Large-volume soap dispenser

A soap dispenser and large-capacity technology, applied in the field of large-capacity soap dispensers, can solve the problems of difficult installation and operation, small capacity, inconvenient one-hand operation, etc., and achieve the effect of simplifying the connection method and prolonging the service cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

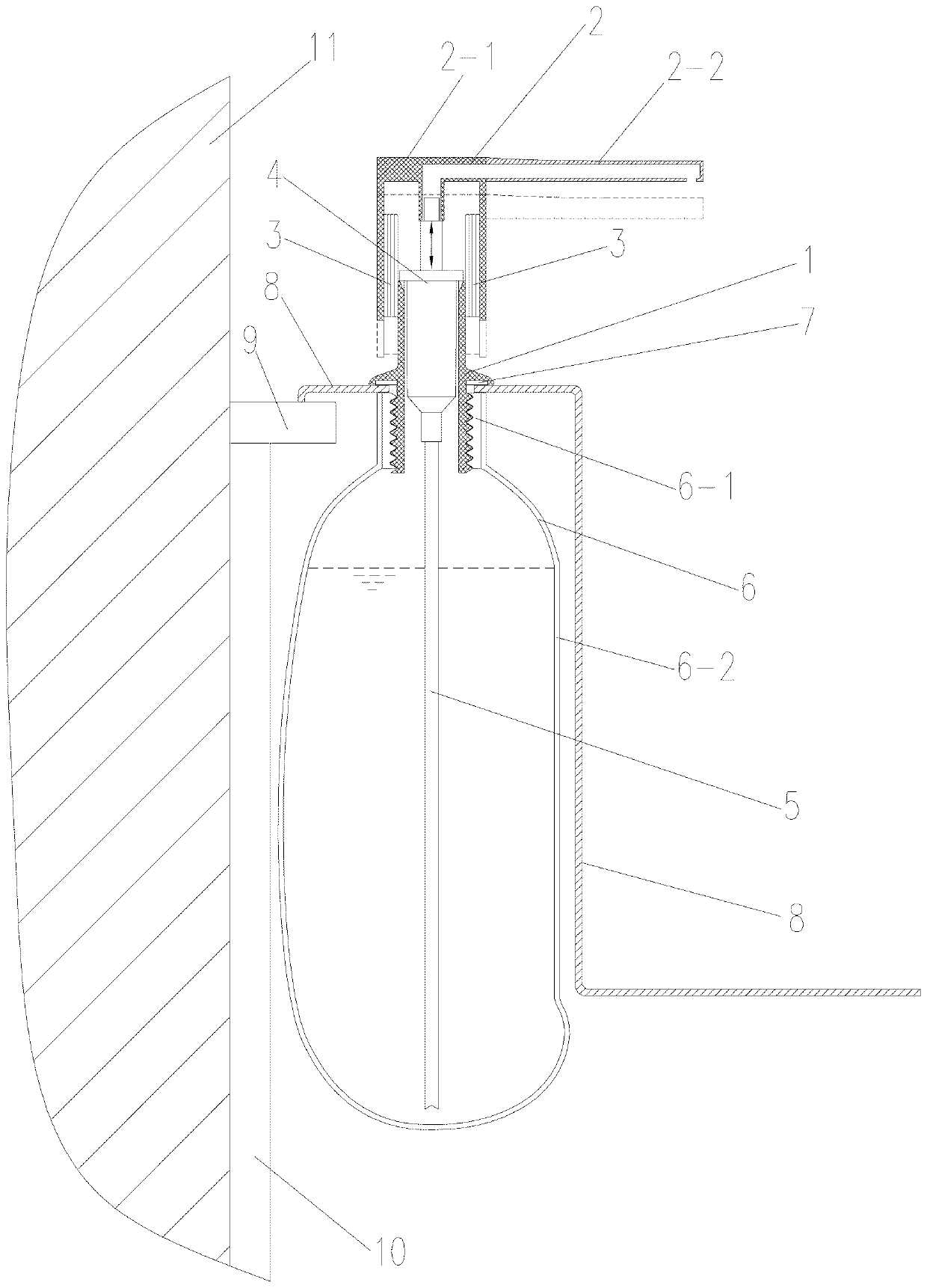

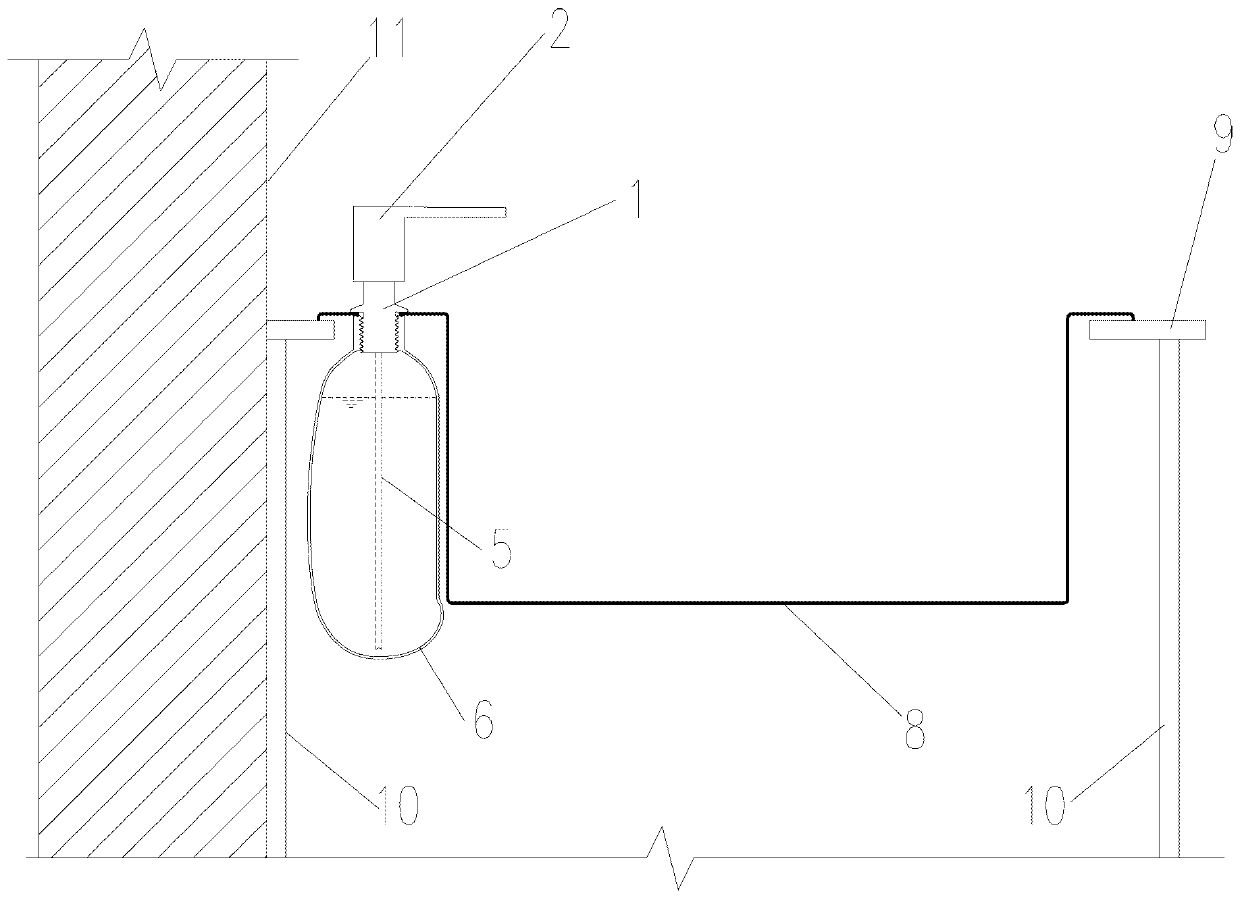

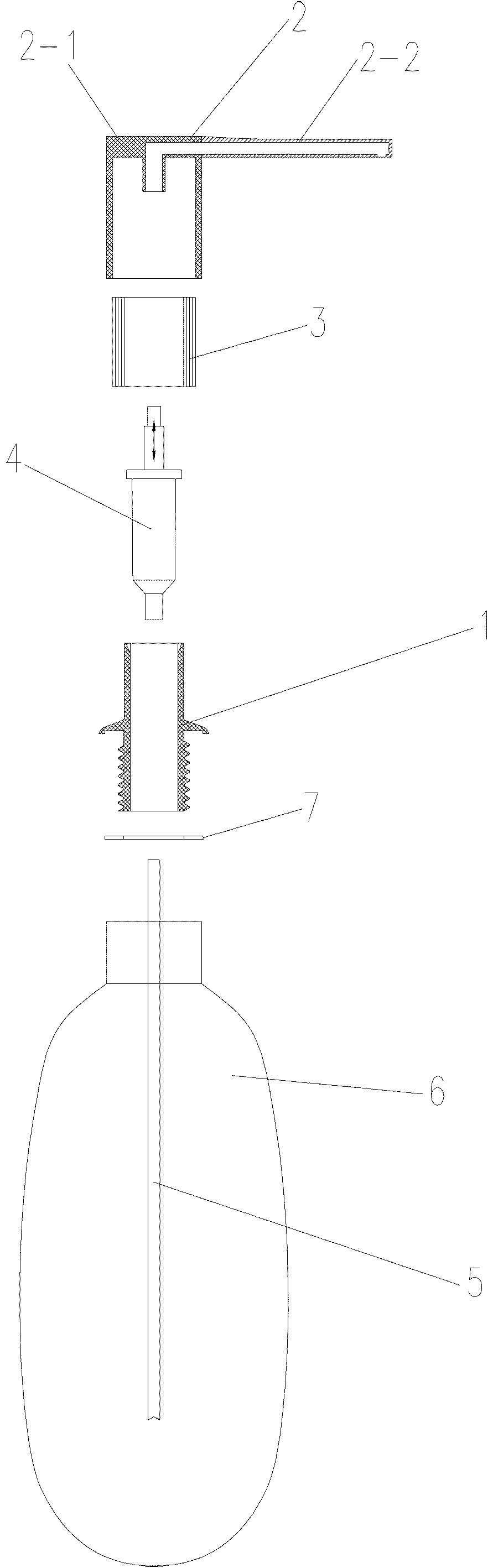

Embodiment 1

[0025] Example 1, the connecting sleeve 1 is made of stainless steel, with an inner diameter of 16 mm, an upper circular tube with an outer diameter of 20 mm, and a polished surface on the outside, and two small gaps with a width of 2 mm are set on the inside of the mouth, which can be stuck by coins or thin steel sheets The gap is rotated, and the middle part of the connecting sleeve 1 is provided with an enlarged skirt with an outer diameter of about 40mm. The lower part of the skirt is embedded with a 2mm thick gasket 7 to prevent leakage; the lower part of the connecting sleeve 1 is an M24 external thread pipe; the pressing head 2 is made of stainless steel Overall processing or welding forming, the inner diameter of the top cover 2-1 is 28mm, the inner diameter of the conduit 2-2 is 4mm, and the wall thickness is not less than 2mm. The linear bearing adopts a finished bearing or a polytetrafluoroethylene tube with an inner diameter of 20.5mm and an outer diameter of 28mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com