Integrated surgical instrument drive device with decoupling function

A technology of surgical instruments and driving devices, which is applied in the direction of surgery, surgical instruments, obstetrics and gynecology instruments, etc. It can solve the problems of unfavorable adjustment of the position of surgical instruments and easy vibration of the system, so as to reduce the working area, increase the volume and quality, reduce the The effect of collision probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

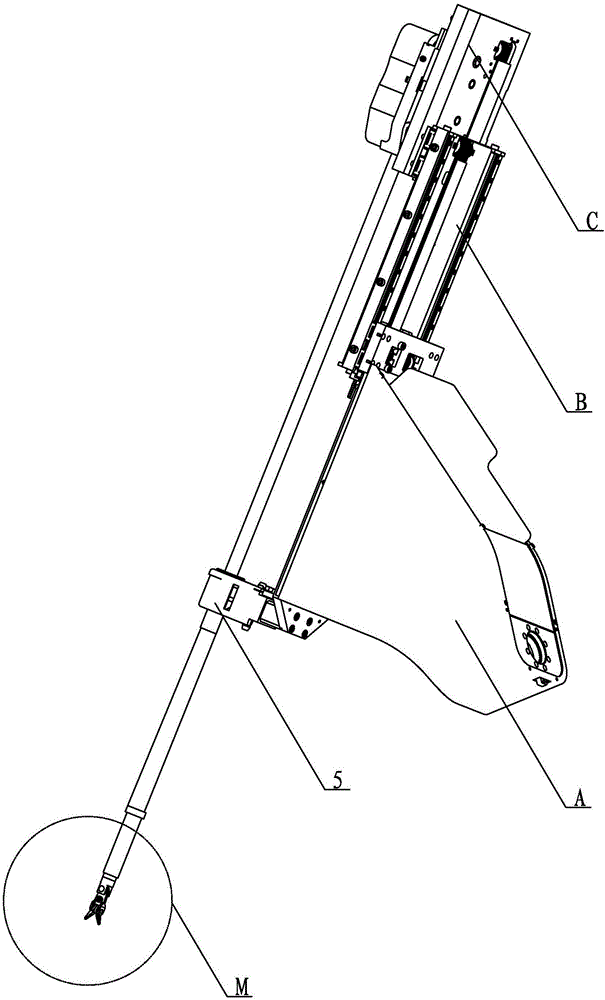

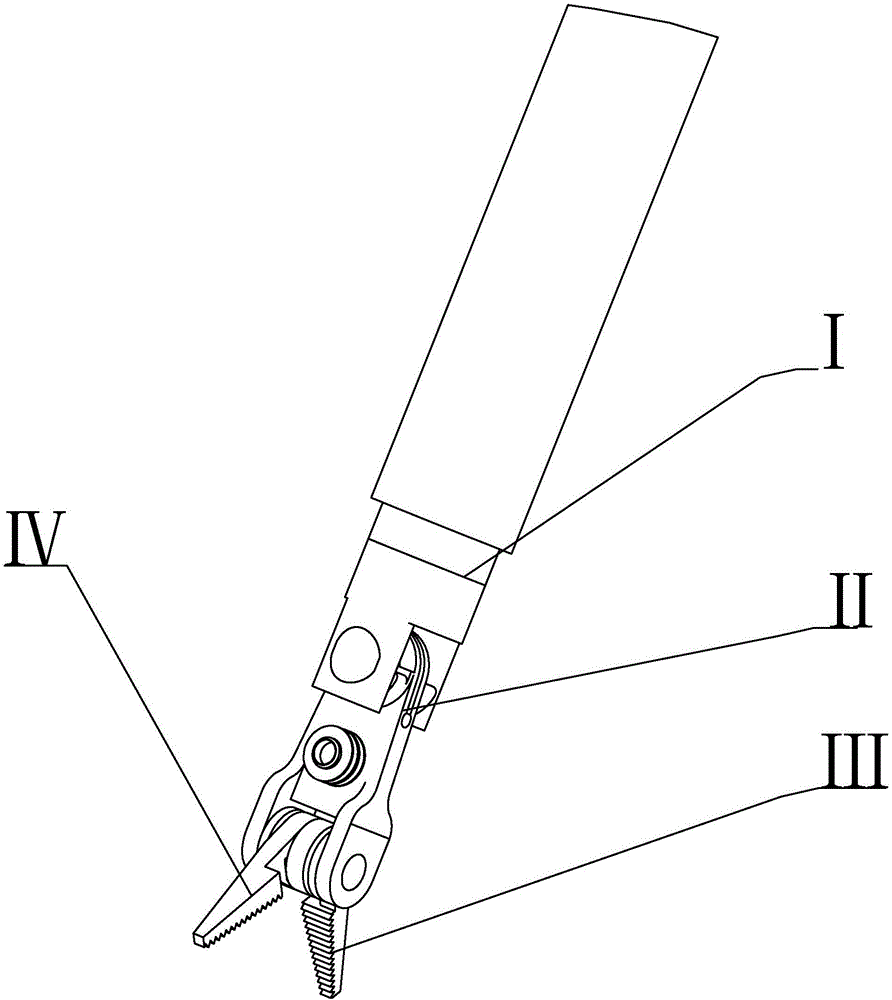

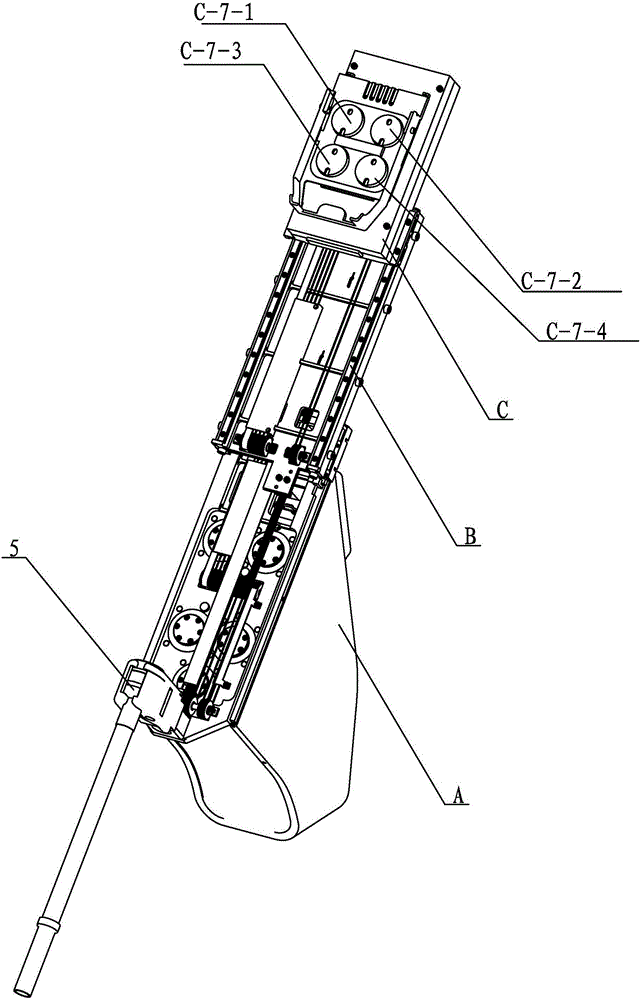

[0019] Specific implementation mode one: combine Figure 1-Figure 35 Describe this embodiment. This embodiment includes a power source assembly A, a decoupling transition assembly B, an interface assembly C, and multiple winding wires D. The power source assembly A, decoupling transition assembly B, and interface assembly C can slide sequentially from bottom to top are interlaced and connected in a decoupled winding manner by a plurality of winding wires D,

[0020] The power source assembly A includes a drive support plate A-1, a drive assembly A-2, a guide wheel assembly A-3 and a slider assembly A-4, and the drive assembly A-2 is installed on the first drive support of the drive support plate A-1 On the end surface A-1-a of the plate, the guide wheel assembly A-3 is installed on the second drive support plate end surface A-1-b, the third drive support plate end surface A-1-c and the second drive support plate end surface A-1-c of the drive support plate A-1 respectively. O...