Inertial confinement and induction drilling device with PDC drill bit

A technology of inertial restraint and drilling device, which is applied to the driving device, drill pipe, drill pipe and other directions for drilling in the wellbore, which can solve the problems of high energy consumption, unsuitable drilling, and no inertial restraint drilling device. , to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

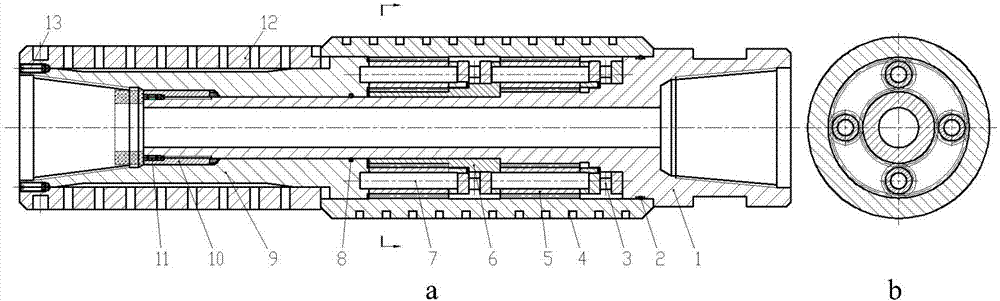

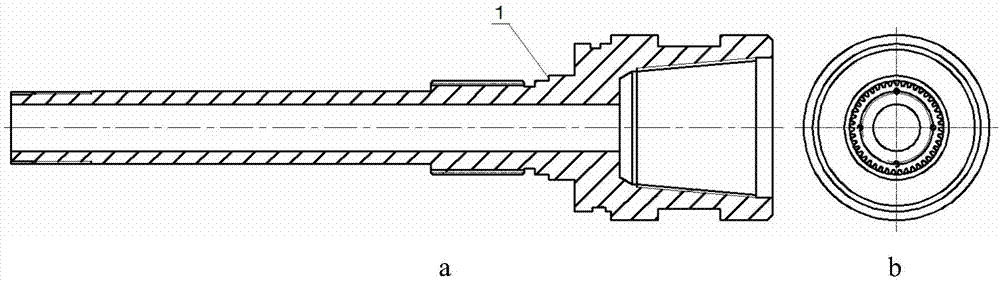

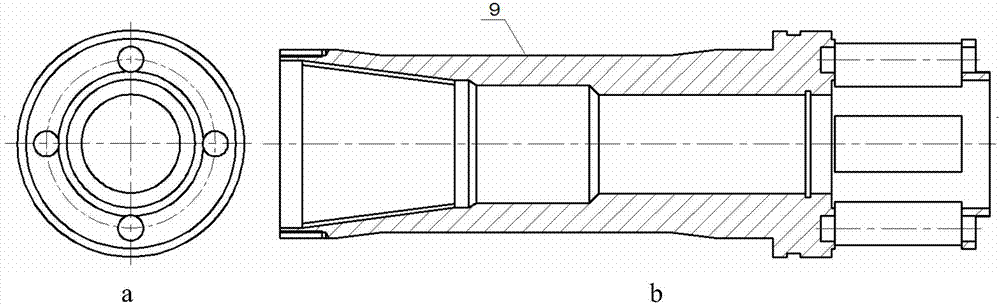

[0043] This embodiment is an inertial constrained drilling device accompanied by a PDC drill bit, which includes a male gear input shaft 1, an inertia double ring gear 4, a planetary gear 5, an end face pressure bearing 3, a planetary carrier output shaft 6, a planetary gear shaft 7, Small sliding bearing bush 8 and multi-head torsion spring 12.

[0044] Wherein: the planetary carrier 6 is set on the outer circumferential surface of the sun gear input shaft 1, and the four planetary gear shafts 7 are evenly distributed on the surface of the planetary carrier; the eight planetary gears 5 are equally divided into two groups, and all the planetary gears are divided into two groups. The two sets of planetary gears are axially arranged on the shafts of the planetary gears, wherein the first set of planetary gears is connected to the drill collar end close to the input shaft of the sun gear; the end face of the first set of planetary gears is connected to the sun gear The inner end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com