High-pressure jet grouting system and construction method with controllable ground pressure and no mud discharge

A high-pressure injection and grouting system technology, which is applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as the difficulty of discharging excess mud, achieve significant beneficial effects, ensure construction quality and progress, and comprehensive process design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

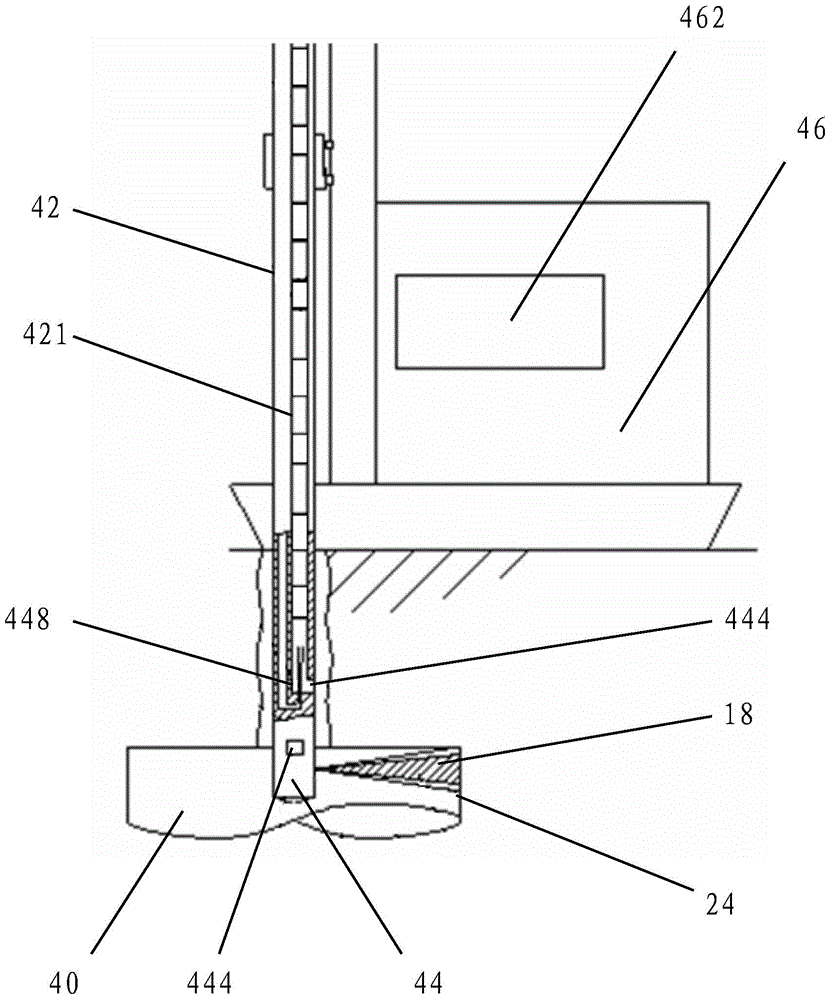

[0073] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

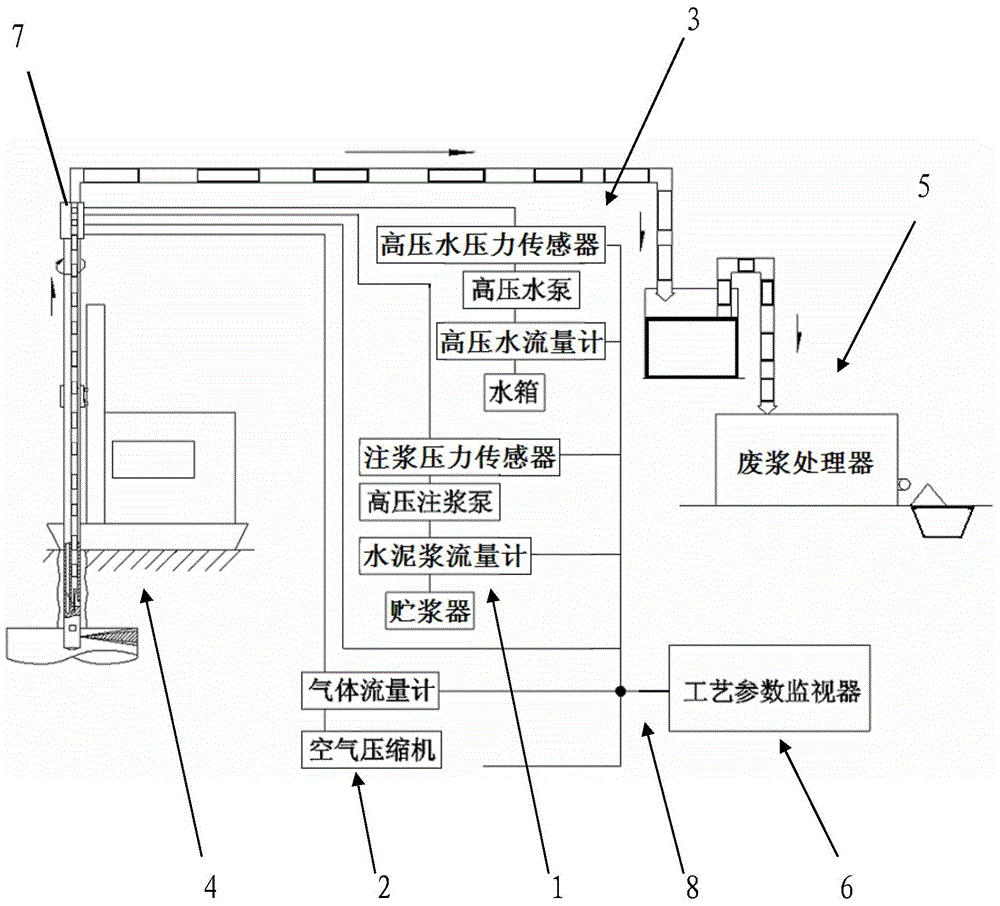

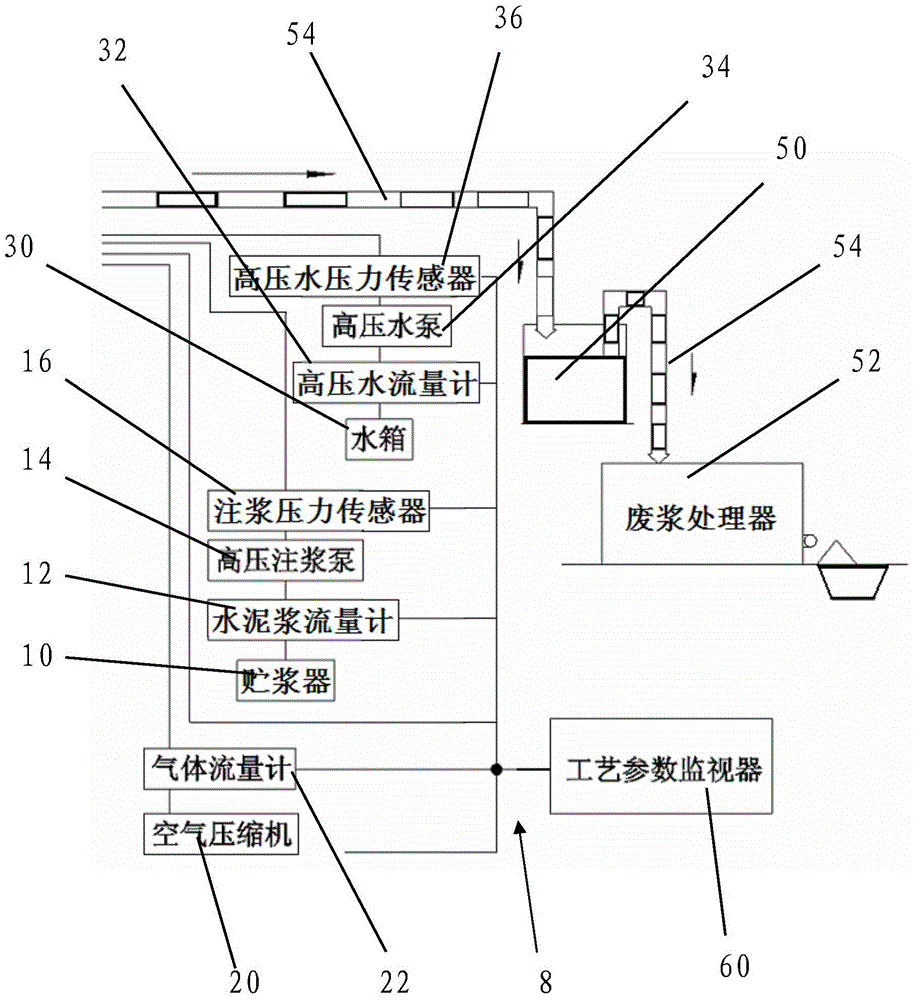

[0074] refer to figure 1 and Figure 7 As shown, the present invention is a high-pressure grouting construction device with controllable internal pressure and no mud leakage. The process of the present invention includes related equipment and construction methods, and aims to solve the problem of uncontrolled discharge of excess mud resulting in ground uplift, and dehydrate the waste mud to ensure construction quality and reduce environmental pollution.

[0075] Such as figure 1 Shown, the high-pressure jet grouting system of the present invention comprises:

[0076] High-pressure cement slurry pumping assembly 1, used for high-pressure pumping to prepare mixed slurry;

[0077] The air injection assembly 2 is used to deliver compressed air to form an air jet during grouting;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com