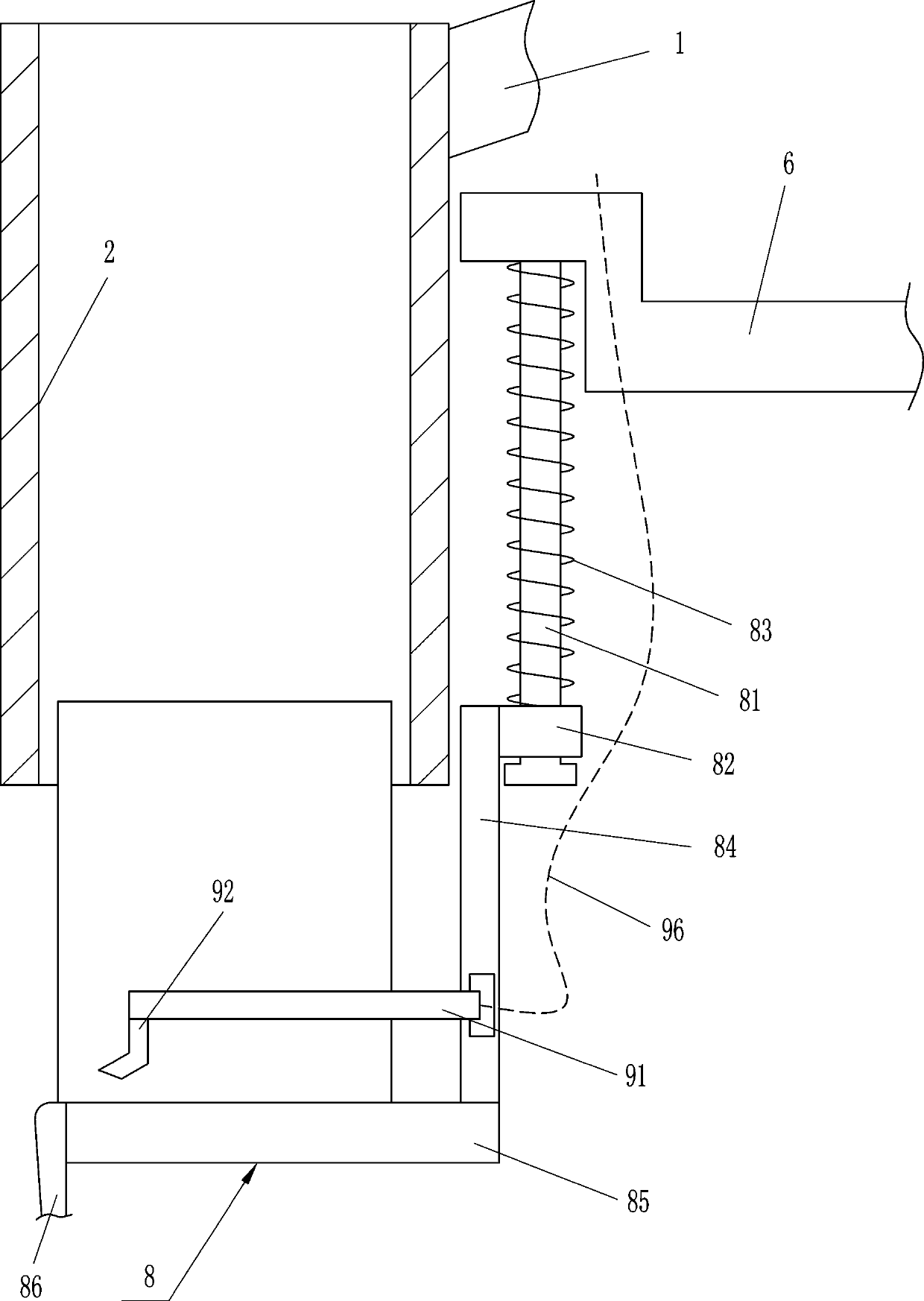

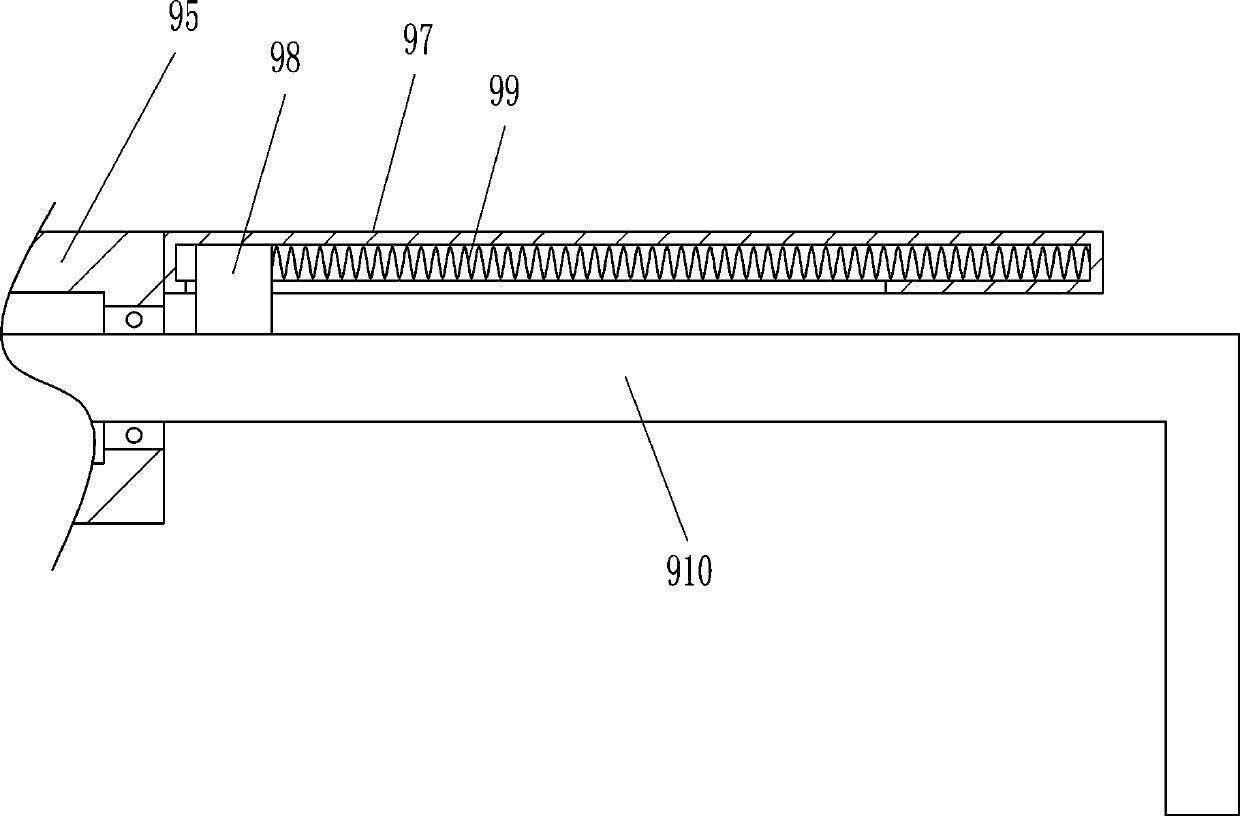

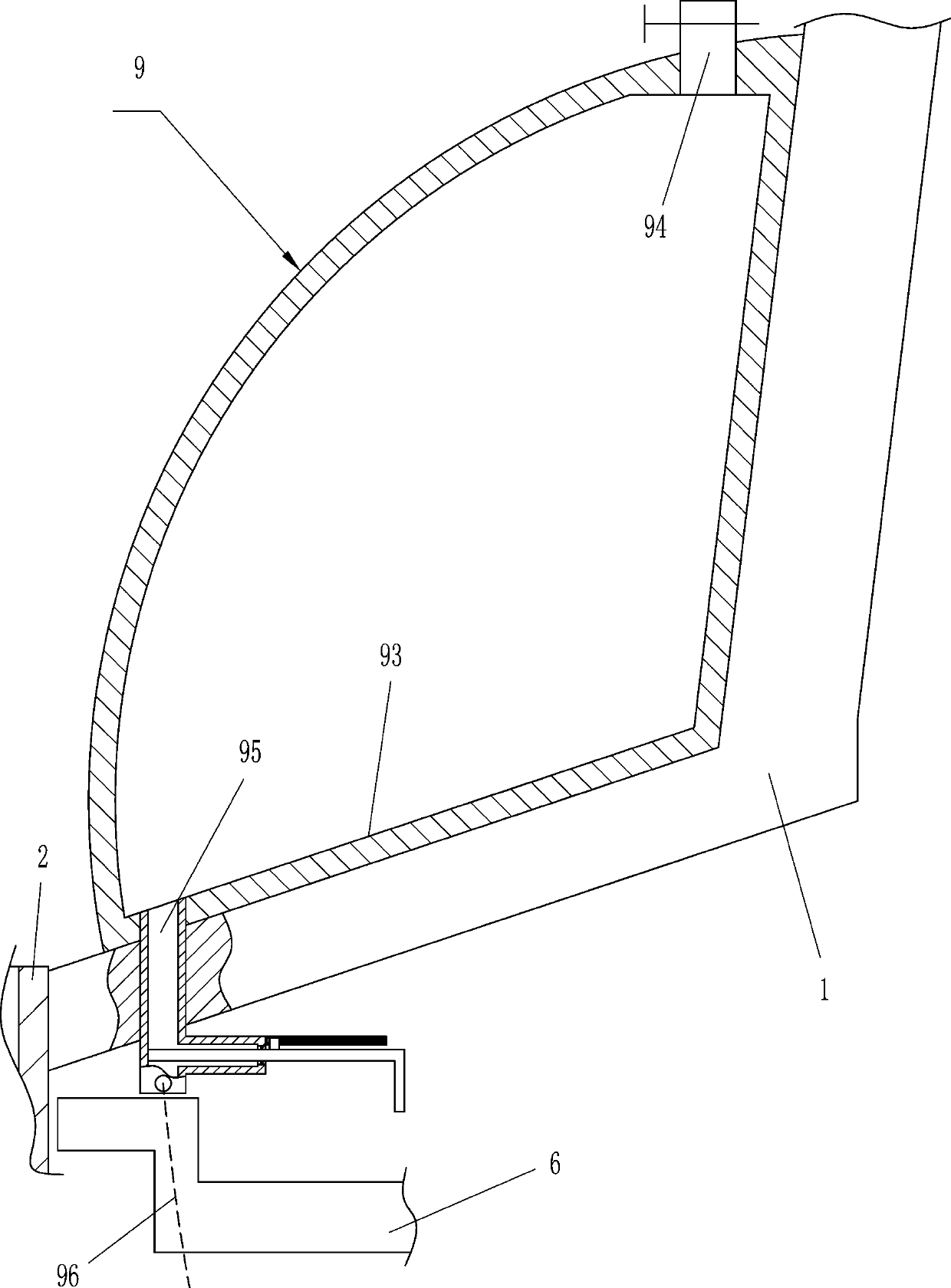

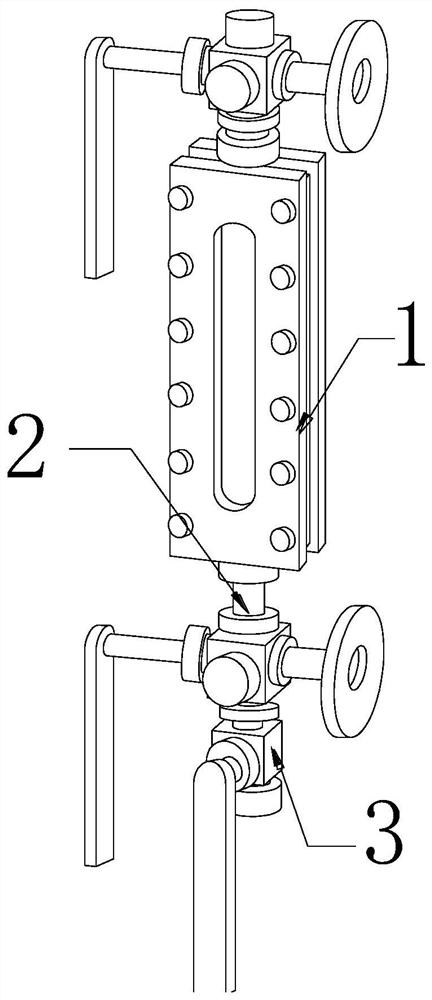

Attachment-to-wall concealed drilling-free blind flange well cementation device

The invention provides an attachment-to-wall concealed drilling-free blind flange well cementation device. The well cementation device comprises an upper pressing ring, a lower pressing ring and a blind flange pressed between the upper pressing ring and the lower pressing ring. A sliding sleeve is arranged on the inner side of the upper pressing ring and can move to the lower pressing ring from the upper pressing ring. The sliding sleeve is provided with a first position and a second position, wherein the first position is located above the blind flange, and the second position is used for clamping the broken blind flange between the sliding sleeve and the lower pressing ring when the sliding sleeve slides downwards to the lower pressing ring. The blind flange is broken through pressure build-up of a well mouth without lowering a drilling tool for removing the blind flange through drilling, and therefore well cementation completion operation time is shortened, and the well cementation completion operation cost is lowered; the broken blind flange is attached to and concealed in the inner wall of a casing string through the sliding sleeve, and therefore the drift diameter of the casing string is guaranteed, and it is effectively avoided that in the follow-up operation, fragments of the broken blind flange are hung on a production pipe column and block the production pipe column; the attachment-to-wall concealed drilling-free blind flange well cementation device is simple in structure, reliable in installation, convenient to use and low in cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

