Device for preparing gratings with different periods and using method thereof

A grating and grating structure technology, which is applied in the field of devices for preparing gratings with different periods, and can solve the problems of high cost and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

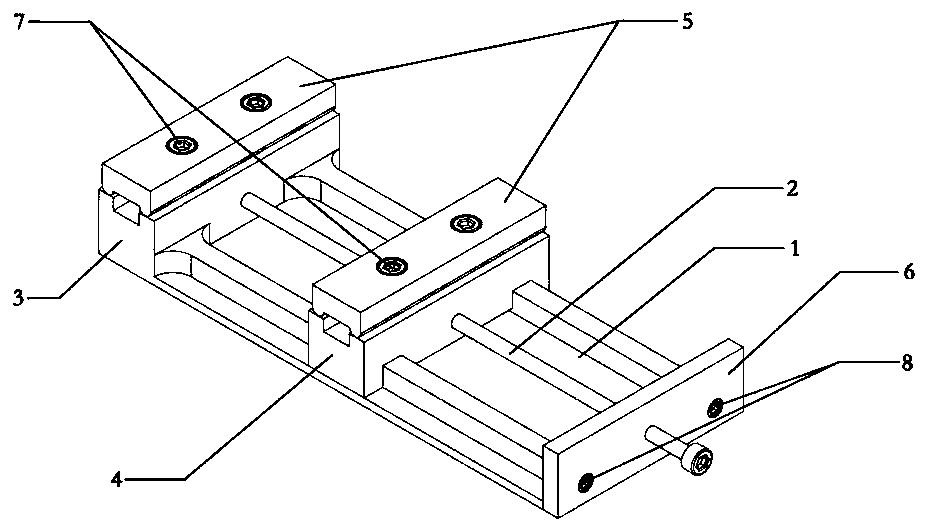

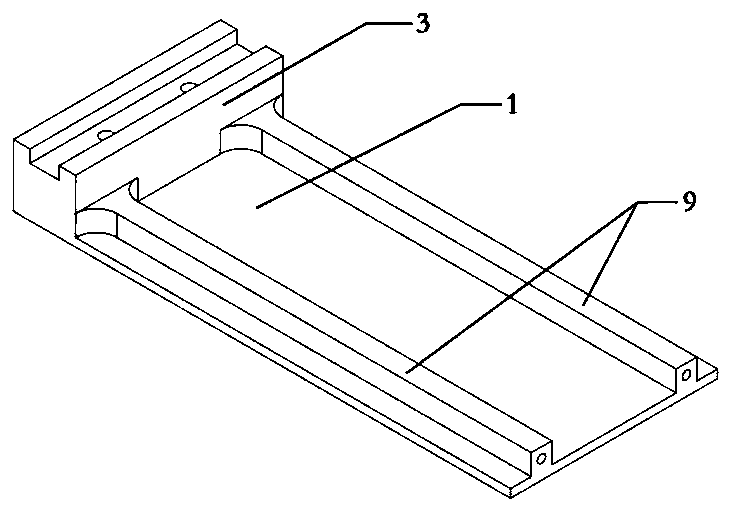

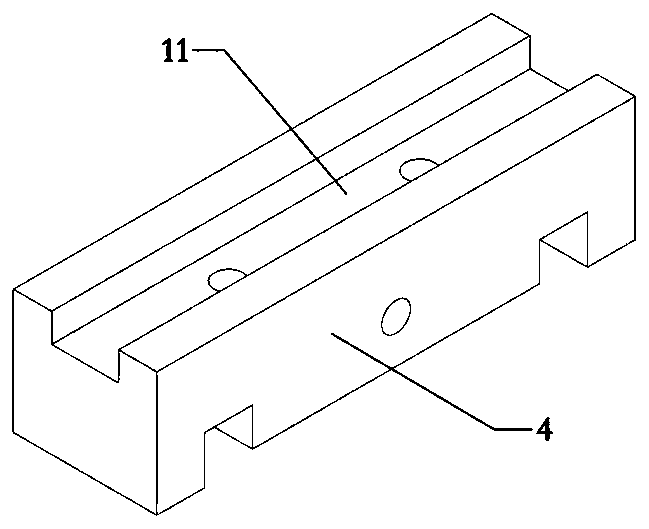

[0025] like figure 1 As shown, a device for preparing different periodic gratings, including a guide rail base 1, a transmission shaft 2, a bearing slider 4, a PDMS fixed cover plate 5, and a limit side plate 6; there are two guide rail grooves under the bearing slider 4 , can straddle the two guide rails of the guide rail base 1; the PDMS fixed cover 5 is fixed with the bearing slider 4 and the guide rail base fixing part 3 through the PDMS fixing screws 7; the limit side plate 6 is fixed by the side plate Screw 8 is fixed with guide rail base 1. The size of the whole device can be adjusted at will, and the semicircular groove under the PDMS fixed cover can be adjusted according to the master material design.

[0026] The present invention also provides a method for using a device for preparing different periodic gratings, comprising the following steps:

[0027] Step 1: Remove the PDMS fixed cover (5), and place the two sides of the PDMS soft template with a grating struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com