Device for manufacturing porous release film

A technology for manufacturing devices and isolation membranes, applied in metal processing and other directions, can solve the problems of high cost of perforated isolation membranes, increase the utilization rate of waste, and pollution of the environment by the bag film, so as to increase the utilization rate of waste, ensure the diameter and wear rate, etc. The effect of permeability and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

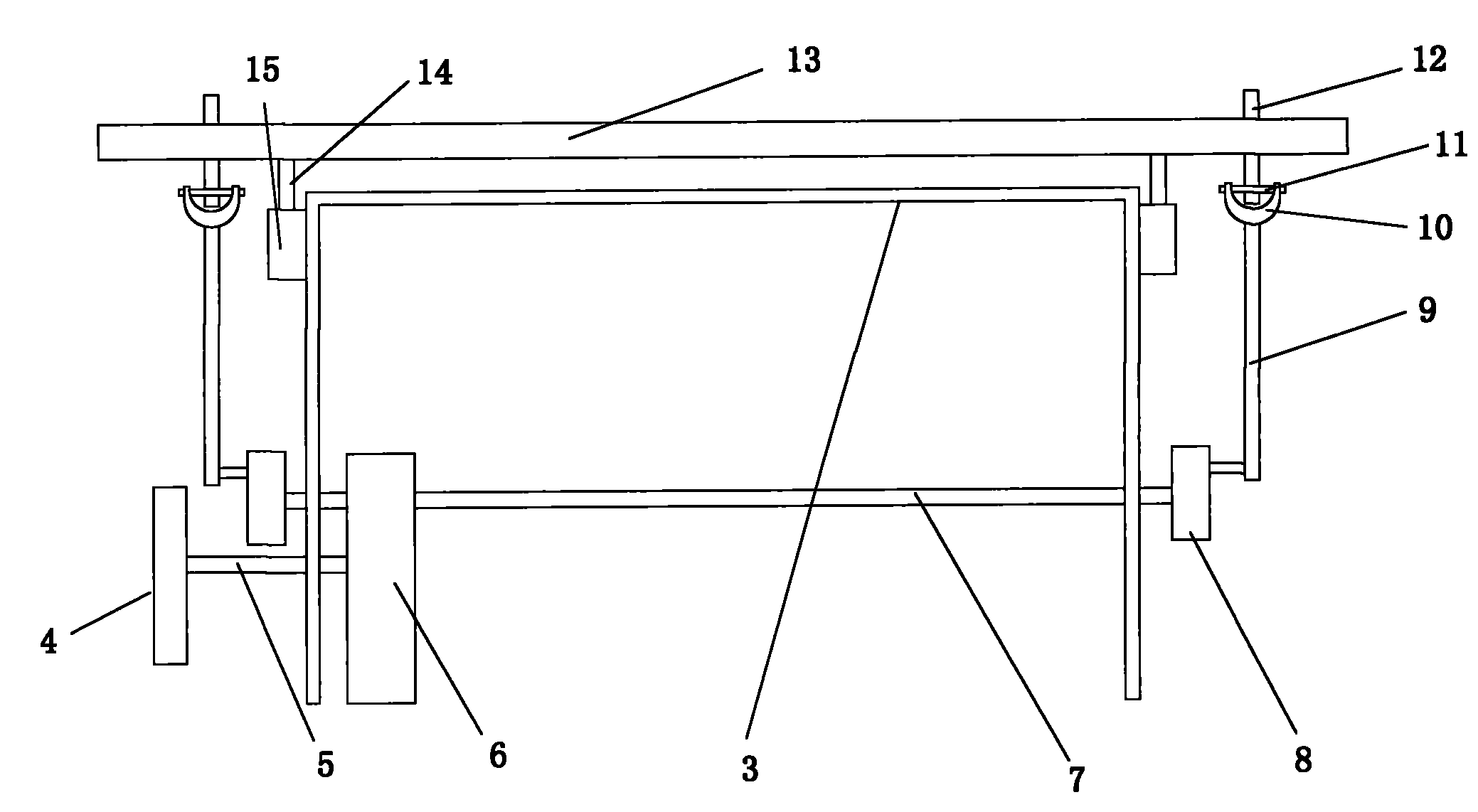