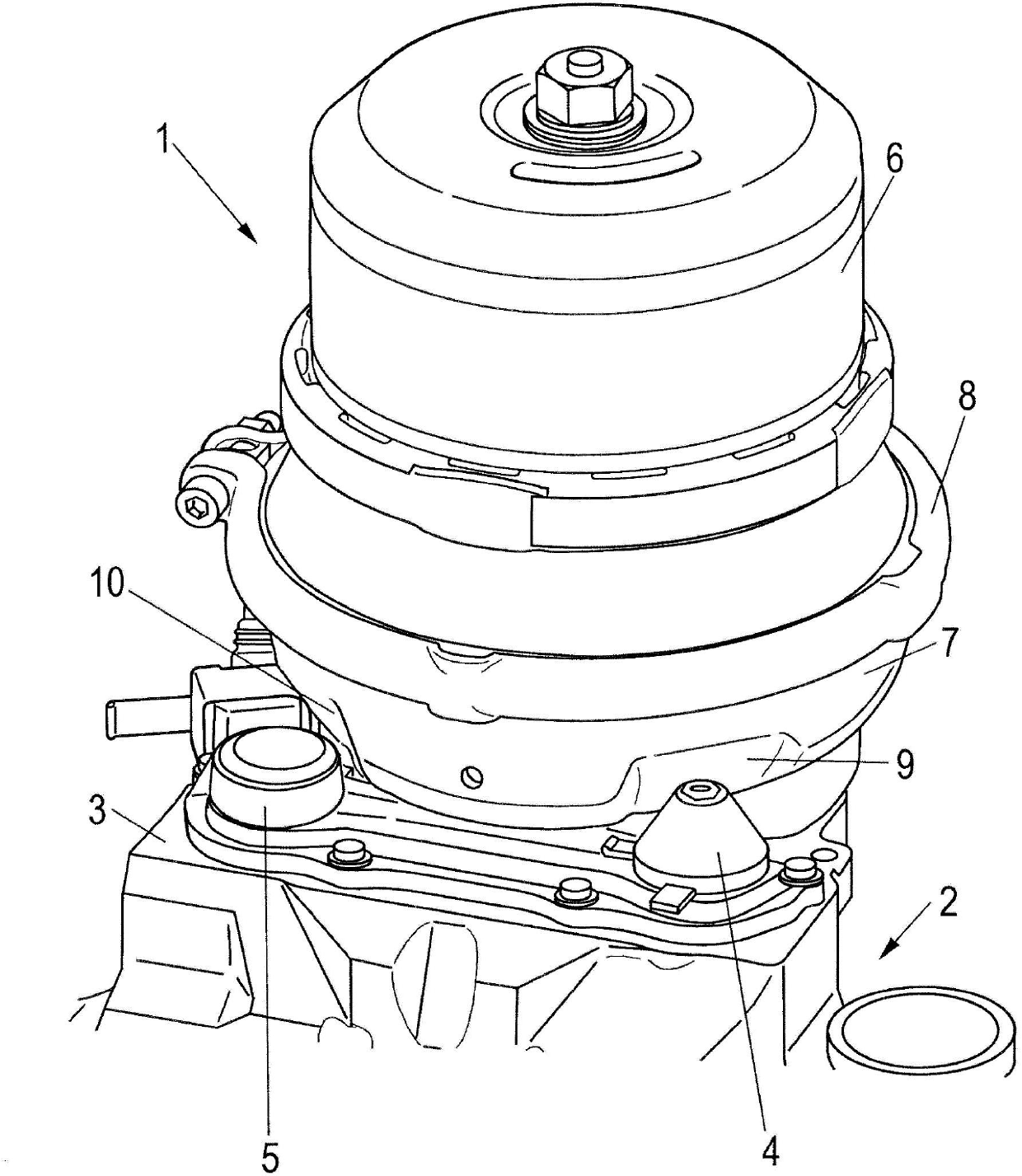

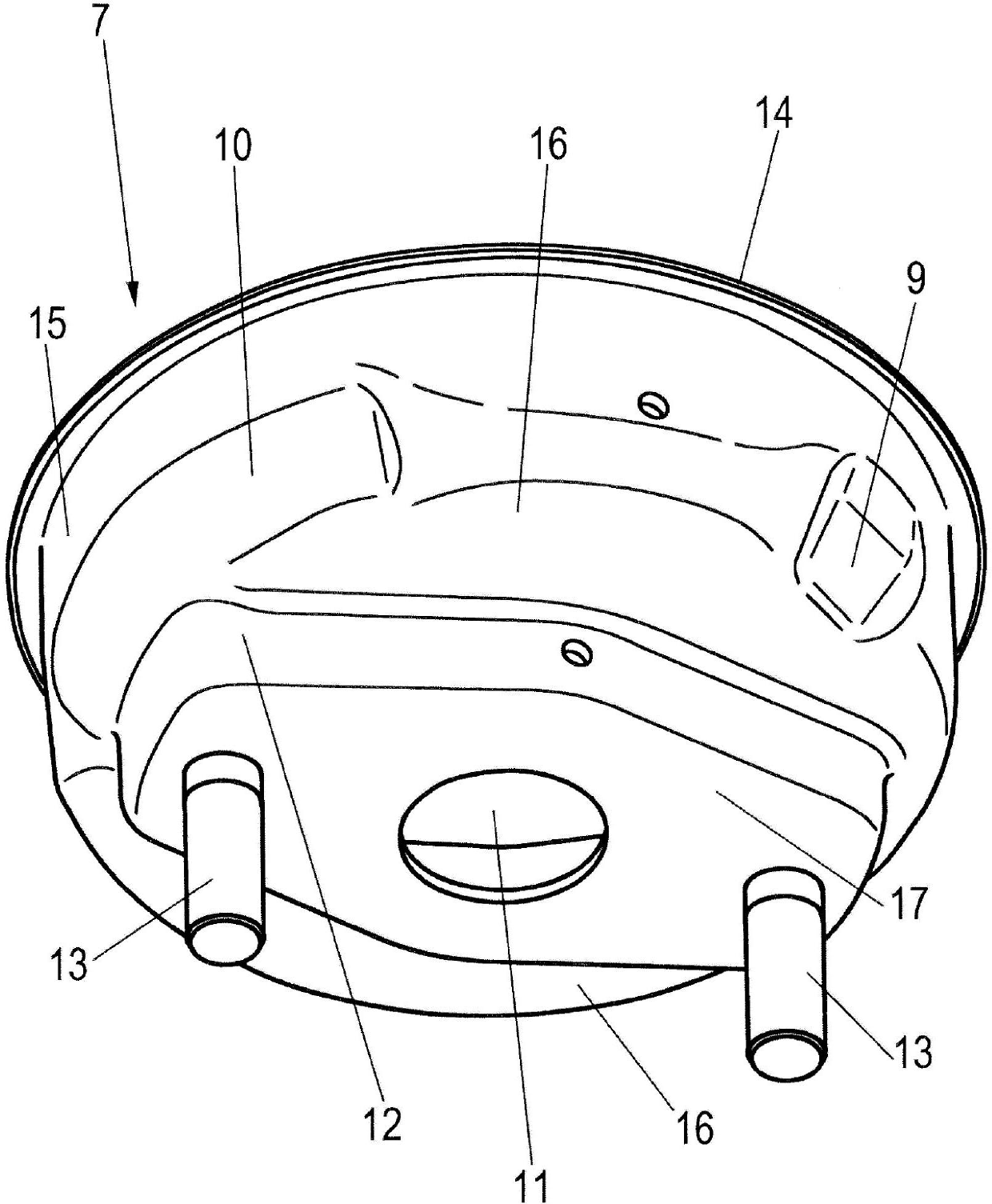

Disc brake

The invention relates to a pneumatically actuable disc brake comprising a brake caliper (2) extending over a brake disc, wherein a brake cylinder (1), to which compressed air can be applied, and at least one further functional part (4, 5) are fastened on a flange (3) of the brake caliper (2), wherein the brake cylinder (1) is provided with at least one indentation (9, 10) at least in the overlapping region with the at least one functional part (4, 5).

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

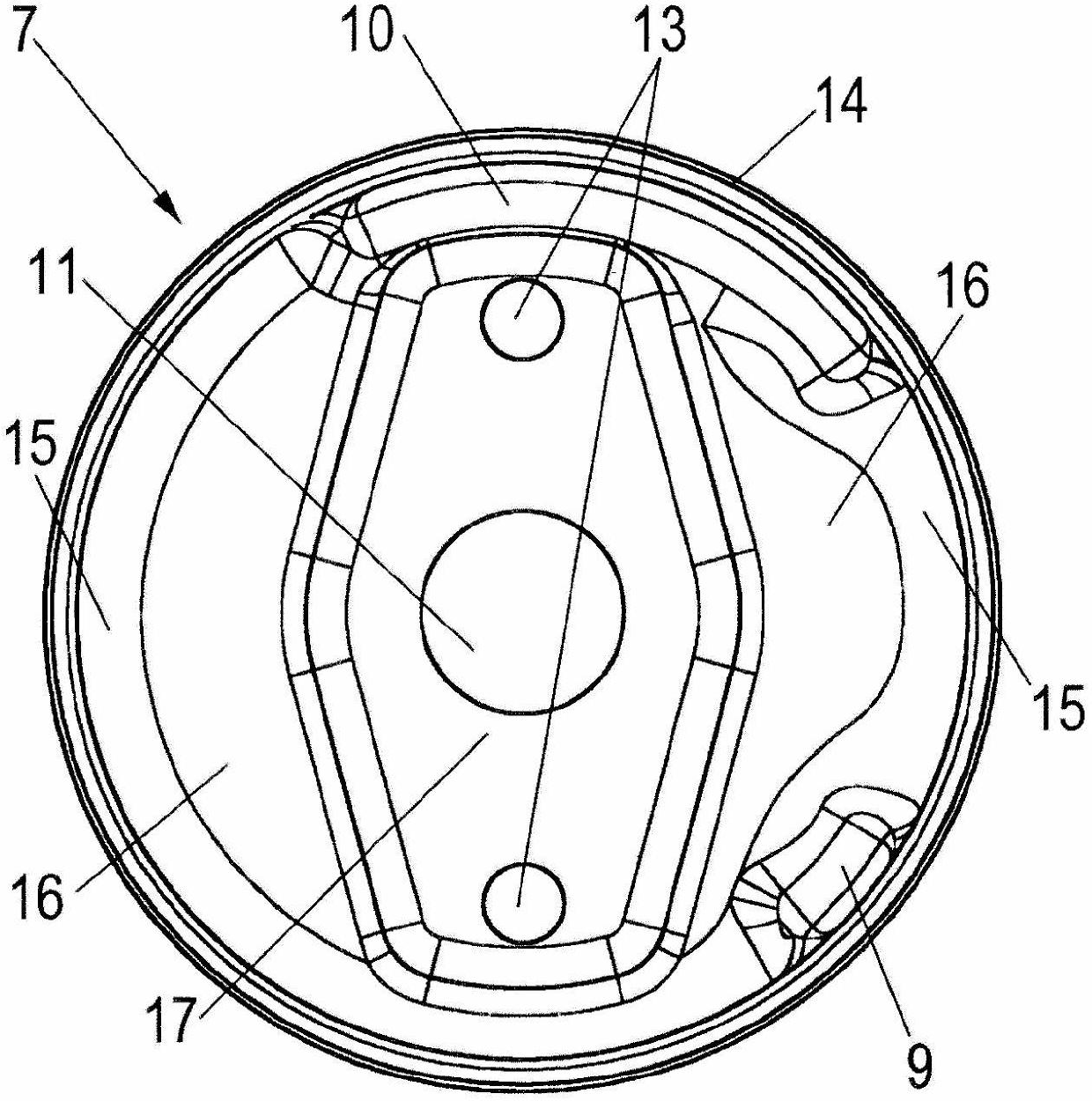

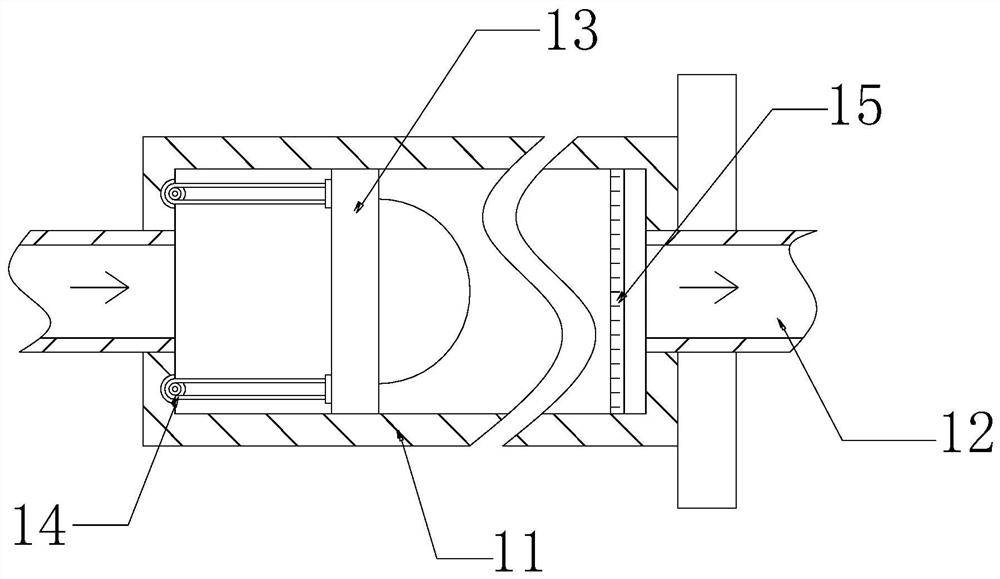

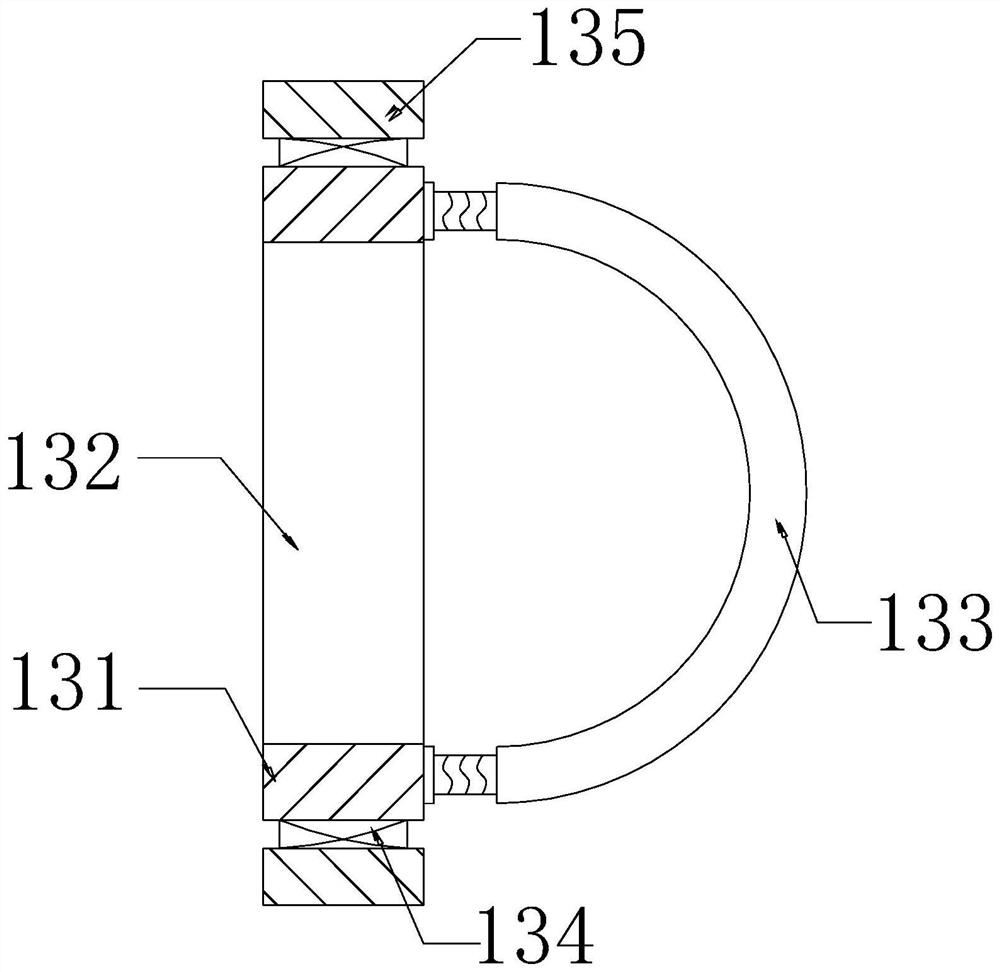

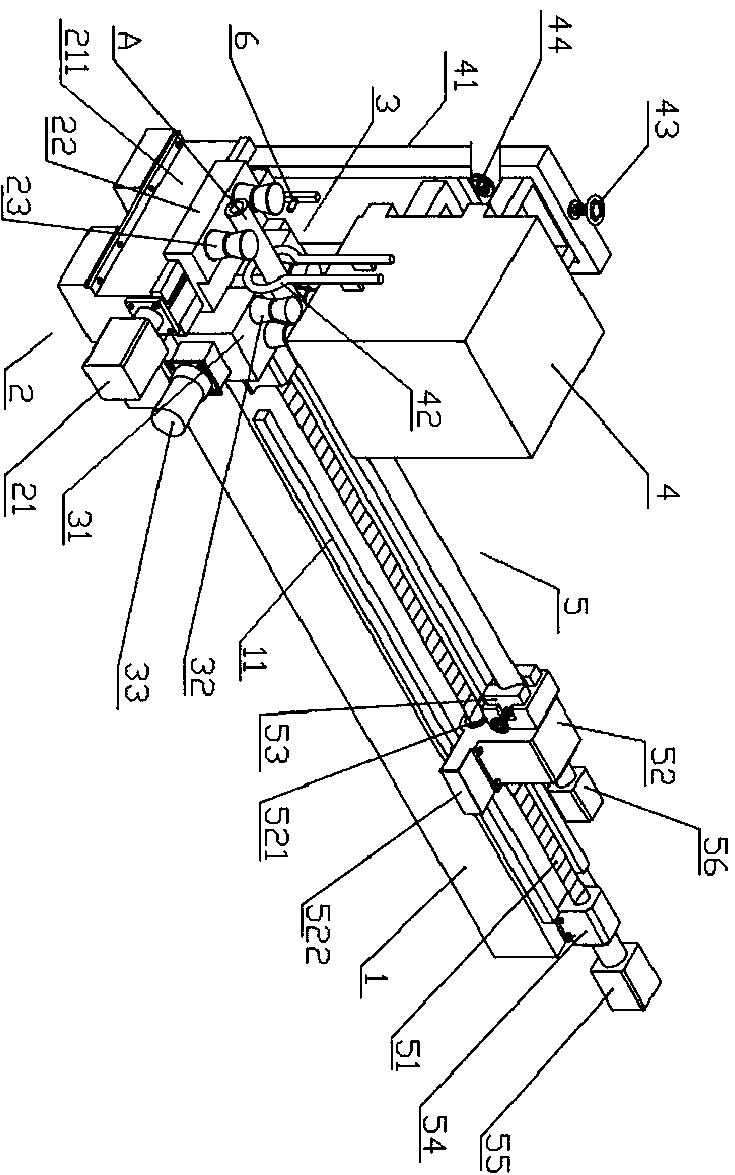

Three-dimensional space pipe bending processing equipment

ActiveCN109127821AGuaranteed thicknessGuaranteed diameterShaping toolsMetal-working feeding devicesThree-dimensional spaceEngineering

The invention relates to the technical field of pipe bending processing machinery, in particular to three-dimensional space pipe bending processing equipment. The equipment comprises a base, a bendingmechanism located at the front end of the base, a clamping mechanism located at the rear end of the bending mechanism, a pushing mechanism located at the rear end of the clamping mechanism, and a heating mechanism located above the clamping mechanism, wherein a certain distance is arranged between the bending mechanism and the clamping mechanism, an induction coil is arranged on the heating mechanism, and the induction coil is located at the distance. The bending mechanism comprises a left adjusting device and a right adjusting device and a clamping device, wherein the clamping device clampsthe pipe to be bent, and the left and the right adjusting devices can respectively drive the clamping device to move in the left and the right directions with respect to the clamping mechanism. The propulsion mechanism moves in the longitudinal direction of the base through a screw rod and screw nut structure, and a servo rotating motor makes the lateral rotating motion to the pipe to be bent on the pushing mechanism. The invention fundamentally changes the traditional process of welding before bending, avoids the hidden danger of welding root in the bent pipe, is the technical reform in the field, and has important progressive significance

