Patents

Literature

38results about How to "Meet optical requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

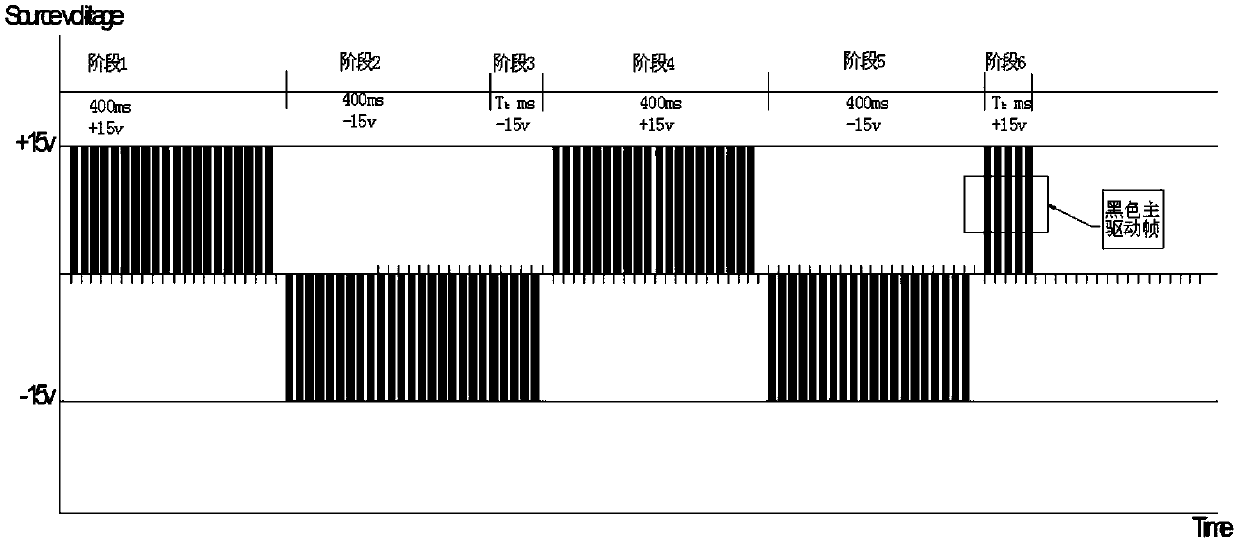

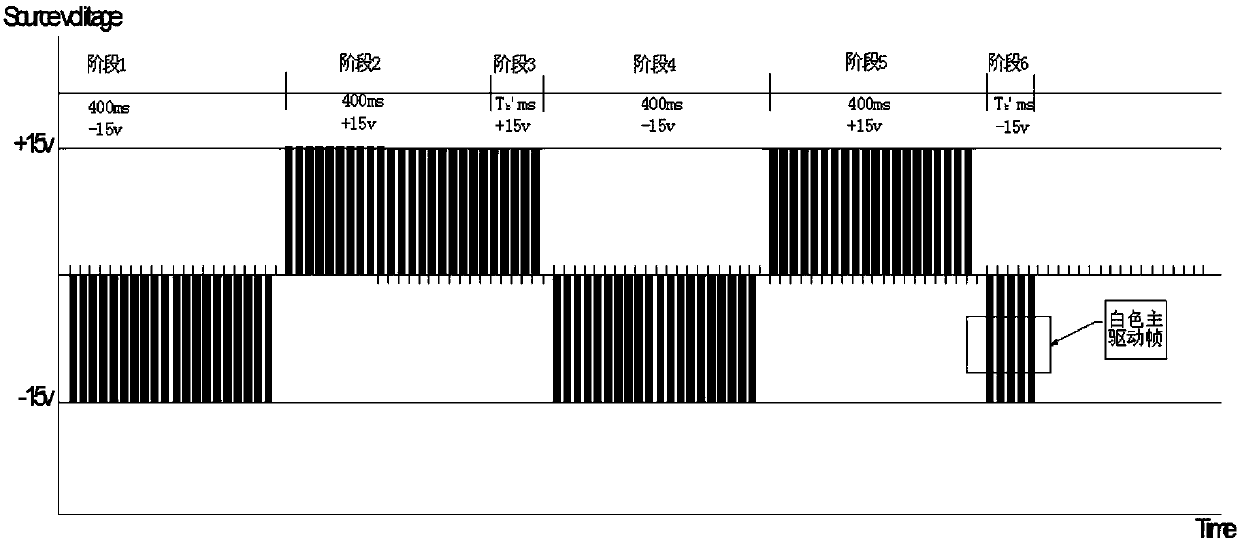

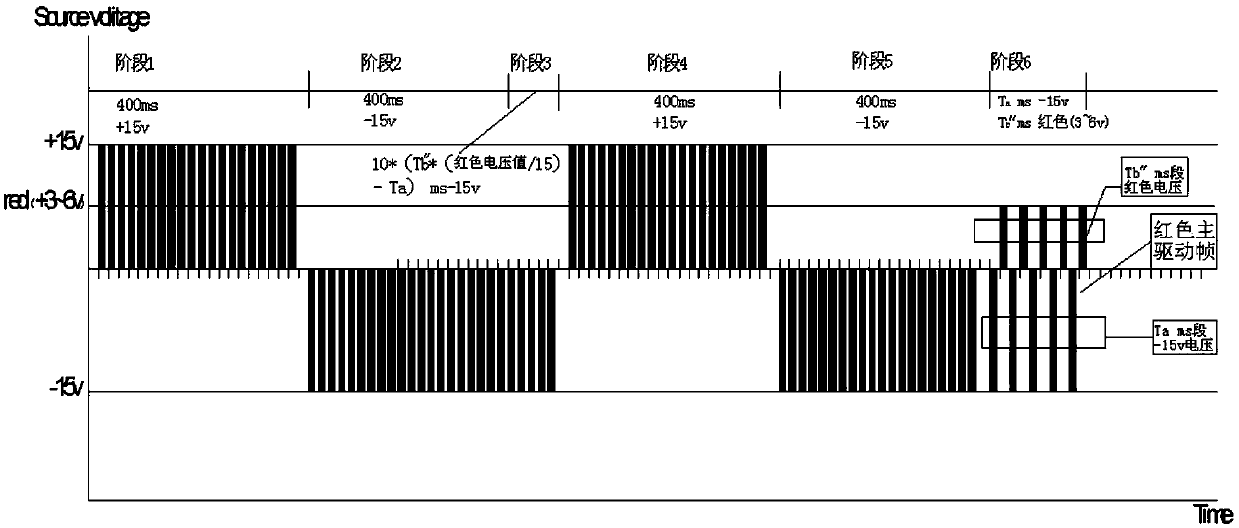

Method for debugging driving waveform of three-color electronic paper module

ActiveCN107633819AMeet optical requirementsImprove general performanceStatic indicating devicesOptical testEmbedded system

The invention provides a method for debugging the driving waveform of a three-color electronic paper module, and the method herein has the characteristics of excellent universality, and excellent comparison and display effects. The method is characterized in that the method includes the following steps: 1. determining master driving frames: driving the three-color electronic paper module by usingblack / white / red picture standard test waveforms, and separately reading the black, white and red optical values of a test picture under three kinds of standard test waveforms by using an optical tester, separately comparing the black, white and red optical values with a standard black L*value, a standard white L* value, and a standard red L* value and a* value, obtaining a standard test waveform that meets optical requirements and obtaining a black / white / red master driving frame of the three-color electronic paper module; 2. determining DC balance frames: separately based on the black master driving frame, the white master driving frame and the red master driving frame, determining the DC balance frames corresponding to the black master driving frame, the white master driving frame and thered master driving frame; and 3. determining driving waveforms which include the DC balance frames that perform first driving and the black master driving frame, the white master driving frame and the red master driving frame that perform follow-up driving.

