Instrument holding mechanical arm used for minimally-invasive robot

A technology of manipulator and robot, applied in the field of medical equipment, can solve the problems of low rigidity, large volume of passive arm manipulator, large number of passive joints, etc., to achieve the effect of increasing volume and quality, reducing the probability of collision, and reducing the working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

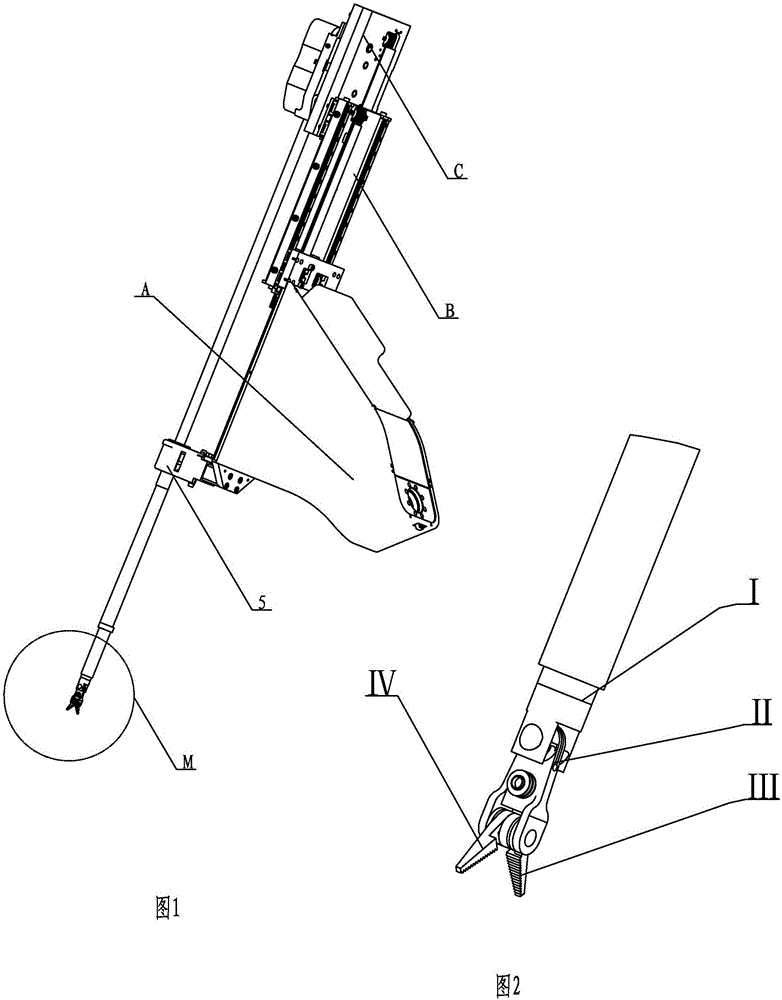

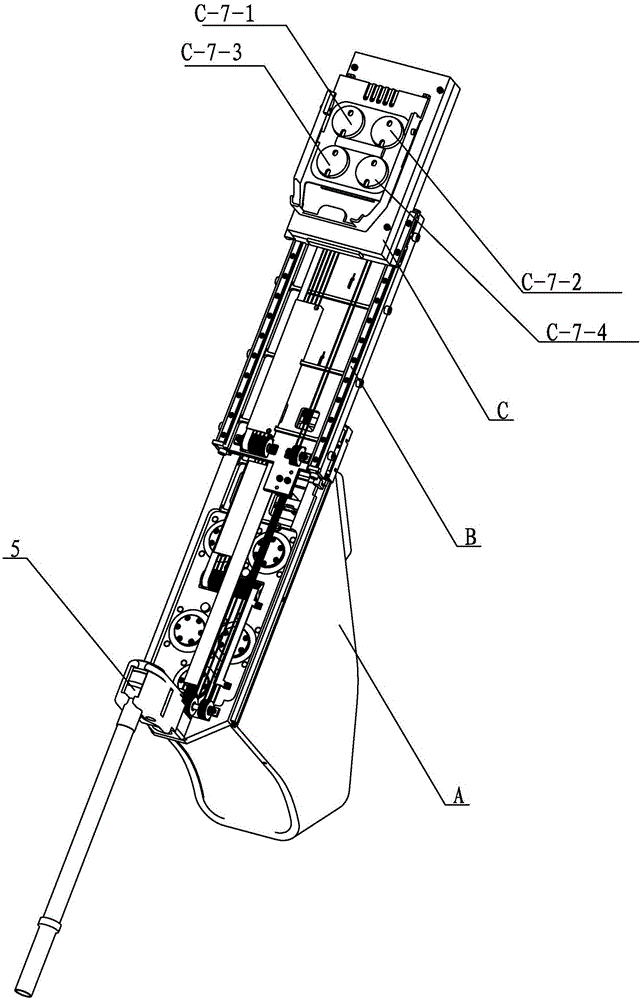

[0022] Specific implementation mode one: combine Figure 1-Figure 49 Describe this embodiment. This embodiment includes a vertical translation safety braking device, a passive joint P2, a first joint K1, a second joint K2 and an integrated surgical instrument drive device. One end of the passive joint P2 is rotatably mounted on the vertical translation On the upper part of the safety brake device, one end of the first joint K1 is rotatably connected to the passive joint P2, one end of the second joint K2 is rotatably connected to the other end of the first joint K1, and the integrated surgical instrument drive device is installed on the second The other end of the joint K2, the vertical translation safety braking device includes a base assembly 1, a guide rail assembly 2 and an outer end interface connector 3; the base assembly 1 includes a box body 1-1, a counterweight 1-2 and at least one Optical axis assembly, at least one optical axis assembly is arranged on the box body 1...