Owner:QINGDAO NPA IND

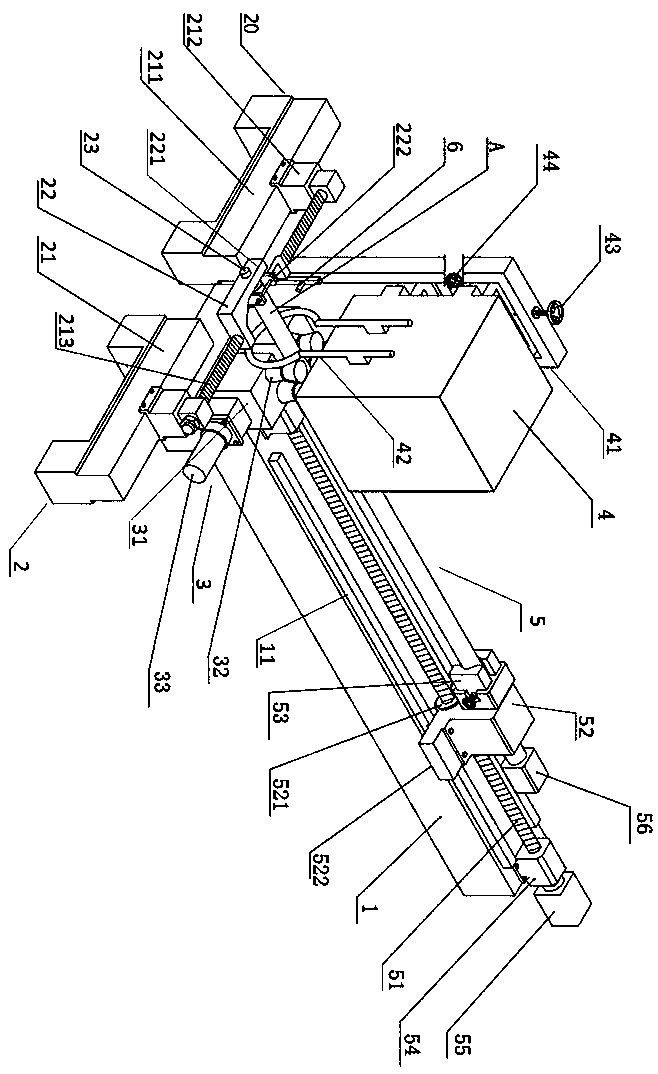

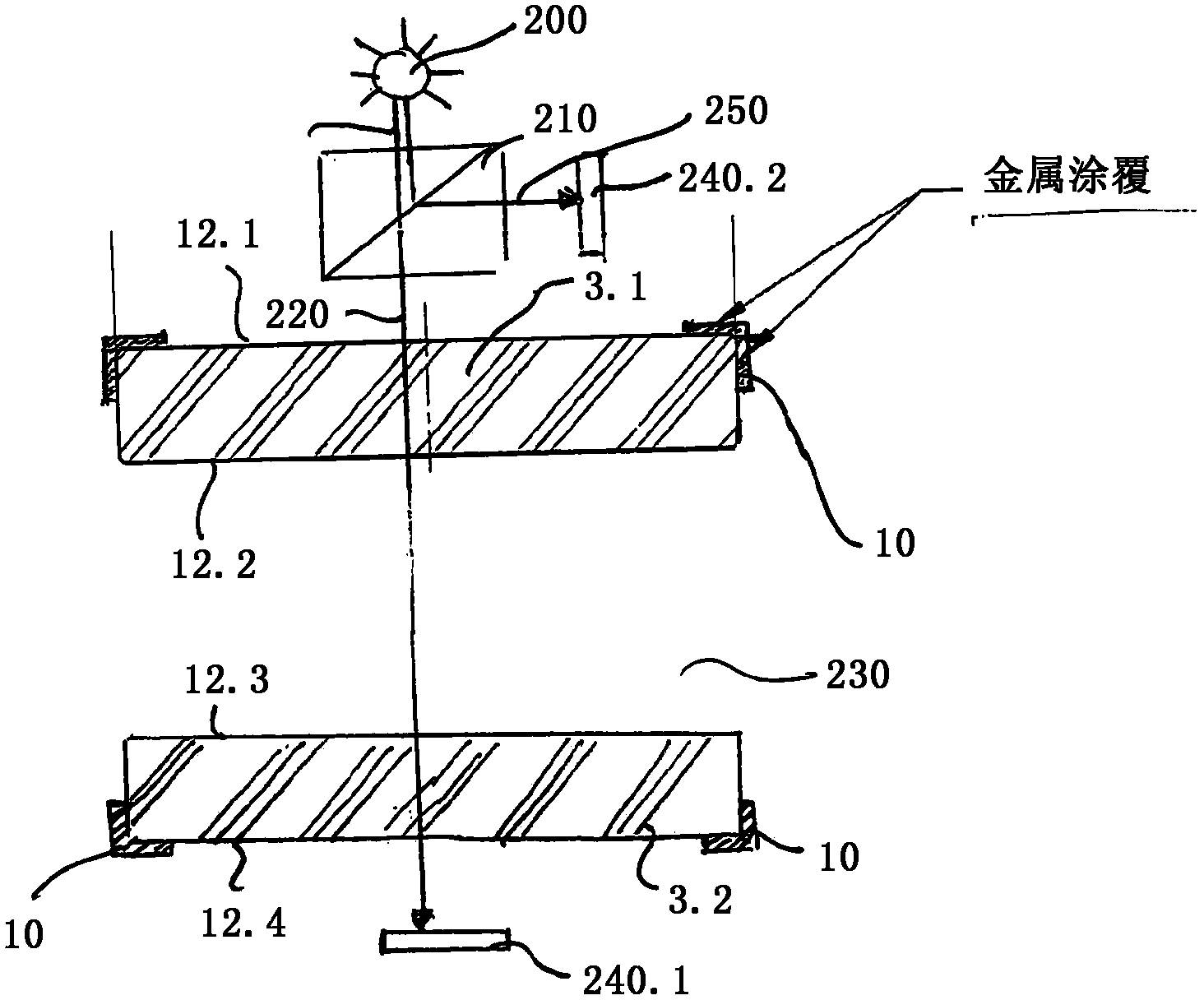

Sensor component for an optical flow rate sensor

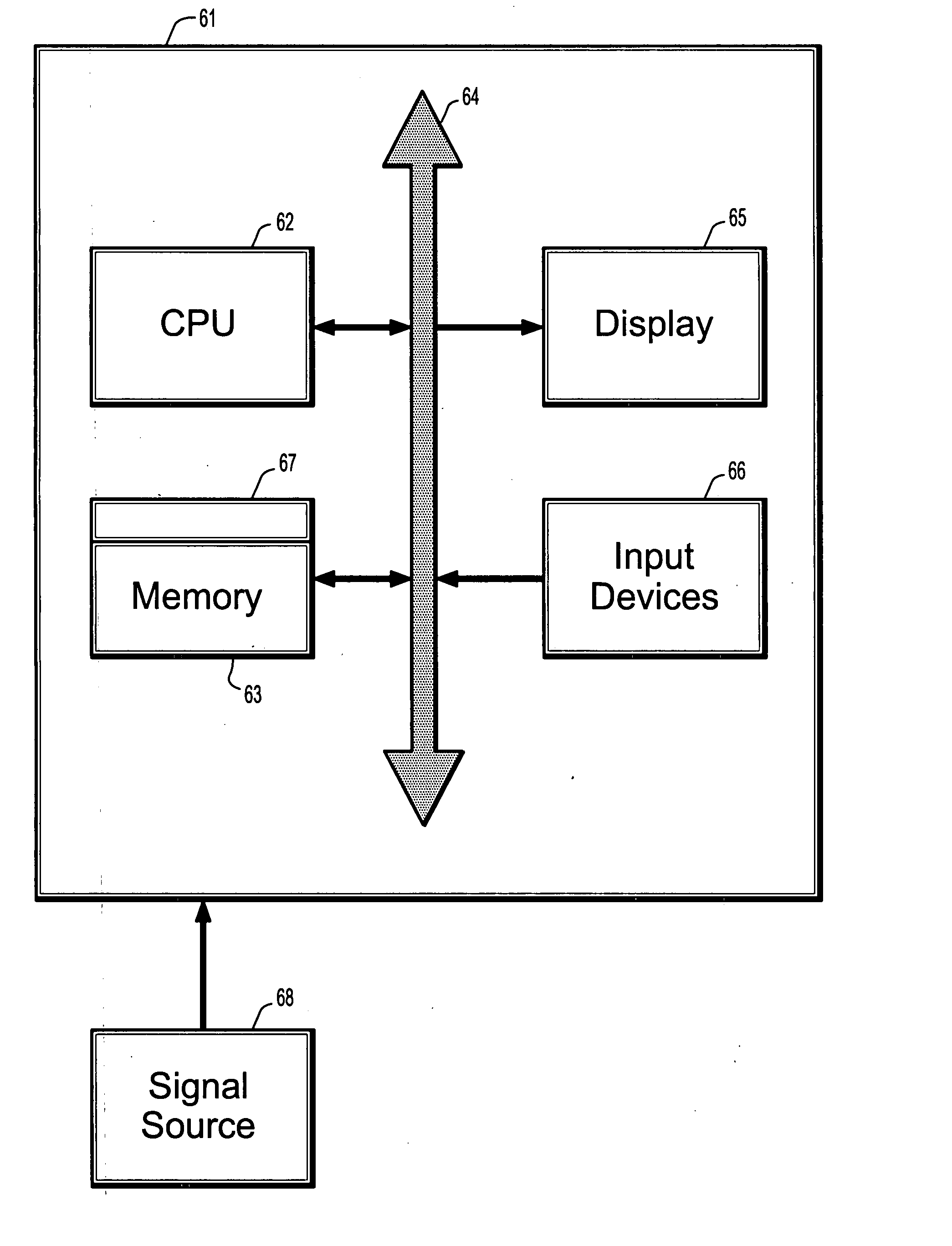

ActiveCN103547909ASize adjustmentGuaranteed diameterTransmissivity measurementsComputational physicsOptical flow

The invention relates to a sensor component for an optical flow rate sensor for fluid and / or gaseous media, comprising at least one component segment and at least one sensor segment, the sensor segment comprising at least two inspection windows in the region of a plurality of cutouts in a sensor segment disposed such that it is possible for light to pass through a transverse section of the sensor segment, or the sensor segment comprising exactly one inspection window in the region of a cutout and a reflective surface, in particular a mirrored or polished surface, being provided on the side opposite the cutout, such that it is possible for light to pass through the sensor segment twice through a transverse section of the sensor segment, characterized in that the sensor component comprises a receiving component that can be inserted in the one or more cutouts and the sight glass is bonded to the receiving component.

Owner:SCHOTT AG

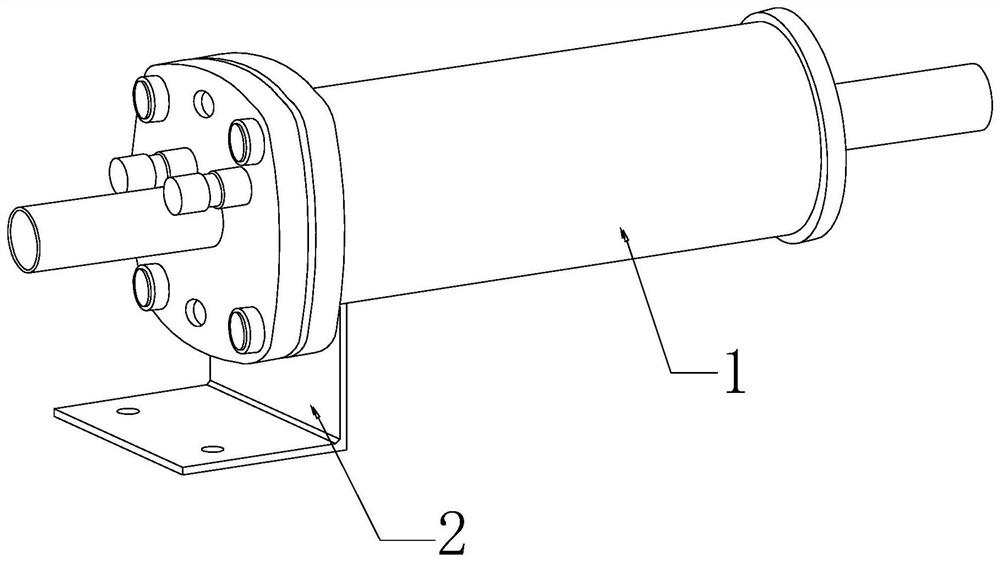

Novel water conservancy detection equipment

PendingCN113041677AAccelerateShorten detection timePreparing sample for investigationTesting waterEnvironmental geologyStructural engineering

The novel water conservancy detection equipment structurally comprises a filter cylinder and a supporting seat, wherein the top end of the supporting seat is welded to the bottom face, close to the left end, of the filter cylinder, the filter cylinder comprises a cylinder body, drainage pipes, a pushing mechanism, a pull rope and a filter net, the drainage pipes are installed in the middles of the two ends of the cylinder body respectively, and the pushing mechanism is sleeved with the cylinder body. According to the invention, the residual liquid in the filter cylinder is easy to form ice blocks, when the liquid is introduced into the filter cylinder again, the forward conveying speed of the liquid is slowed down due to the resistance of the ice blocks, and the ice blocks are impacted by the push plate of the pushing mechanism, so that the ice blocks are crushed, the forward conveying speed of the liquid is accelerated, the filtering speed of the liquid is accelerated, and the water quality detection time is shortened; and the impurities in the liquid are adhered to the inner wall of the cylinder body so as to reduce the diameter of the inner wall of the cylinder body, and the impurities on the inner wall of the cylinder body are removed through the removing block of the pushing block, so that the original diameter of the inner wall of the cylinder body can be kept, and free movement of the pushing mechanism is facilitated.

Owner:宁夏鑫源建设工程有限公司

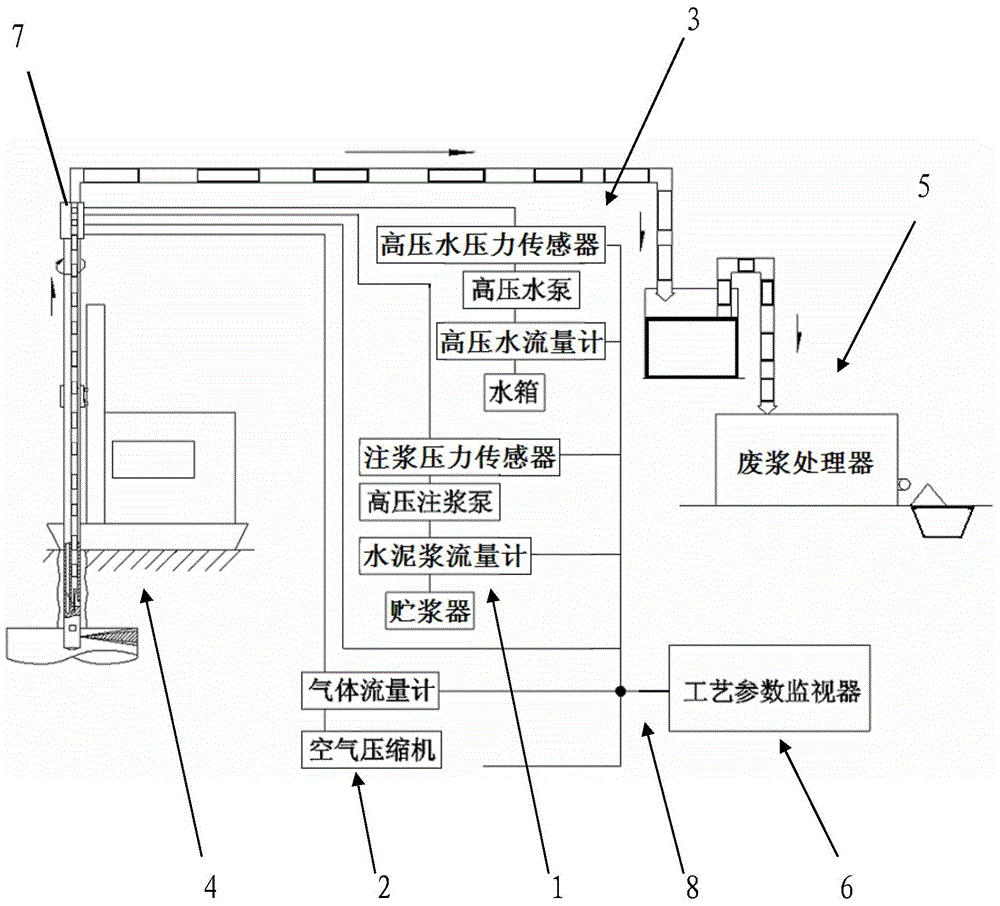

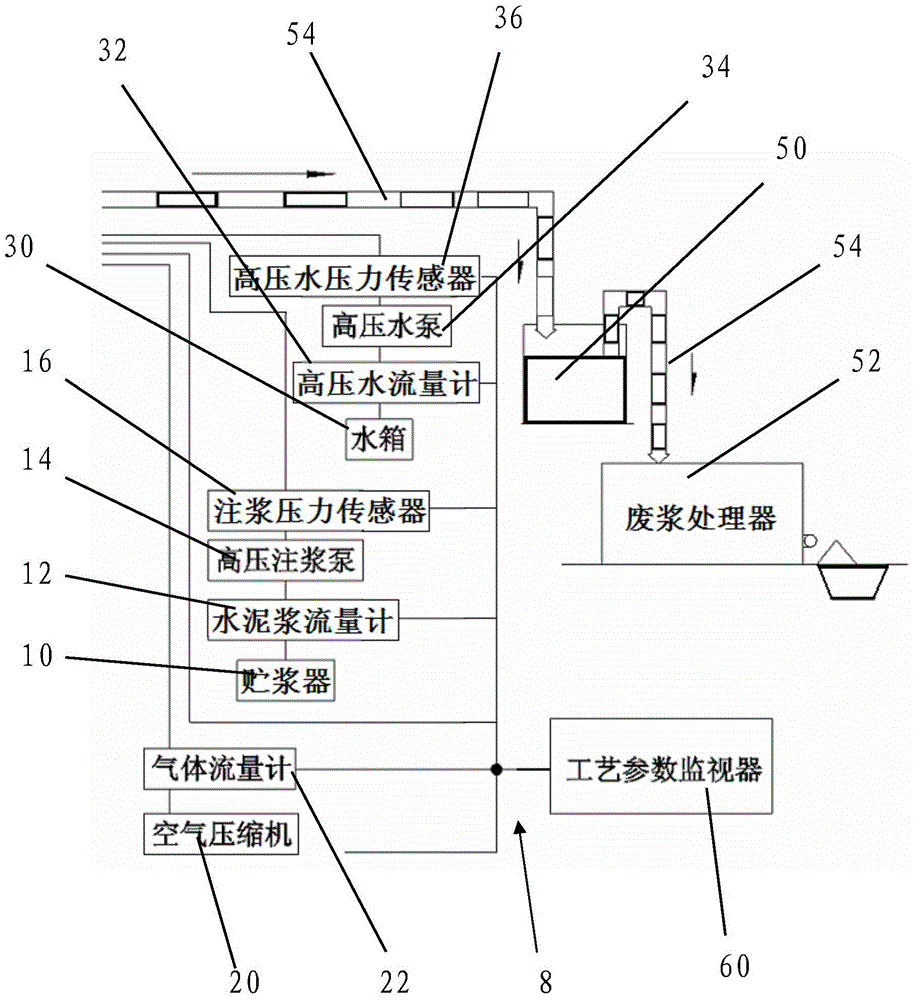

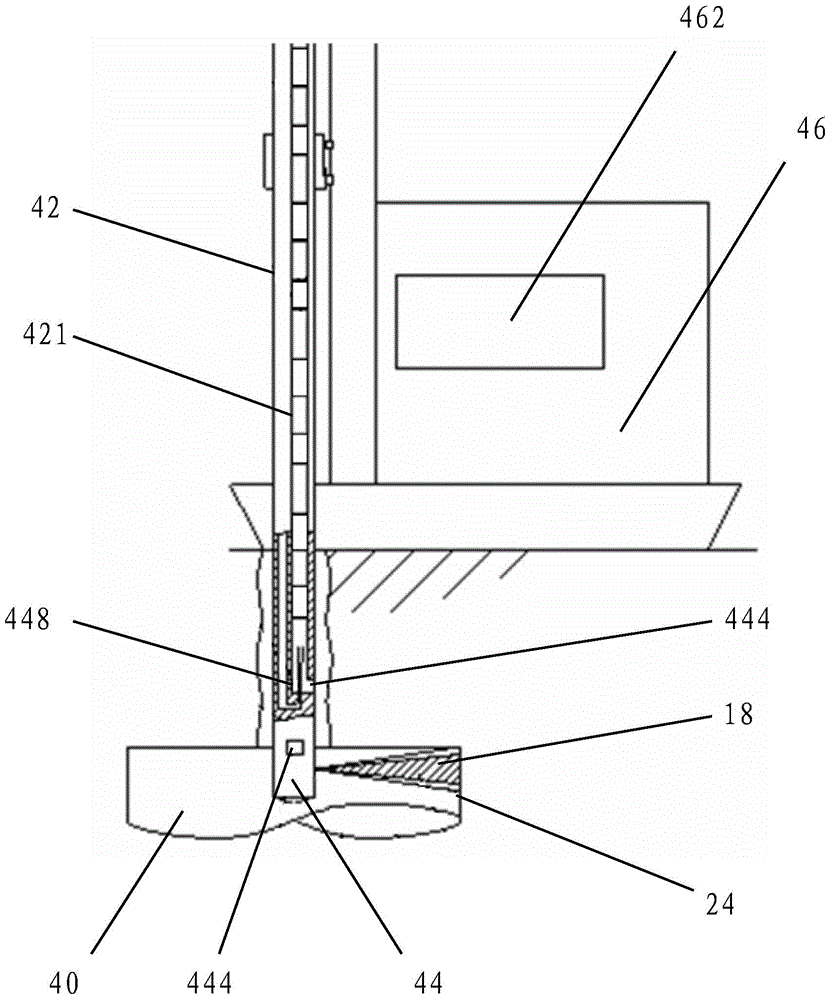

High-pressure jet grouting system and construction method with controllable ground pressure and no mud discharge