Owner:江西兴泰科技股份有限公司

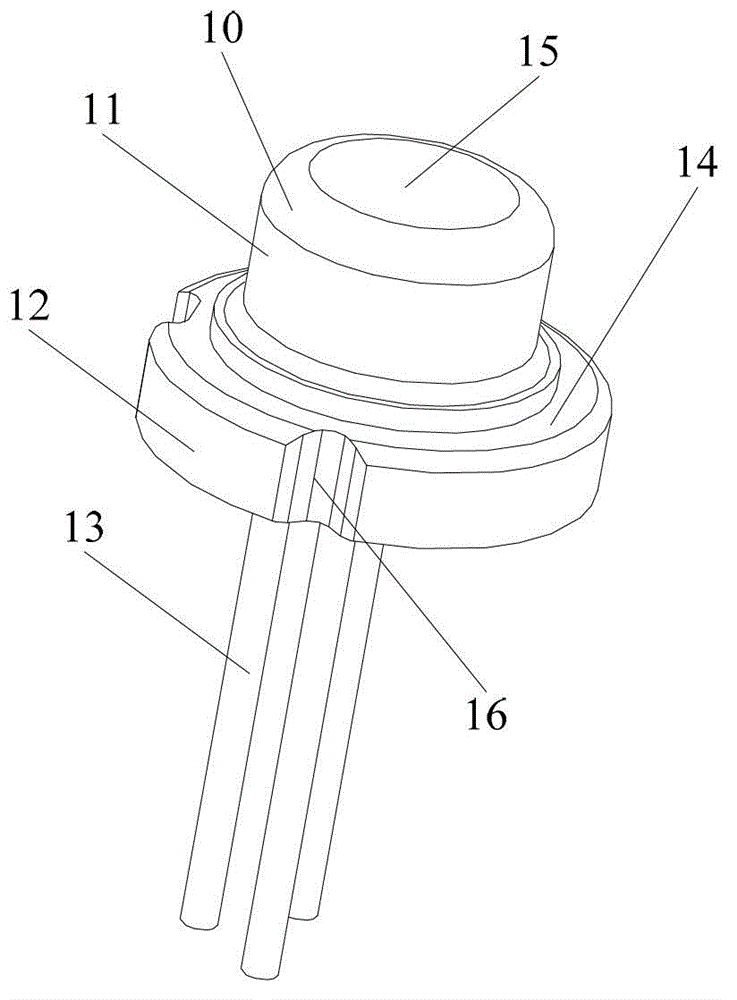

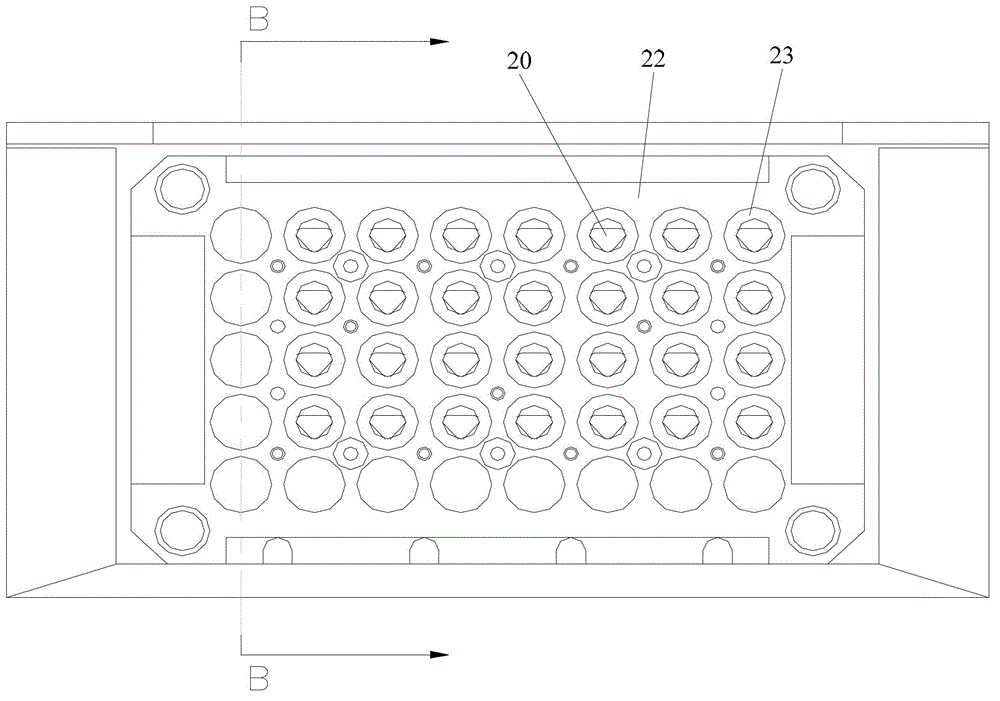

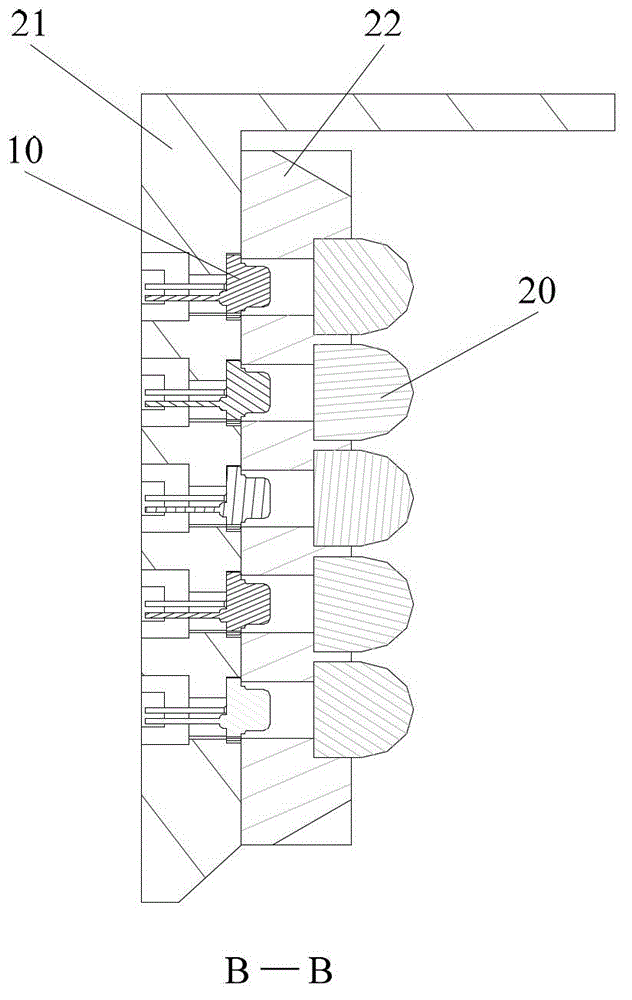

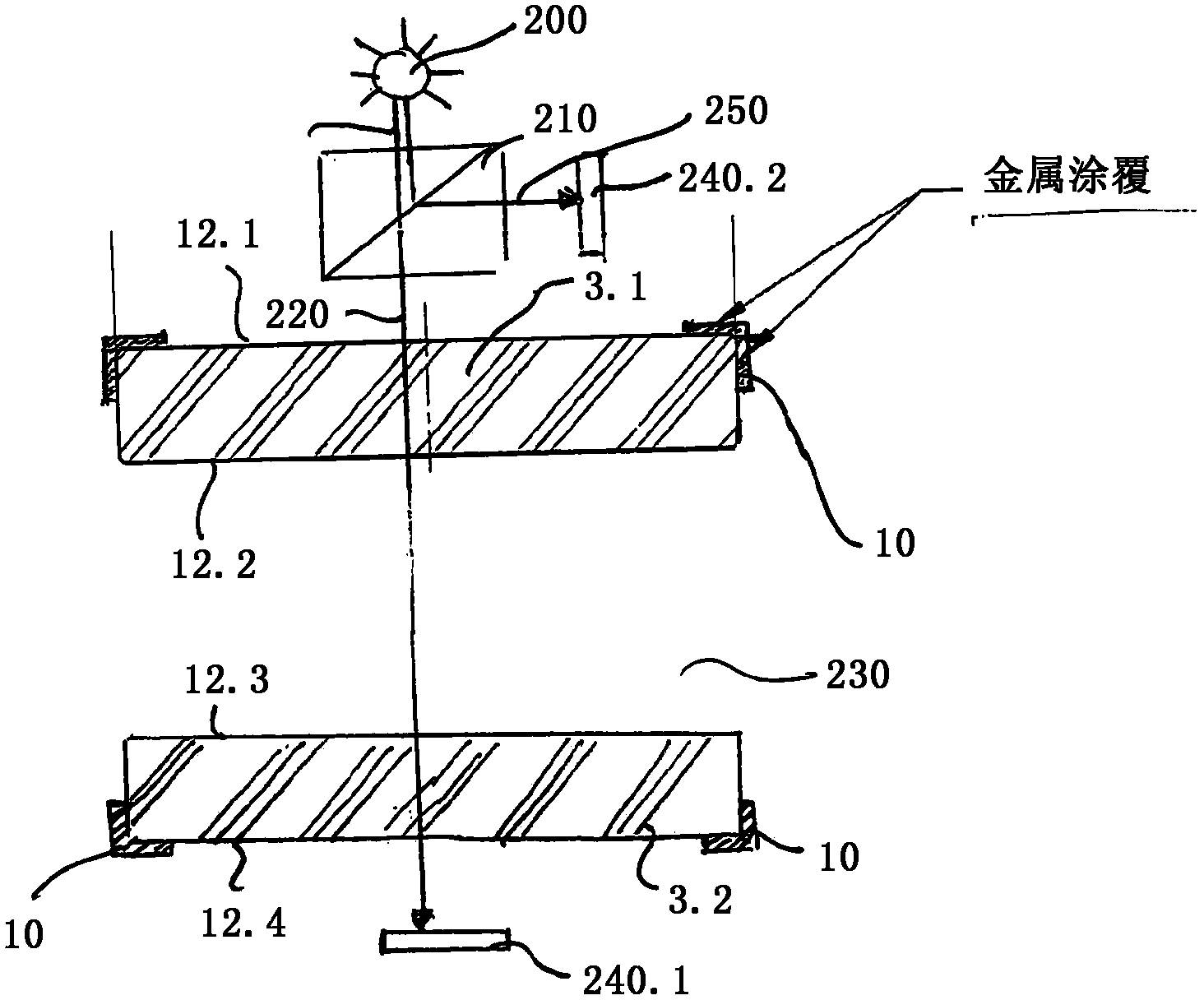

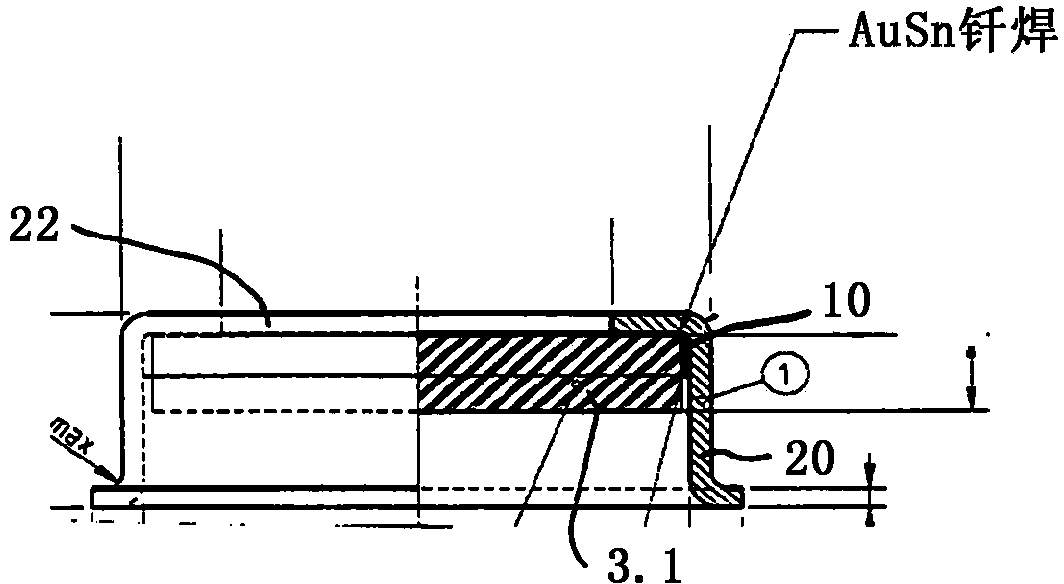

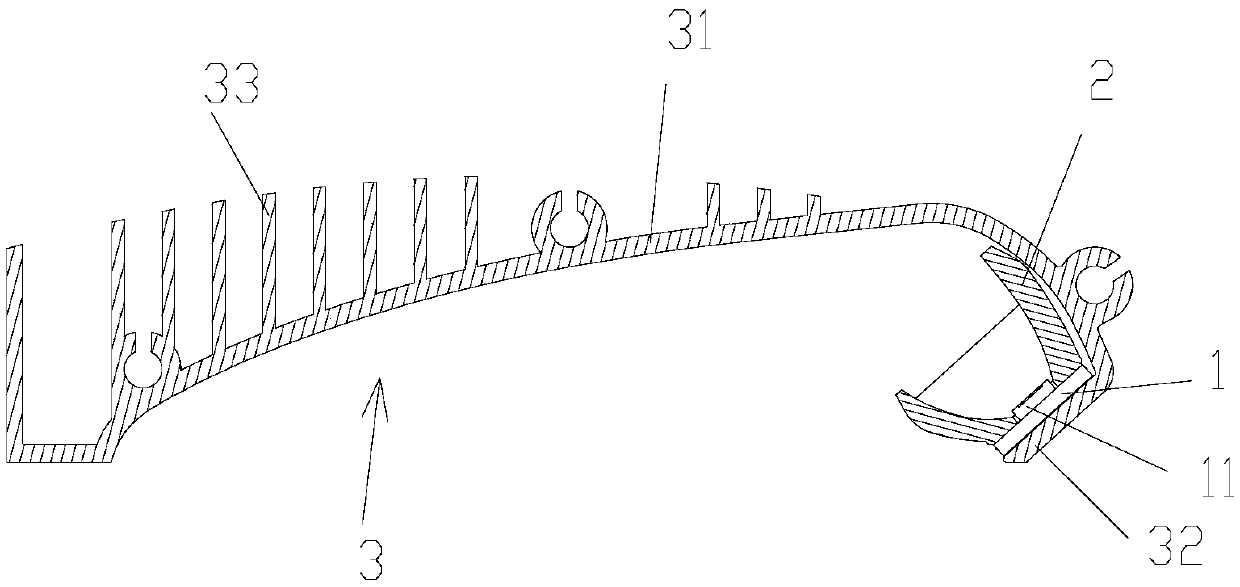

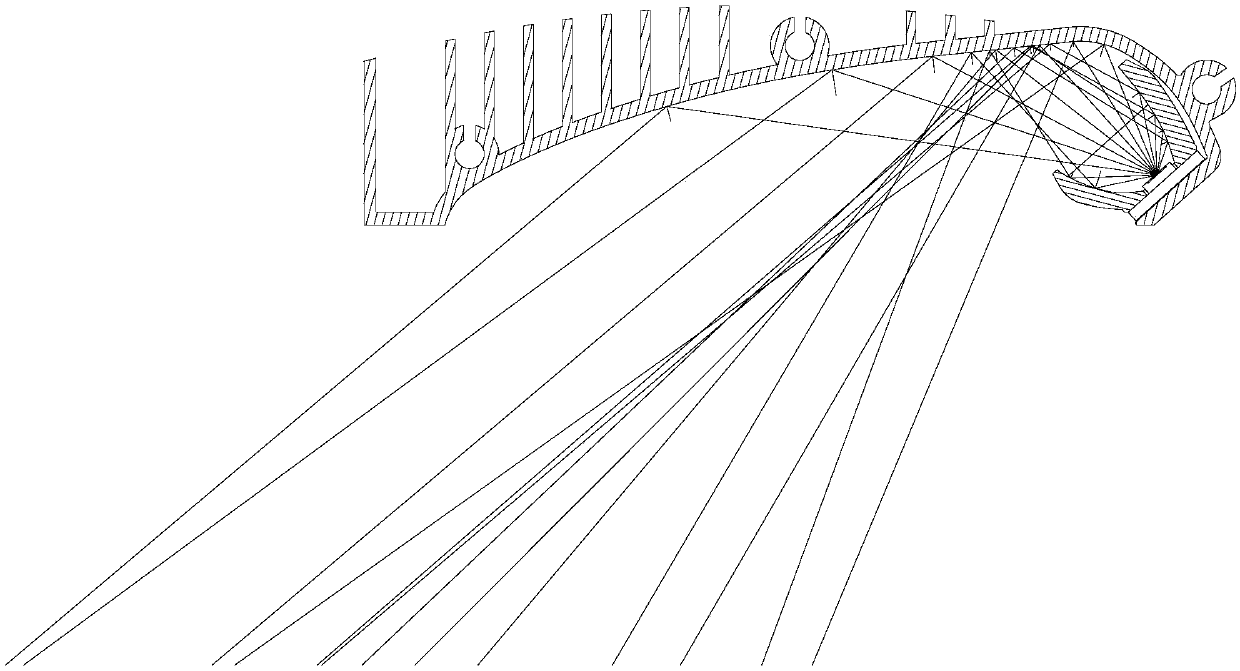

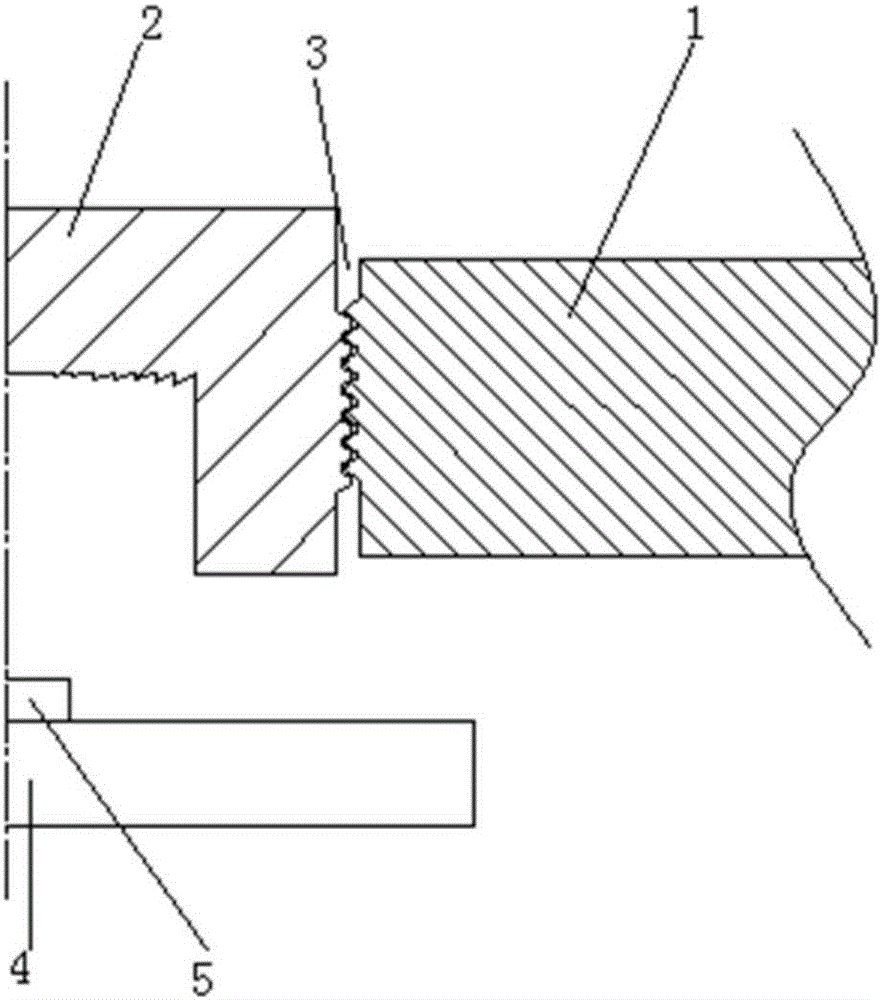

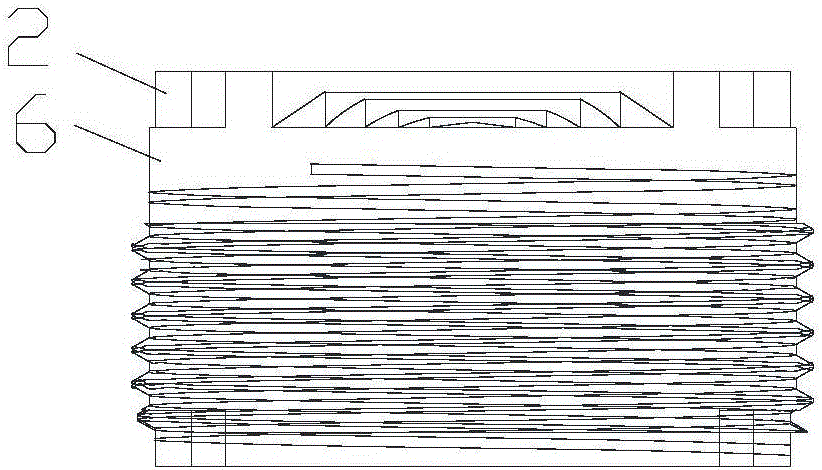

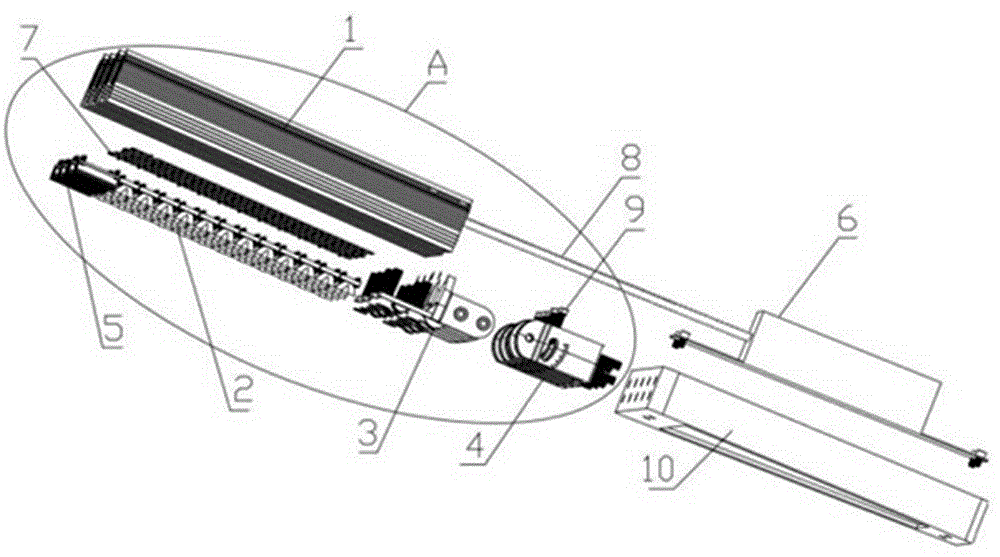

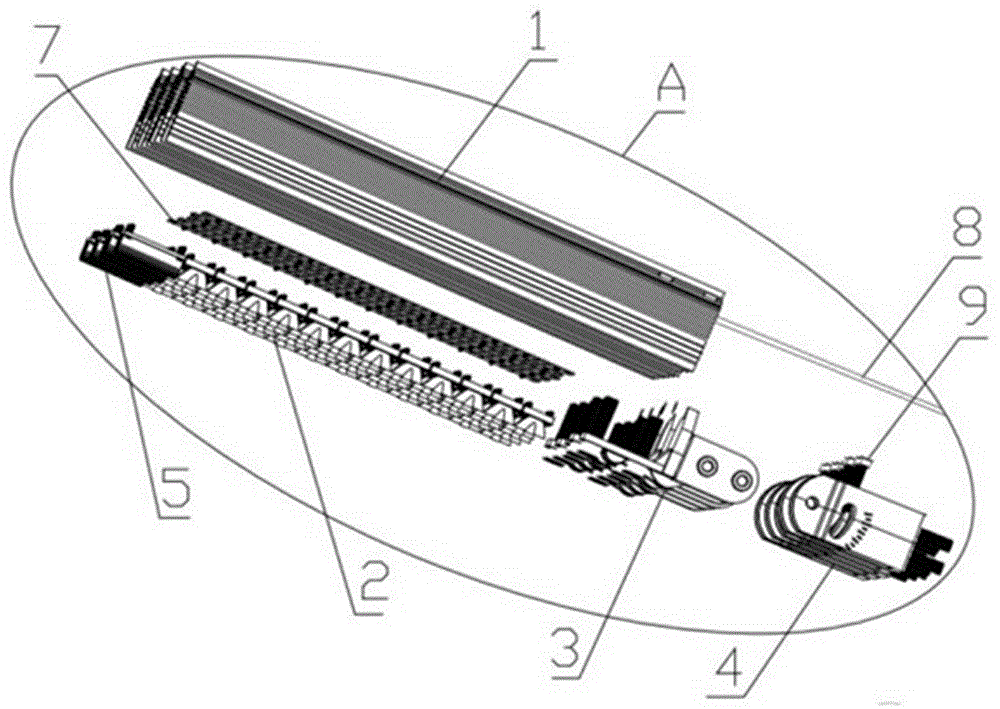

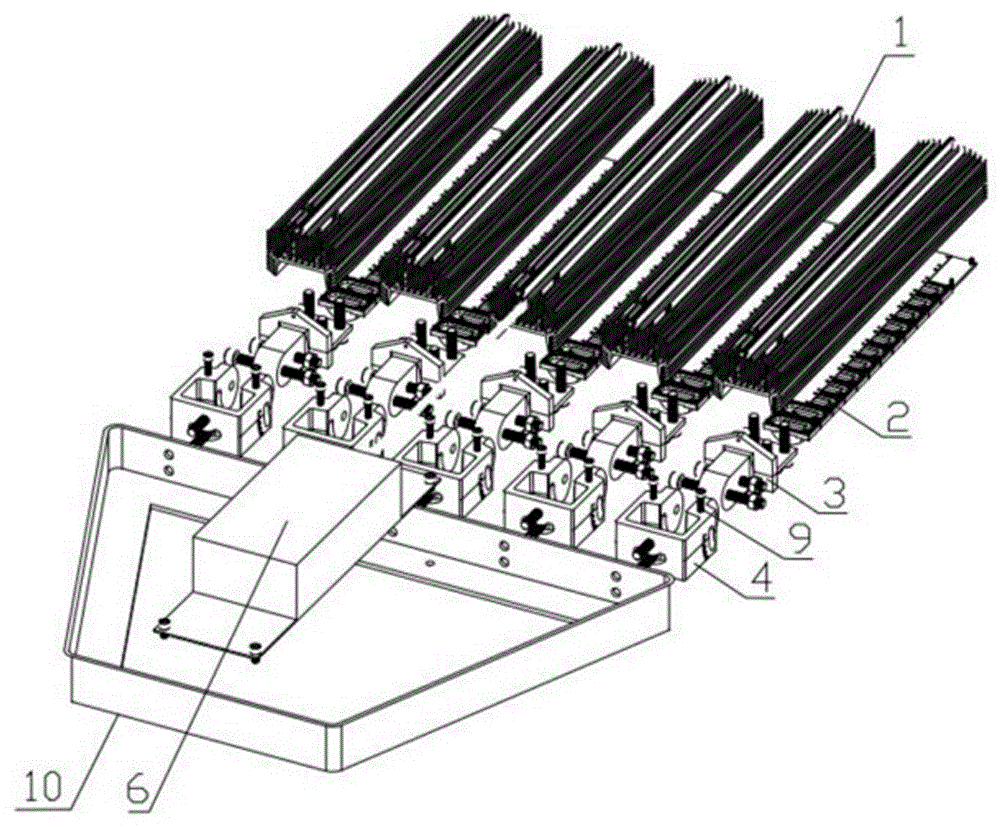

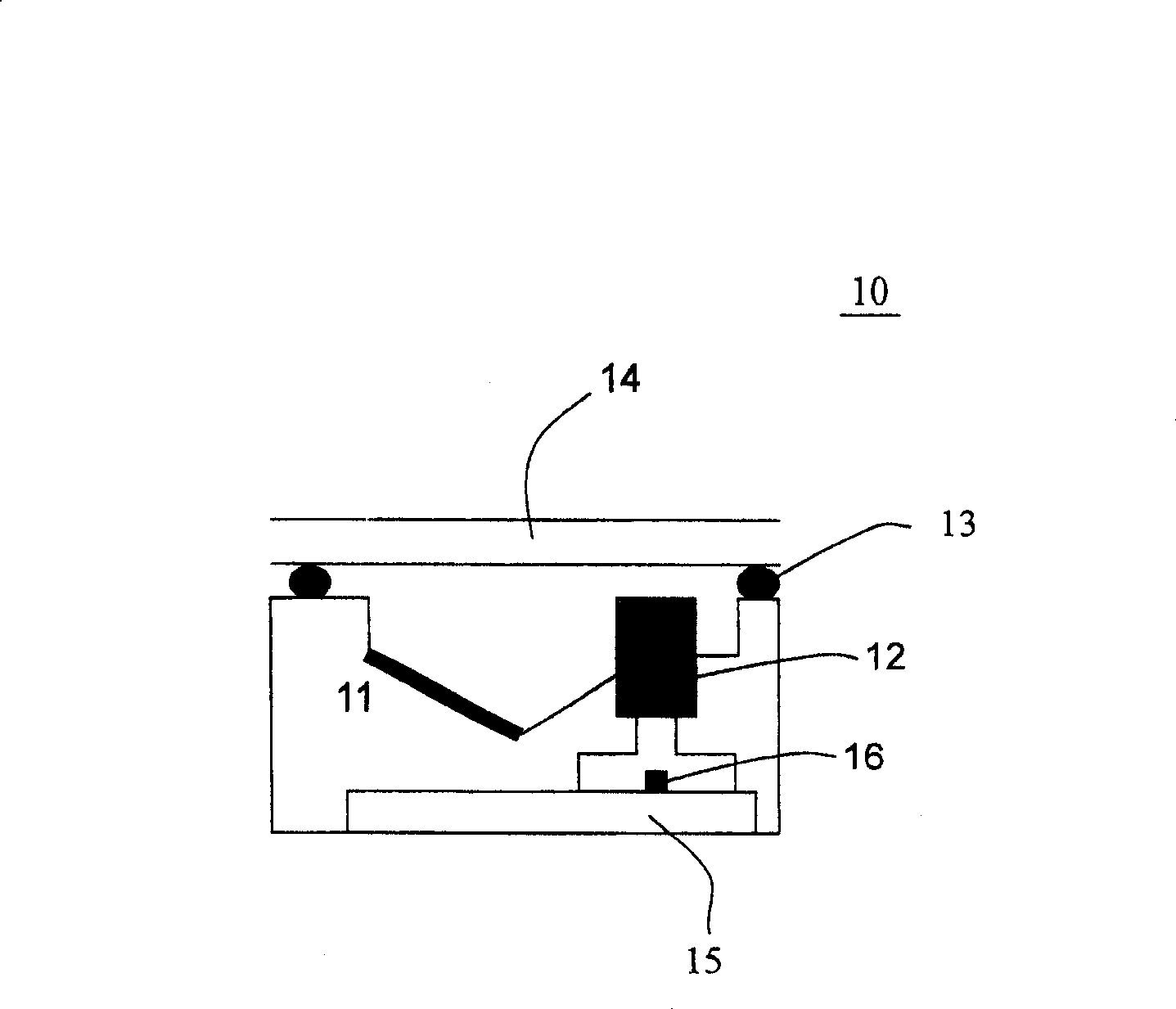

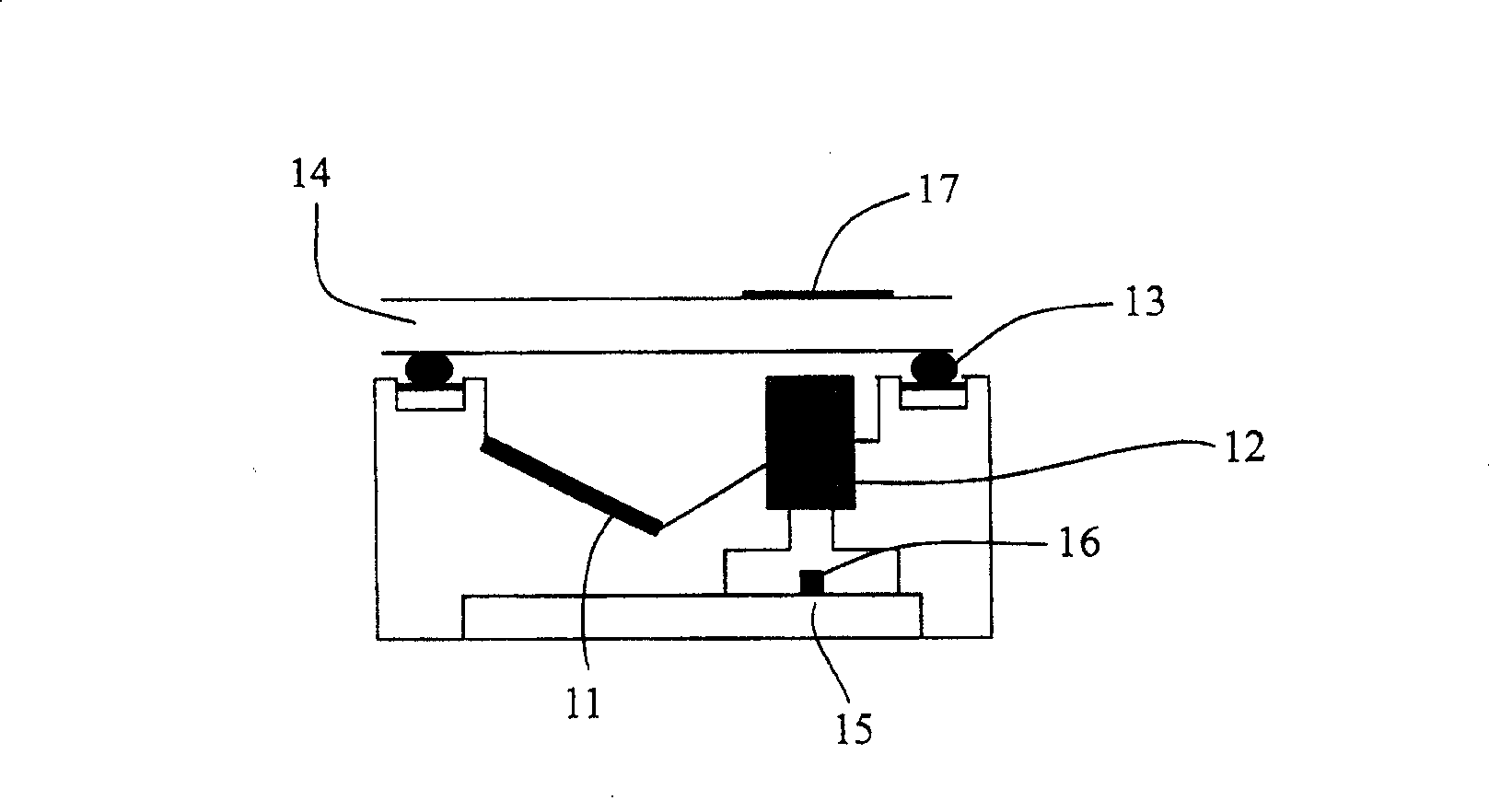

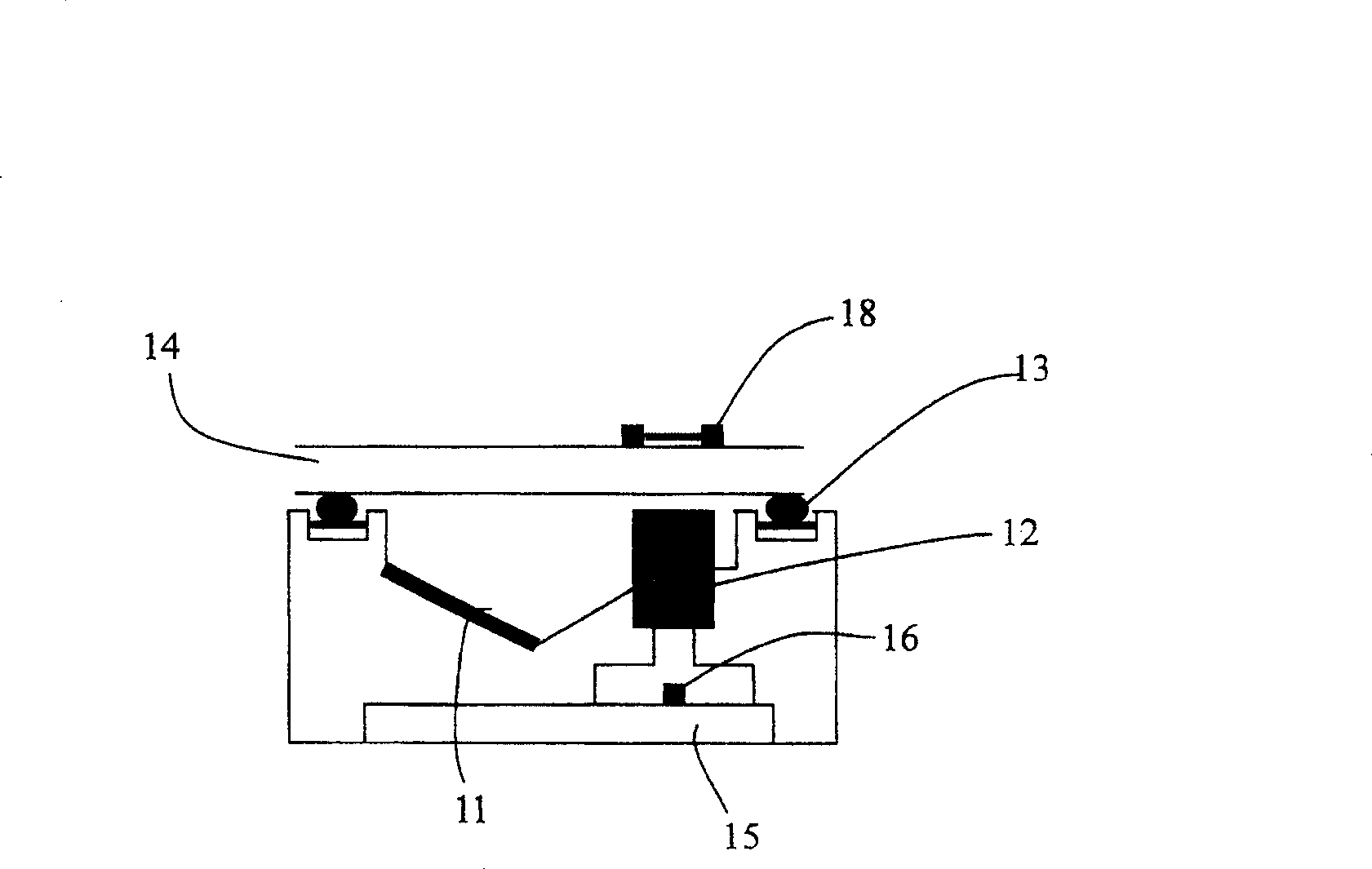

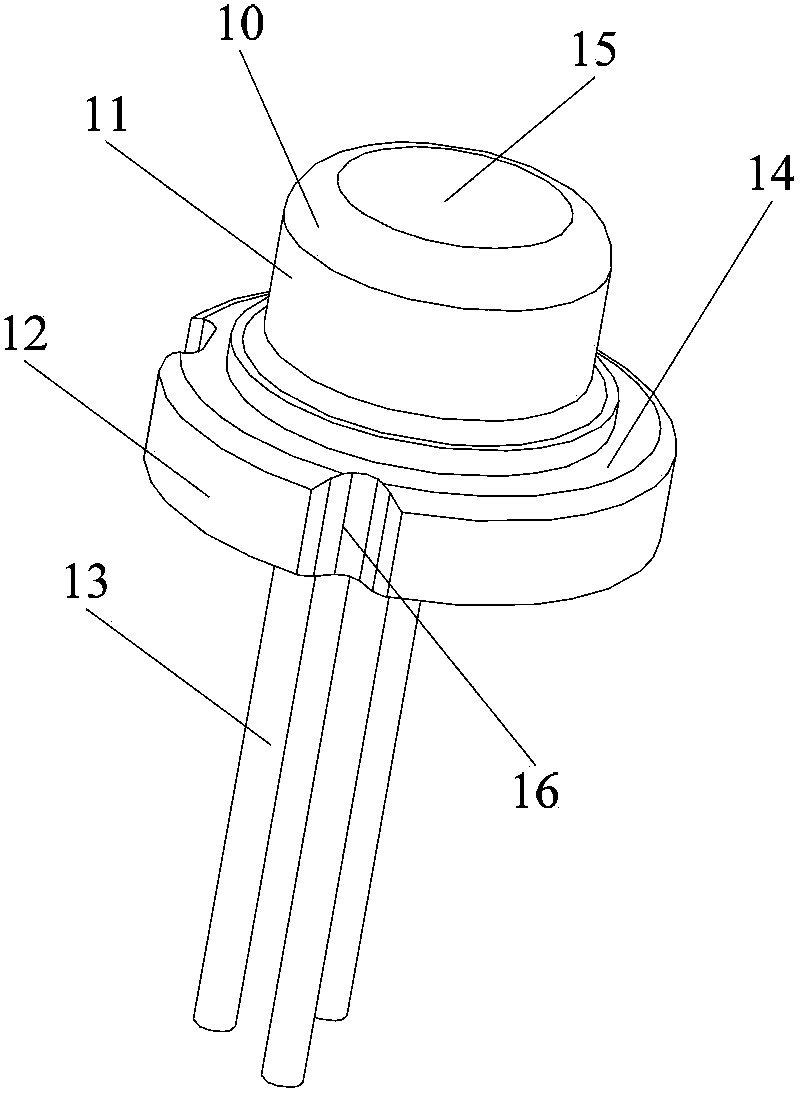

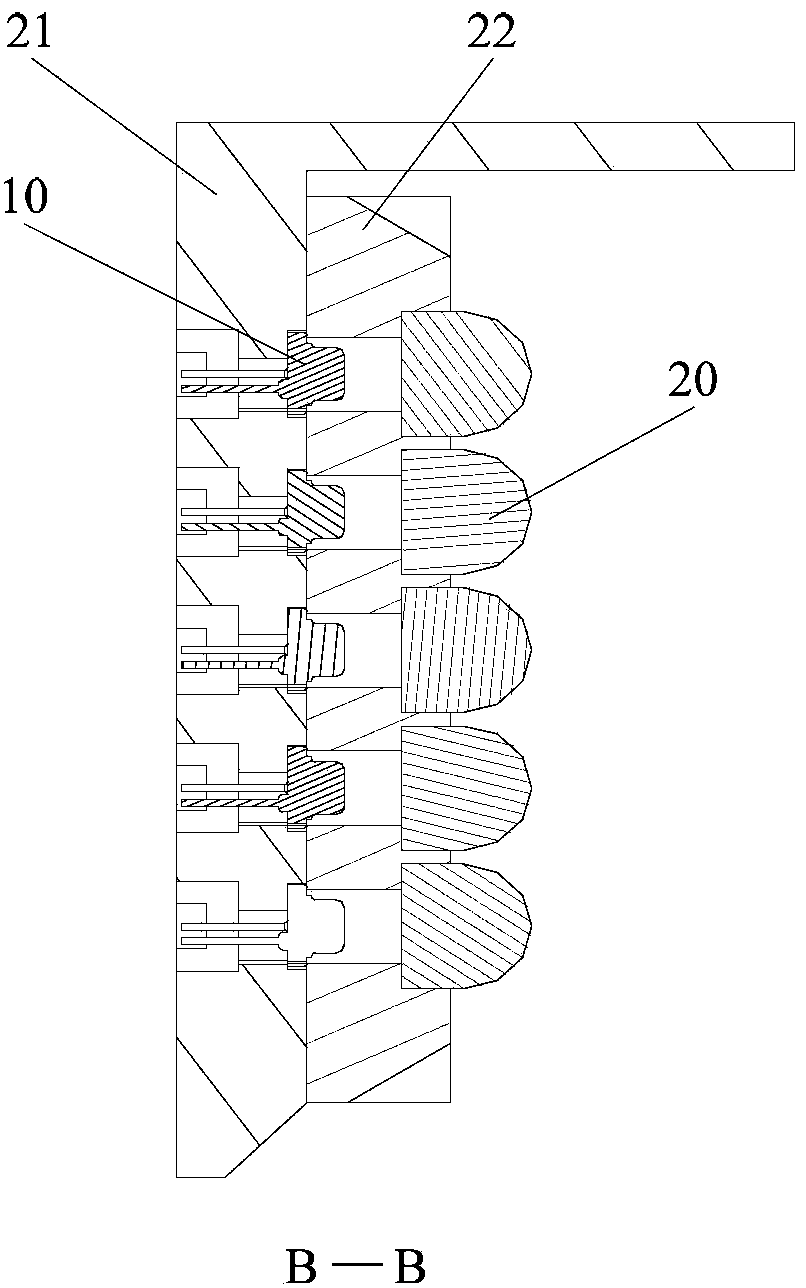

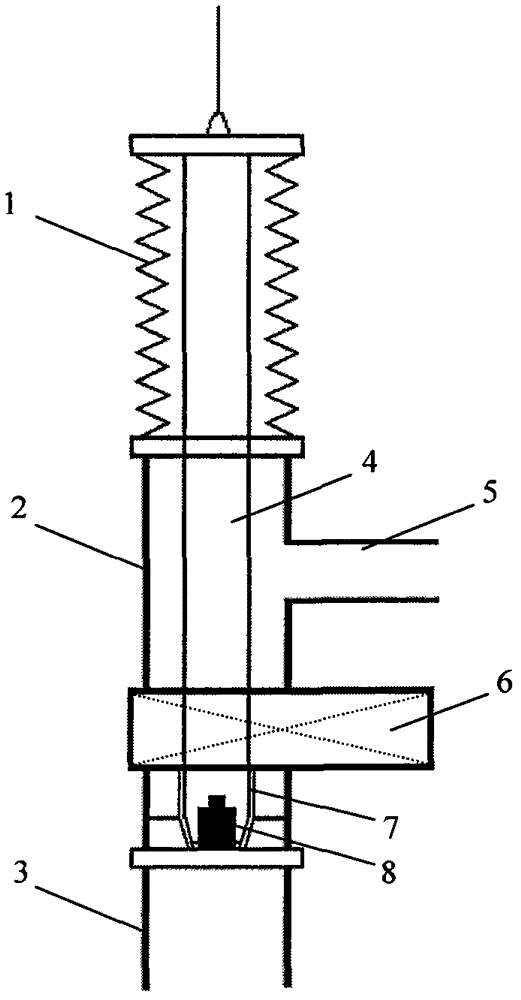

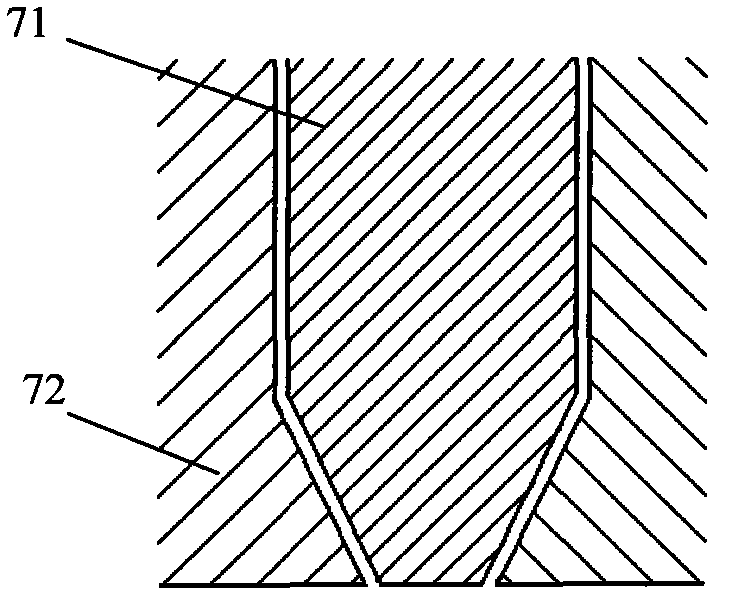

Fixing device of array laser device

ActiveCN102868081AMeet optical requirementsLow machining accuracy requirementsLaser arrangementsLaser constructional detailsOptoelectronicsLaser

The invention discloses a fixing device of an array laser device. The fixing device of the array laser device disclosed by the invention comprises a laser device bottom plate, a laser device pressing plate, a plurality of mirror holders, a plurality of elastic gaskets and mirror holder pressing plates. With the adoption of the fixing device of the array laser device disclosed by the invention, optical requirements of the array laser device can be met and the requirements on the machining precision can be lowered at the same time.

