Space pipe bending equipment

A space bending pipe and equipment technology, applied in the direction of metal processing equipment, forming tools, feeding devices, etc., can solve the problems of far-reaching influence on the use of pipe bending, low quality pass rate, and difficult grinding of solder joints, so as to avoid internal welding Root hidden dangers, good quality, and the effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

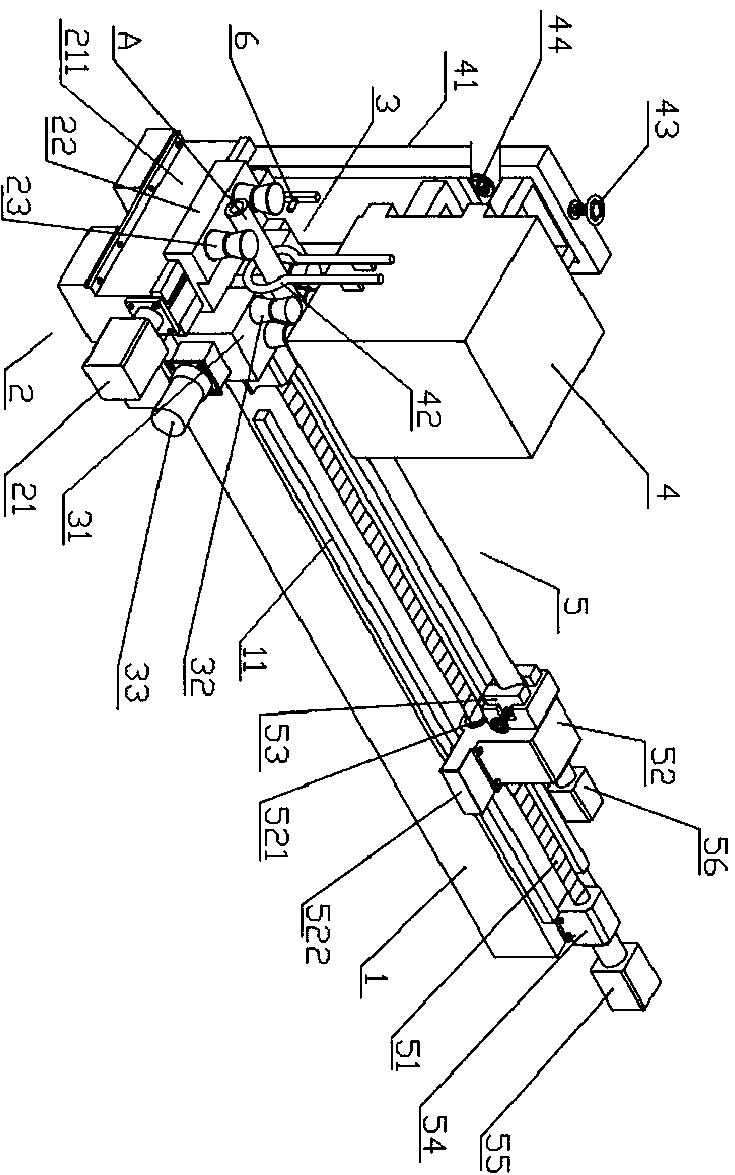

[0018] A space bending device of the present invention will be described in detail below with reference to the accompanying drawings.

[0019] like figure 1 As shown, a space bending equipment includes a machine base 1, which is a cuboid structure, which is convenient for loading other structures. A bending mechanism 2 is installed on the front end of the above-mentioned machine base 1 , and the bending mechanism 2 is directly installed and fixed on the machine base 1 .

[0020] The specific structure of the bending mechanism 2 is as follows: the bending mechanism 2 includes a screw power device 21 and a moving device 22 coupled to the screw power device through a nut. The screw power device 21 is laterally fixed on the machine base 1 by the carriage frame 211 on the side, and the screw power device 21 realizes power transmission by a driving motor. The screw power unit 21 is provided with a screw as the name implies, and the moving device 22 is provided with a nut, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com