The invention provides a slurry-discharge-free high-pressure jet grouting system with pressure in the ground controllable and a construction method. The high-pressure jet grouting system comprises a high-pressure cement slurry pumping assembly, an air jet assembly, a high-pressure water pumping assembly, a rotary jet slurry discharging assembly, a slurry discharging treating assembly and a monitoring assembly. The high-pressure jet grouting construction method includes the steps that the rotary jet slurry discharging assembly is assembled and placed down in a positioned mode; a fluid director is installed and connected with the rotary jet slurry discharging assembly in a conducting mode; all the assemblies are assembled and respectively connected with the fluid director; the monitoring assembly is installed and respectively connected with all the assemblies through signal transmission lines; jet grouting is performed, and the rotary jet slurry discharging assembly is lifted step by step; the whole jet grouting process is monitored in real time through the monitoring assembly; all the devices are washed after jet grouting. The problem that redundant slurry leaks to cause ground upheaval is solved, and waste slurry is dewatered to ensure construction quality and reduce environmental pollution.

Owner:N I T CO LTD +3

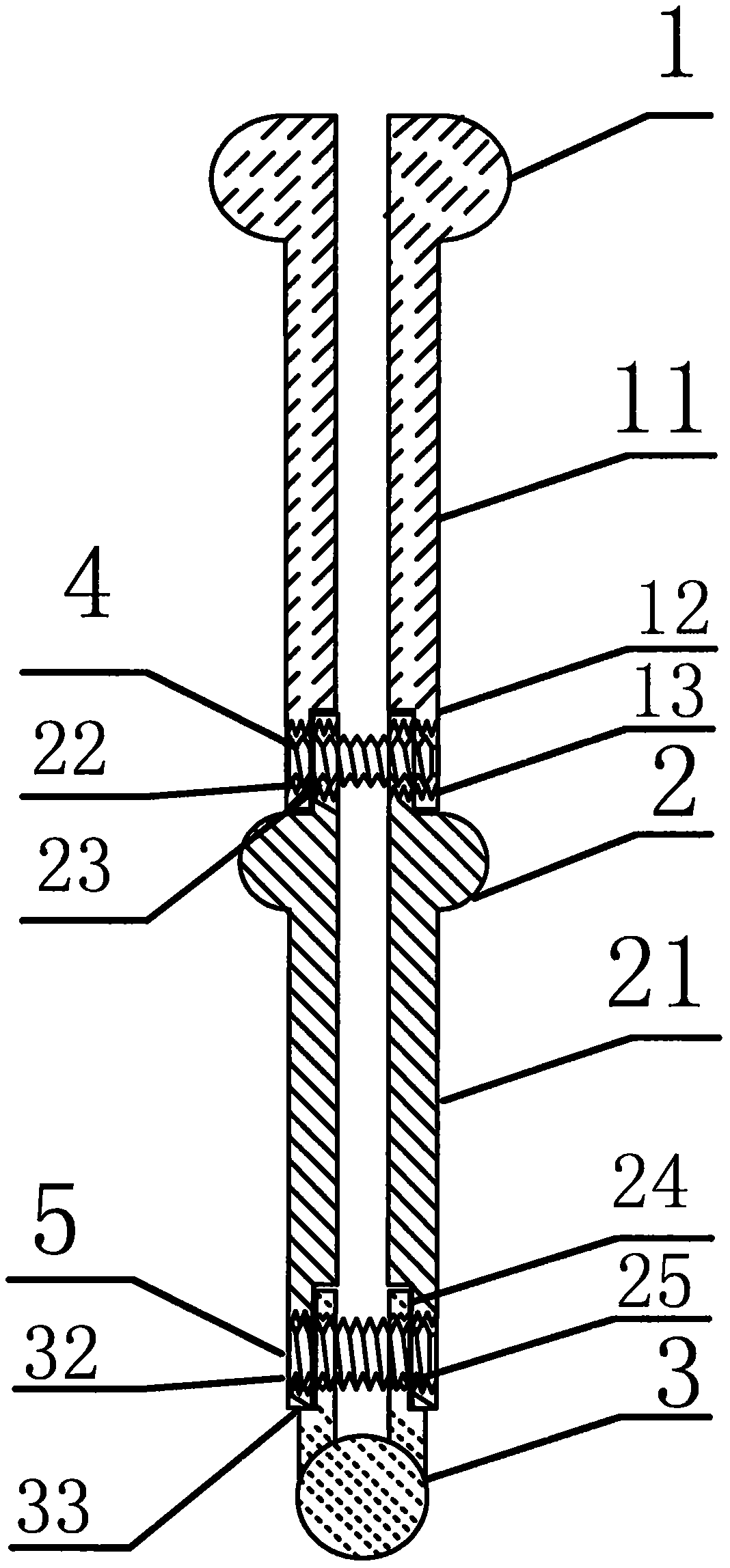

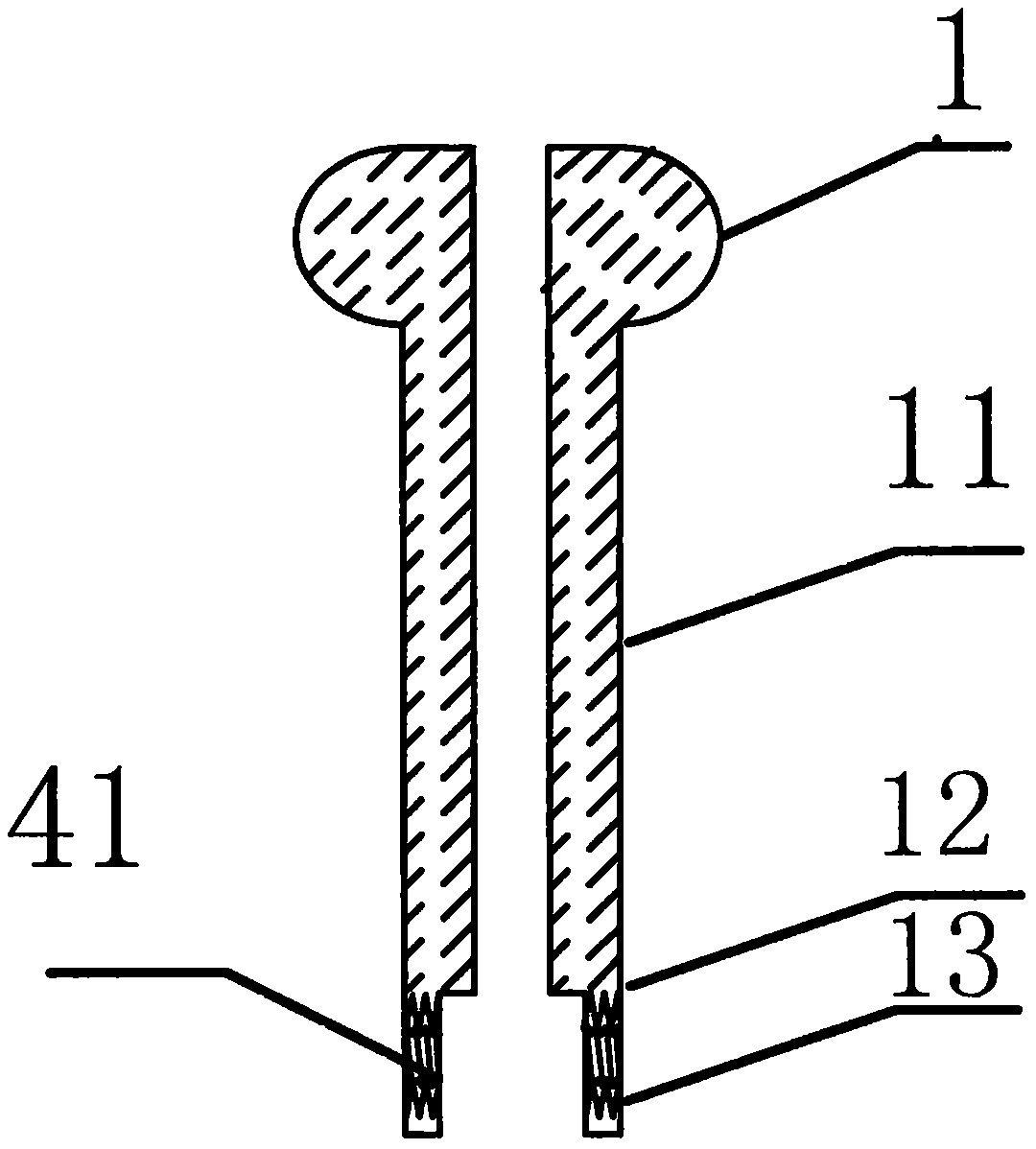

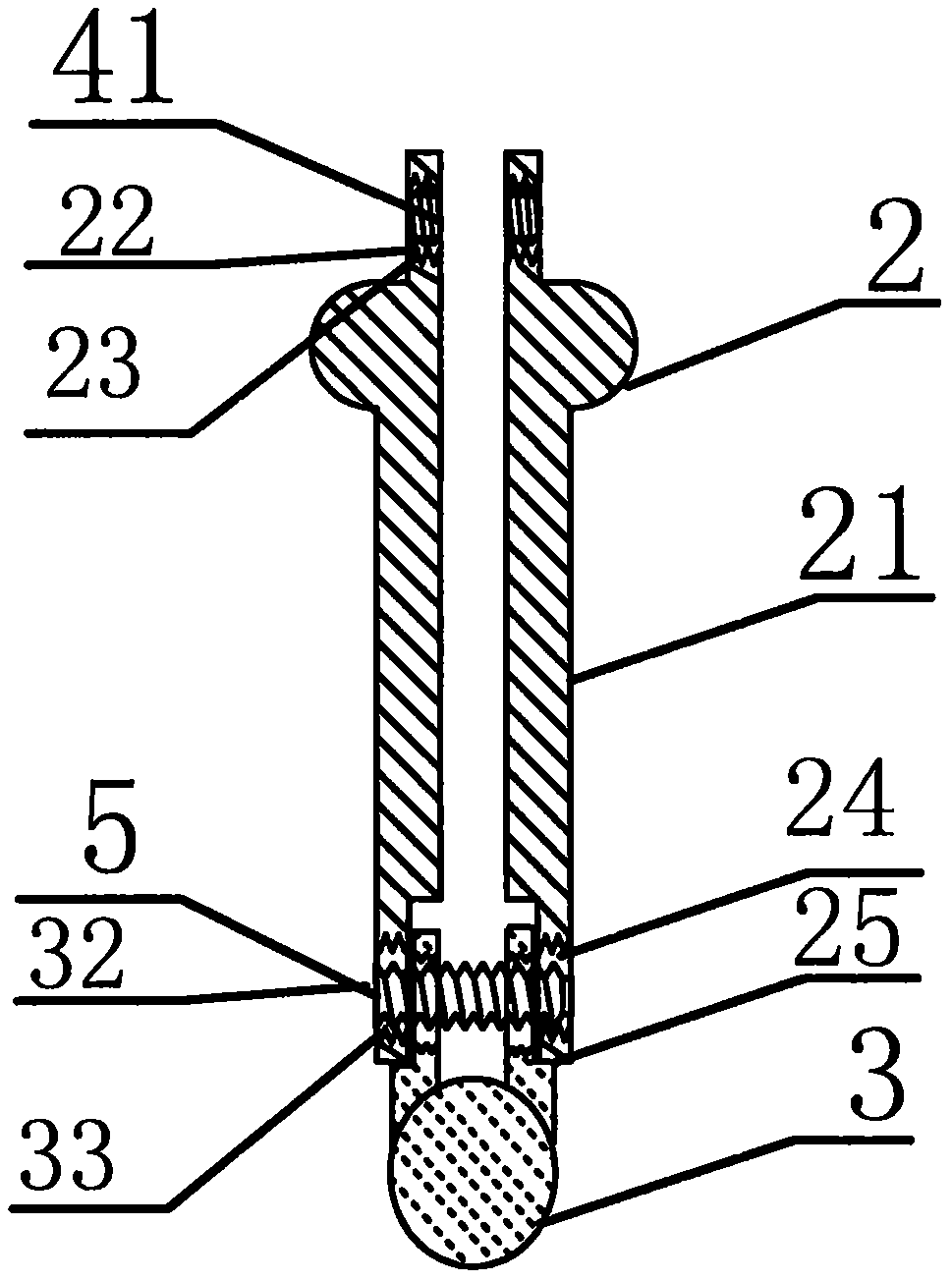

Multilevel interlinked shear seat-sealing ball

InactiveCN107795297AGuaranteed diameterImprove cleanlinessFluid removalWell/borehole valve arrangementsHigh angleGround pressure

The invention provides a new type of "multi-stage serial shearing seat sealing ball" device, comprising: an upper hollow seat sealing ball, an upper hollow pressure transmission connecting rod; a middle hollow seat sealing ball, a middle hollow pressure transmission connecting rod; a lower solid seat a block ball; and a set of shear pins. The present invention is put into the ground; it falls downhole along with the oil pipe or casing, and reaches the position of the downhole sliding sleeve. In highly deviated well sections or horizontal well sections: pump the completion fluid or mud through the surface, and push the "multi-stage serial shear seat seal ball" to the position of the downhole sliding sleeve; then, pressurize the ground to open the downhole sliding sleeve . No need for steel wire work; no need for cable feeding; no need for coiled tubing work; no need for hydraulic control pipeline work outside the oil pipe, and the "multi-stage chain shear seat seal ball" can be used to continuously open or close multiple sliding sleeves in one trip, saving rig time. It can also replace the highly deviated well sections and horizontal well sections that cannot be reached by steel wires and cables, and can open or close multiple sliding sleeves continuously, saving costs. After opening or closing multiple sliding sleeves, the oil and gas in the tubing can be produced normally, which saves costs; there is no limit to the depth of entry and the flow rate of oil and gas wells.