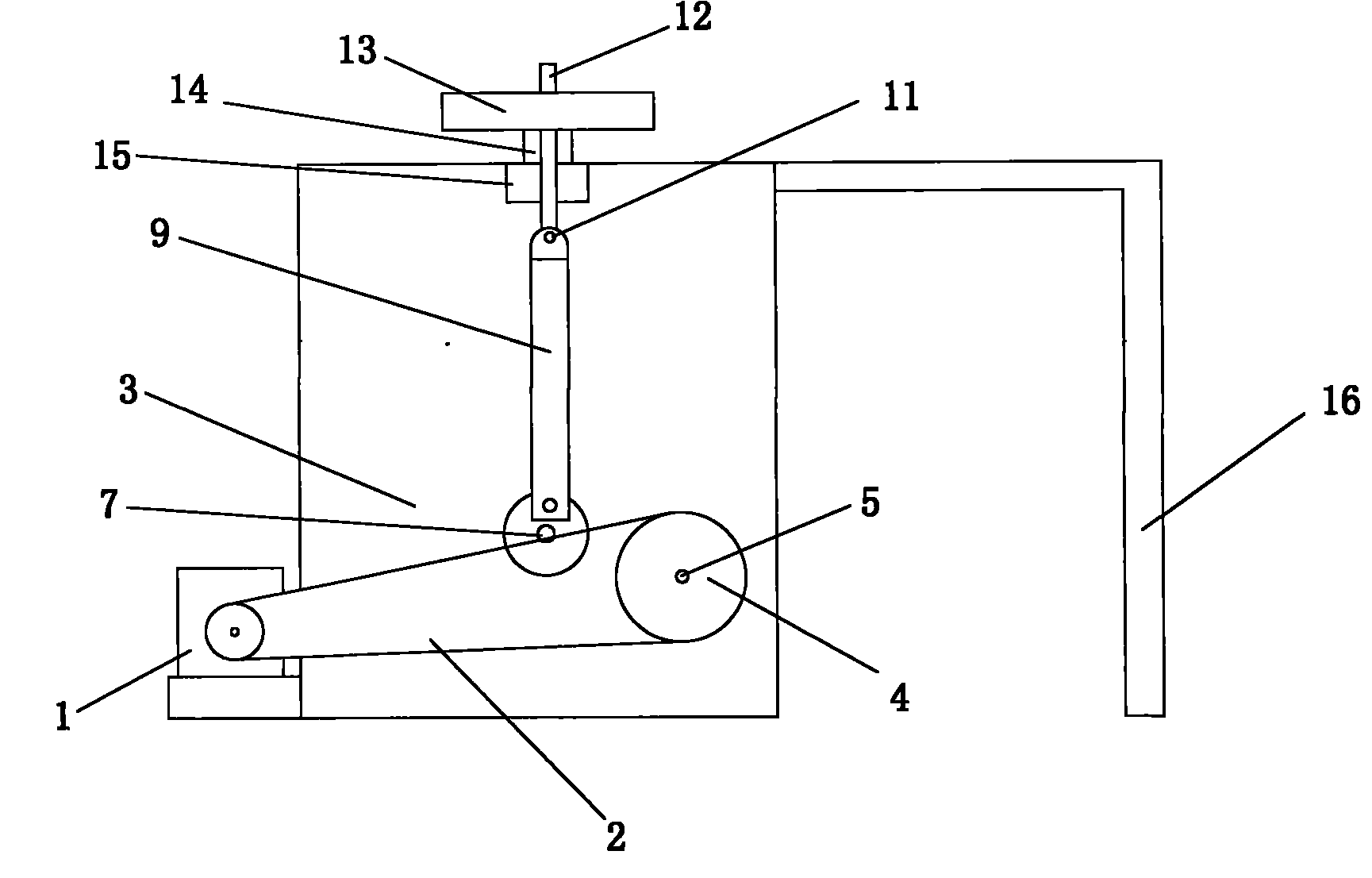

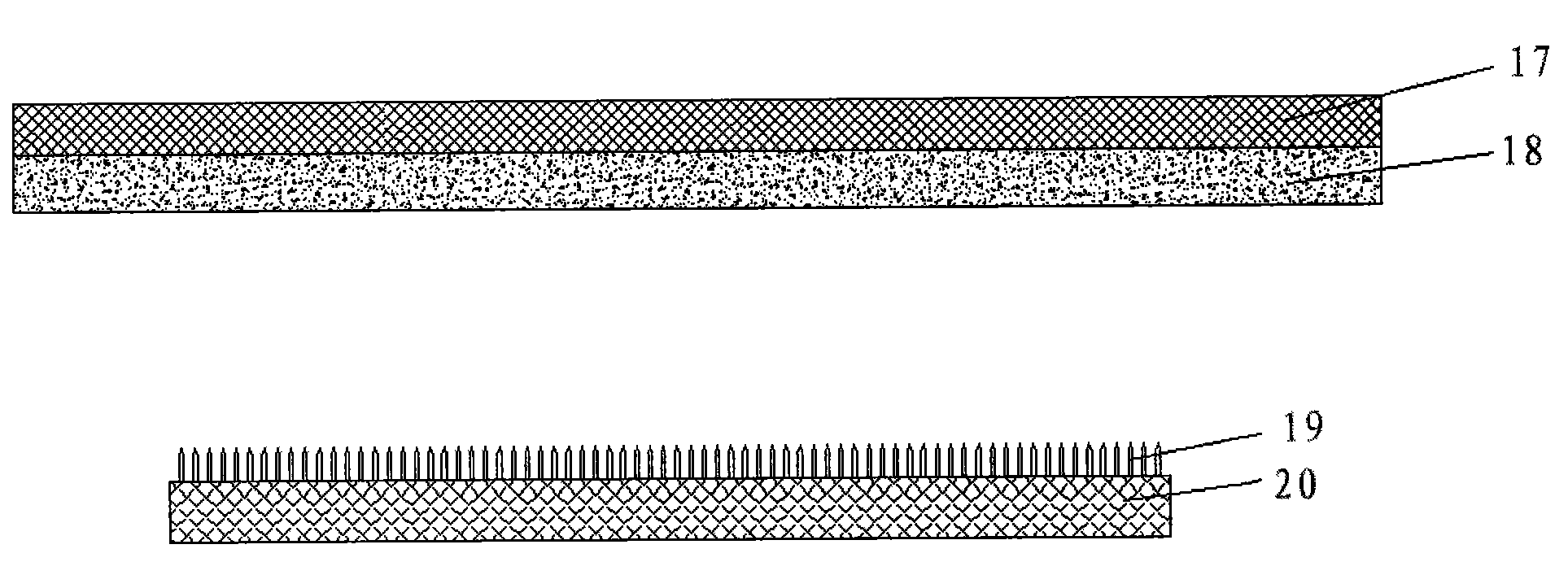

[0012] The following drawings further describe the present invention

[0013] Such as figure 1 with 2 As shown, a perforated isolation film manufacturing device includes a motor 1, a workbench 3, a reduction box 6, a pressing plate 13, a side frame 16 and a needle plate 20, and the front part of the workbench 3 is fixedly connected with a side frame 16, The operator can place other auxiliary tools on the side frame 16 , and the operator can also conveniently place the recovered vacuum bag film from the side frame 16 to the workbench 3 .

[0014] A motor 1 is arranged under the rear side of the workbench 3, the output shaft of the motor 1 is connected with the pulley 3 through the belt 2, the pulley 3 is connected with the reduction box 6 arranged under the workbench 3 through the main shaft 5, and the reduction box 6 is provided with a secondary shaft 7, and the two ends of the secondary shaft 7 are respectively connected with the runners 8 arranged on both sides below the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com