Sensor component for an optical flow rate sensor

A flow sensor and sensor technology, applied in scientific instruments, material analysis through optical means, instruments, etc., to save processing time and meet optical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

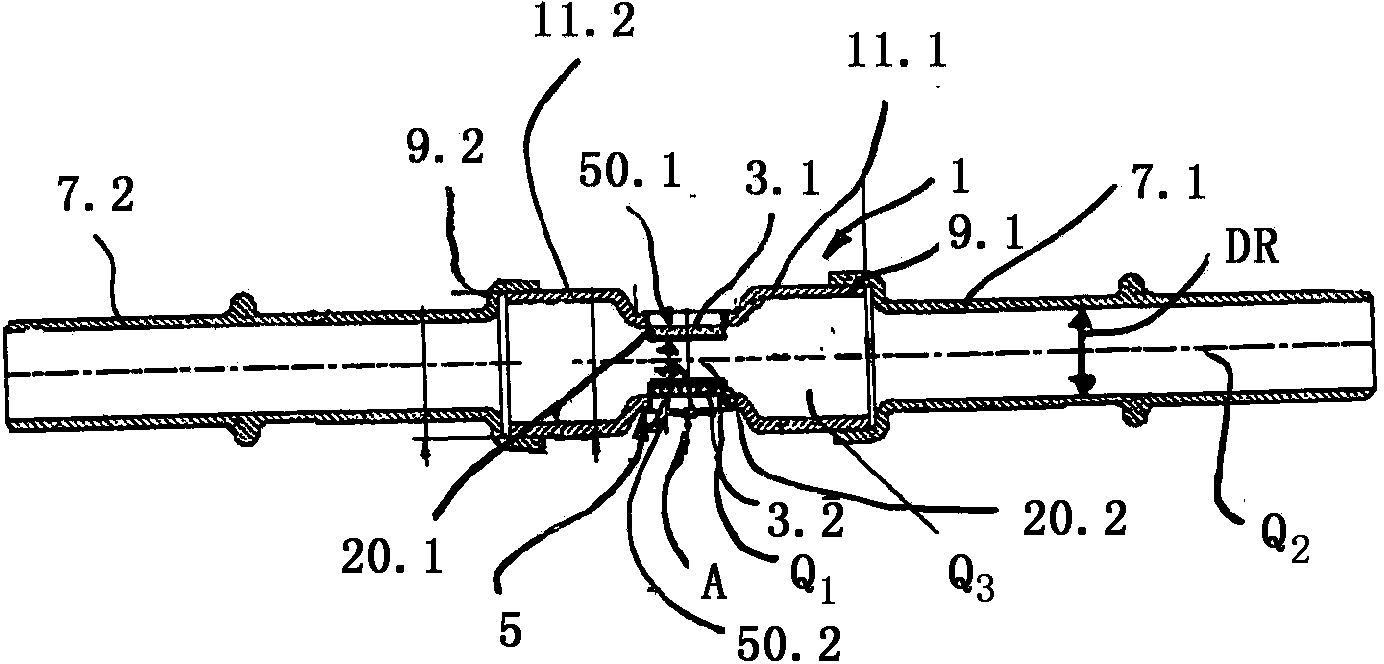

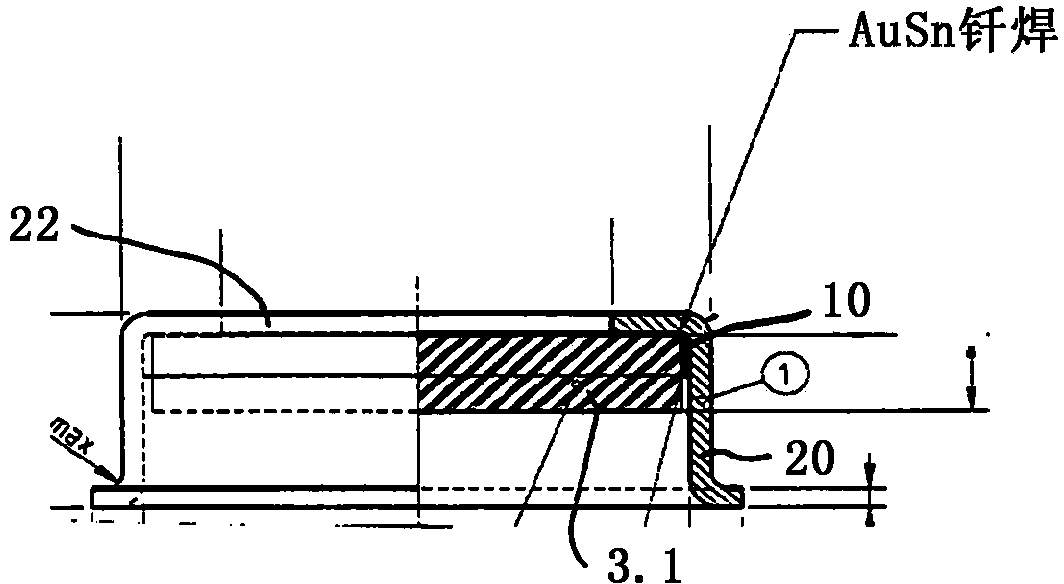

[0066] figure 1 The sensor component 1 according to the invention is shown in a schematic view with two sight glasses 3 . 2 , 3 . 1 installed in the region of the sensor section 5 for the sensor component of the optical flow sensor 4 . The sight glass 3.2, 3.1 currently utilizes metal solder or glass solder with the containment member (which is referred to here as in image 3 Covers 20 , 20 . 1 , 20 . 2 as specifically described in ) are connected and fitted into each recess 50 . 1 , 50 . 2 of the sensor component and are materially interlocked with the sensor component 1 , for example by soldering or laser welding. connect. The sensor component 1 and thus the optical flow sensor is again mounted or coupled to the pipe with the pipe pieces 7.1, 7.2. The connection of the pipes 7 . 1 , 7 . 2 to the sensor components of the optical flow sensor 1 takes place in the regions 9 . 1 , 9 . 2 of the sensor components 1 . The sensor component 1 of the optical flow sensor comprises, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com