Owner:陈晓新

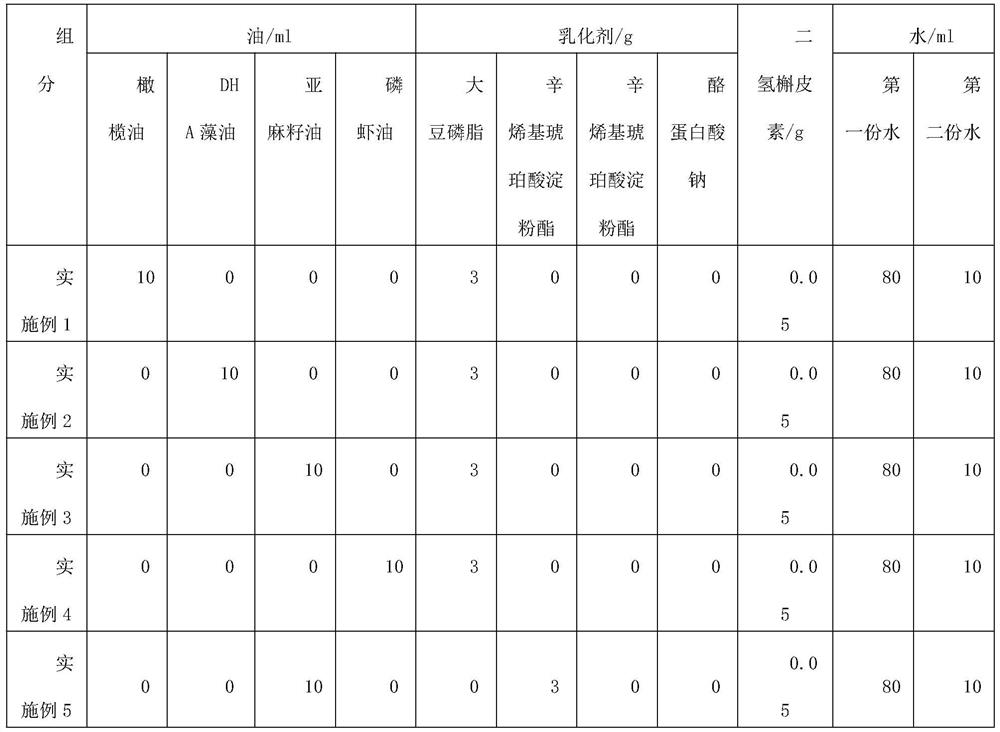

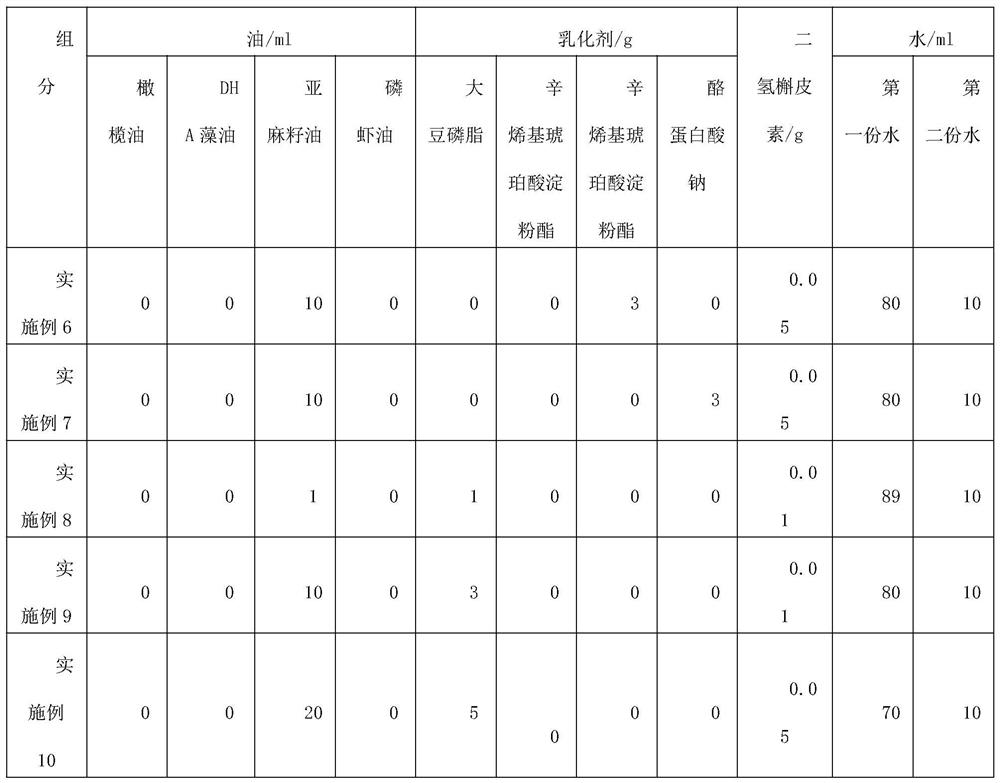

Dihydroquercetin nano-emulsion, and preparation method and application thereof

PendingCN113826906AGuaranteed concentrationGuaranteed diameterVitamin food ingredientsLipidic food ingredientsAqueous solubilityFood structure

The invention discloses a dihydroquercetin nano-emulsion, and a preparation method and application thereof. The dihydroquercetin nano-emulsion is prepared from the following raw materials in parts by weight: 1-20 parts of oil, 1-5 parts of emulsifying agents, 0.01-0.05 part of dihydroquercetin and 80-99 parts of water. The preparation method of the dihydroquercetin nano-emulsion comprises the following steps: S1, dividing water into two parts, mixing and stirring the first part of water and an emulsifier, and heating the second part of water to 100 DEG C to obtain boiled water; S2, preparing a primary crude emulsion; and S3, carrying out homogeneous reaction on the primary crude emulsion obtained in the step S2. The invention also discloses application of the dihydroquercetin nano-emulsion in a food structure modification base material. According to the invention, an antioxidant nano-emulsion is produced, so that the defects of poor water solubility and low bioavailability of the current dihydroquercetin are overcome.

Owner:蕴能(大连)生物科技有限公司

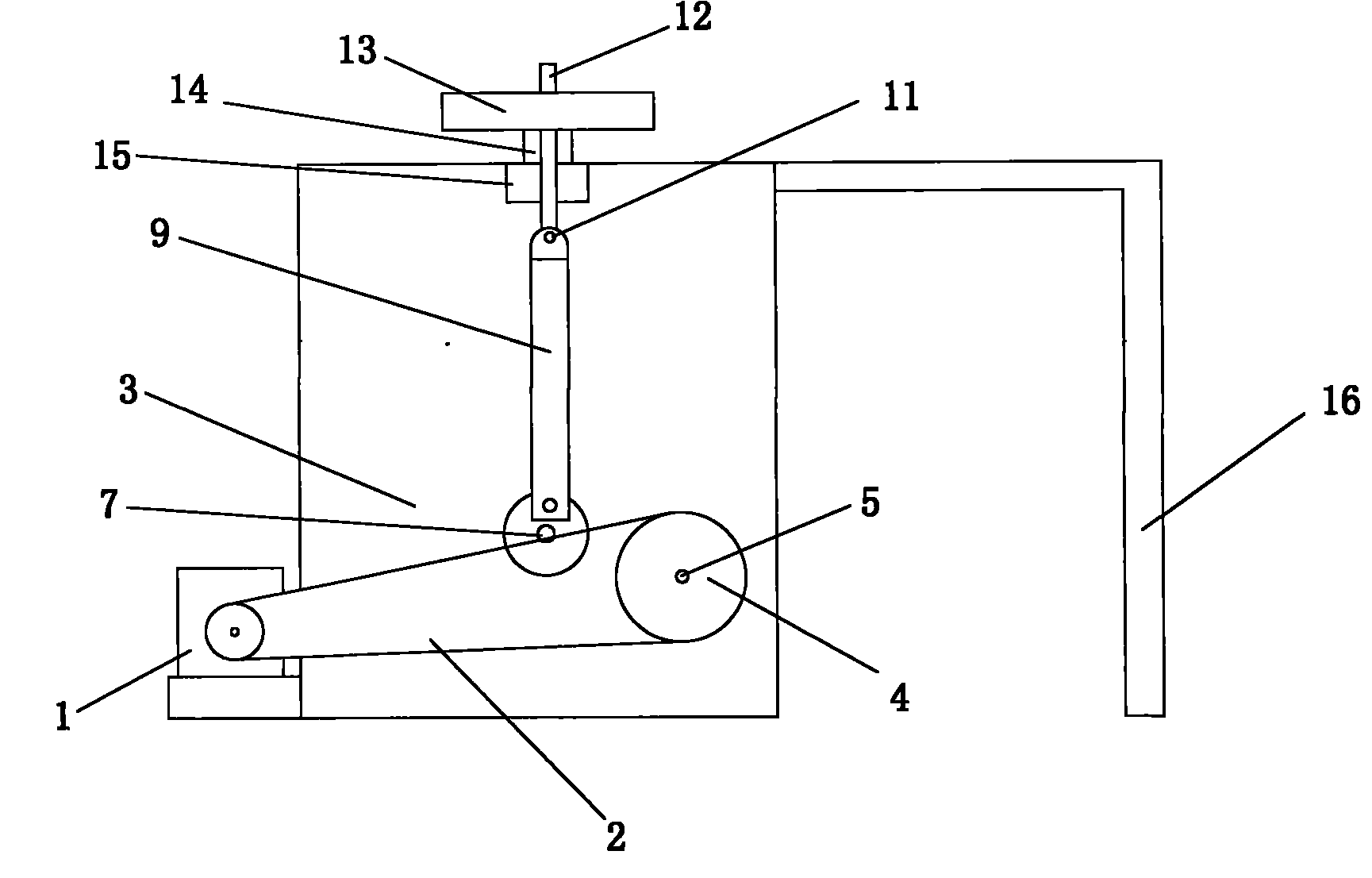

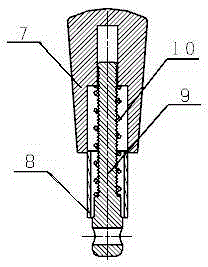

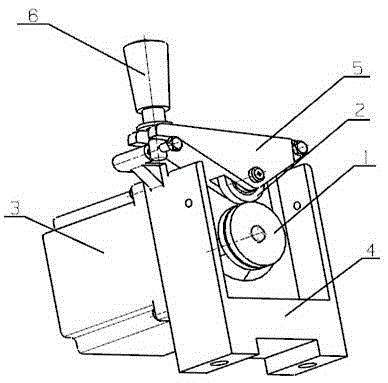

Wire feeding mechanism having variable pressing force and used for film plating machine

InactiveCN105200371AGuaranteed diameterChange sizeVacuum evaporation coatingSputtering coatingDrive wheelEngineering

The invention relates to a wire feeding mechanism having variable pressing force and used for a film plating machine. The wire feeding mechanism comprises a driving wheel, a pressing wheel, a motor, a bottom plate, a pressing plate and a pressing mechanism, wherein the driving wheel is mounted on the bottom plate, the pressing wheel is arranged above the driving wheel and mounted in the pressing plate, one end of the pressing plate is movably hinged with the bottom plate, and the other end of the pressing plate is connected with the bottom plate through the pressing mechanism; the pressing mechanism comprises a pressing handle, a sleeve and a pressing rod, the pressing handle is in spinning connection with the pressing rod through threads, a spring sleeving the pressing rod and used for adjusting pressing force is arranged in the pressing handle, the lower end of the pressing rod is rotationally connected with the bottom plate, the pressing force is changed by changing the position of the pressing mechanism, and the wire feeding stability and reliability are improved. The wire feeding mechanism can control the pressing force according to the diameter of wires and the thickness of a plated film and adjusts the wire feeding speed, and the stability and the reliability of wire feeding are improved.

Owner:SHANGHAI INST OF TECH

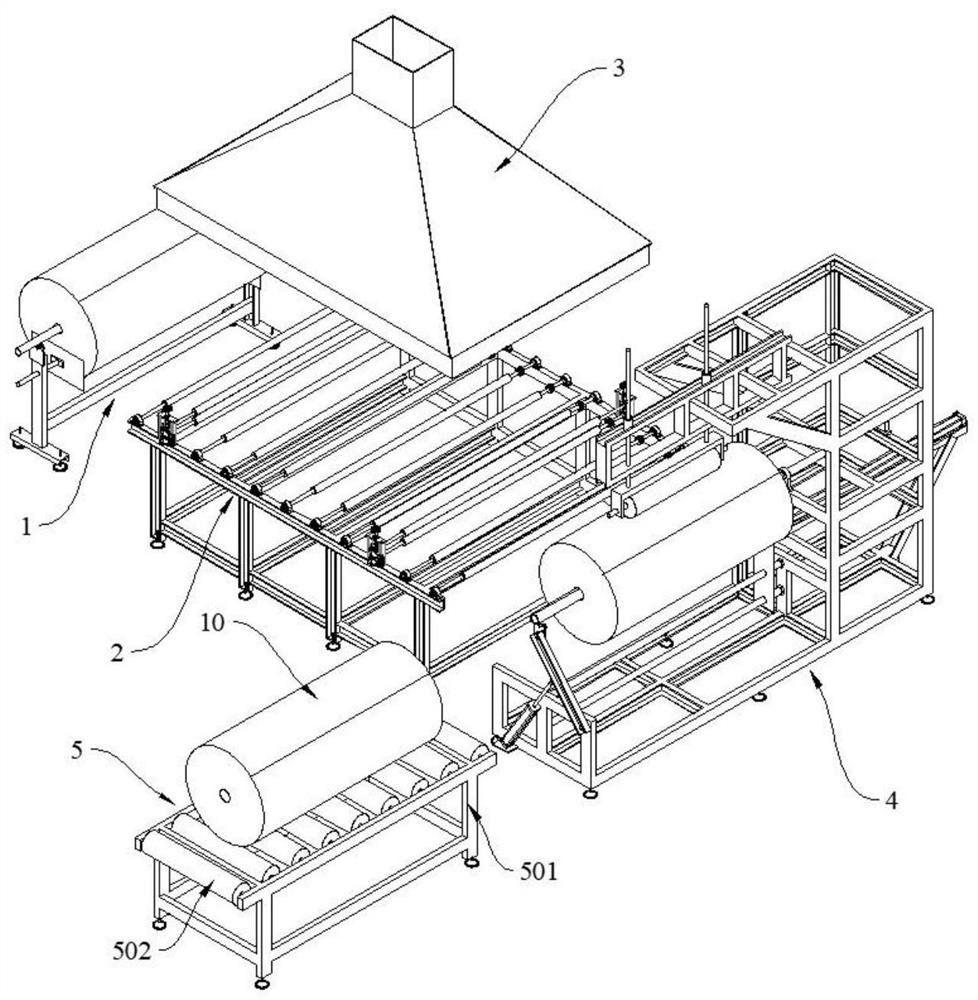

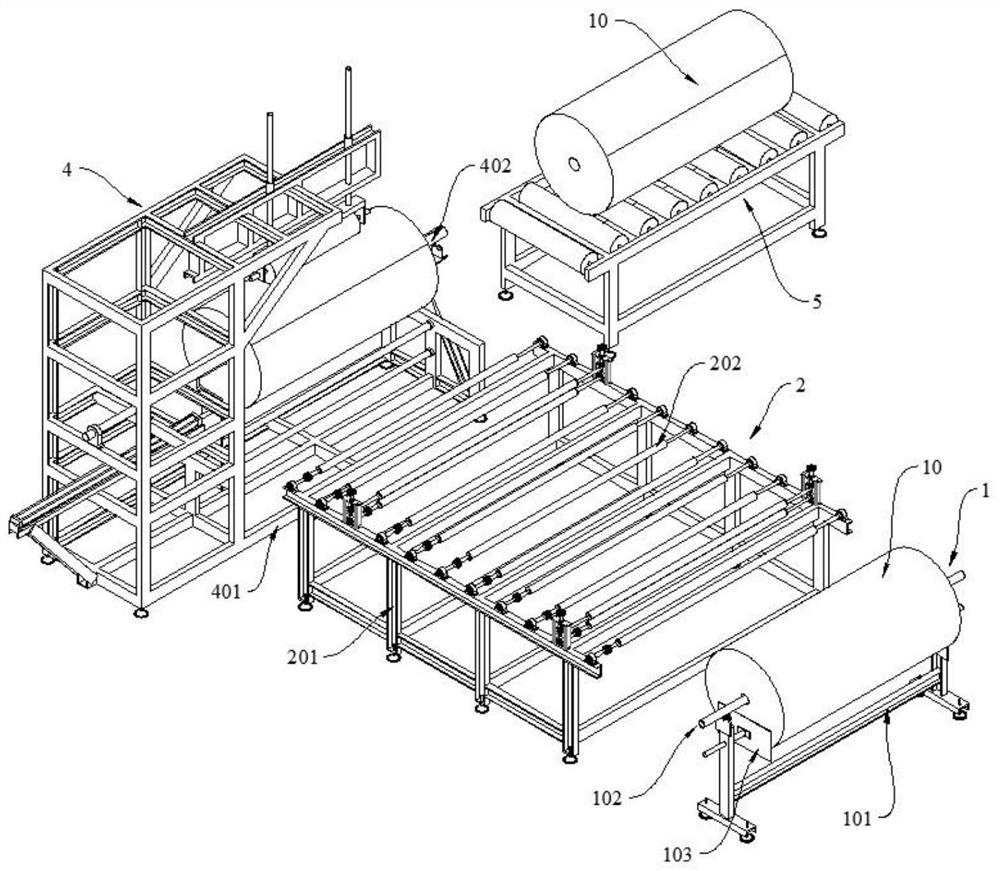

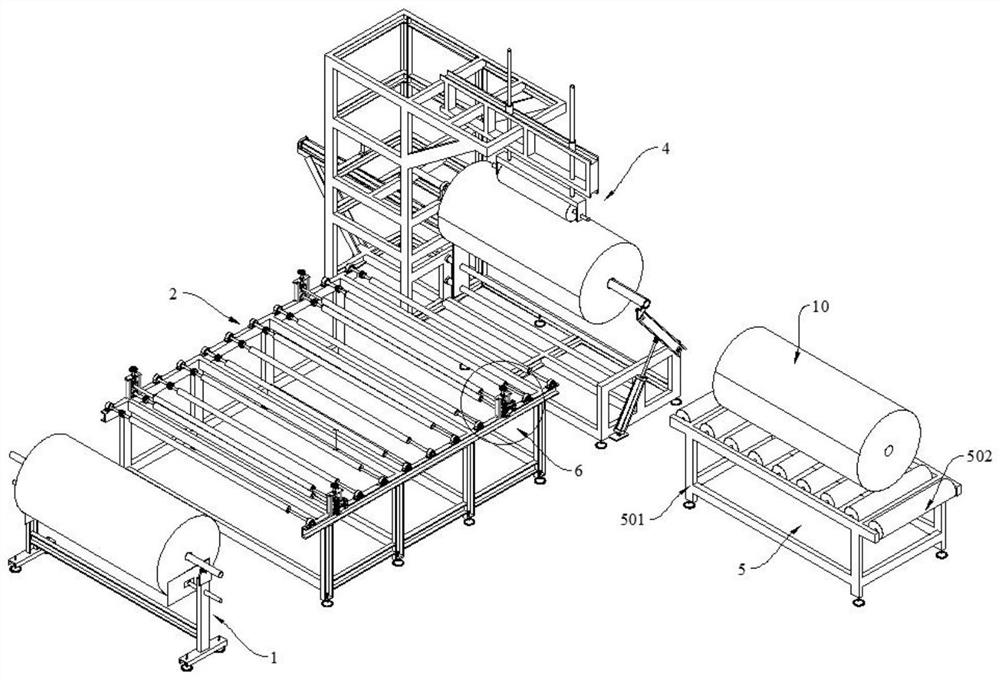

Rewinding device for aerogel composite coiled material and operation method

PendingCN113651155AImprove production efficiency and product qualityReduce damageDirt cleaningCleaning using gasesTransfer mechanismManufacturing engineering

The invention discloses a rewinding device for an aerogel composite coiled material and an operation method, and relates to the technical field of aerogel composite coiled material production. The rewinding device comprises an unwinding mechanism, a conveying mechanism, a dust collection mechanism, a winding mechanism and a transferring mechanism, wherein the unwinding mechanism comprises an unwinding support, a first roll shaft is fixedly installed on the upper side of the unwinding support, the conveying mechanism comprises a conveying support, a plurality of second roller shafts are fixedly installed on the upper side of the conveying support, a plurality of transmission assemblies are further fixedly installed on the upper side of the conveying support, the winding mechanism comprises a winding support and a winding roller shaft, one end of the winding roller shaft is fixedly installed on one side face of the winding support, and a pressing assembly and a discharging assembly are fixedly installed on the winding support. By arranging the conveying mechanism and the winding mechanism, the operation that an aerogel composite coiled material needs to be manually spread for heat dissipation and then manually wound in an existing production process is avoided, time and labor are saved, comprehensive inspection of a product is facilitated, and the production efficiency and the product quality are improved.