Owner:HISENSE

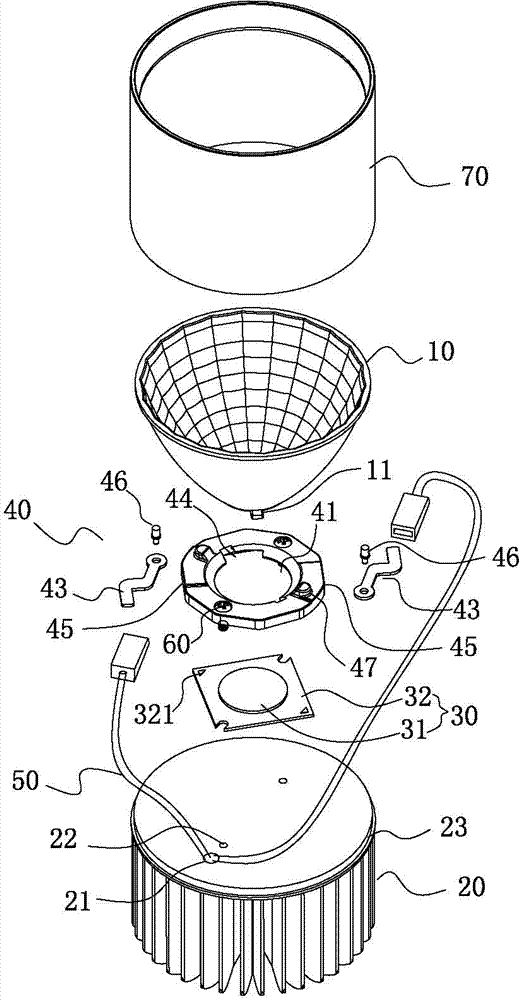

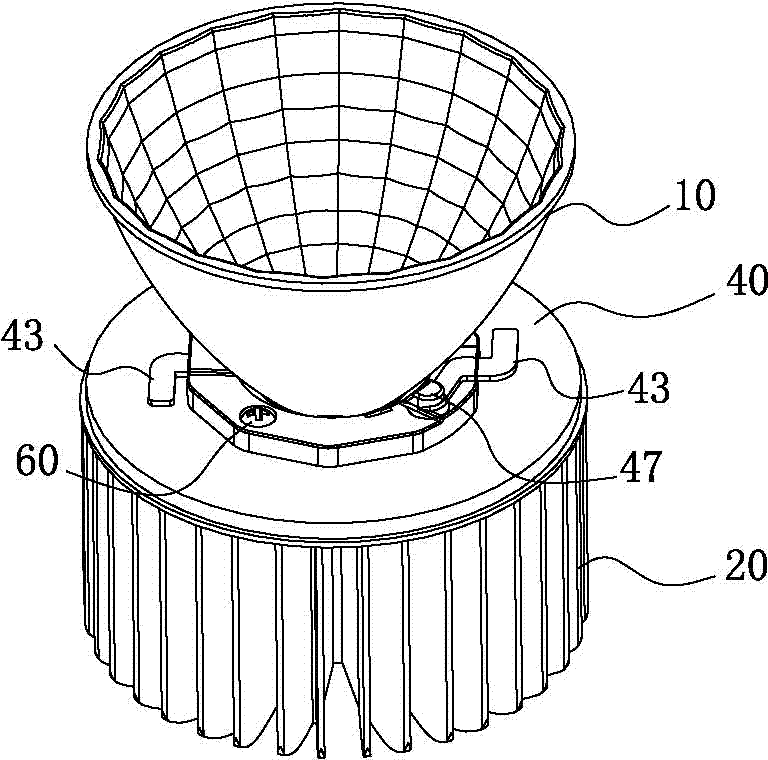

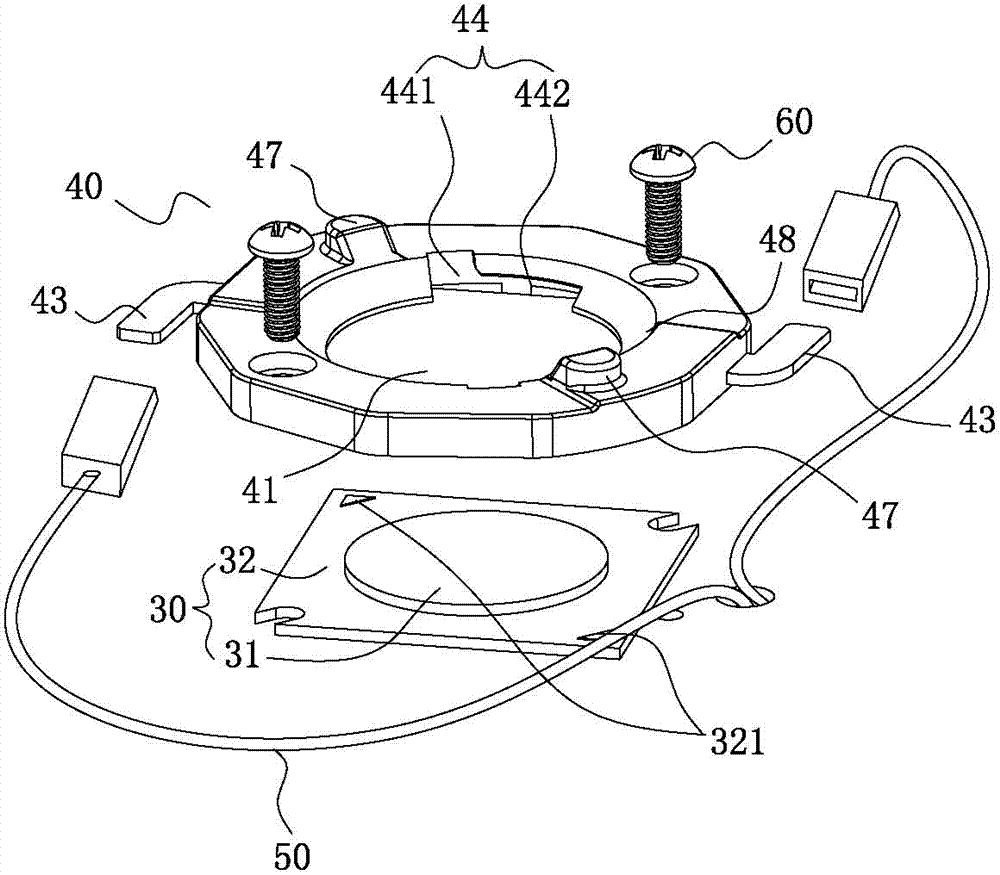

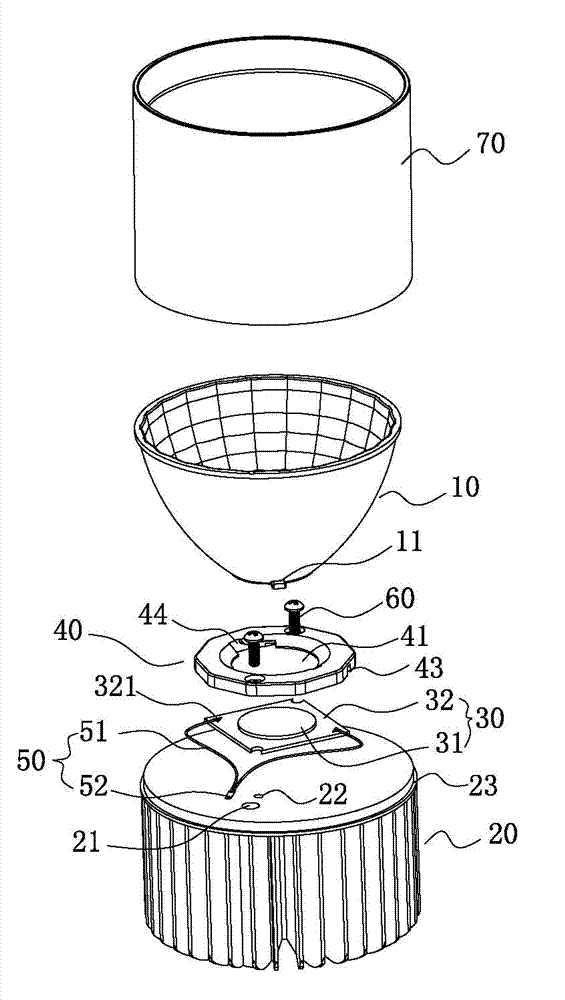

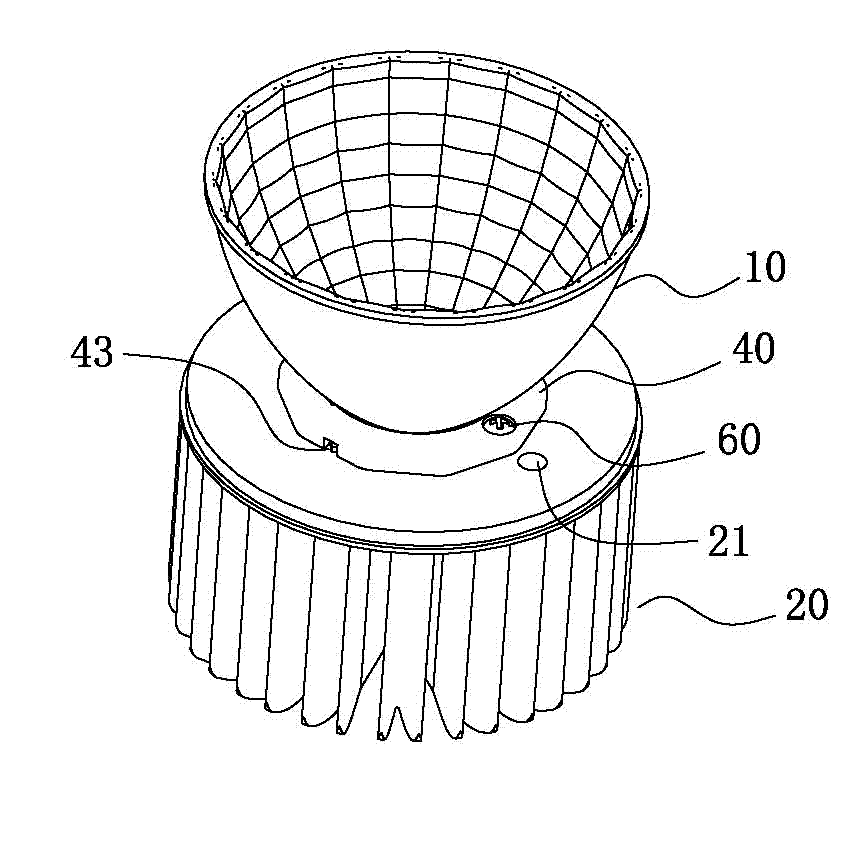

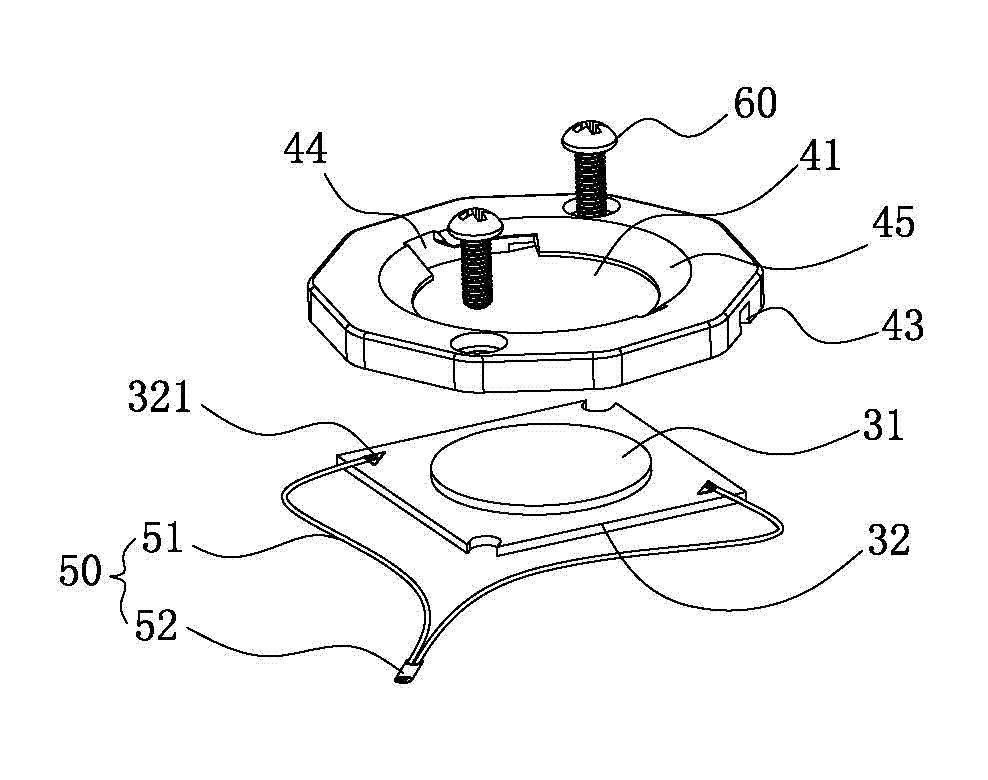

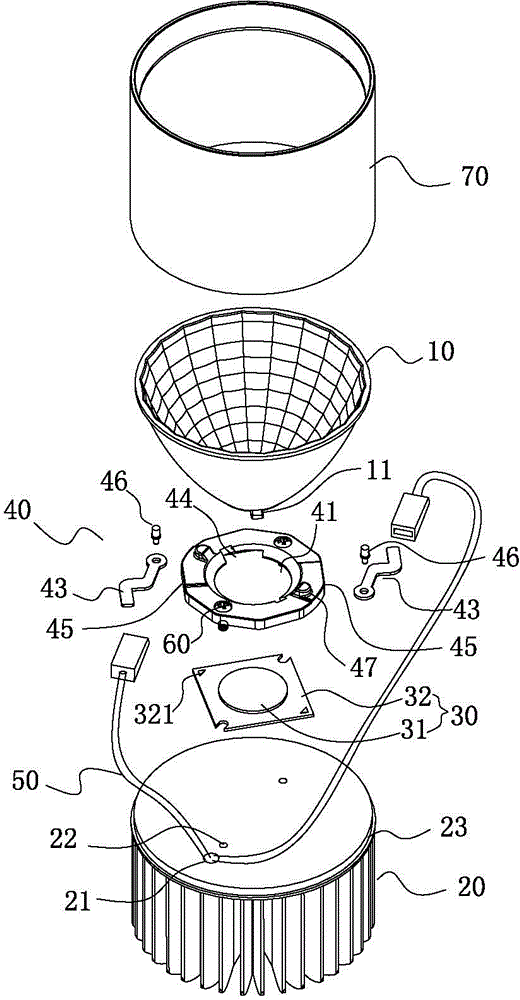

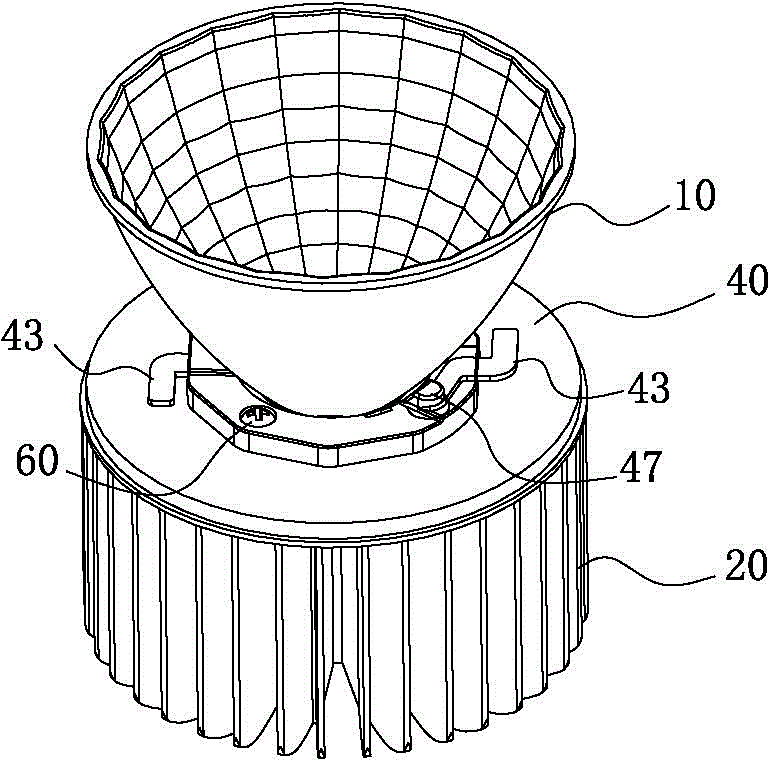

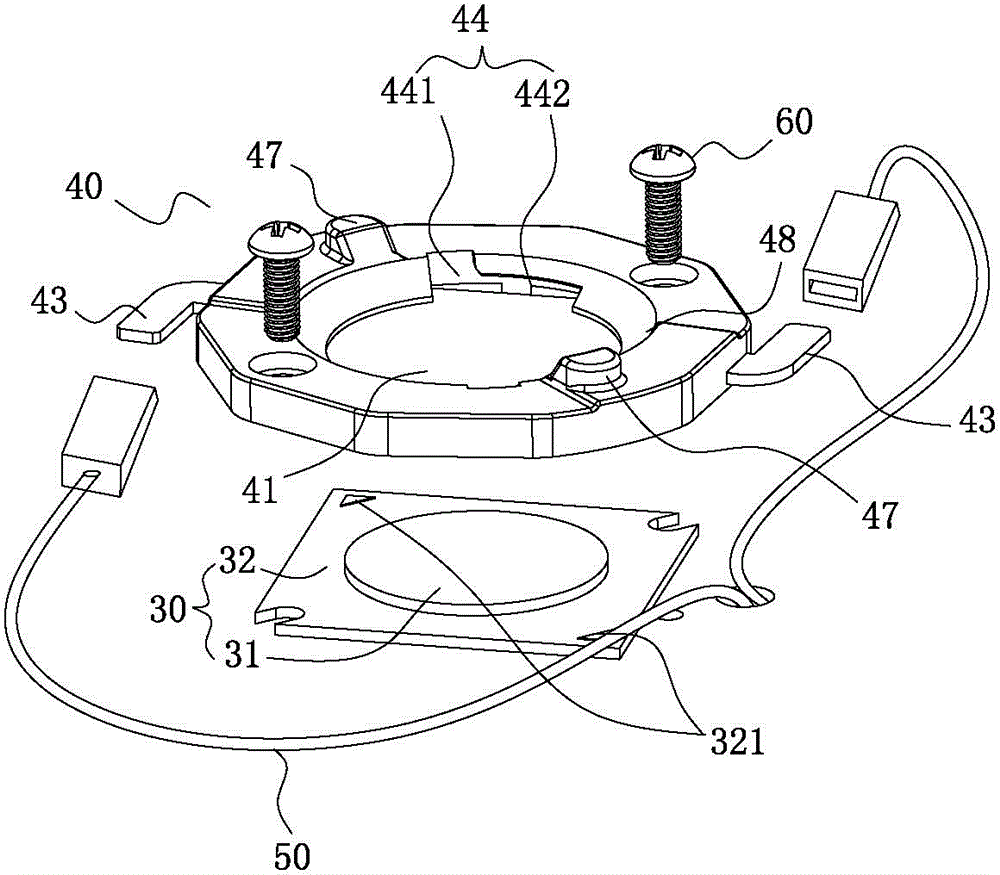

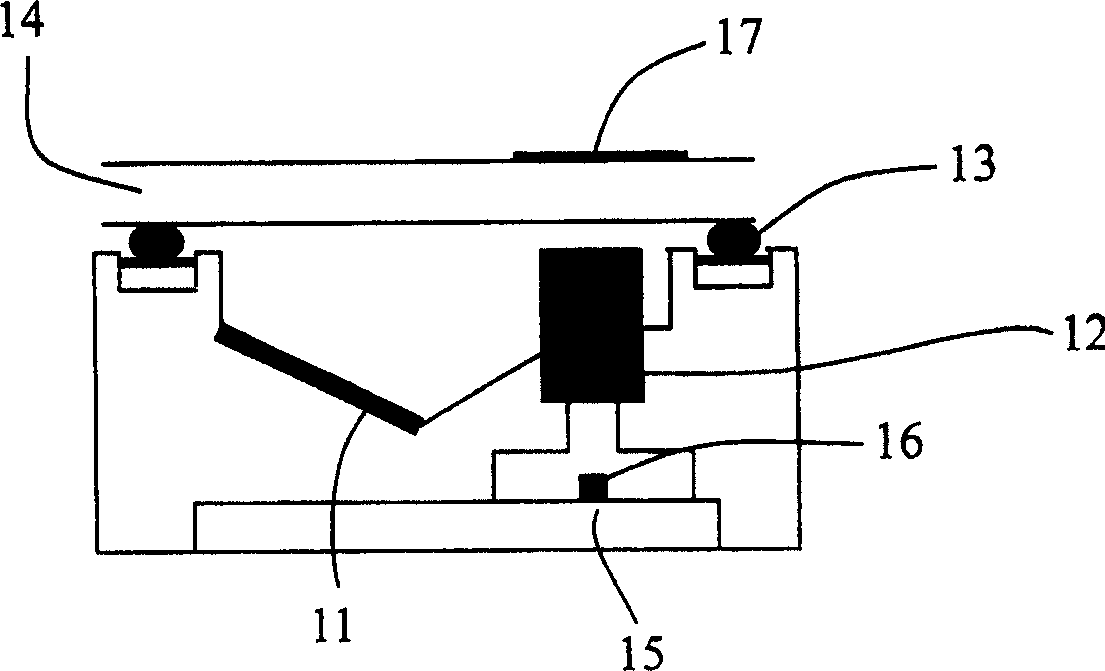

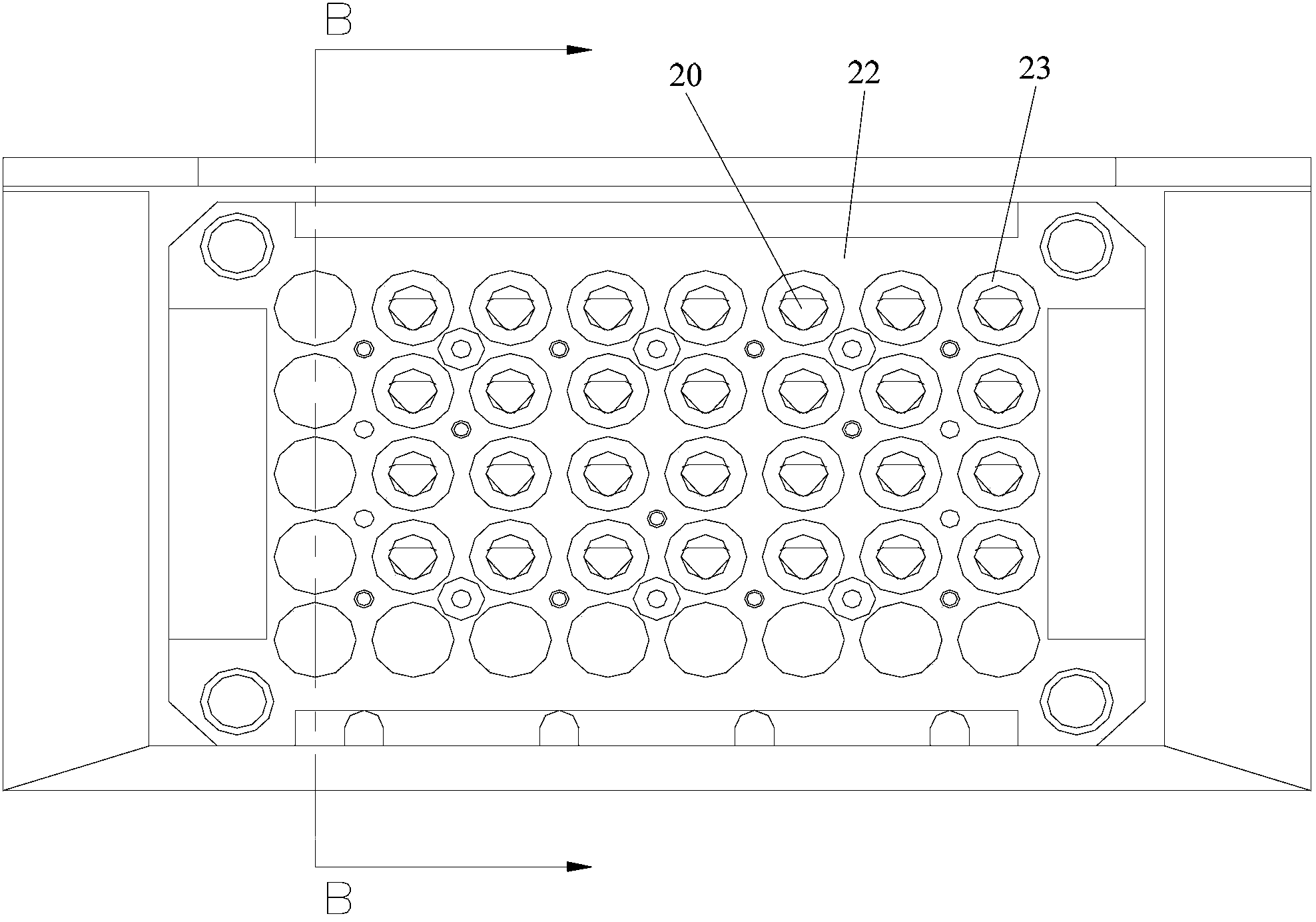

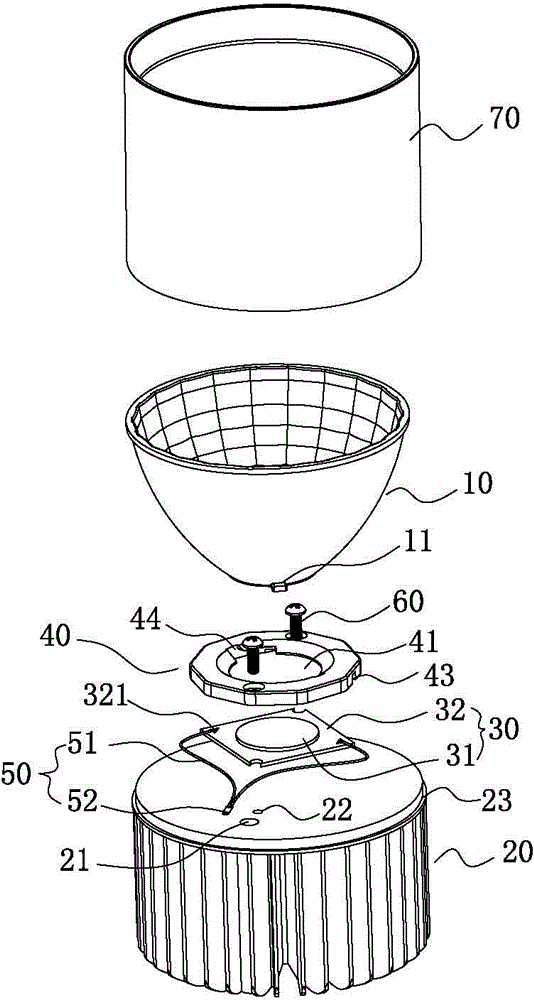

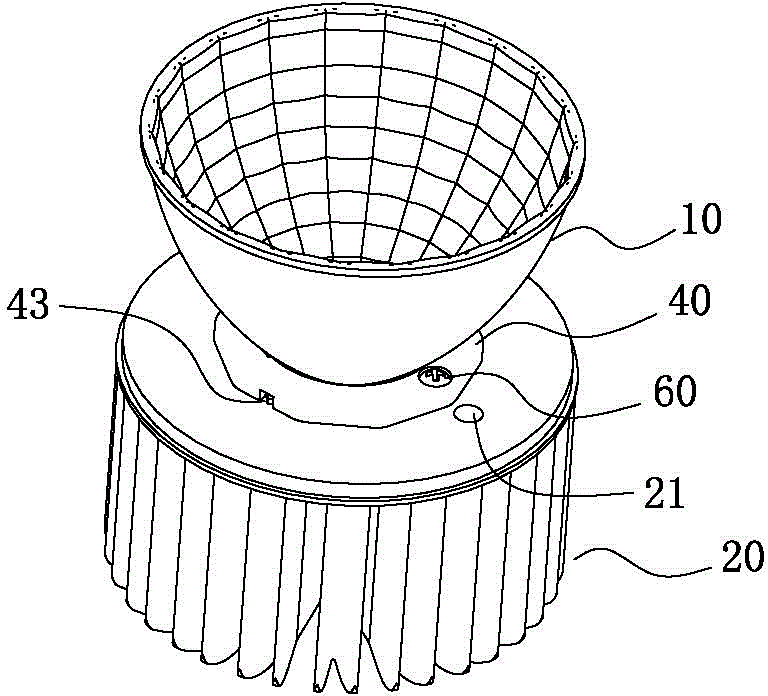

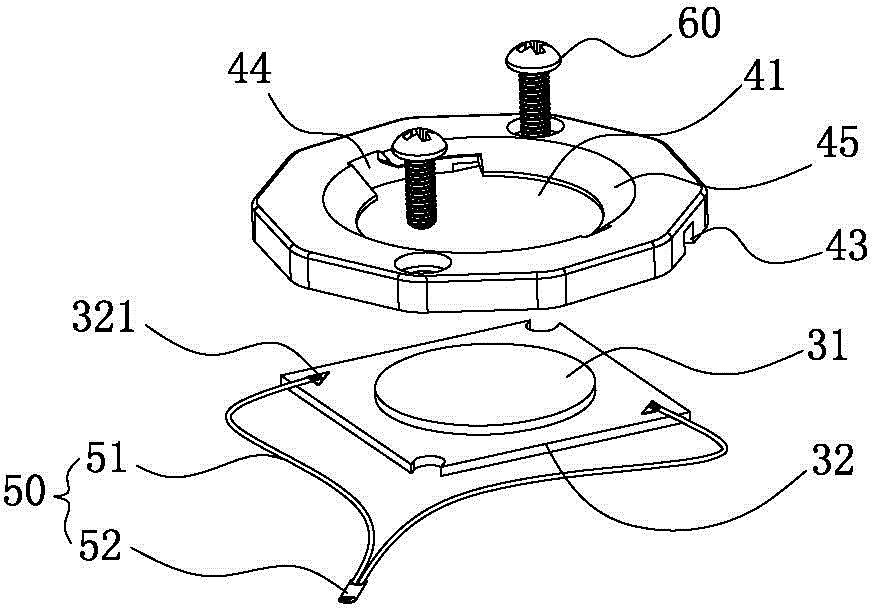

Electric contact and connection type COB (chip on board)-LED light source module

ActiveCN102853301AAdequate heat dissipationEasy to assemble and disassemblePoint-like light sourceElectric circuit arrangementsConnection typeOn board