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination Figure 19 Explain that the power source assembly A of this embodiment also includes a power source cover A-5, a driver A-8, a guide shaft A-6 and a winding wire fixing assembly A-7 at the power source, and the power source cover A-5 Covered on the drive support frame A-1 and multiple drive components A-2, the winding wire fixing component A-7 at the power source is installed on the drive support plate A-1, the driver A-8 and the guide shaft A-6 are installed On drive support frame A-1. With this embodiment set up in this way, the power supply is more stable. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

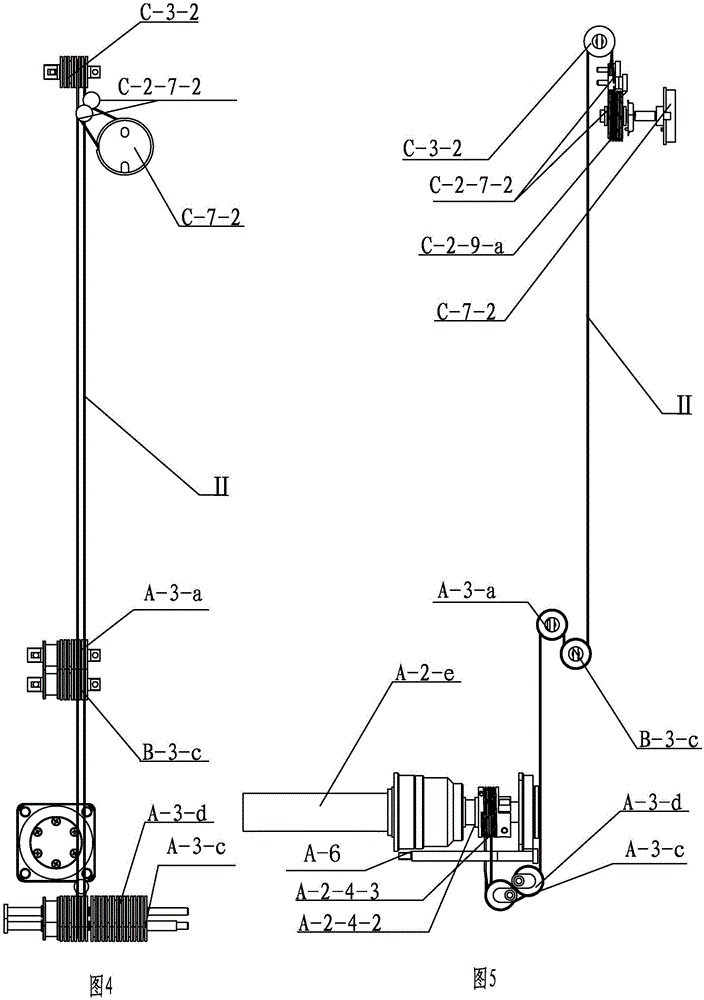

[0028] Specific implementation mode three: combination Figure 23 and Figure 33 Explain that the drive assembly A-2 of this embodiment includes five motor drive assemblies, respectively the first motor drive assembly A-2-a, the second motor drive assembly A-2-b, the third motor drive assembly A-2- c. The fourth motor drive assembly A-2-d and the fifth motor drive assembly A-2-e, wherein the structures of the five motor drive assemblies are the same and different in that the helix of the second motor drive assembly A-2-b The wheel is a double wire wheel A-2-9, and the first motor drive assembly A-2-a includes a drive motor A-2-1, a motor support frame A-2-2, a harmonic reducer A-2-3, Drive spiral wheel A-2-4, drive rotation shaft A-2-5, drive spiral support block A-2-6 and drive cover A-2-7, drive motor A-2-1 is installed on the motor support frame One end of the body A-2-2, one end of the driving screw shaft A-2-5 is connected with the flex spline of the harmonic reducer A-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com