Owner:安徽弘徽科技有限公司

Space pipe bending equipment

InactiveCN109127822AImprove efficiencyGood qualityShaping toolsMetal-working feeding devicesEngineeringInduction coil

The invention relates to the technical field of pipe bending machining machinery, in particular to space pipe bending equipment. The space pipe bending equipment comprises a machine base, a bending mechanism located at one end of the machine base, a clamping mechanism located at the rear end of the bending mechanism, a propelling mechanism located at the rear end of the clamping mechanism, and a heating mechanism located above the bending mechanism and / or the clamping mechanism; a gap is formed between the bending mechanism and the clamping mechanism, an induction coil is arranged on the heating mechanism, and the induction coil is located in the gap; the bending mechanism comprises a moving device, and the moving device loads a pipe to be bent to move in the left-right direction relativeto the clamping mechanism; the propelling mechanism moves forwards on the machine base by adopting a screw rod and nut principle; and the pipe to be bent passes through the bending mechanism, penetrates through the induction coil and the clamping mechanism, and then is clamped on the propelling mechanism. According to the space pipe bending equipment, the traditional process of first welding and then bending is fundamentally changed, so that the hidden danger of a weld root in the bent pipe is avoided, an innovation of the technology in the field is achieved, and the important progress significance is achieved.

Owner:QINGDAO NPA IND

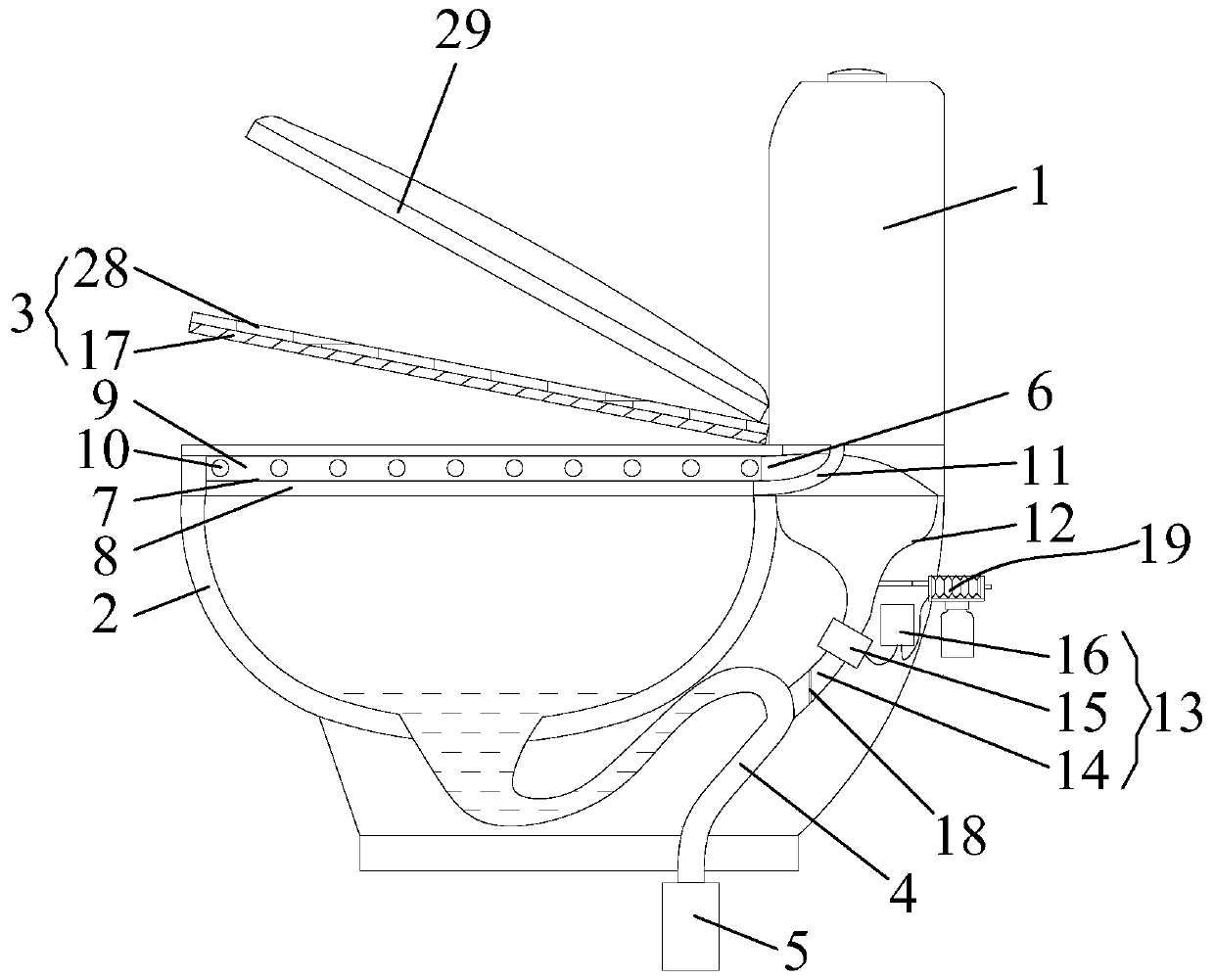

Toilet with ventilation function

InactiveCN107514037BGuaranteed diameterDon't worry about the service lifeBathroom coversLavatory sanitorySiphonToilet

The invention discloses a toilet with a ventilation function. The toilet comprises a water tank, a toilet body, a seat ring and a siphon pipe, the seat ring is hinged to the top of the toilet body, and the siphon pipe is located on the bottom in the toilet body; an inner cavity of the toilet body is communicated with one end of the siphon pipe, the other end of the siphon pipe is used for being connected with a drain pipe, and the water tank and the toilet body are of an integrated structure; a cavity is formed in the top of the toilet body, the cavity is divided into a water channel in the lower portion and an air channel in the upper portion through a partition plate, and the air channel is communicated with the inner cavity through a plurality of air holes; the water channel is communicated with the inner cavity through a plurality of drain holes, the water tank is communicated with the portion, close to the water tank, of the water channel through the drain pipe, and an air exhausting device is connected with the portion, close to the water tank, of the air channel through a main air pipe. The toilet with the ventilation function has the air exhausting function, can effectively remove the odor, and effectively improves the toilet environment.

Owner:RUGAO FUDA ENG & TECH RES INST CO LTD

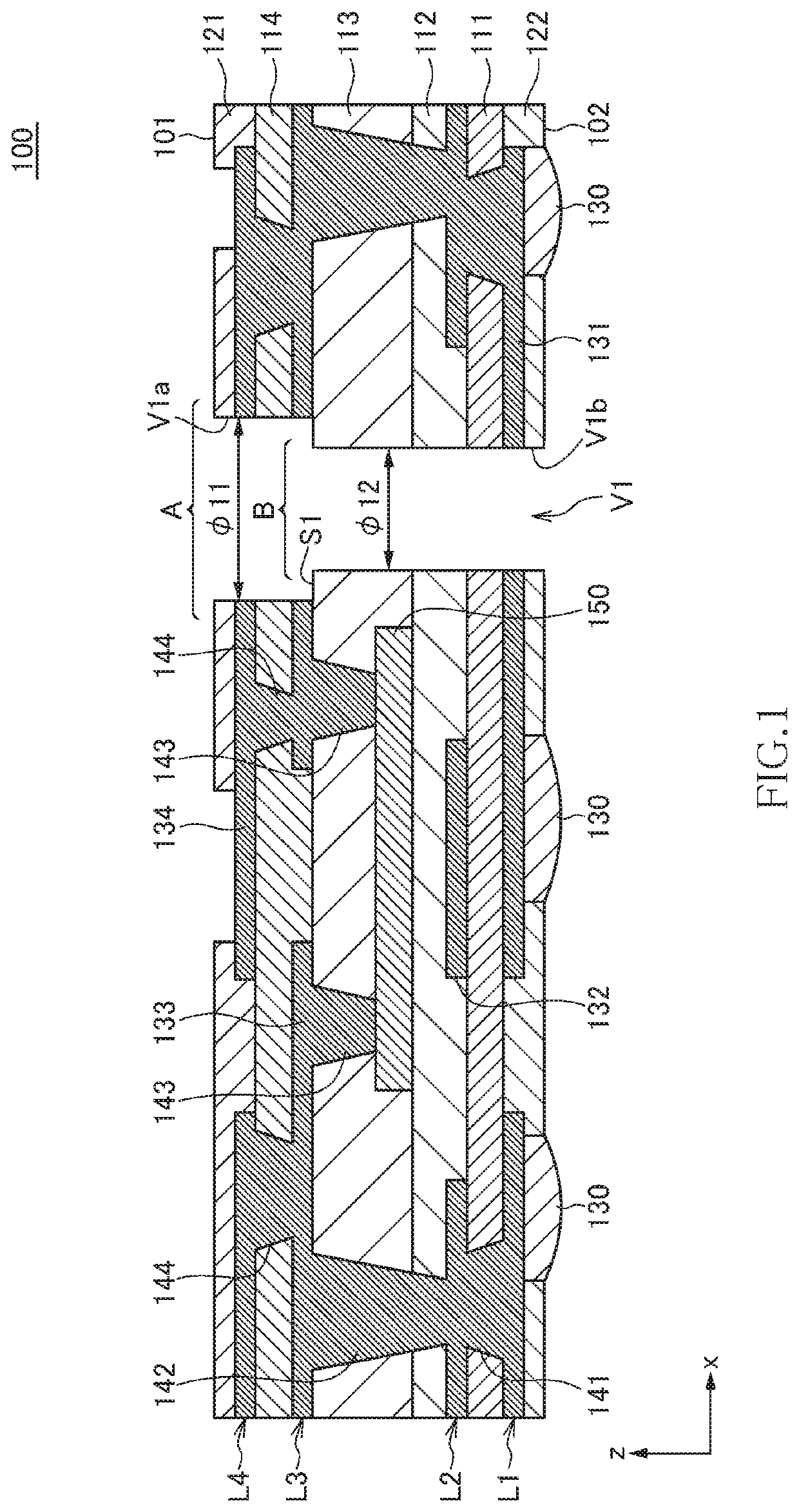

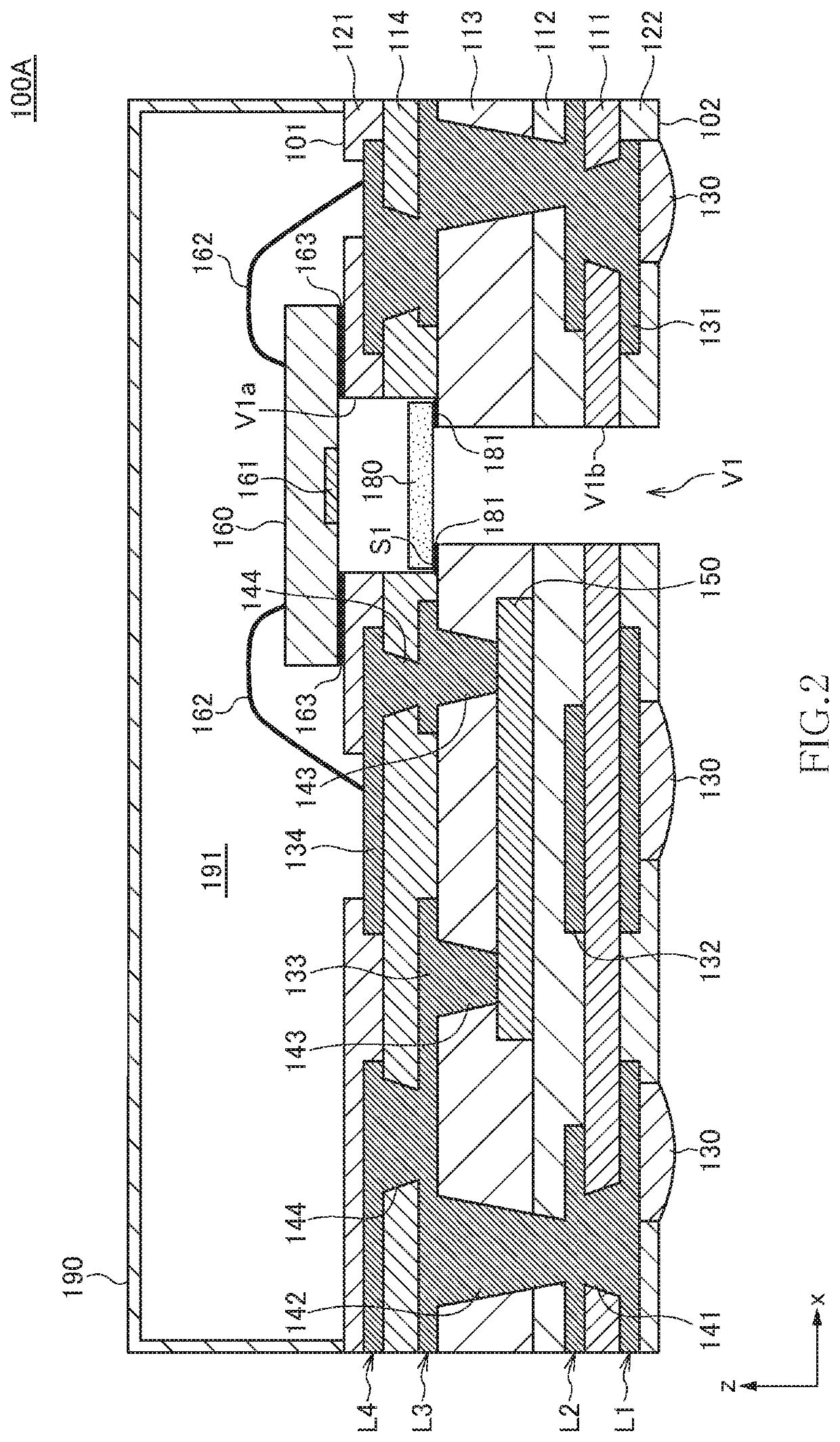

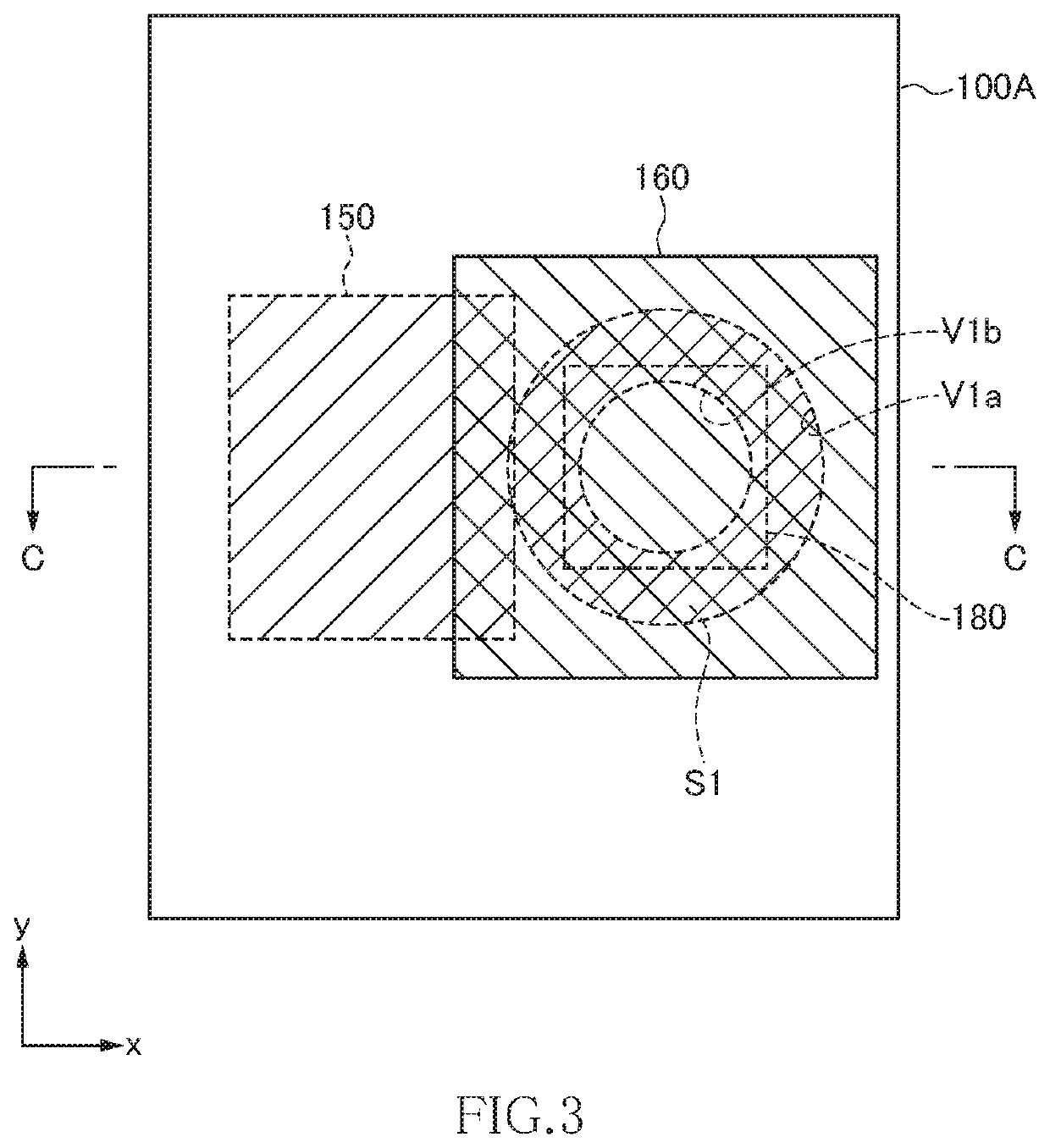

Sensor package substrate and sensor module having the same

ActiveUS20200109047A1Stably disposeEasy to shapeTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringMechanical engineering

Disclosed herein is a sensor package substrate that includes a first mounting area for mounting a sensor chip. The sensor package substrate has a through hole formed at a position overlapping the first mounting area in a plan view so as to penetrate the sensor package substrate from one surface to the other surface. The through hole includes a first section having a first diameter and a second section having a second diameter smaller than the first diameter. A step part inside the through hole positioned at a boundary between the first and second sections constitutes a second mounting area for mounting an anti-dust filter.