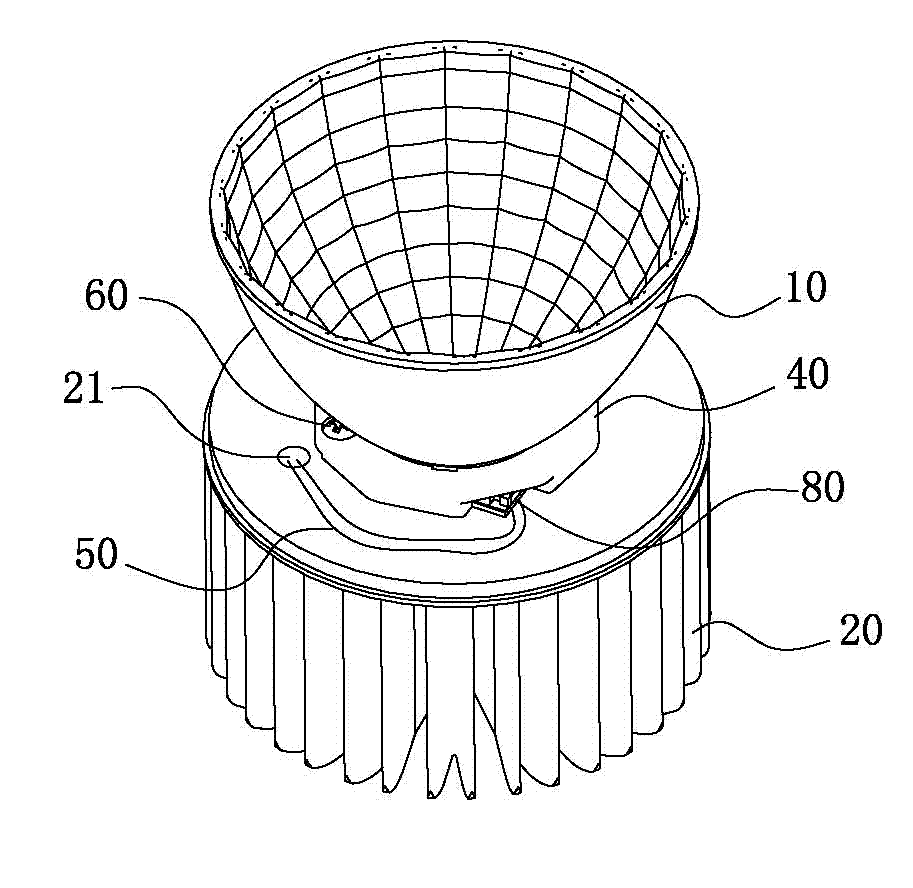

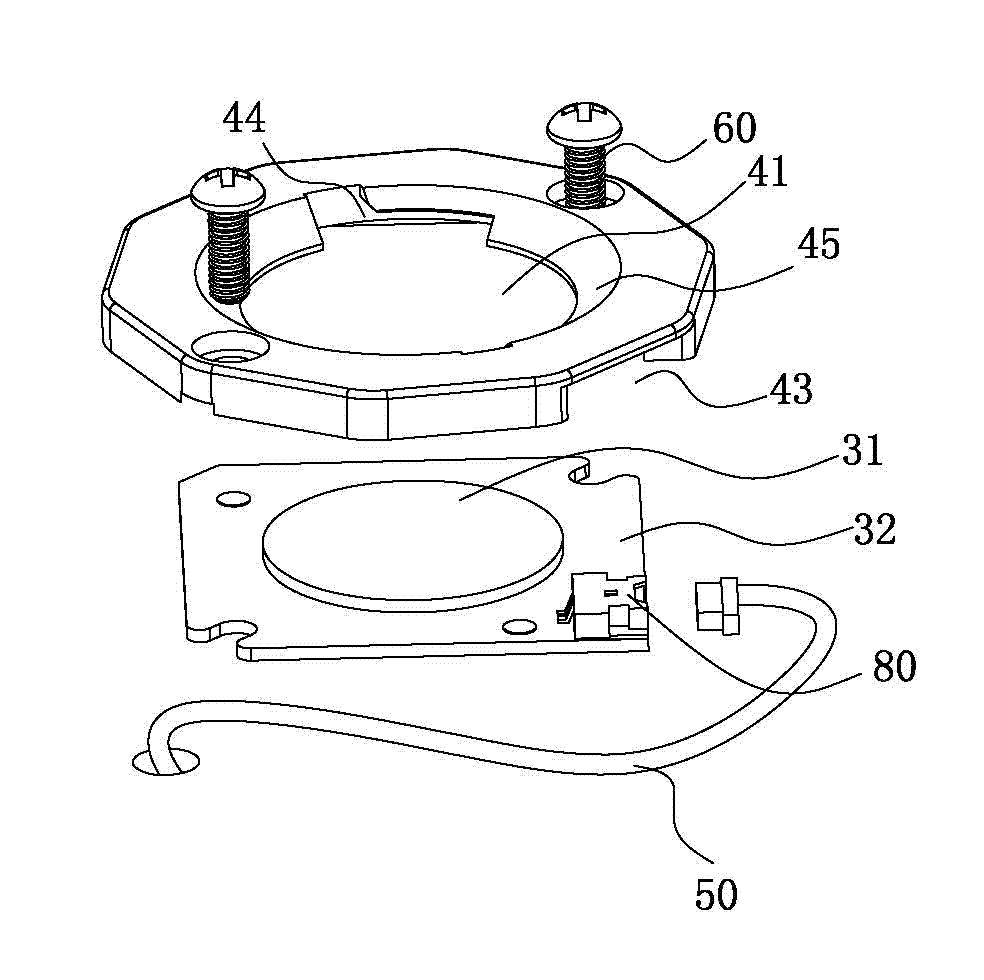

The invention relates to an electric contact and connection type COB (chip on board)-LED light source module which comprises a reflection cup, a radiator, a COB-LED light source component, an electrical interface support and two single-core wires. Fastening grooves are arranged on the inner wall of a through hole of the electrical interface support, each fastening groove is formed by connection of an insertion opening with a sliding groove, fasteners corresponding to the fastening grooves are arranged at the outer edge of a small mouth of the reflection cup, a slot for insertion of a conducting strip is arranged on each of two side faces of the electrical interface support, and a telescopic conducting column is arranged in an accommodating cavity connected with the inner end of each slot. When the electric contact and connection type COB-LED light source module is assembled, the inner end of each conducting strip is connectedly sleeved on the corresponding conducting column, the exposed outer end of each conducting strip is mutually inserted with an insertion connector of the corresponding single-core wire, the bottom end of each conducting column penetrates through the electrical interface support to be pressed on a corresponding electric contact on a PCB (printed circuit board). Therefore, the electric contact and connection type COB-LED light source module has the advantages of compact structure, space saving and good radiating effect.

Owner:KINGSUN OPTOELECTRONIC CO LTD

Welded type COB (chip on board)-LED light source module

ActiveCN102853298AEasy to assemble and disassembleCompact structurePoint-like light sourceElectric circuit arrangementsOn boardEngineering

The invention relates to a welded type COB (chip on board)-LED light source module which comprises a reflection cup, a radiator, a COB-LED light source component, an electrical interface support and a welding core wire. When the welded type COB-LED light source module is assembled, ends of two single-core wires of the welding core wire are correspondingly welded on corresponding welding points on a PCB (printed circuit board), the PCB in the COB-LED light source component is mounted in a mounting groove on the bottom surface of the electrical interface support, an LED chip in the COB-LED light source component exposes outside through a through hole in the middle of the electrical interface support, the two single-core wires welded on the PCB are led out through corresponding lead grooves respectively, and a plurality of screws penetrate through corresponding mounting holes to enable the electrical interface support and the COB-LED light source component to be in threaded connection on corresponding threaded holes of the radiator. By the structure, the welded type COB-LED light source module is compact in structure, convenient to assemble and disassemble, space-saving and good in radiating effect.

Owner:KINGSUN OPTOELECTRONIC CO LTD

Electric contact and connection type COB (chip on board)-LED light source module

InactiveCN102853301BAdequate heat dissipationEasy to assemble and disassemblePoint-like light sourceElectric circuit arrangementsConnection typeOn board

The invention relates to an electric contact and connection type COB (chip on board)-LED light source module which comprises a reflection cup, a radiator, a COB-LED light source component, an electrical interface support and two single-core wires. Fastening grooves are arranged on the inner wall of a through hole of the electrical interface support, each fastening groove is formed by connection of an insertion opening with a sliding groove, fasteners corresponding to the fastening grooves are arranged at the outer edge of a small mouth of the reflection cup, a slot for insertion of a conducting strip is arranged on each of two side faces of the electrical interface support, and a telescopic conducting column is arranged in an accommodating cavity connected with the inner end of each slot. When the electric contact and connection type COB-LED light source module is assembled, the inner end of each conducting strip is connectedly sleeved on the corresponding conducting column, the exposed outer end of each conducting strip is mutually inserted with an insertion connector of the corresponding single-core wire, the bottom end of each conducting column penetrates through the electrical interface support to be pressed on a corresponding electric contact on a PCB (printed circuit board). Therefore, the electric contact and connection type COB-LED light source module has the advantages of compact structure, space saving and good radiating effect.

Owner:KINGSUN OPTOELECTRONIC CO LTD

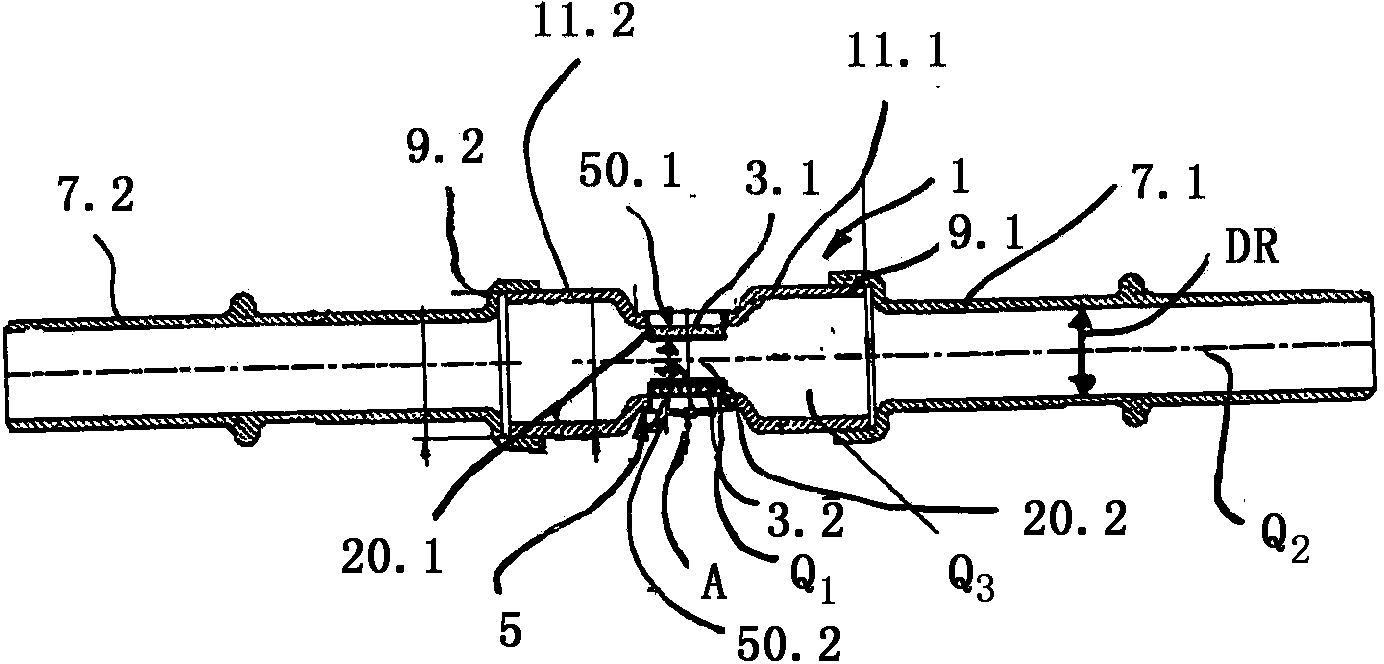

Sensor component for an optical flow rate sensor

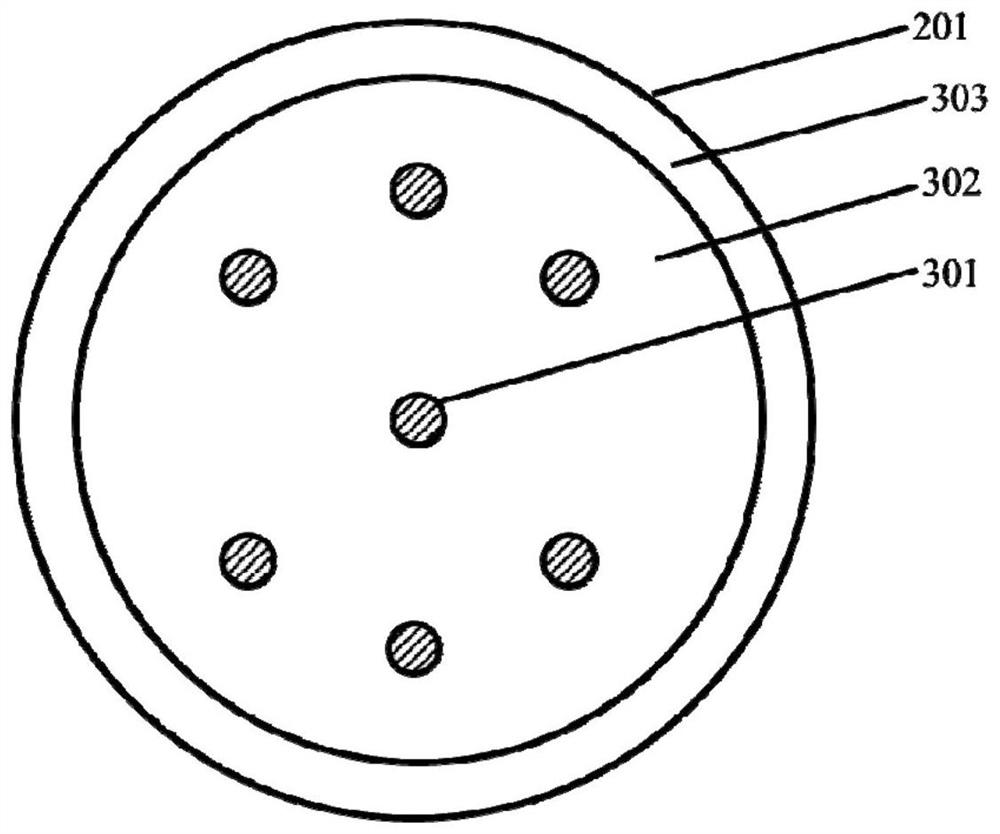

ActiveCN103547909ASize adjustmentGuaranteed diameterTransmissivity measurementsComputational physicsOptical flow

The invention relates to a sensor component for an optical flow rate sensor for fluid and / or gaseous media, comprising at least one component segment and at least one sensor segment, the sensor segment comprising at least two inspection windows in the region of a plurality of cutouts in a sensor segment disposed such that it is possible for light to pass through a transverse section of the sensor segment, or the sensor segment comprising exactly one inspection window in the region of a cutout and a reflective surface, in particular a mirrored or polished surface, being provided on the side opposite the cutout, such that it is possible for light to pass through the sensor segment twice through a transverse section of the sensor segment, characterized in that the sensor component comprises a receiving component that can be inserted in the one or more cutouts and the sight glass is bonded to the receiving component.