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 19 Explain that the power source assembly A of this embodiment also includes a power source cover A-5, a driver A-8, a guide shaft A-6 and a winding wire fixing assembly A-7 at the power source, and the power source cover A-5 Covered on the drive support frame A-1 and multiple drive components A-2, the winding wire fixing component A-7 at the power source is installed on the drive support plate A-1, the driver A-8 and the guide shaft A-6 are installed On drive support frame A-1. With this embodiment set up in this way, the power supply is more stable. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 23 and Figure 33 Explain that the drive assembly A-2 of this embodiment includes five motor drive assemblies, respectively the first motor drive assembly A-2-a, the second motor drive assembly A-2-b, the third motor drive assembly A-2- c. The fourth motor drive assembly A-2-d and the fifth motor drive assembly A-2-e, wherein the structures of the five motor drive assemblies are the same and different in that the helix of the second motor drive assembly A-2-b The wheel is a double wire wheel A-2-9, and the first motor drive assembly A-2-a includes a drive motor A-2-1, a motor support frame A-2-2, a harmonic reducer A-2-3, Drive spiral wheel A-2-4, drive rotation shaft A-2-5, drive spiral support block A-2-6 and drive cover A-2-7, drive motor A-2-1 is installed on the motor support frame One end of the body A-2-2, one end of the driving screw shaft A-2-5 is connected with the flex spline of the harmonic reducer A-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com