Owner:TDK CORPARATION

Cultivation equipment for quickly burying seedling raising cup

ActiveCN110800424AReduce manual operation timeEasy to operateWatering devicesTransplantingAgricultural scienceAgricultural engineering

The invention relates to the field of seedling raising, in particular to cultivation equipment for quickly burying a seedling raising cup. The technical problem is how to provide the cultivation equipment for quickly burying the seedling raising cup, wherein the equipment does not need to consume a large amount of manual time and can dig a pit hole to satisfy the placement of the seedling raisingcup. The cultivation equipment for quickly burying the seedling raising cup comprises a mounting handle, a placing box and the like, wherein the placing box is arranged on the left lower side of the mounting handle. The mounting box is moved downwards by pressing the mounting handle downwards, and a soil pulling device pulls away the soil under the placing box, so that the equipment is simple in operation, does not need to consume a large amount of manpower to carry out pit excavation, and can ensure that the diameter of the soil pit pulled away each time is equal; and by starting a watering device to irrigate a seedling bag in the process of moving a transverse moving rod rightward, the manual operation time for burying and cultivating the seedling bag can be saved .

Owner:长沙博观生物科技有限公司

Wastewater filtering equipment for stewing sanitary napkins

InactiveCN112742088ASpeed up emissionsReduce cloggingStationary filtering element filtersFiberWastewater

The invention discloses wastewater filtering equipment for stewing sanitary napkins. The structure of the wastewater filtering equipment comprises a machine body, a liquid inlet pipe, a residue discharge pipe and drainage pipes, the liquid inlet pipe is fixed to the top of the machine body, the residue discharge pipe is vertically welded to the center of the bottom face of the machine body, and the drainage pipes are arranged on the two sides of the machine body respectively. Wastewater contains a fiber material, the fiber material absorbs water, expands and adheres to drainage holes in a filter screen, a pushing mechanism swings under the thrust of liquid, the filter screen is impacted in the swinging process, the filter screen vibrates, and substances adhering to the inner wall fall off, so that blockage of the drainage holes of the filter screen is reduced, the wastewater drainage speed is increased, and the wastewater filtering speed is further increased; and due to the fact that the outer wall of the push block is an uneven surface, a small amount of substances are prone to remaining on the outer wall of a push block, a removing roller in the clamping groove is movably matched with the push block, a scraping block removes the substances remaining on the outer wall of the push block, the diameter of the outer wall of the removing block can be kept, and the speed of the removing block entering a filter screen drainage hole can be increased.

Owner:李惠明

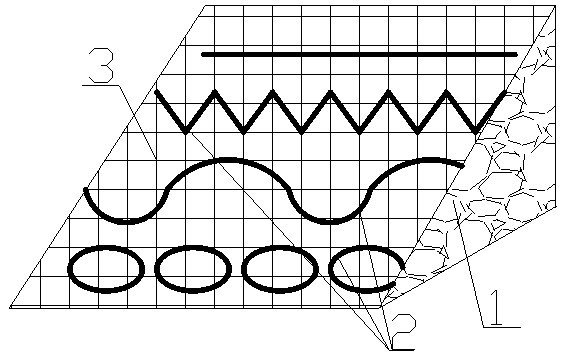

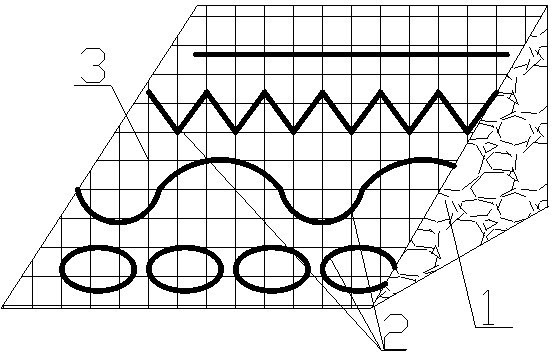

Slope protection structure by using plant growing rope to conduct karst side slope nursing

The invention discloses a slope protection structure by using a plant growing rope to conduct karst side slope nursing. The slope protection structure comprises a side slope (1) needing nursing. The plant growing rope (2) made of a weaving rope is placed on the side slope (1), a soil engineering net (3) is covered above or below the plant growing rope (2), and the plant growing rope (2) is connected onto the soil engineering net (3). The plant growing rope is paved on a slope where vegetation regeneration is required to be conducted. The plant growing rope is used for preventing artificial soil sprayed on the slope and a nutrition matrix containing seeds from falling from the slope, providing an attaching platform for attaching the artificial soil and the nutrition matrix containing the seeds to a palisades slope, well guaranteeing unfolding of roots when the plant grows, and laying a good foundation for growing of the plant. The plant growing rope is made of a grass-nature weaving rope, preferentially a hemp rope, therefore preventing effect is improved, production cost is reduced, and the diameter of the plant growing rope can be guaranteed. Compared with a plant growing plate, the plant growing rope has good flexibility and can be attached to the slope closely, and the preventing effect on the artificial soil is improved.

Owner:GUIZHOU JIAOKAN ECOLOGICAL GARDENS

Water utilization coefficient farmland water level monitoring equipment

PendingCN113029277ASpeed up filteringLarge thrustMachines/enginesLevel indicatorsEnvironmental engineeringMoss

The invention discloses water utilization coefficient farmland water level monitoring equipment which structurally comprises a reading dial, a connecting pipe and a water inlet pipe. As fine weeds are easily clamped in filter holes of a filter screen, an expansion plate is arranged at the bottom of a sliding ball, the expansion plate moves up and down to impact the filter screen so that the weeds in the filter holes of the filter screen fall off and are discharged, and the filter screen is pushed to vibrate so that impurities at the bottom shake and fall off. The filtering speed of liquid introduced into a connecting pipe can be increased, the thrust of the liquid to the sliding ball is increased, the moving speed of the sliding ball is increased, and the phenomenon that the water level monitoring value of a farmland monitored by a monitoring instrument is deviated is reduced. Due to the fact that liquid is introduced into a pipe body for a long time and moss grows on the inner wall of the pipe body, pushing blocks are arranged on the two sides of the sliding ball, the moss on the inner wall of the pipe body is removed through removing rings in the pushing blocks, the original diameter of the inner wall of the pipe body can be kept, and the sliding ball can freely move up and down in the pipe body.

Owner:严立敏

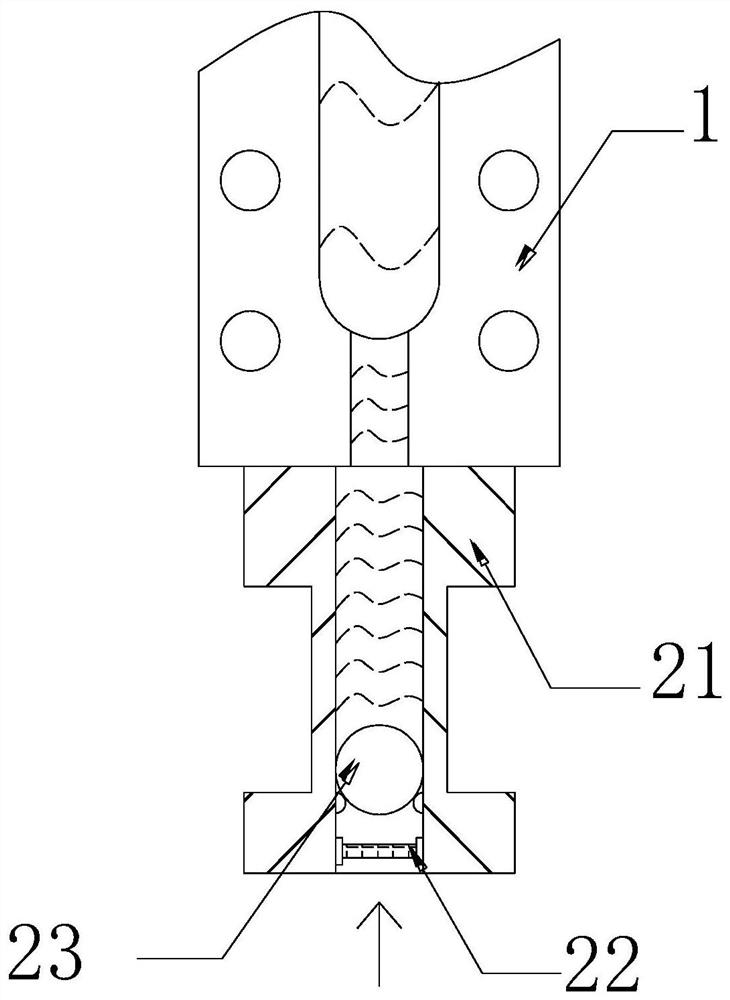

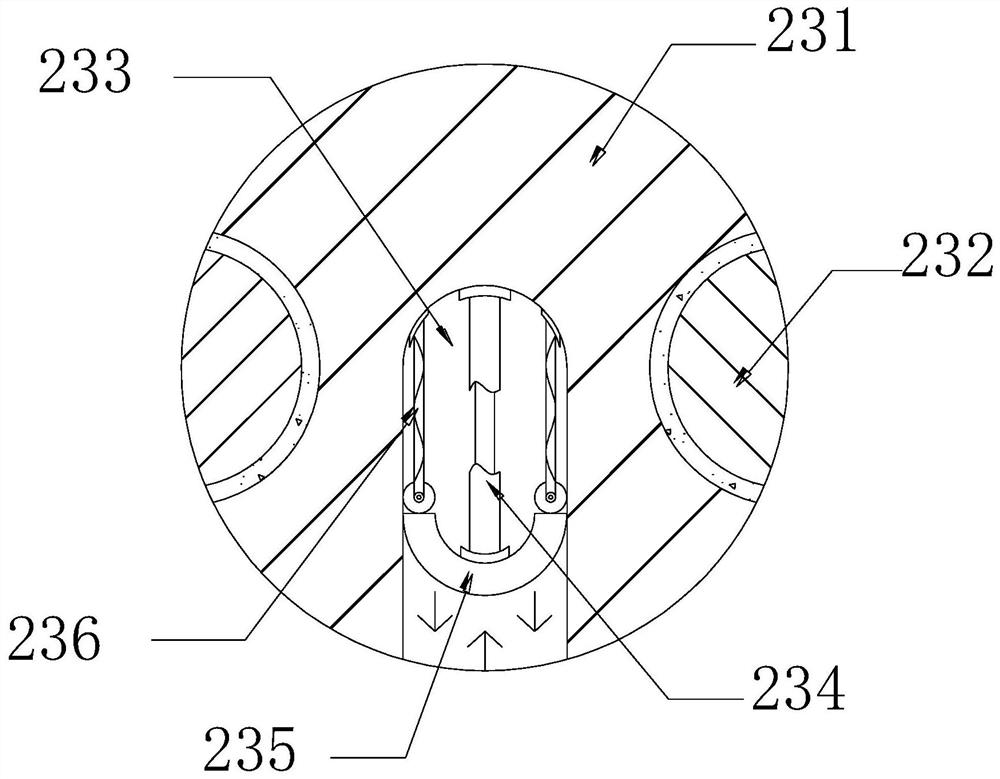

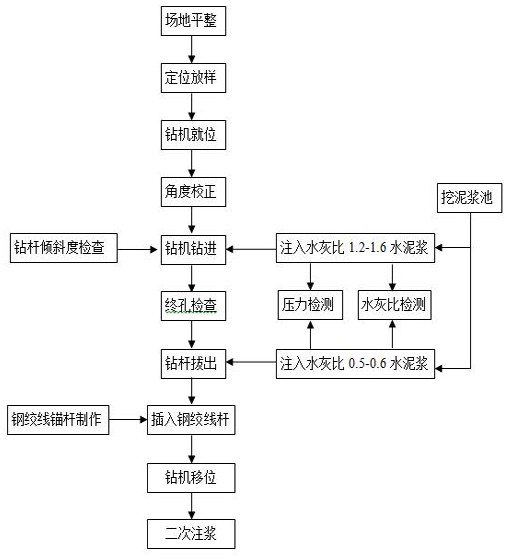

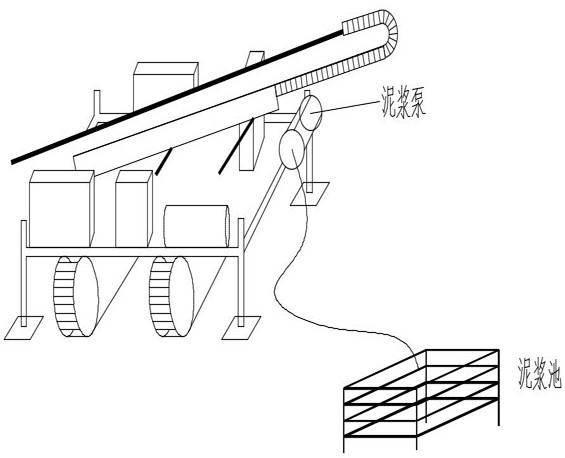

Construction method of full-bonding support anchor rod

InactiveCN111676966AAvoid collapsing holesAvoid neckingExcavationsBulkheads/pilesArchitectural engineeringSlurry

The invention relates to the technical field of building construction, and discloses a construction method of a full-bonding support anchor rod. The construction method of the full-bonding support anchor rod comprises the following operation steps of 1, leveling a site; 2, manufacturing the anchor rod; 3, positioning the position of the anchor rod; 4, preparing a drilling machine; 5, digging a mudpit; 6, enabling the drilling machine to be in place; 7, drilling by the drilling machine; 8, mounting the anchor rod; 9, carrying out hole opening slurry supplementing and secondary grouting; and 10, carrying out tensioning. According to the construction method of the full-bonding support anchor rod, in the support anchor rod construction under the unfavorable geology of silty clay and the like,the phenomena of hole collapse and necking in the anchor rod hole forming process can be effectively avoided, and it is guaranteed that the diameter of an anchor hole meets the design requirement; and the plumpness of cement paste in an anchor rod formed hole is completely guaranteed through the mud replacement technology and the secondary grouting technology, the full length of the support anchor rod is fully bonded with cement mortar, it is guaranteed that an anchor rod body makes full contact with a soil body, the bonding friction resistance between the anchor rod body and the soil body isenhanced, and therefore the foundation pit supporting strength is guaranteed.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