Owner:SCHOTT AG

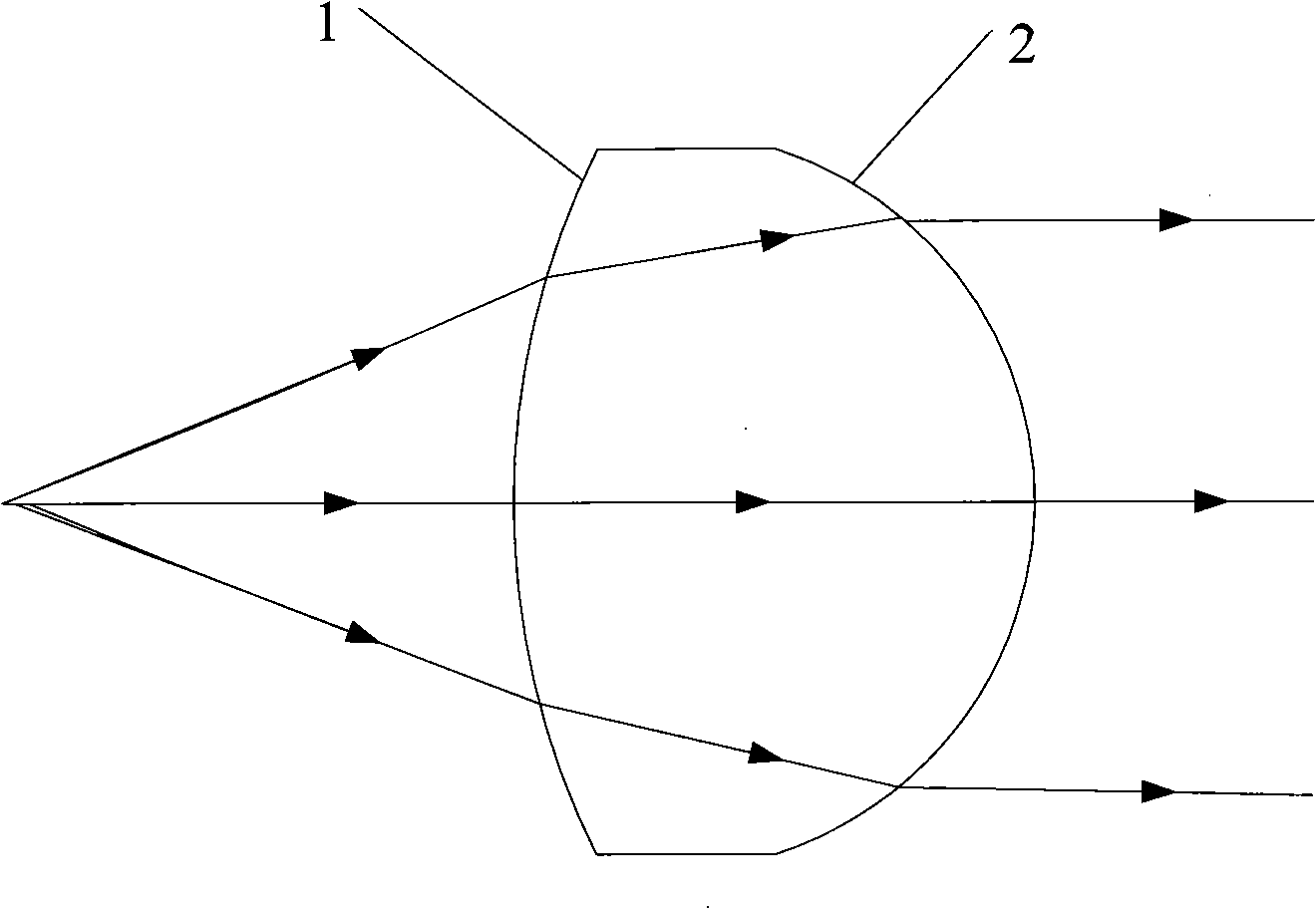

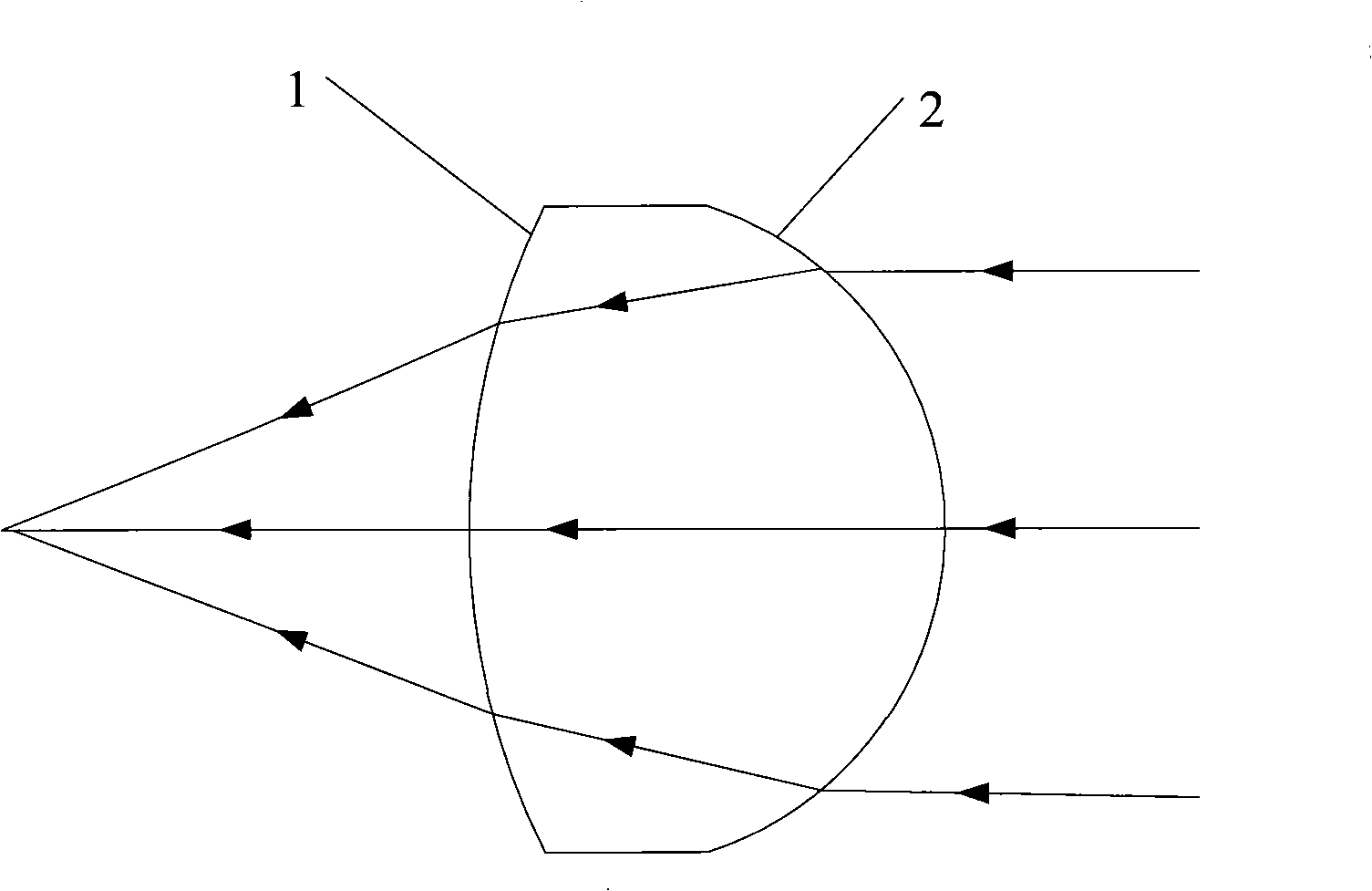

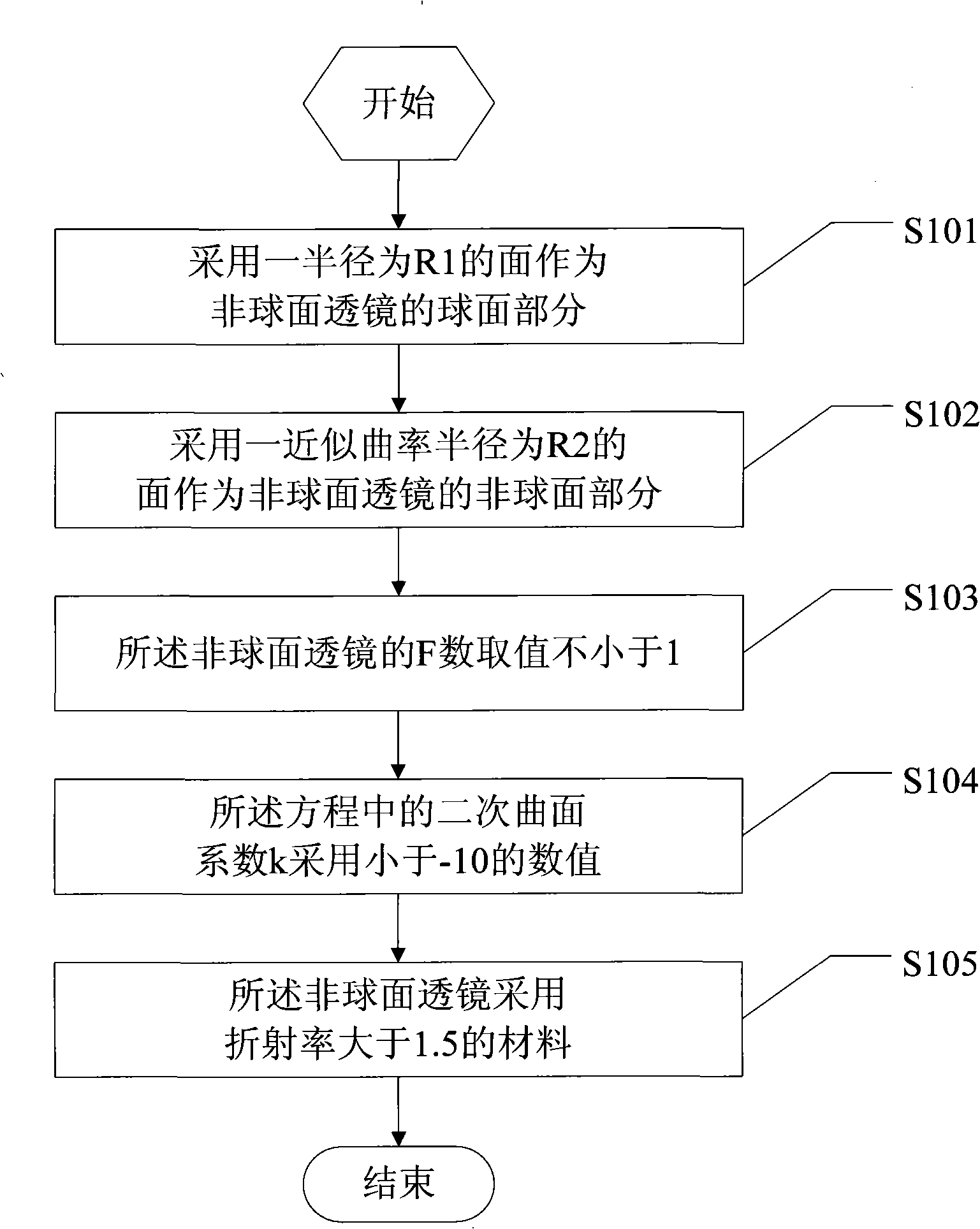

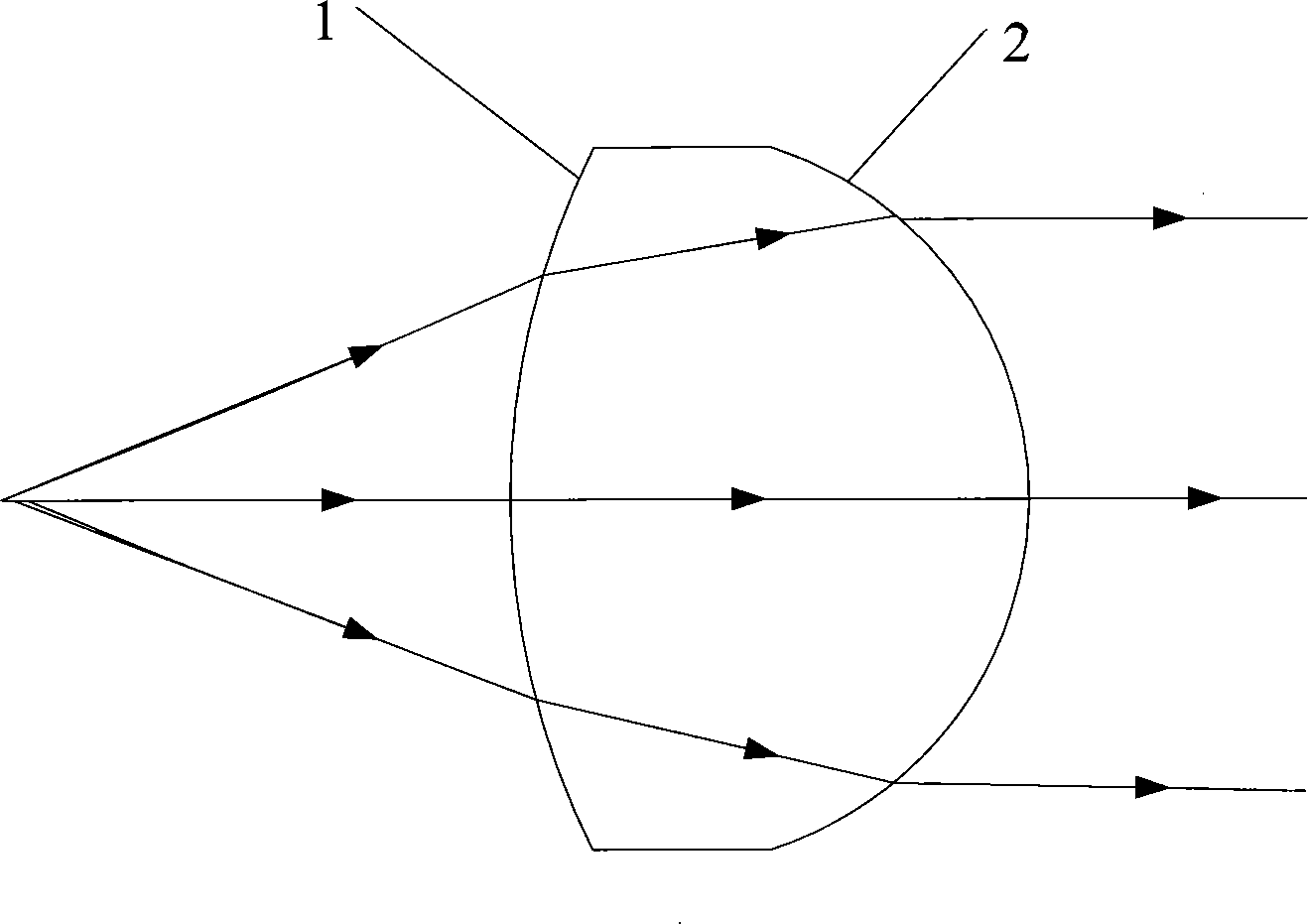

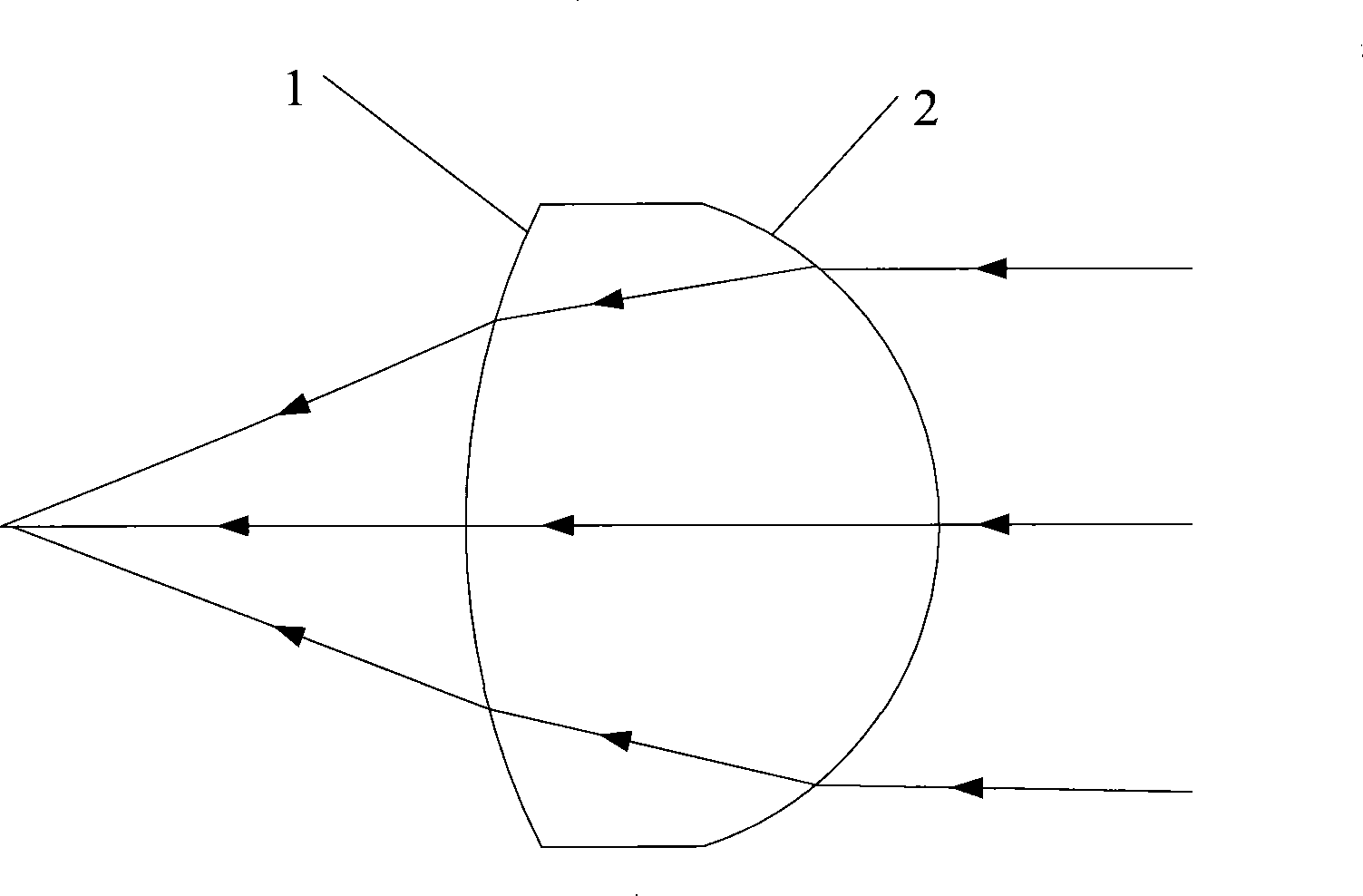

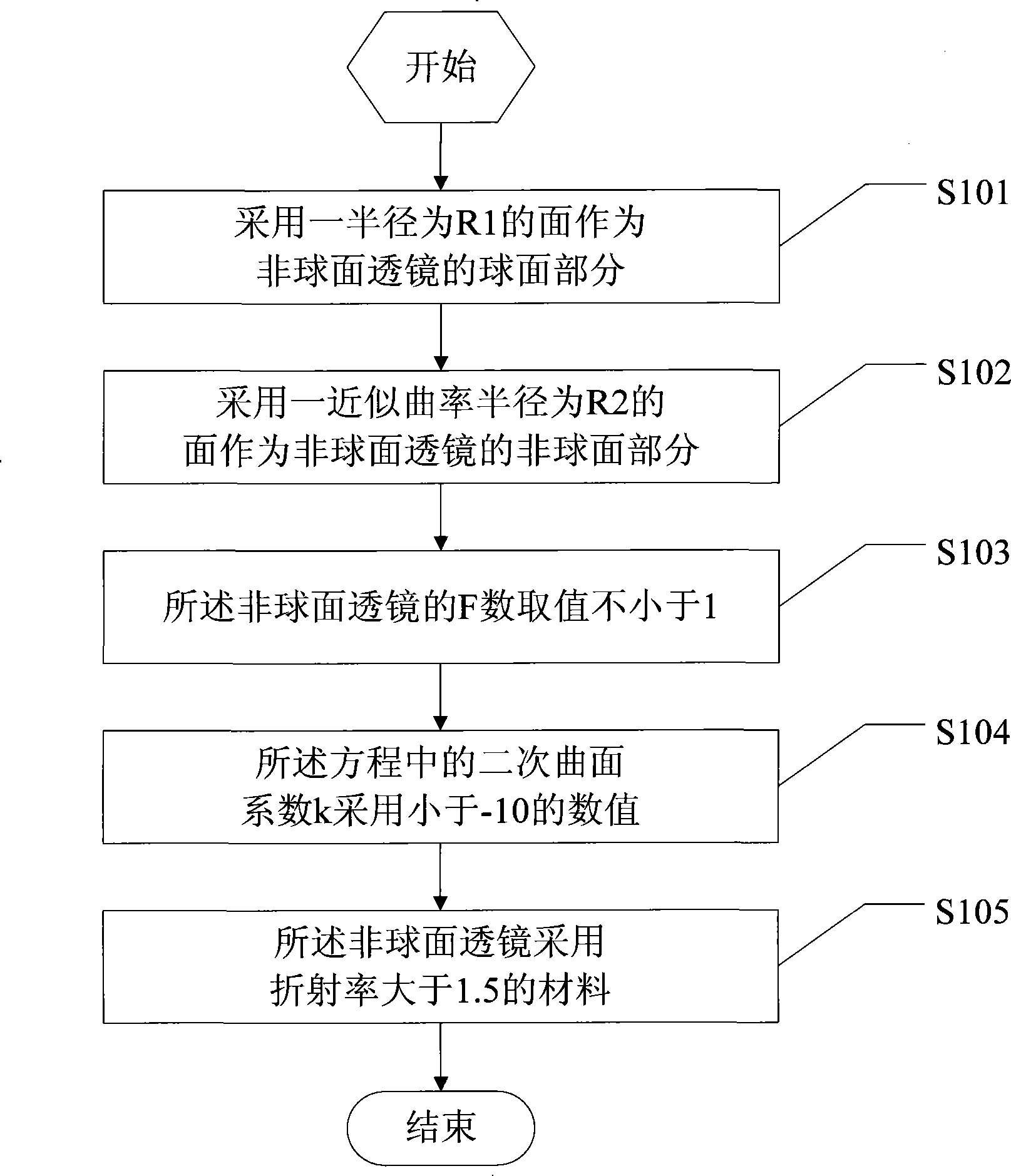

Non-spherical lens design method and non-spherical lens

The invention embodiment discloses a design method of an aspherical lens, which comprises: the surface with the semidiameter of R1 is taken as the spherical surface part of the aspherical lens; the surface with the approximate curvature radius of R2 is used as the aspherical surface part of the aspherical lens; the approximate curvature radius is the curvature radius value of the aspherical surface obtained by the spherical surface, and the absolute value of R2 is more than or equal to the double absolute value of R1. The invention embodiment also discloses an aspherical lens, and R2 is controlled to ensure that the absolute value of R2 is more than or equal to the double absolute value of R1. Therefore, the aspherical surface part of a correction system chromatic aberration is smoother than the spherical surface part, and the designed aspherical surface part lens can meet the optical requirement in using and is easy for processing and testing.

Owner:深圳市新岸通讯技术有限公司

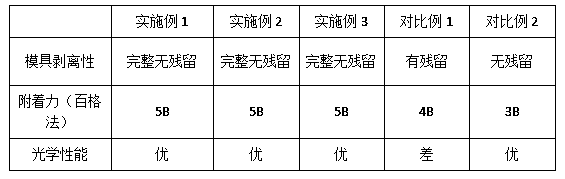

UV (ultraviolet) optical adhesive

InactiveCN109735290AHigh speedReduce foulingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesOligomerAdhesive

The invention discloses UV (ultraviolet) optical adhesive, made from, by weight, 30-60 parts of an acrylate oligomer, 30-50 parts of an acrylate monomer, 1-4 parts of a photopolymerization initiator,and 3-5 parts of an adhesion promotion aid. The UV optical adhesive has the advantages that the finished adhesive has reliable indexes, the yield is increased, fewer defects are shown to customers, mobility and curing speed of the adhesive are increased, and coating speed is increased so that production efficiency is improved.

Owner:苏州宝瑞德纳米光学材料有限公司

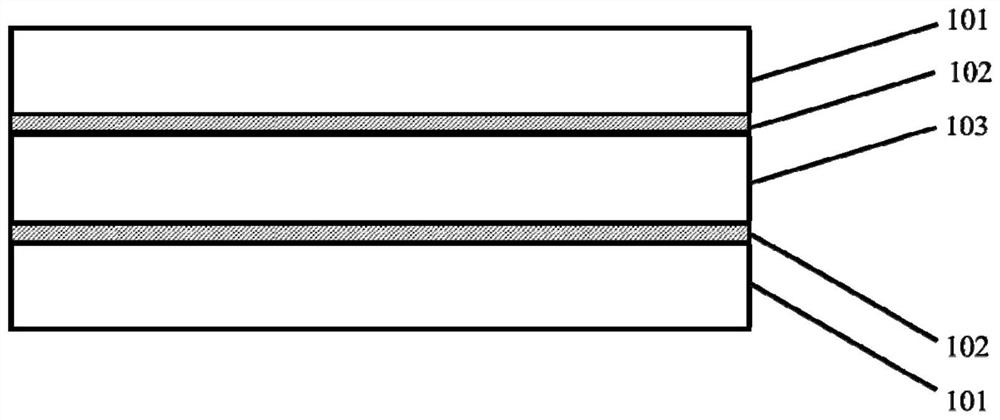

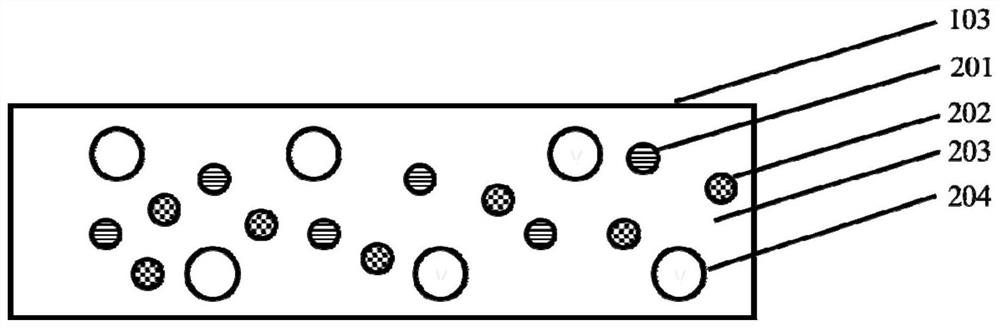

Novel barrier-free quantum dot film and preparation method thereof

PendingCN113619204AImprove stabilityEasy to produceMaterial nanotechnologyNon-macromolecular adhesive additivesMicrosphereAdhesive glue

The invention provides a novel barrier-free quantum dot film and a preparation method thereof, and relates to the technical field of optical films. According to the preparation method, quantum dots and matrix particles are subjected to melt extrusion molding granulation and crushing to form quantum dot matrix microspheres, and then the surfaces of the quantum dot matrix microspheres are coated with a water-blocking and oxygen-isolating coating, so that the stability of the quantum dots is improved; or quantum dots and oil-soluble monomers are subjected to a polymerization reaction to generate quantum dot polymer microspheres, and the quantum dots are wrapped in the polymer microspheres, so that the quantum dots are isolated from water and oxygen, and the stability of the quantum dots is improved; and the quantum dot matrix microspheres or the quantum dot polymer microspheres and scattering particles are dispersed in a resin glue in proportion, and a barrier-free quantum dot film is obtained after the resin glue is cured. According to the invention, the water-blocking and oxygen-isolating performance of the quantum dots is improved, a traditional blocking layer does not need to be used, and the production cost of the quantum dot film is greatly reduced.