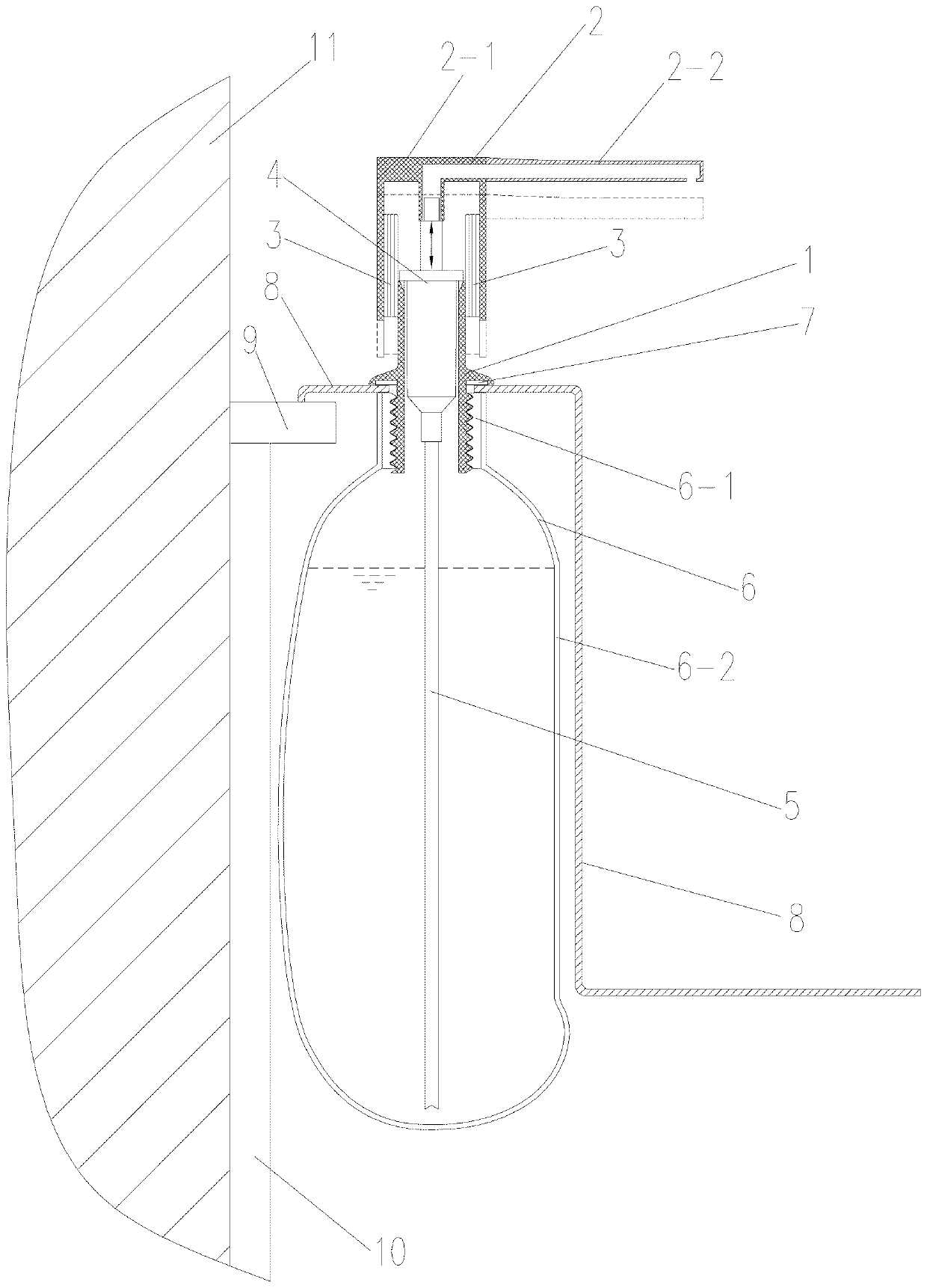

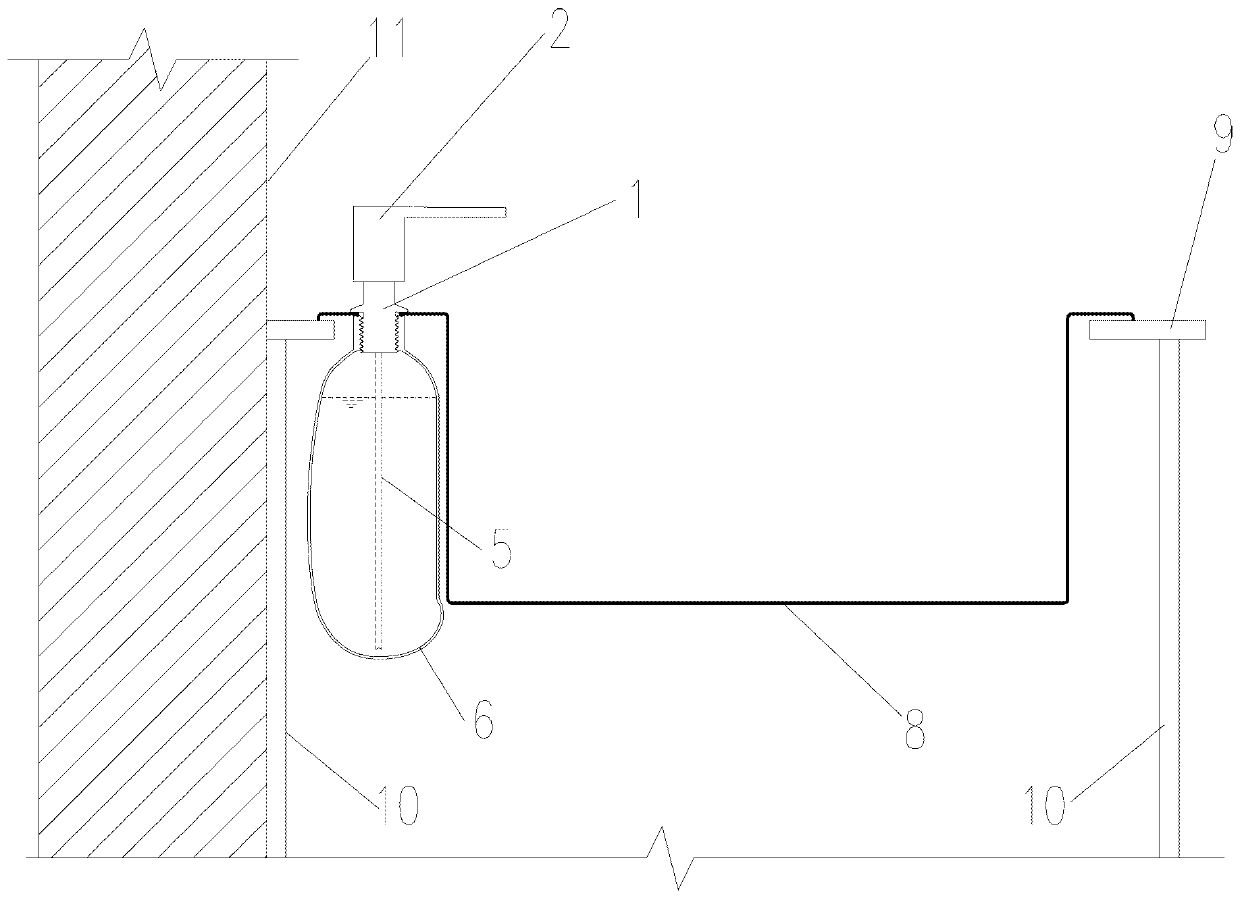

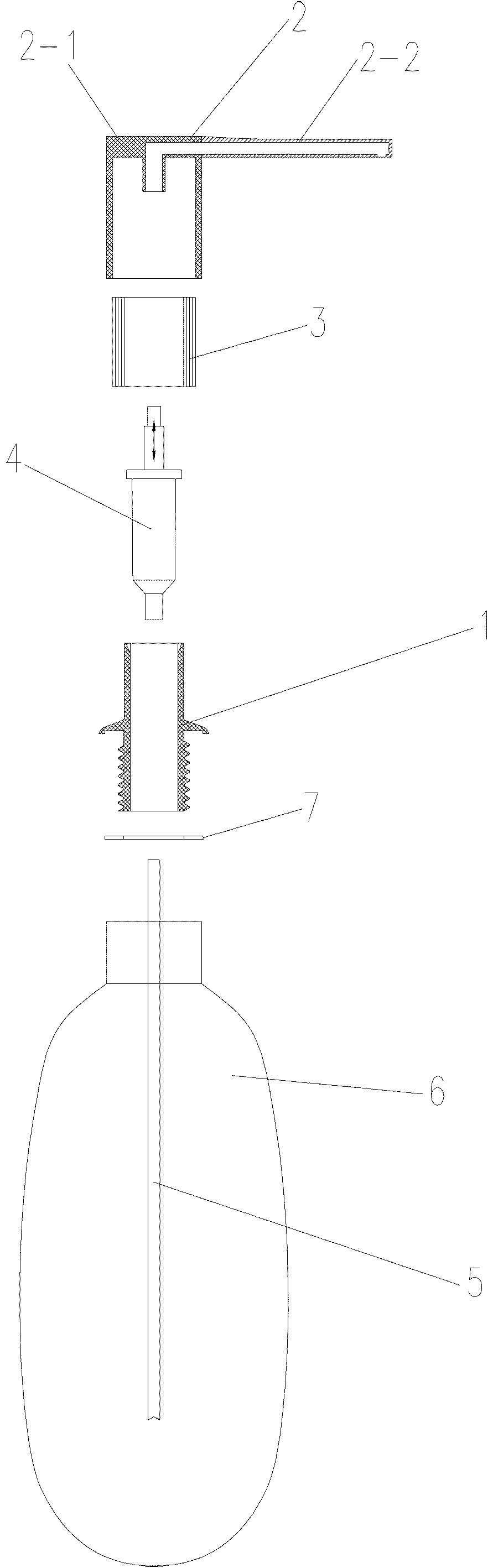

Large-volume soap dispenser

InactiveCN109998411AExtend the life cycleEasy to connectHolders and dispensersThreaded pipeEngineering

The invention relates to a large-volume soap dispenser capable of being mounted on a sink. The large-volume soap dispenser is composed of a connecting sleeve, a pressing head, a linear bearing, a liquid soap pump, a liquid soap pipe, a liquid soap bottle and a sealing pad, wherein two small gaps are arranged at the inner side of an upper opening part of the connecting sleeve, the gaps are clampedby adopting thin steel sheets or coins, the connecting sleeve is rotated, an external threaded pipe is arranged at the lower part of the connecting sleeve, the connecting sleeve passes through a roundhole of the sink to be connected with internal threads of the opening of the liquid soap bottle, and the liquid soap bottle adopts a flexible bag; and the linear bearing is arranged in the pressing head, so that the sliding performance with the connecting sleeve is increased. For the soap dispenser, the liquid soap bottle adopts the flexible material, meanwhile, during the mounting process, the self-rotation is not needed, and therefore, super-large-volume liquid soap bottles of various shapes can be adopted; the internal threads of the opening of the liquid soap bottle can be taken as a locking nut for connecting of the soap dispenser with the sink, and the structure is simple; and due to the linear bearing, the eccentric pressing operation of the pressing head can be realized.

Owner:上海班升科技有限公司

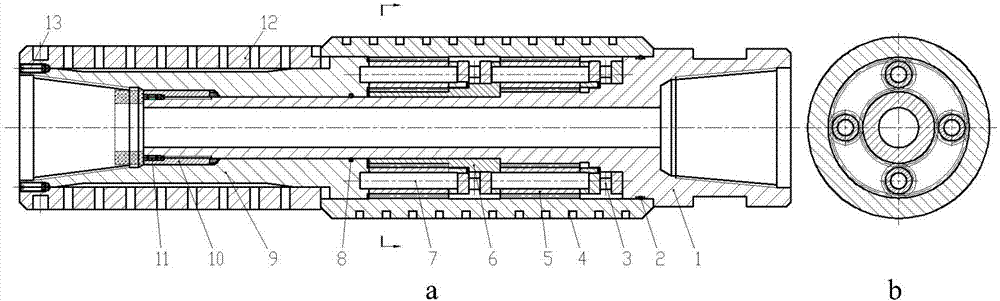

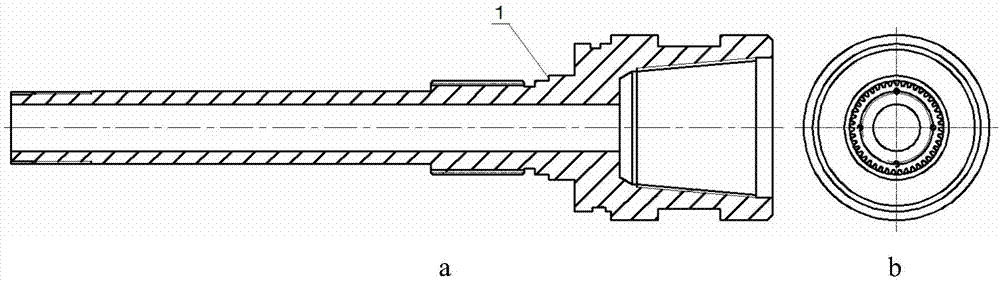

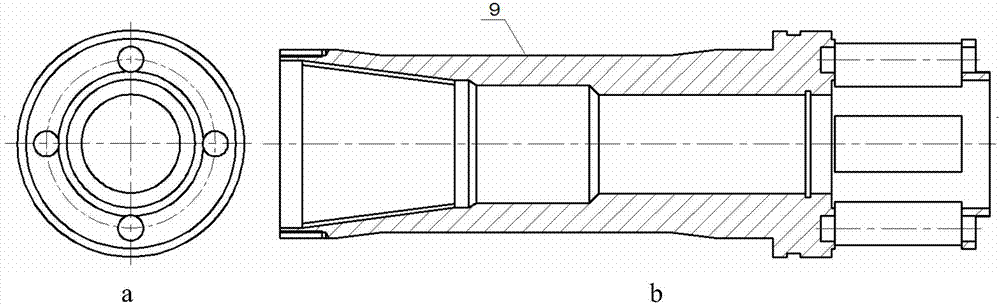

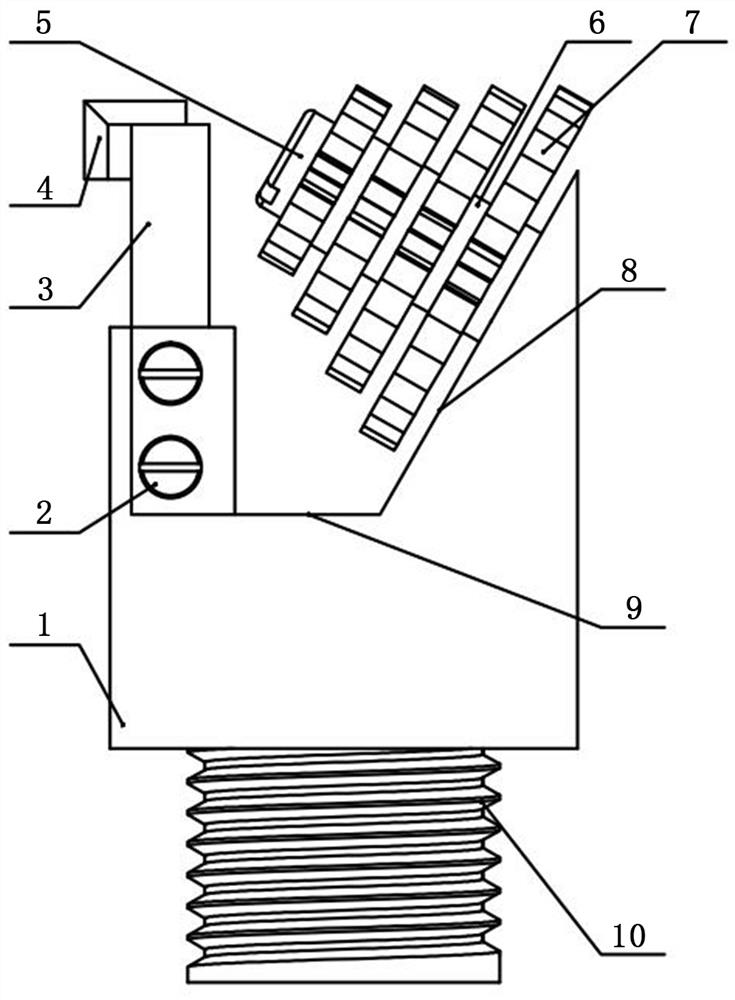

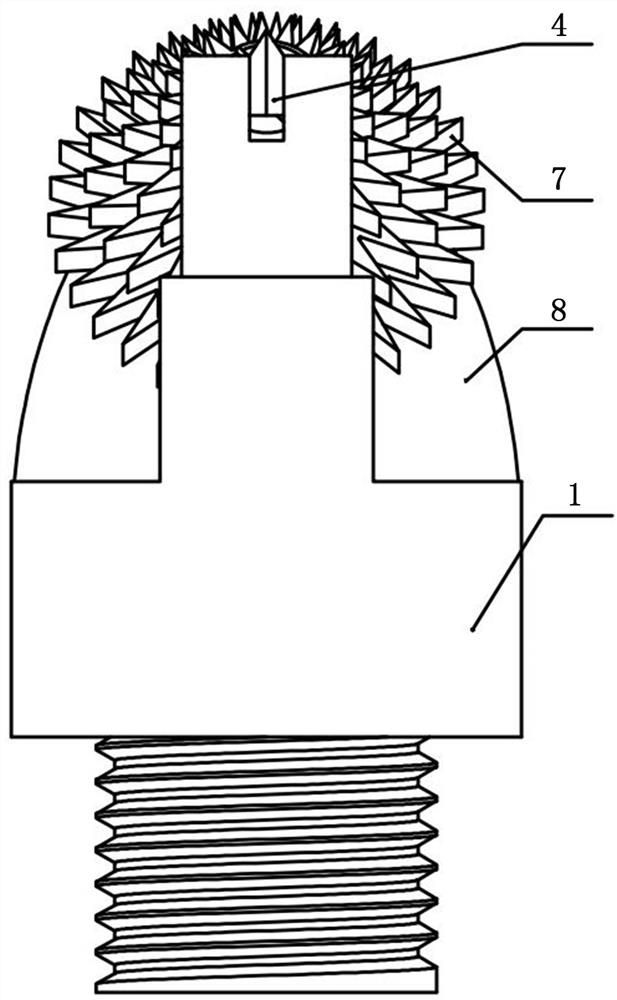

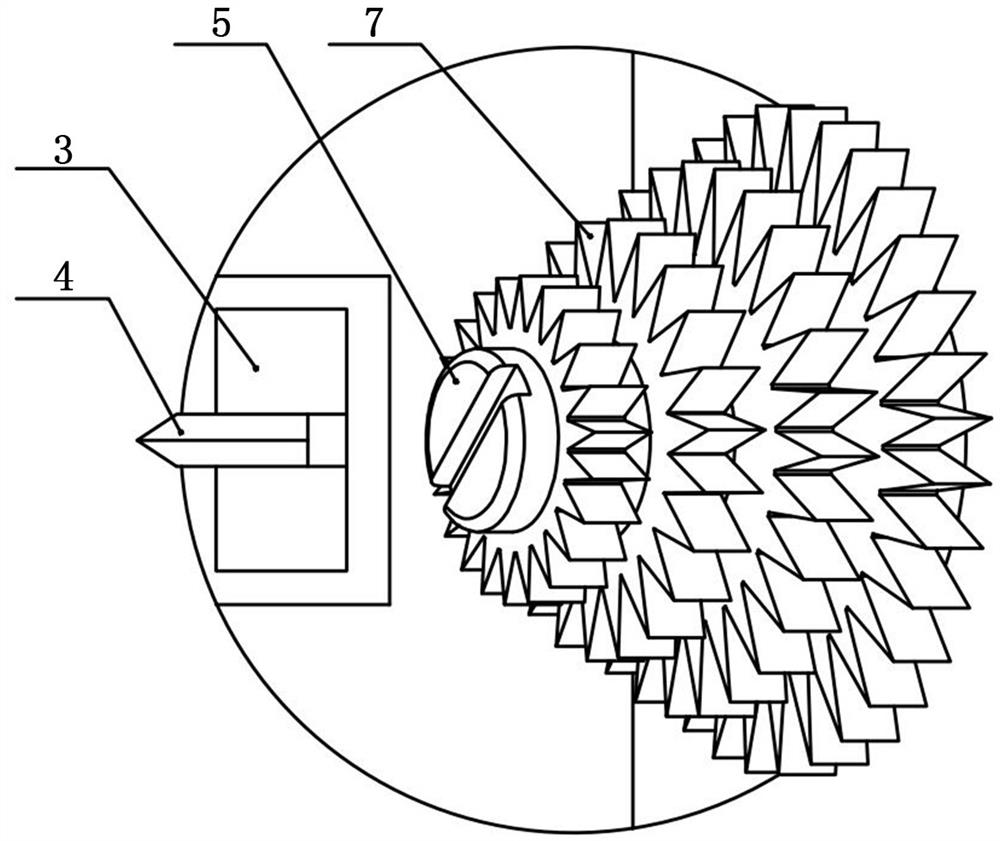

Miniature roller bit suitable for indoor micro-drilling test in oil and gas drilling industry

The invention provides a miniature roller bit suitable for an indoor micro-drilling test in the oil and gas drilling industry. The technical problems of well bottom mode change, low effective drilling depth, large test data error and rock core waste of a miniature roller bit in the prior art are solved. The miniature roller bit comprises a drill bit seat (1), and the drilling face of the drill bit seat (1) is composed of an inclined face (8) and a horizontal face (9); a roller shaft (5) is fixed on the inclined face (8), the roller shaft (5) is perpendicular to the inclined face (8), and a roller is mounted on the roller shaft (5); and a lengthening rod (3) is fixed on the horizontal face (9), and gauge protection teeth (4) are connected to the lengthening rod (3). According to the miniature roller bit, the roller ensures that the well bottom is always a horizontal face, and the gauge protection teeth (4) ensure that the diameter of a well bottom broken pit is not changed in the drilling process, so that continuous drilling on one rock core is realized, invalid drilling is reduced, rock core waste is avoided, and the indoor micro-drilling test efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com