Owner:NANJING BREADY ELECTRONICS CO LTD

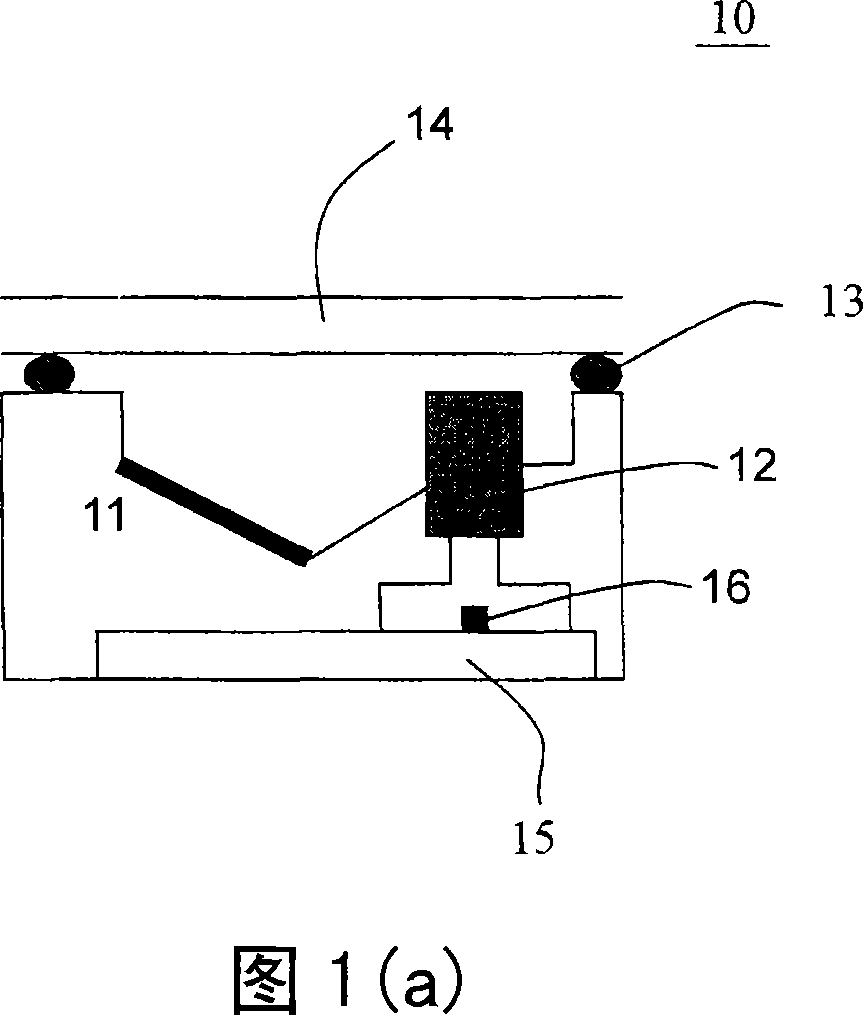

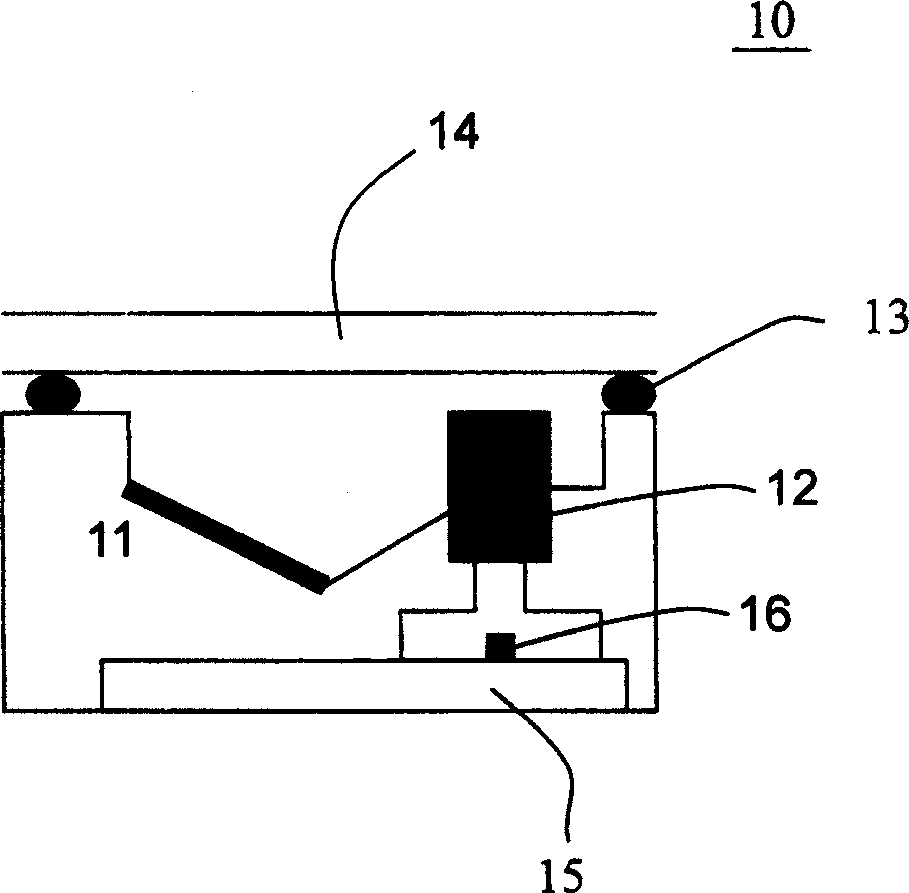

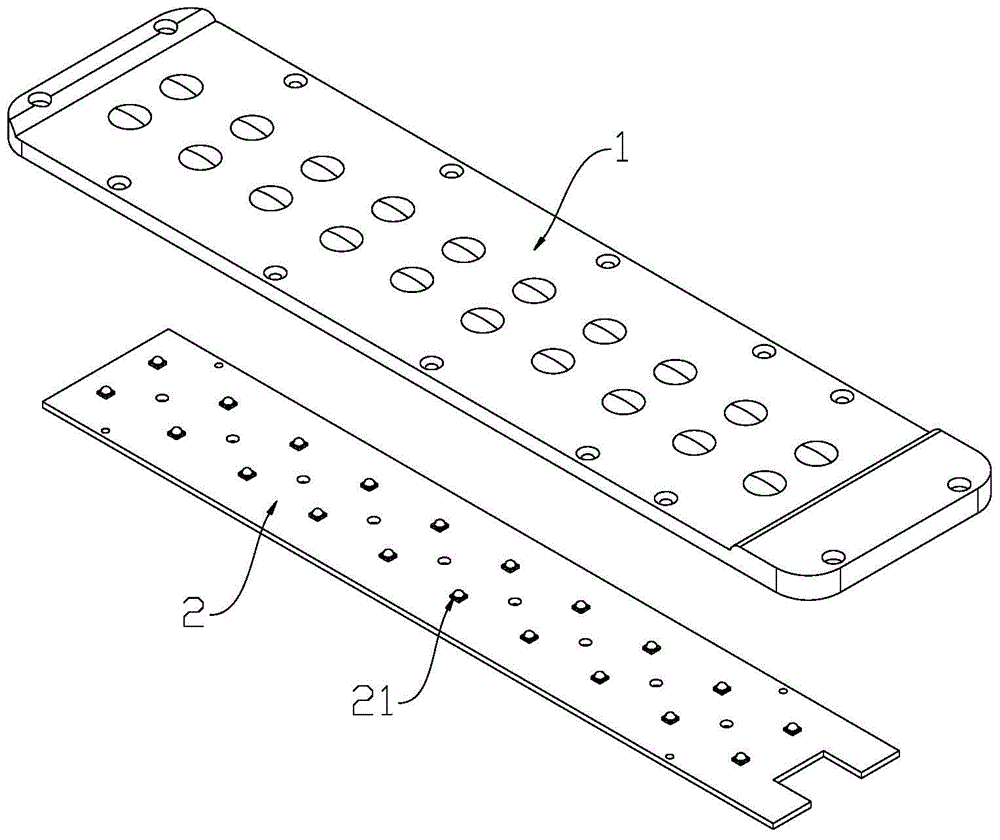

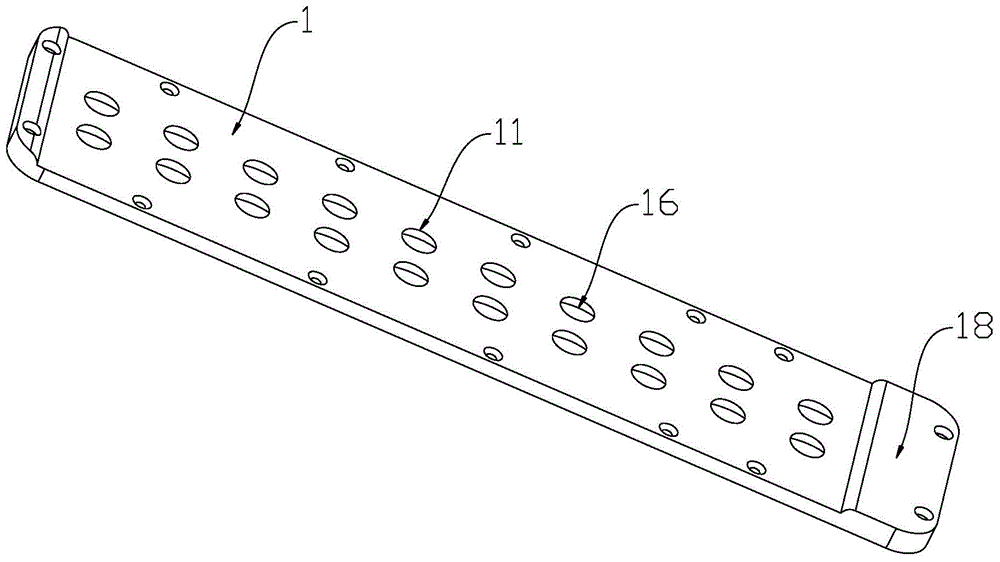

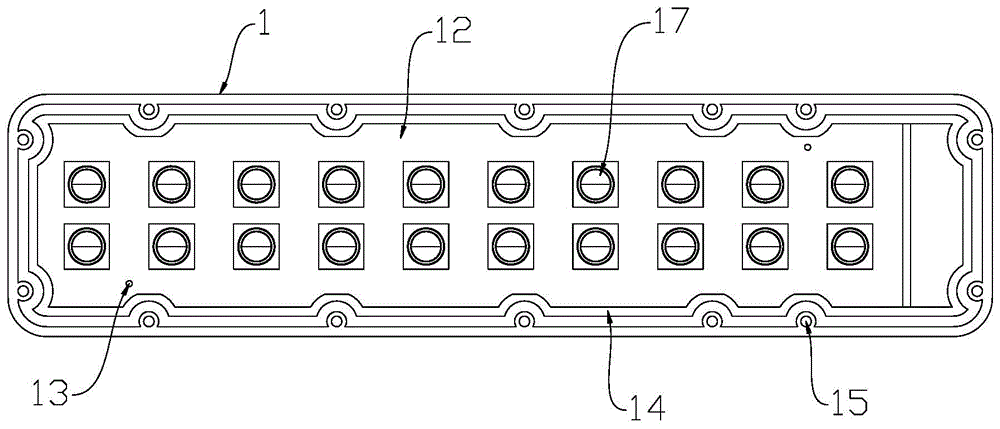

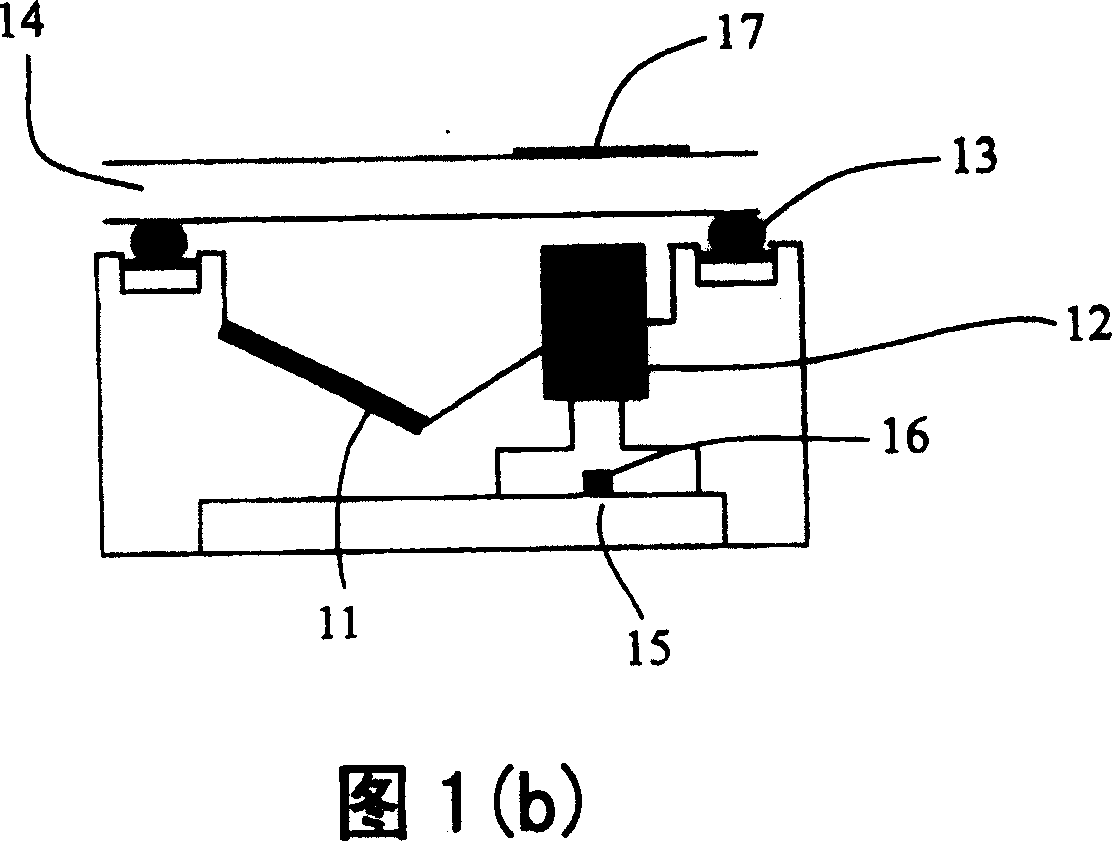

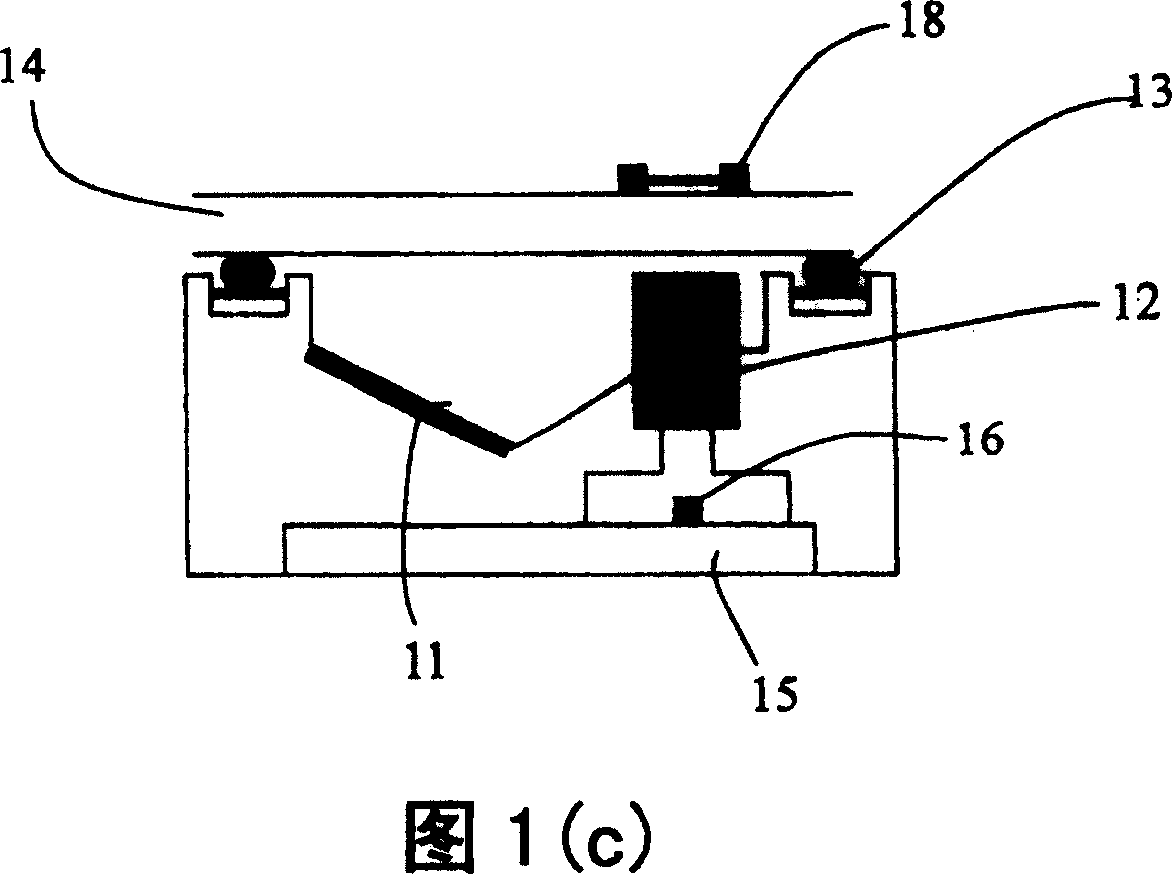

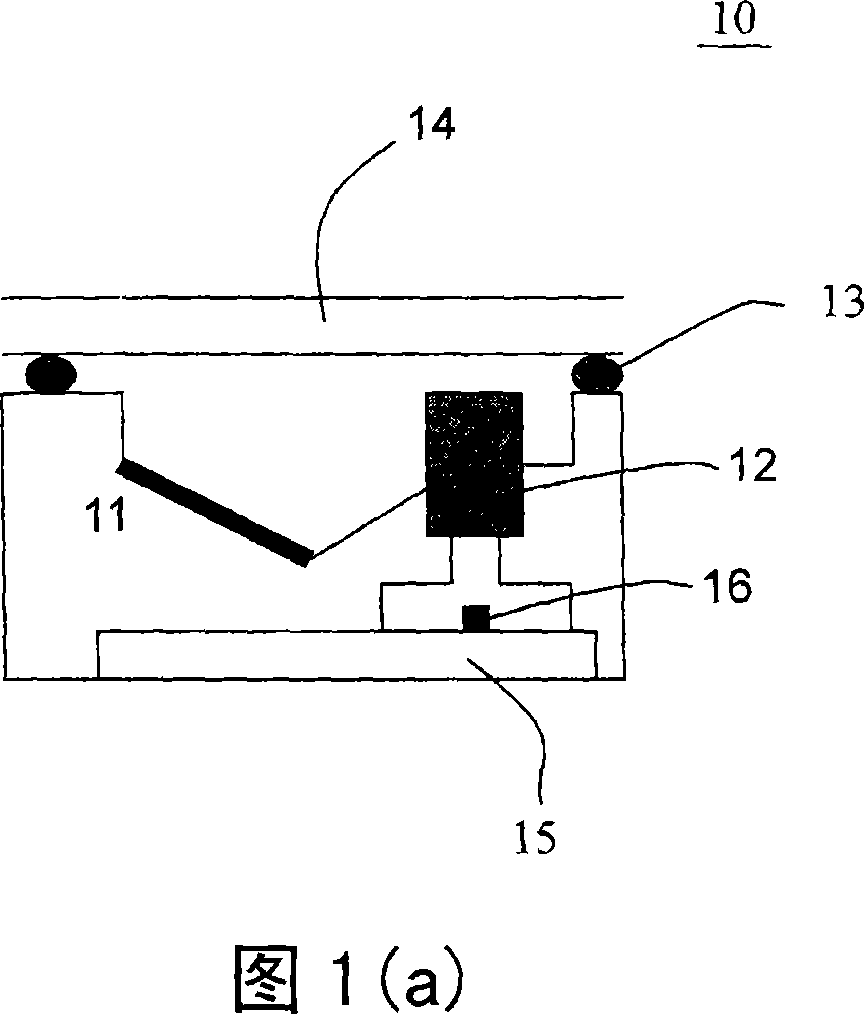

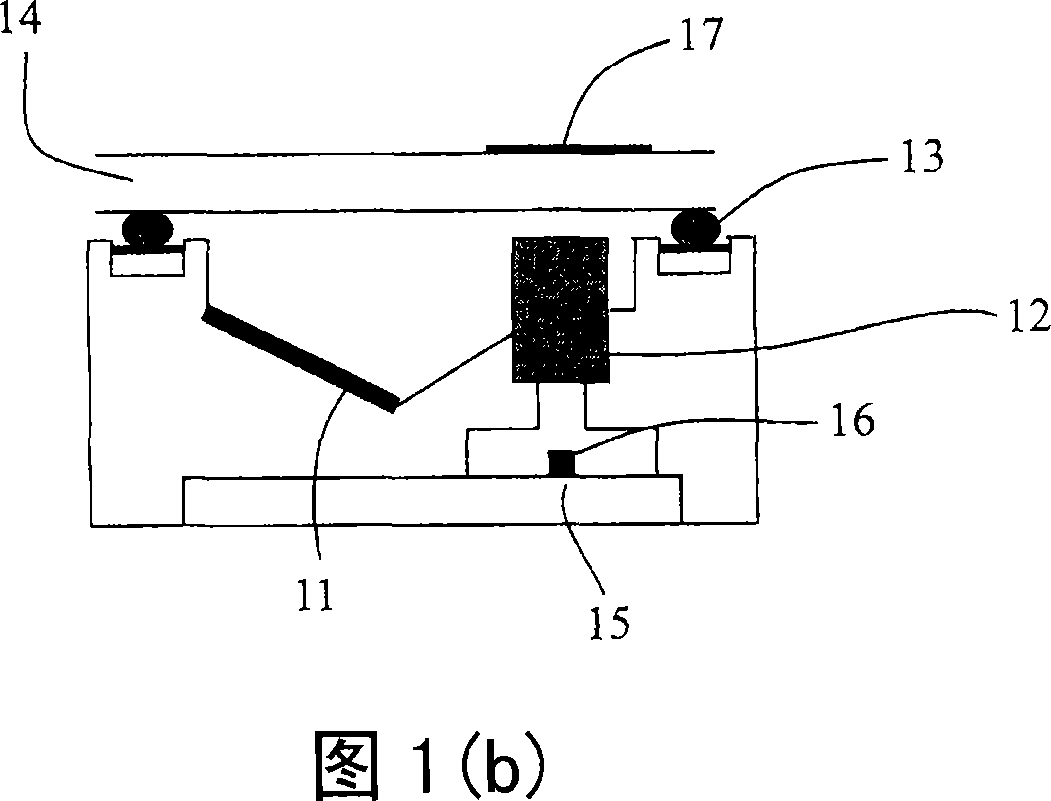

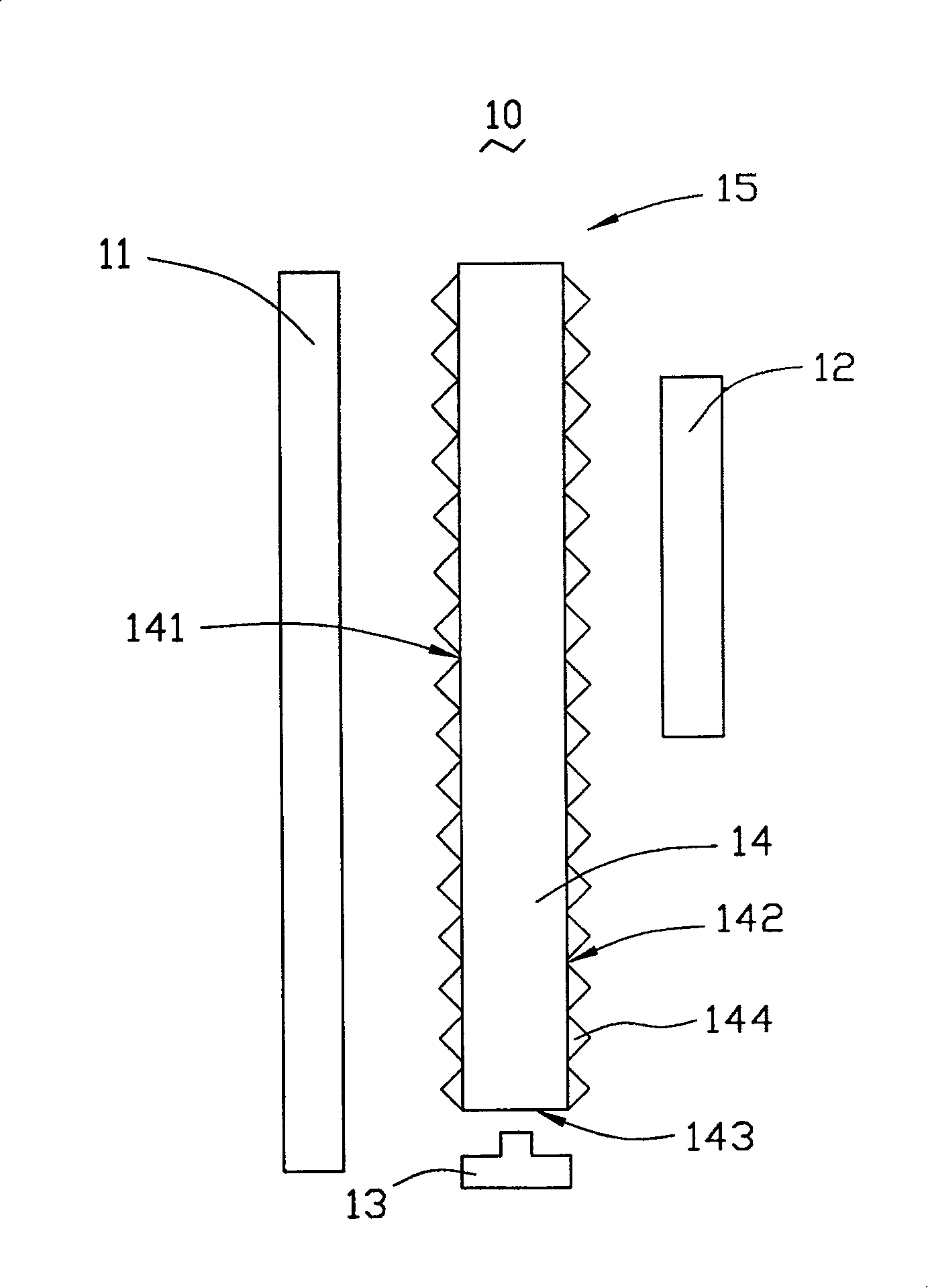

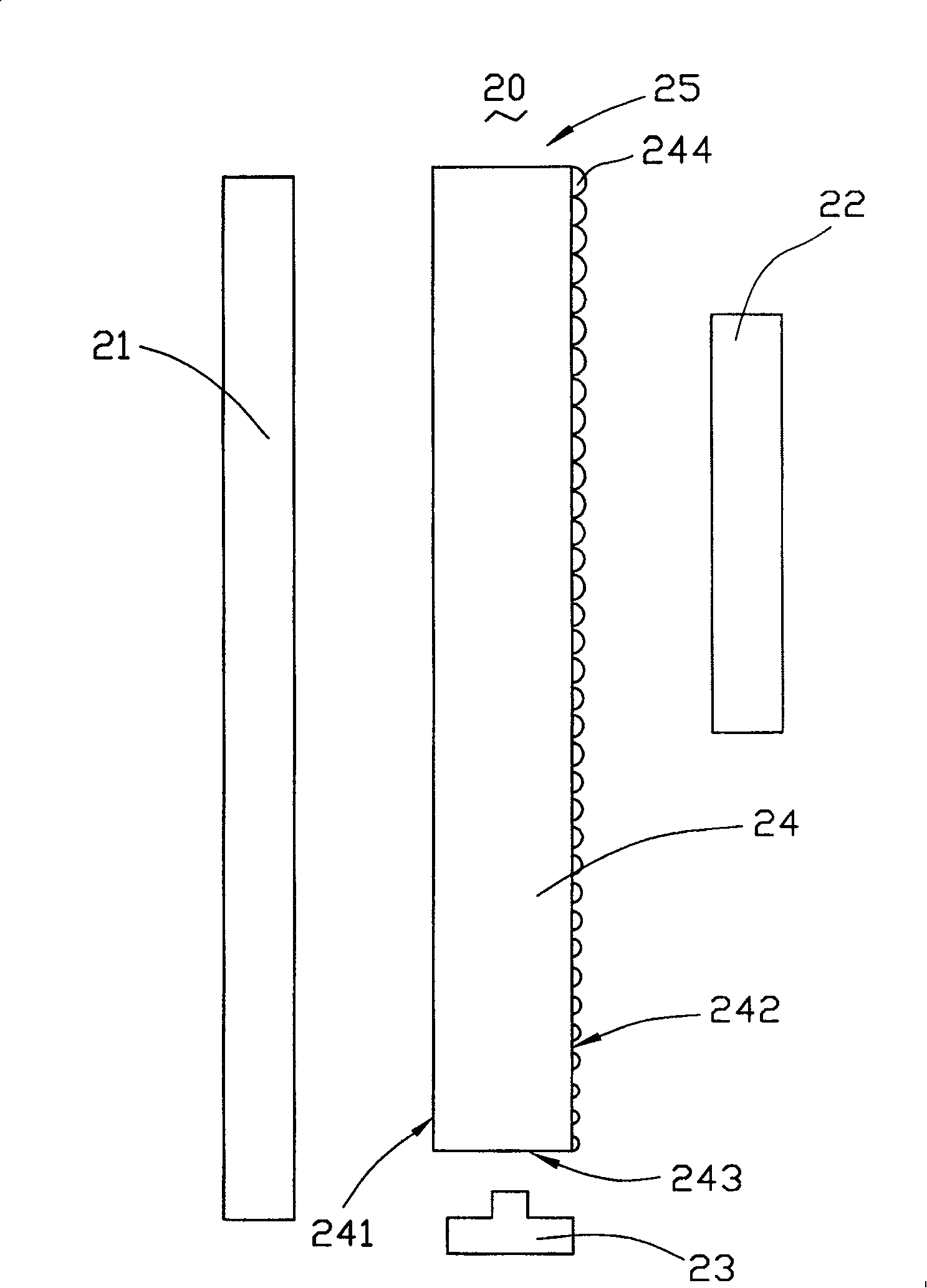

Contact image scanner with multi focallength and multi resolution

ActiveCN101026671AMeet the needs of scanning surfaces of different heightsReach scan capacityPictoral communicationLensImage resolutionMulti resolution

The image scanner includes following parts: a circuit board; at least two sets of sensitizing element array (SEA) including first set of SEA and second set of SEA, and the two sets of SEA arranged parallel to each other located above the circuit board; at least one set of columnar lens composed of first and second columnar lenses; first columnar lens and second columnar lens suspended on the corresponding first set of SEA and second set of SEA; a first glass is suspended on the set of columnar lens; a second glass is suspended between the first columnar lens and the first set of SEA. Using two sets of SEA, the set of columnar lens, and the second glass forms at least two focuses and resolutions in order to scan different objects to be scanned on the glass.

Owner:WUXI CREATIVE SENSOR TECH

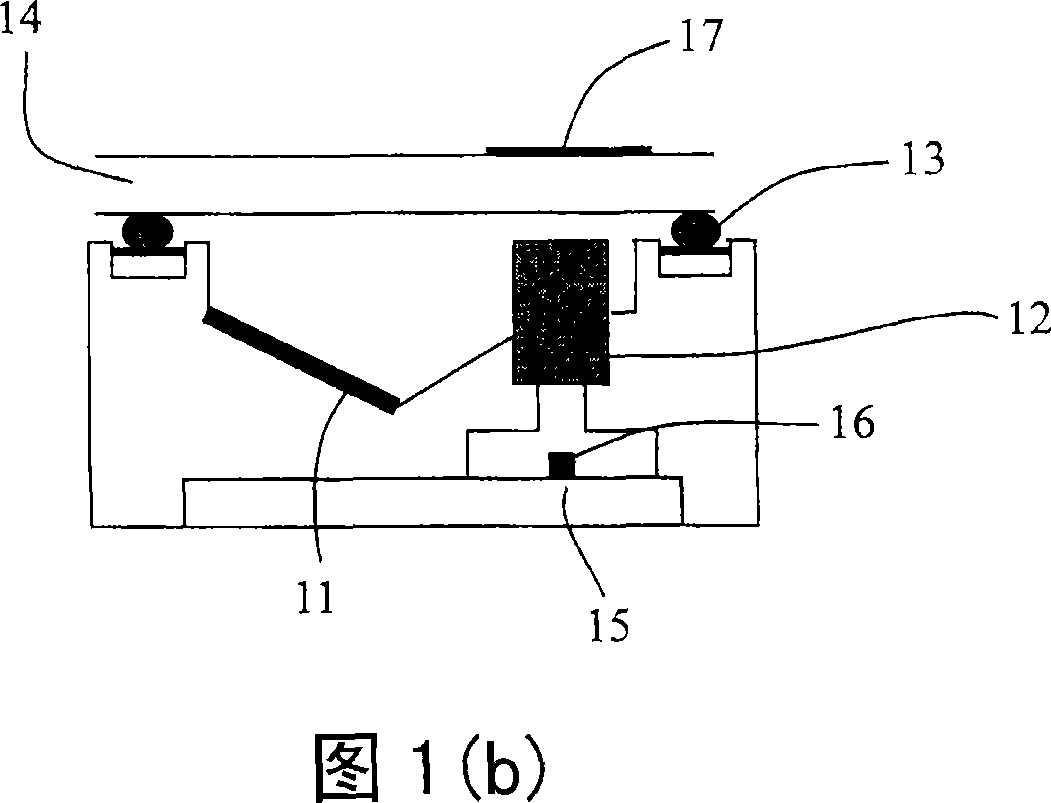

Contact type image scanner with multi-focus and multi resolution ratio

ActiveCN1735123AMeet the needs of scanning surfaces of different heightsReach scan capacityPictoral communicationLensImage resolutionEngineering

This invention provides a contact image scanner with multi focus and resolution, which comprises: a circuit board, at least two set of photosensitive element arrays composed of first and second set photosensitive element arrays arranged on circuit board of single row, at least one set of cylinder lens of first and second lens opposite separately to the said photosensitive element arrays and upper suspended, and a first glass suspended upper the cylinder lens. The combination of circuit board, photosensitive element arrays and cylinder lens matches with the position regulation, variety, thickness, and vertical distance, to form more than two focus and resolution for scanning to image with different focus.

Owner:南昌菱光科技有限公司

Plug-in type COB (chip on board)-LED light source module

InactiveCN102853300AEasy to assemble and disassembleCompact structurePoint-like light sourceLighting heating/cooling arrangementsOn boardEngineering

The invention relates to a plug-in type COB (chip on board)-LED light source module which comprises a reflection cup, a radiator, a COB-LED light source component, an electrical interface support and a double-core wire. When the plug-in type COB-LED light source module is assembled, one end of the double-core wire is plugged on a double-core socket, a PCB (printed circuit board) in the COB-LED light source component is mounted in a mounting groove at the bottom of the electrical interface support, an LED chip in the COB-LED light source component exposes outside through a through hole in the middle of the electrical interface support, and the double-core wire of the double-core socket plugged on the PCB is led out by the aid of the mounting groove; a plurality of screws penetrate through corresponding mounting holes to enable the electrical interface support and the COB-LED light source component to be in threaded connection on corresponding threaded holes of the radiator. By the structure, the plug-in type COB-LED light source module is compact in structure, convenient to assemble and disassemble, space-saving and good in radiating effect.

Owner:KINGSUN OPTOELECTRONIC CO LTD

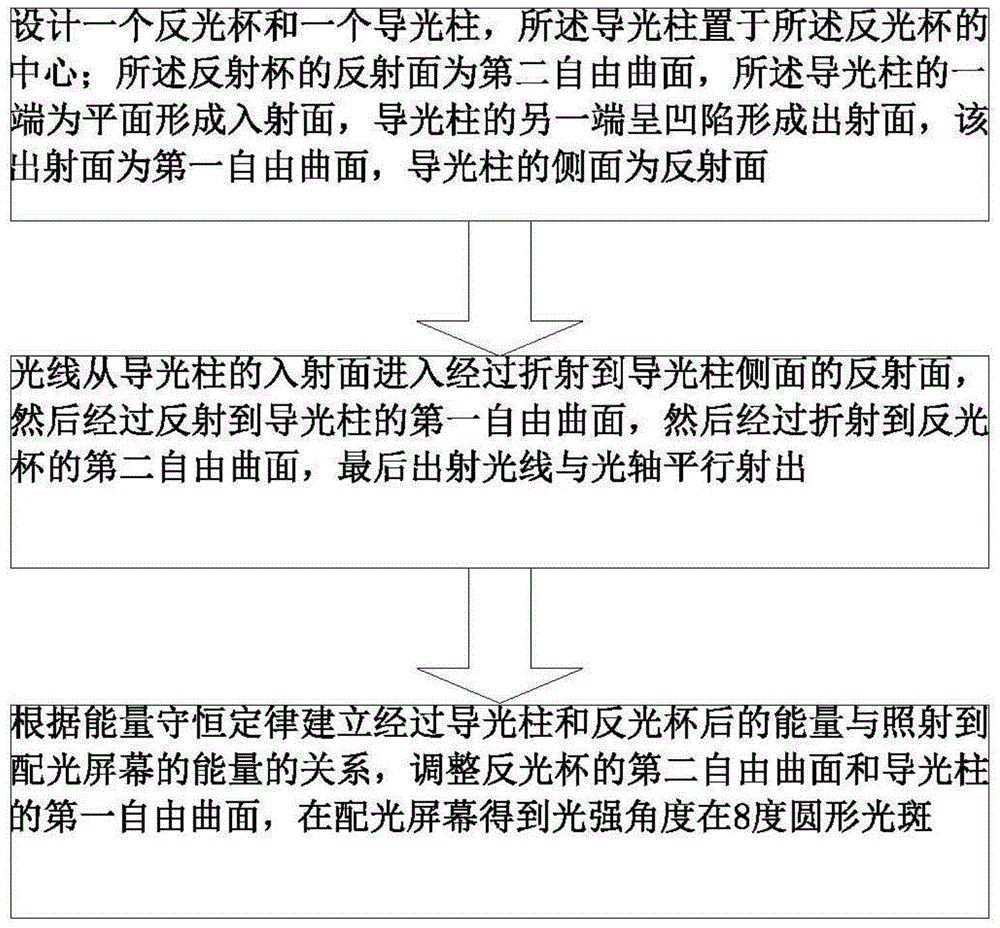

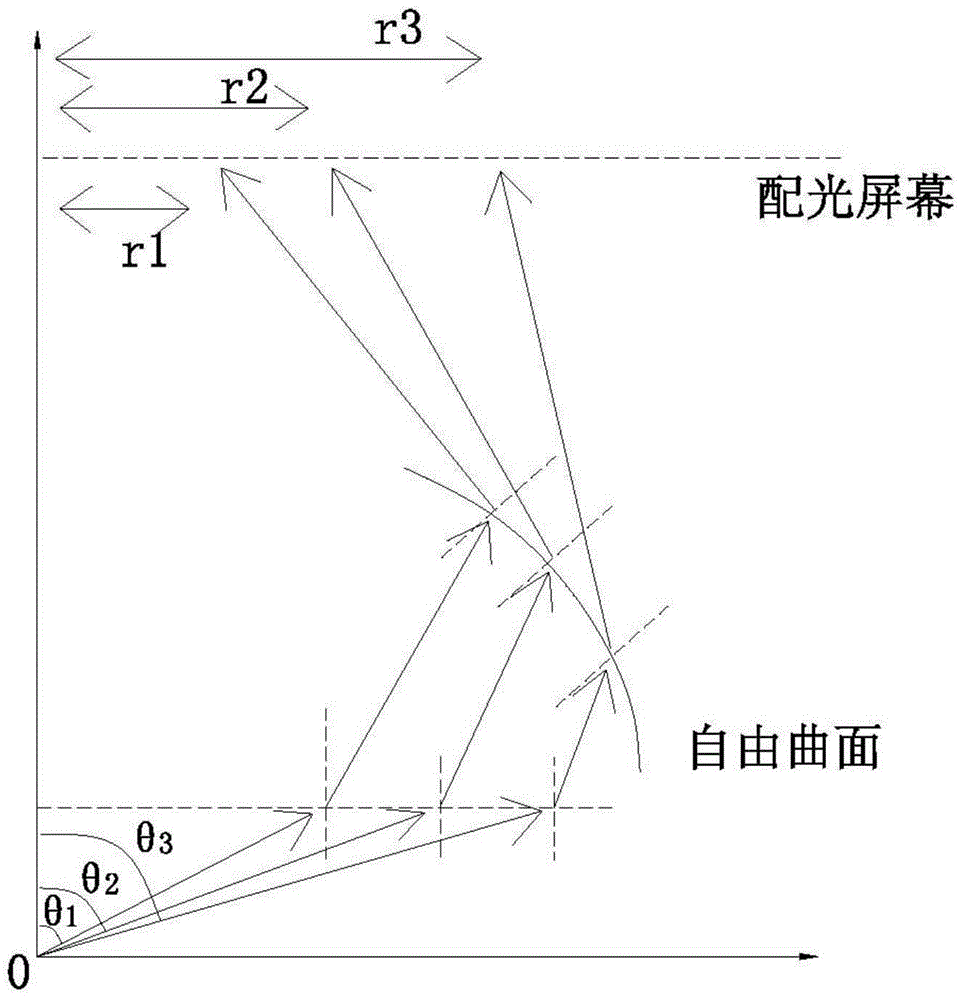

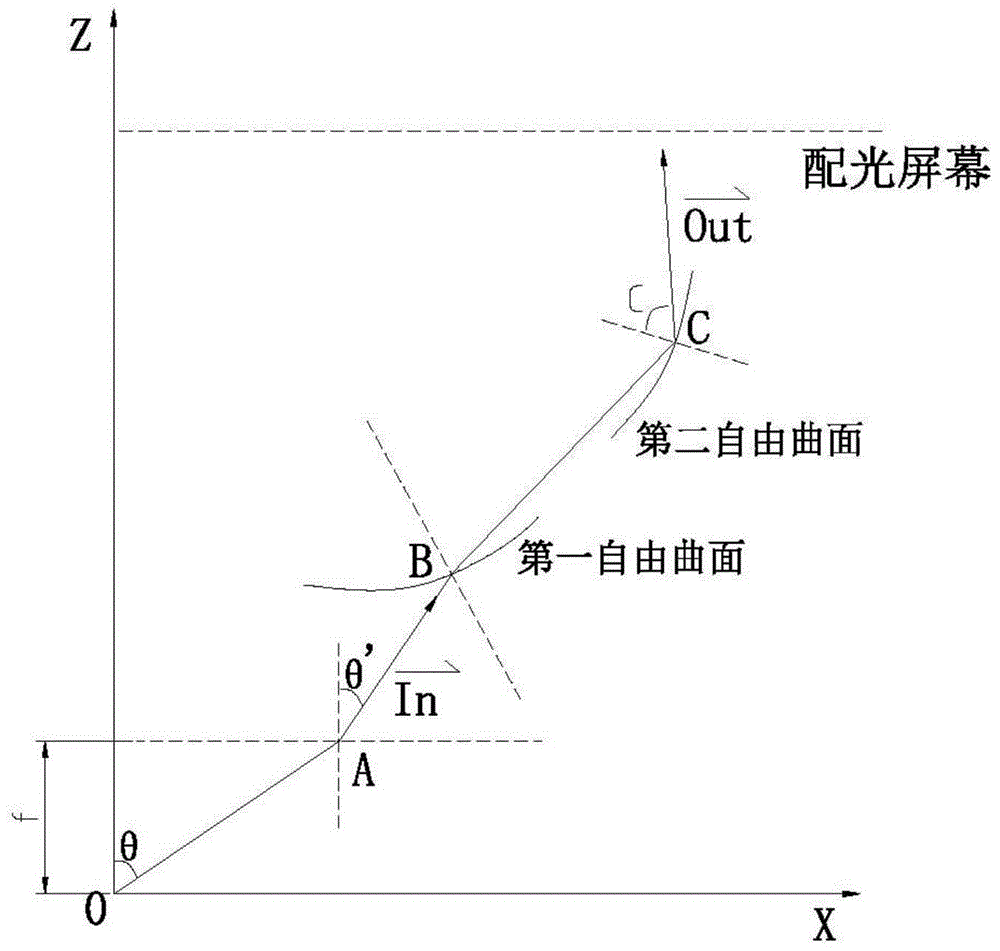

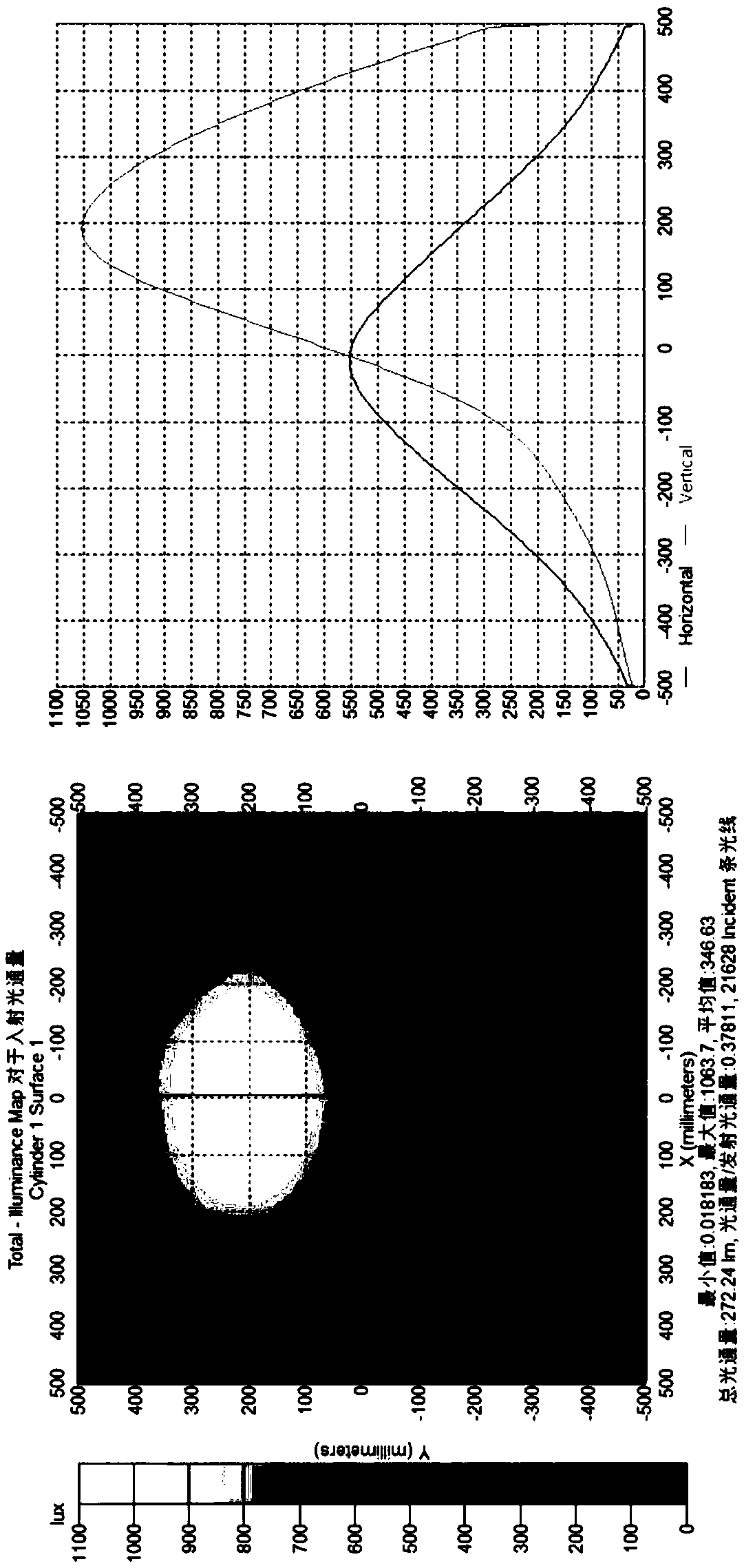

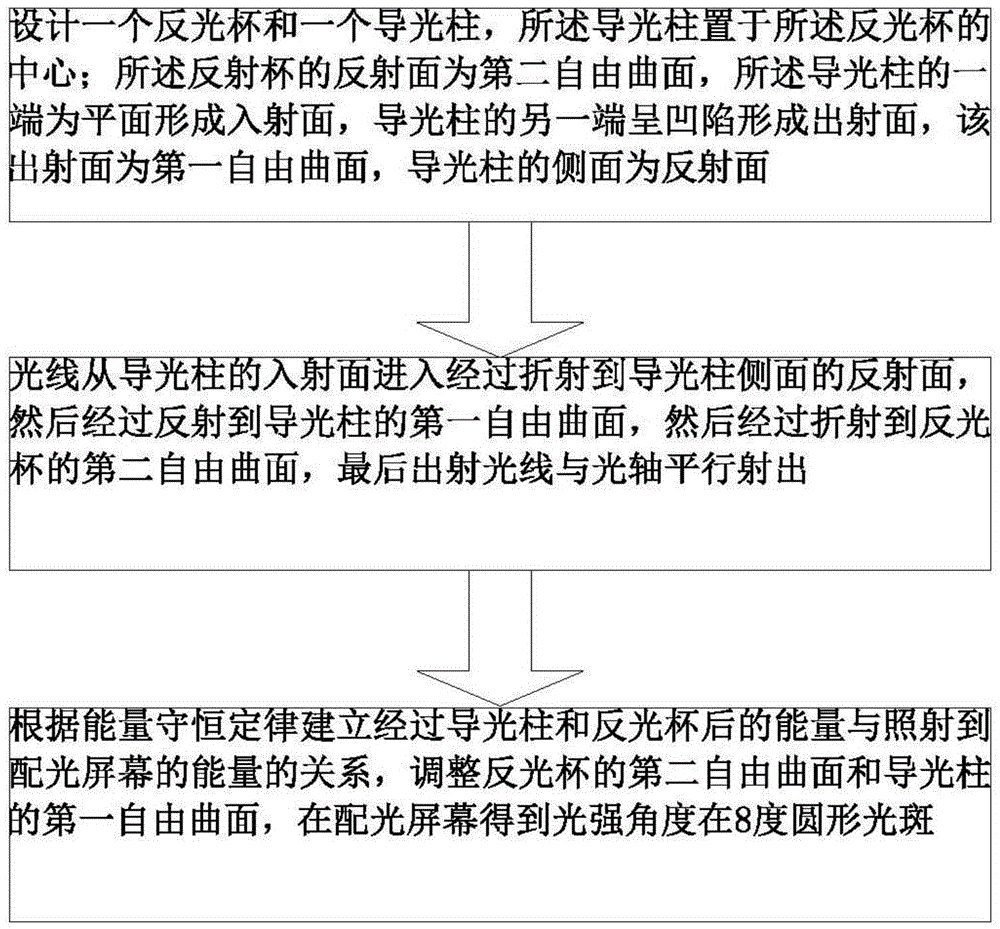

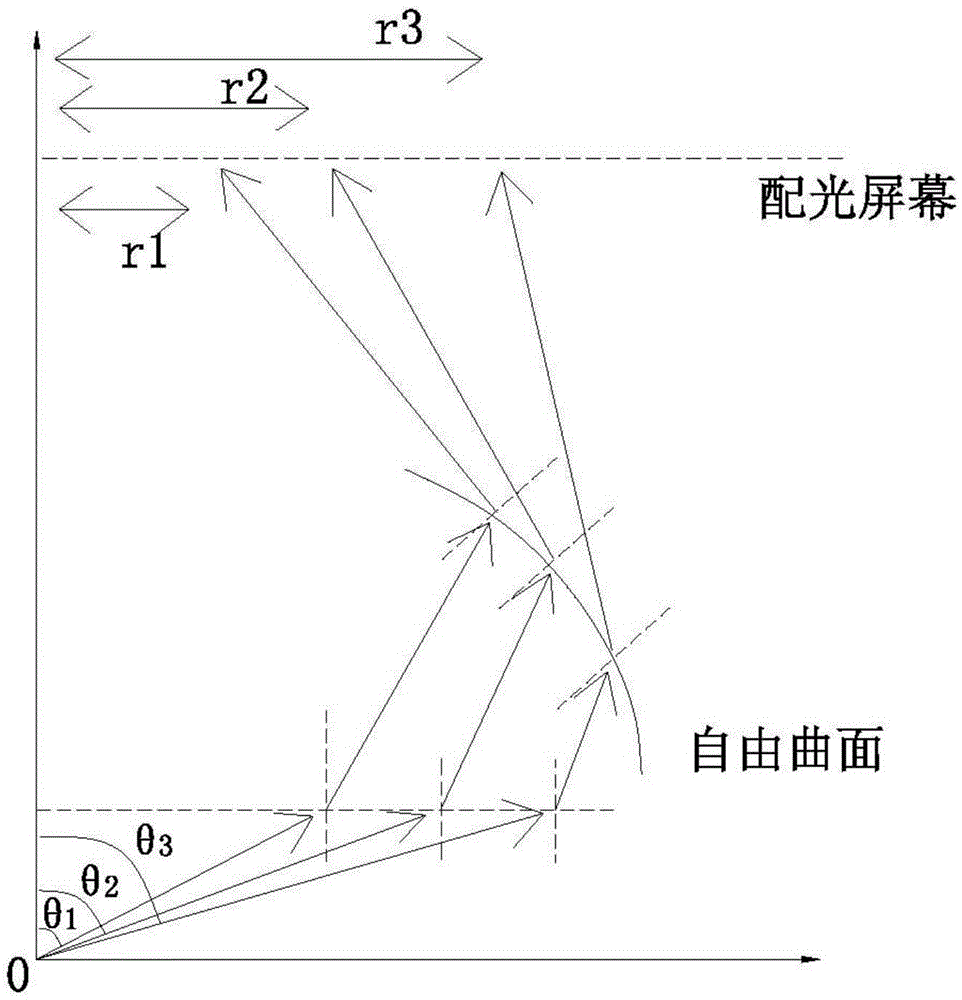

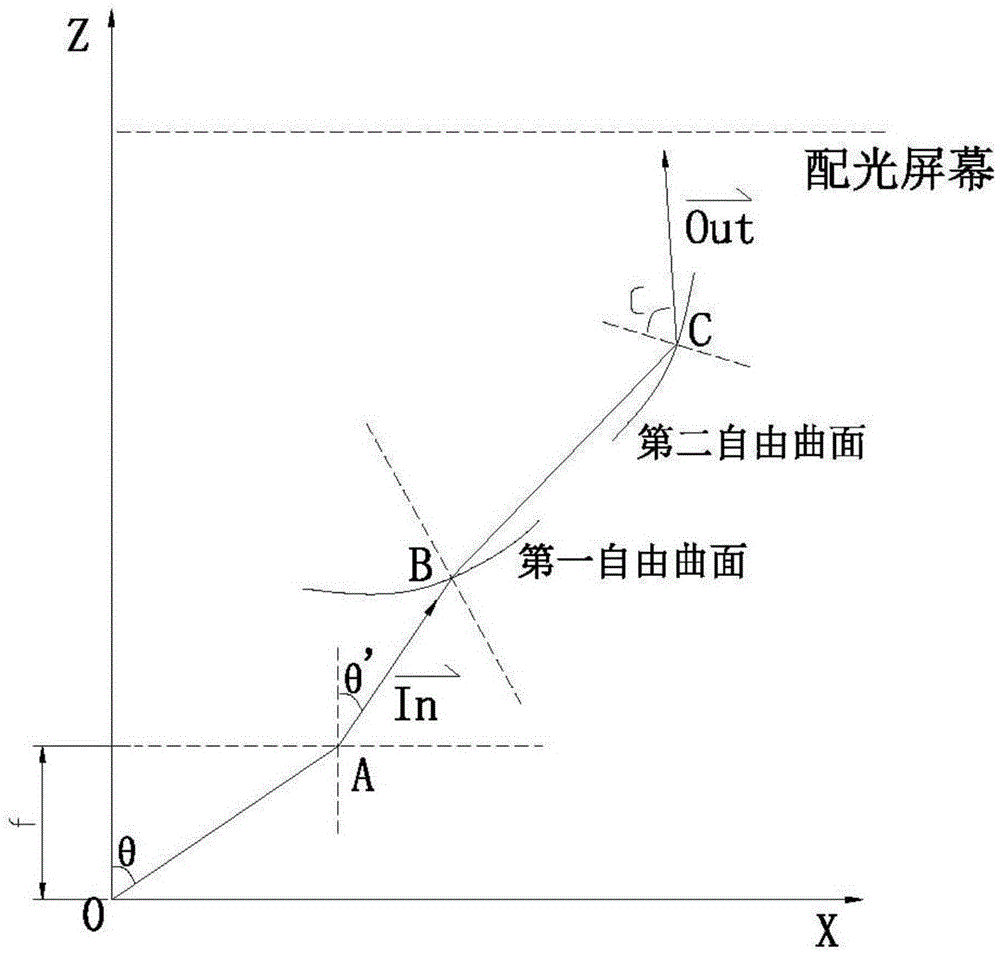

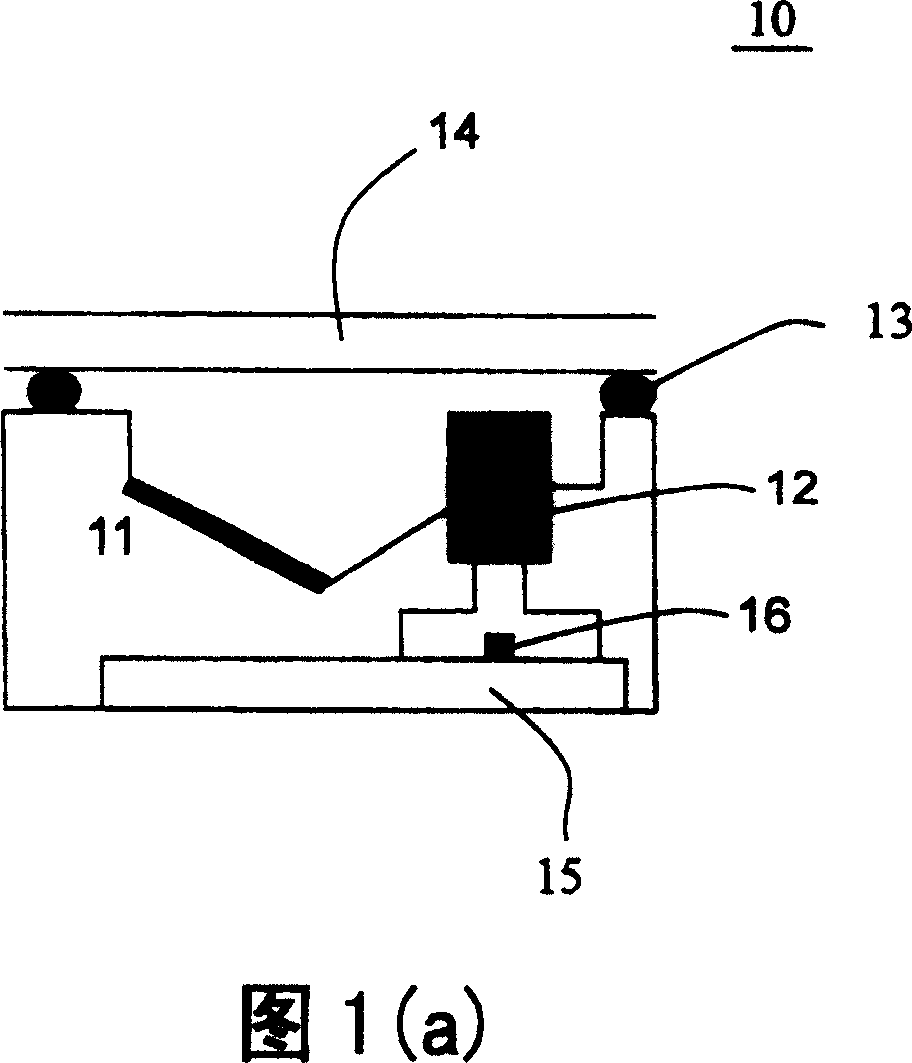

Optical design method enabling half-intensity angle to be located on 8-degree round spot

ActiveCN104534407AMeet optical requirementsMechanical apparatusVehicle headlampsExit surfaceLight pillar

An optical design method enabling a half-intensity angle to be located on a 8-degree round spot comprises the steps that (1) a reflection cup and a light guiding pillar are designed, wherein the light guiding pillar is arranged at the center of the reflection cup, the reflection surface of the reflection cup is a second free-form surface, one end of the light guiding pillar is a plane and serves as an incident plane, the other end of the light guiding pillar is concave and serves as an exit surface which is a first free-form surface, and the side face of the light guiding pillar is a reflection surface; (2) light enters through the incident plane of the light guiding pillar and is refracted to the reflection surface on the side face of the light guiding pillar, reflected to the first free-form surface of the light guiding pillar, refracted to the second free-form surface of the reflection cup, and finally emitted in the direction parallel to the optical axis; (3) the relationship between the energy obtained after light passes through the light guiding pillar and the reflection cup and the energy irradiated on a light distribution screen is established according to the energy conservation law, the second free-form surface of the reflection cup and the first free-form surface of the light guiding pillar are adjusted, and the half-intensity angle is obtained on the 8-degree round spot of the light distribution screen.

Owner:GUANGDONG RAYTON INTELLIGENT OPTO CO LTD

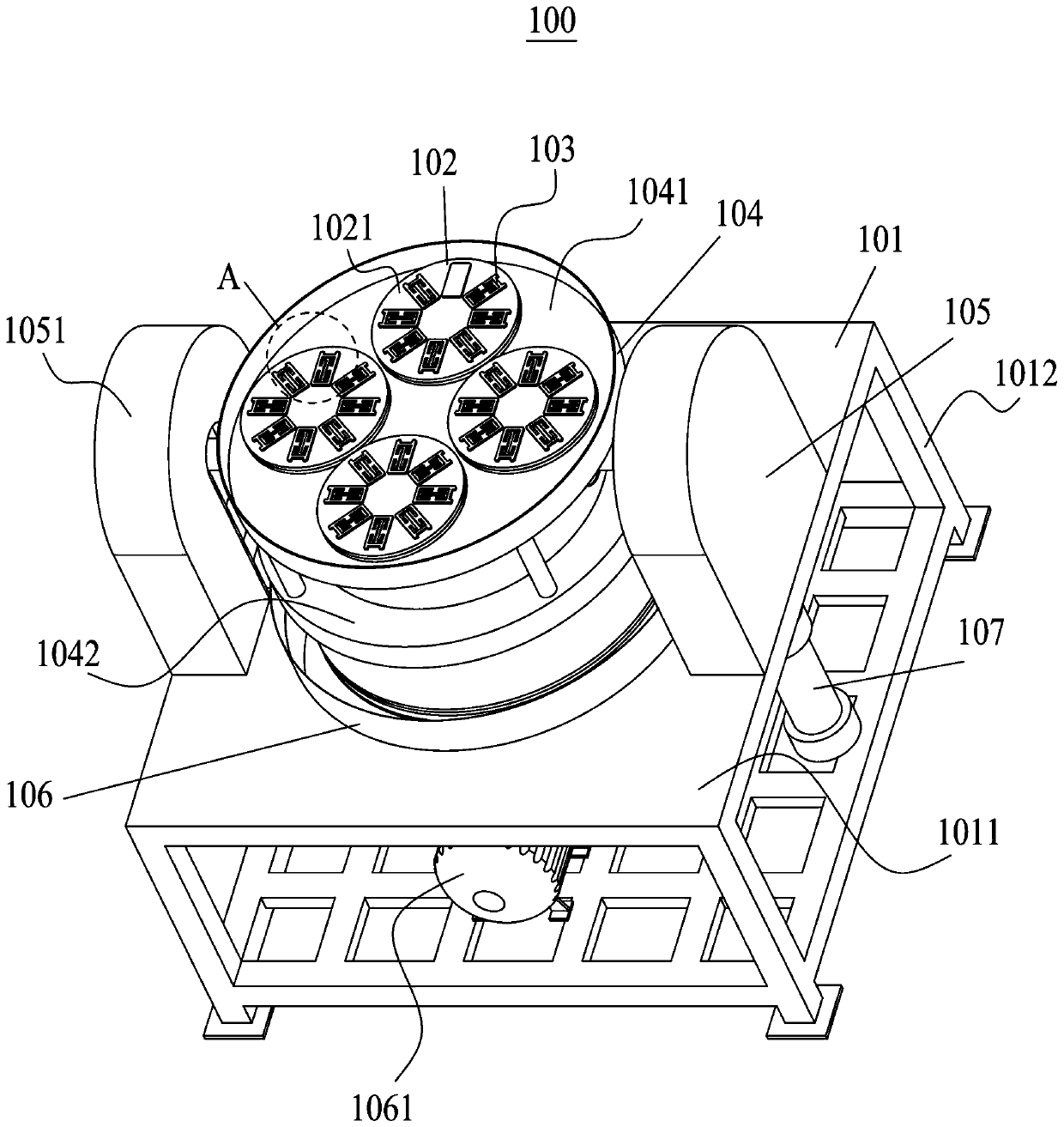

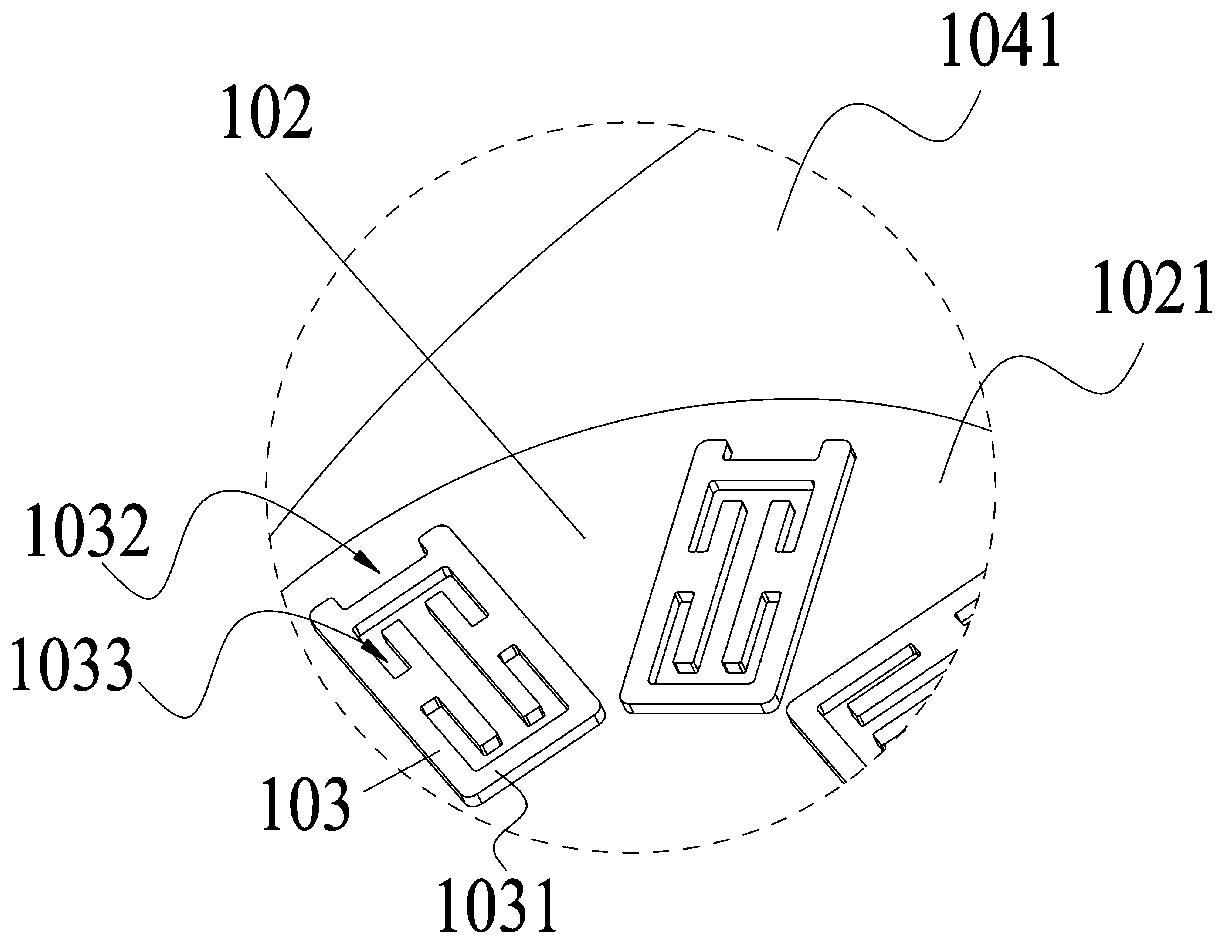

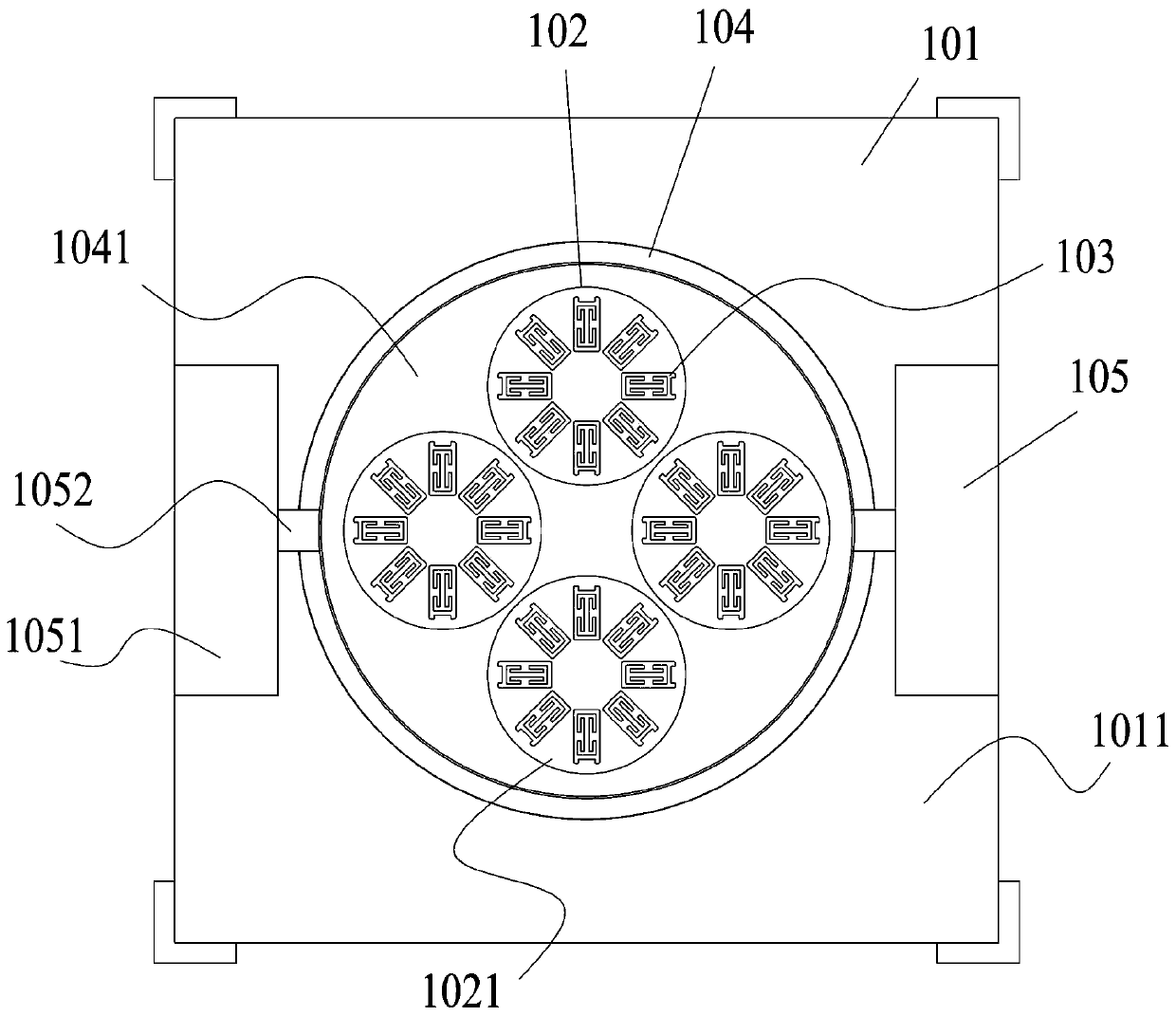

Glass cover plate machining method and polishing machine related to glass cover plate machining

PendingCN110170918AReduce knife marksReduce interference fringesPolishing machinesGrinding machinesGlass coverMachining

The invention discloses a glass cover plate machining method and a polishing machine related to glass cover plate machining, and relates to the glass machining technology. The polishing machine comprises at least two jig discs a fixing disc device, a turnover mechanism, a polishing device and a lifting device, wherein each jig disc is provided with at least two jigs for fixing a glass cover plate;the fixing disc device is fixed to a turnover shaft rod of the turnover mechanism; the turnover mechanism comprises a power device for driving the turnover shaft rod, and the turnover shaft rod is used for driving a first fixing disc and a second fixing disc to turn at the same time; the polishing device is used for polishing the glass cover plates; and the lifting device is used for driving a polishing carpet layer and the glass cover plates arranged on the fixing disc device to contact during polishing treatment or go away from each other during non-polishing treatment. Through the polishing machine provided by the invention, interference fringes in the camera shooting hole forming zones of the glass cover plates can be decreased, and the optical requirements for the camera shooting hole forming zones of the glass cover plates are met.

Owner:深圳市信濠光电科技股份有限公司

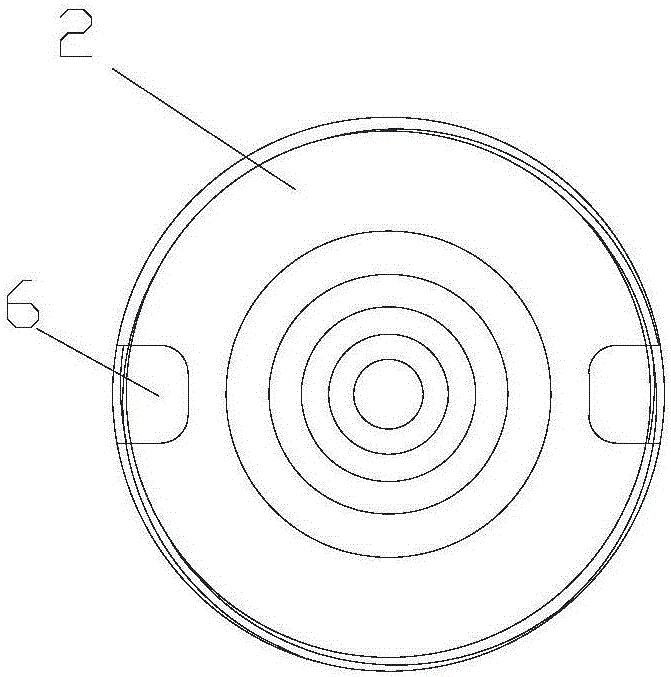

LED lamp dustproof module lens

ActiveCN104896328ANot easy to gatherNot easy to wipe cleanPlanar light sourcesElectric lightingEngineeringLED lamp

The invention discloses an LED lamp dustproof module lens. The LED lamp dustproof module lens comprises at least one LED body. Each LED body comprises a lens body and an LED lamp panel, wherein the lens body is internally provided with a containing space groove used for installing the LED lamp panel; the outer surface of the lens body is a plane; the plane is provided with protrusions used for light refraction; the protrusions are 0.5 mm high. The whole outer surface of the LED lamp dustproof module lens is of a structure similar to the plane, and the micro protrusions are arranged on the planes and are only 0.5 mm high, so that ash is not prone to being accumulated on the outer surface of the lens. Meanwhile, the ash layer is easily wiped and cleaned up, and the influence of later environment factors on the luminous efficiency of lamps is greatly reduced.

Owner:CHONGQING SILIAN OPTOELECTRONICS SCI & TECH

Light-emitting module considering both heat dissipation and light distribution requirements and LED table lamp

PendingCN109556010AReduce lossesPlay the role of secondary light distributionLighting heating/cooling arrangementsCoatingsEngineeringLED lamp

The invention relates to a light-emitting module considering both heat dissipation and light distribution requirements and an LED table lamp. The light-emitting module comprises an LED lamp panel assembly, a light condenser and a heat dissipation light reflector, wherein the heat dissipation light reflector comprises a light-reflecting part and a fixing part which are integrally formed, the fixingpart is positioned at one end of the heat dissipation light reflector, inclines and overturns inwards, the LED lamp panel assembly is arranged on the inner surface of the fixing part, light rays emitted by an LED lamp on the LED lamp panel assembly are slantwise upward, the light condenser is positioned in front of the LED lamp panel and is used for collecting the light rays emitted by the LED lamp to the light-reflecting face of the heat dissipation light reflector, and the light-reflecting face reflects the light rays for illumination use. The functions of the heat dissipator and the lightreflector are integrated, the device is manufactured in an integral forming manner, and the light-reflecting face can play the role of secondary light distribution and also has the heat dissipation effect, so that the requirements of heat dissipation and light distribution are considered; and the number of the parts is very small, so that the assembly is very easy, meanwhile, the space inside thetable lamp is saved, and finally, the cost of the whole lamp is reduced.

Owner:SHENZHEN DELED LED

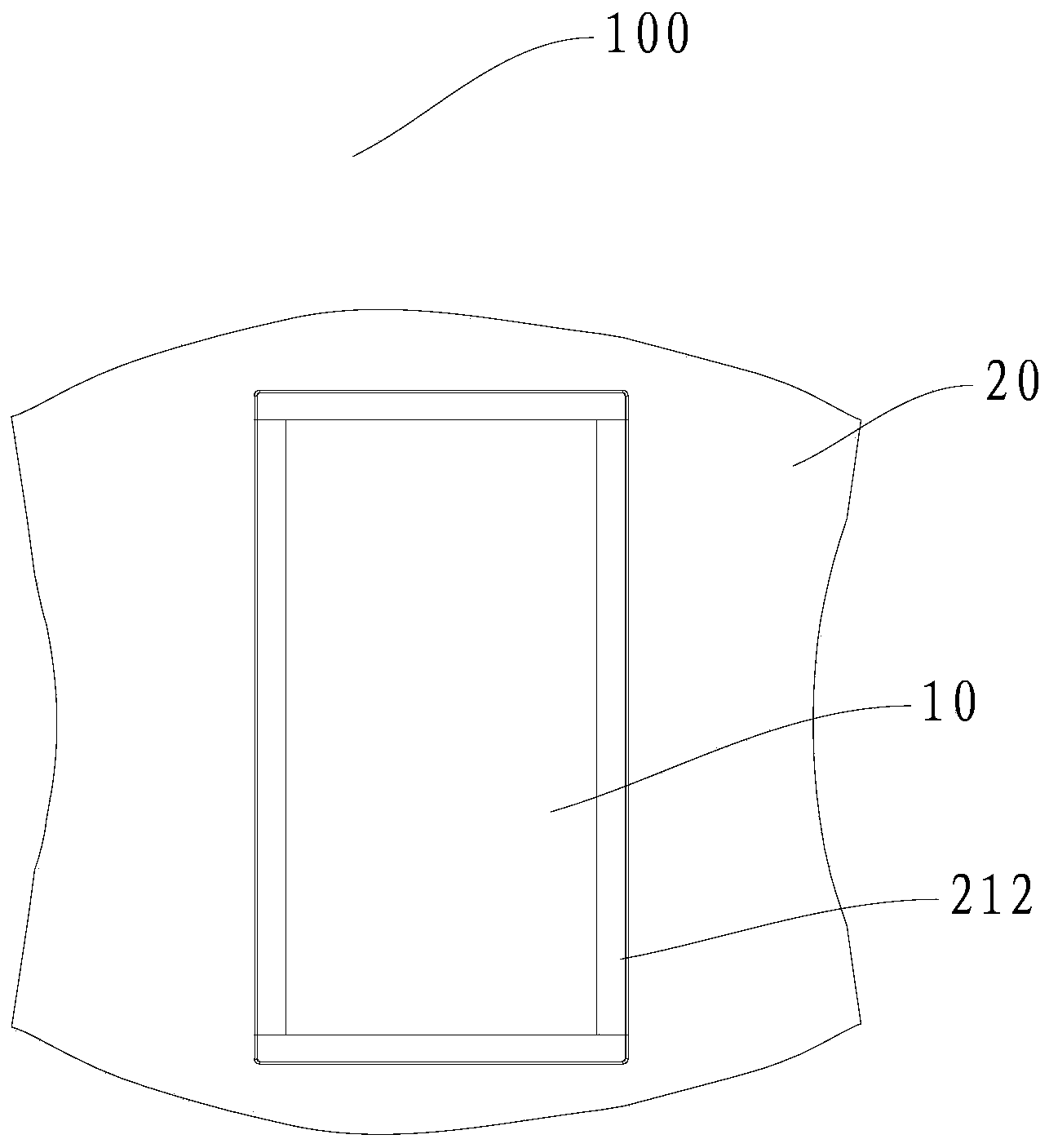

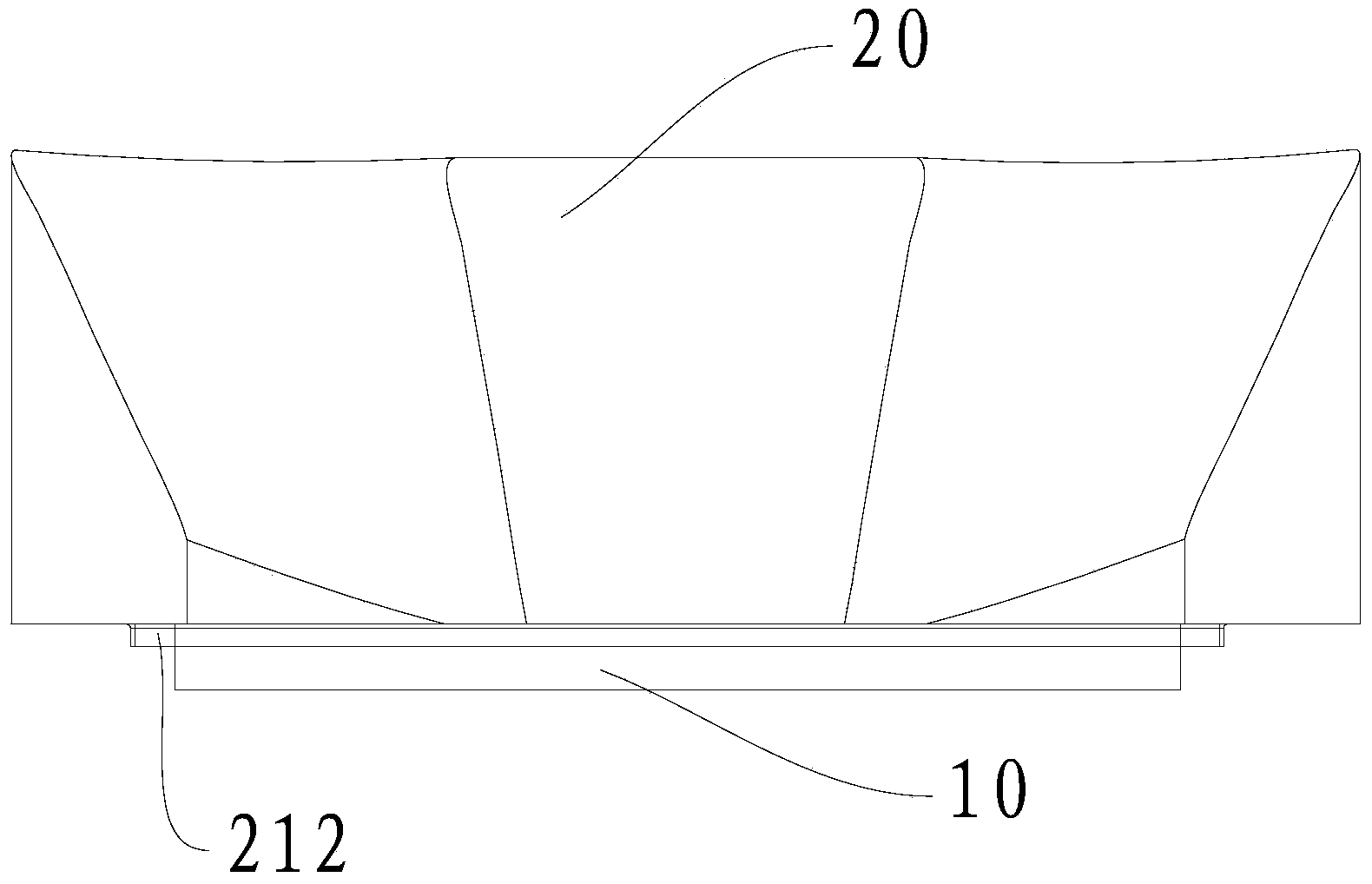

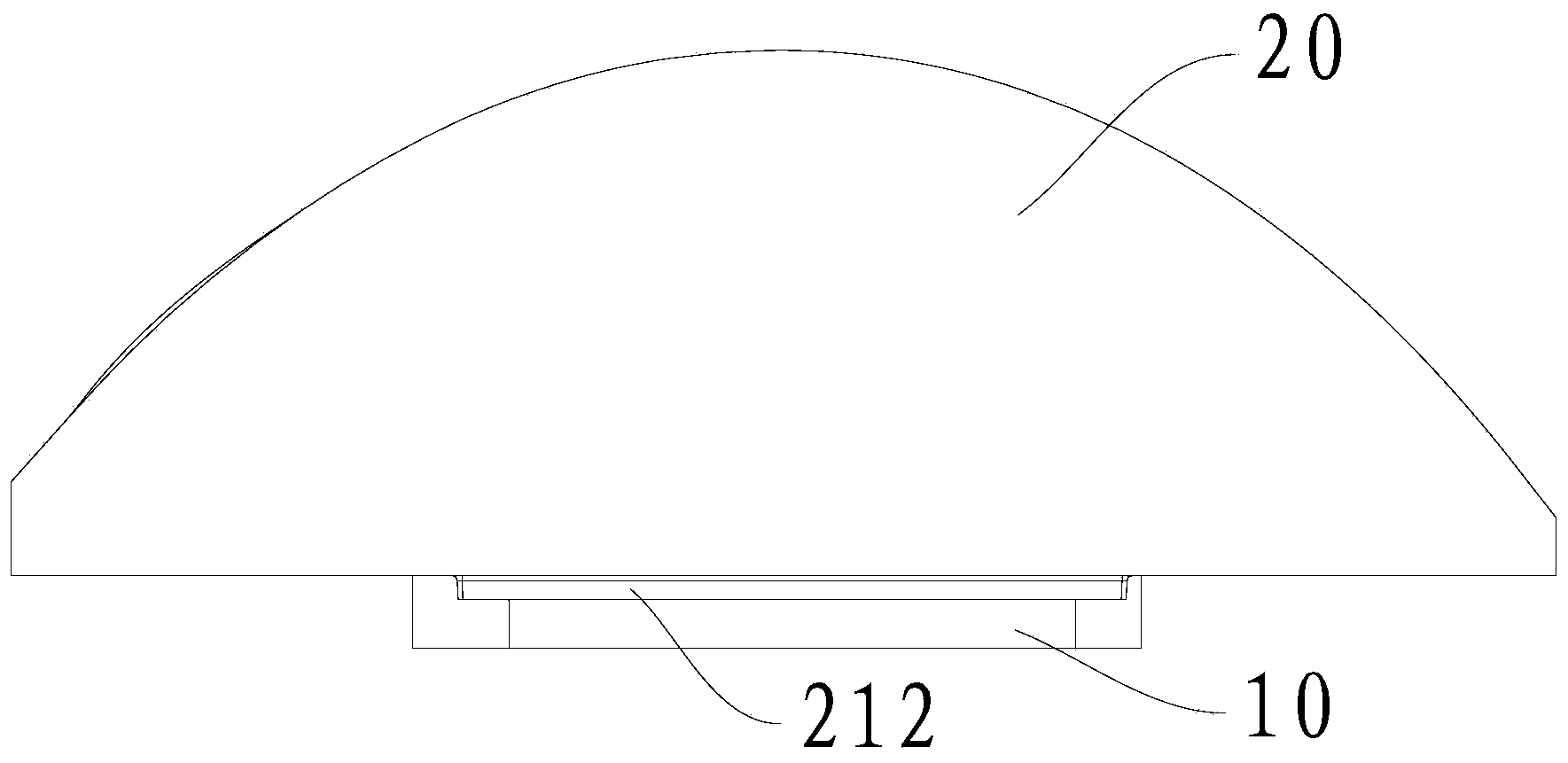

Mobile terminal

InactiveCN106686287AReduced dimensional tolerance requirementsReduce processing difficultyTelevision system detailsColor television detailsEngineeringFlash-lamp

The present invention provides a mobile terminal. The mobile terminal comprises a body and a flash lamp module set; the flash lamp module set comprises a light source and a flash lamp cover movably arranged on the body; a mounting hole is formed in the body; the light source is arranged in the mounting hole; and the flash lamp cover covers the light source. According to the mobile terminal of the invention, the location of the flash lamp cover can be adjusted, the dimensional tolerance requirements of a mobile terminal shell and the flash lamp cover can be greatly decreased, the processing difficulty of the mobile terminal shell and the flash lamp cover can be decreased, the yield of the mobile terminal can be improved, the assembling difficulty of the mobile terminal can be reduced, and costs can be decreased.

Owner:VIVO MOBILE COMM CO LTD

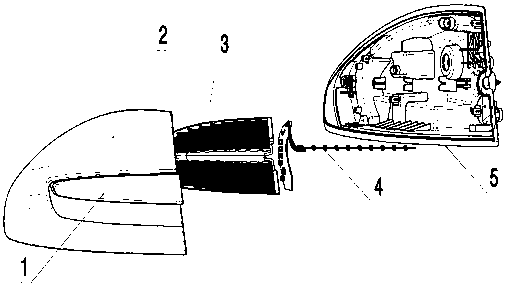

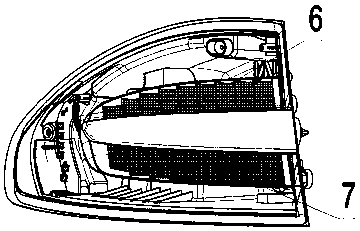

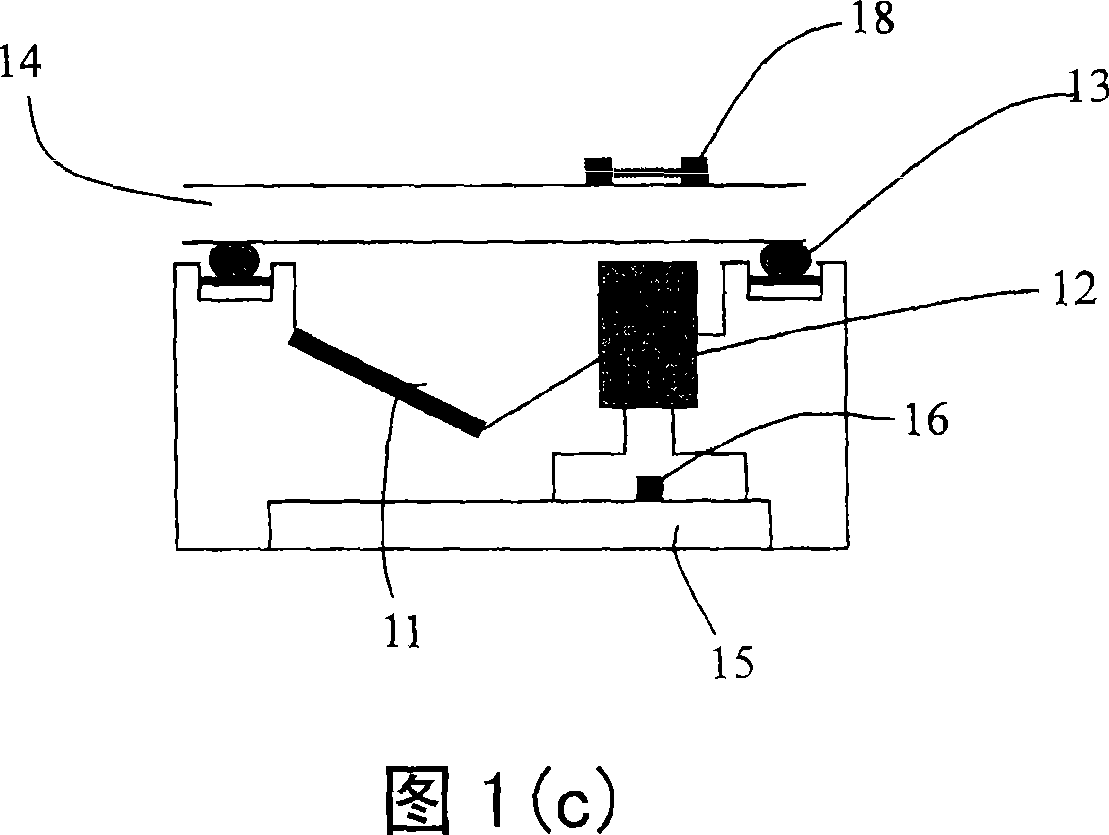

Structure combining two-side LEDs with reflection bowl to achieve steering function of tail light and function of brake light

InactiveCN109780502AReduce Tolerance StackupMeet optical requirementsOptical signallingLight fasteningsEffect lightEngineering

The invention discloses a structure combining a PCBA with two-side LEDs with a reflection bowl to achieve a steering function of a tail light and a function of a brake light. According to the structure, a shell body is taken as a main assembly body, one PCB is fixedly located in the middle of the shell body through a clamping groove to form one sub assembly body, the shell body is partitioned intoupper and lower light chambers through a chrome plated strip, LED light sources of the upper and lower sides of the PCBA respectively and vertically give out light up and down, and after reflection of the reflection bowl, the functions of a steering light and the brake light are separately achieved. The structure not only can generate a uniform lighting effect on the premise of meeting the statutory optical requirements, but also can meet the functions in the narrower and narrower space according to the shape trend, the PCBA with the two-side LEDs is used for installment of the PCB in the smallest space, the one PCBA can achieve two optical functions, and through the design, not only is the shell body space saved to meet the requirement for a thin and long shape, but also the reflection mode of the reflection bowl is utilized for making the whole illuminating effect more uniform.

Owner:HUBEI HUAZHONG MAGNETI MARELLI AUTOMOTIVE LIGHTING CO LTD

Non-spherical lens design method and non-spherical lens

The invention embodiment discloses a design method of an aspherical lens, which comprises: the surface with the semidiameter of R1 is taken as the spherical surface part of the aspherical lens; the surface with the approximate curvature radius of R2 is used as the aspherical surface part of the aspherical lens; the approximate curvature radius is the curvature radius value of the aspherical surface obtained by the spherical surface, and the absolute value of R2 is more than or equal to the double absolute value of R1. The invention embodiment also discloses an aspherical lens, and R2 is controlled to ensure that the absolute value of R2 is more than or equal to the double absolute value of R1. Therefore, the aspherical surface part of a correction system chromatic aberration is smoother than the spherical surface part, and the designed aspherical surface part lens can meet the optical requirement in using and is easy for processing and testing.

Owner:深圳市新岸通讯技术有限公司

LED (light-emitting diode) high pole street lamp

InactiveCN105605509AImprove conversion efficiencyIncrease profitPoint-like light sourceLighting support devicesEngineeringAlloy

The invention provides an LED (light-emitting diode) high pole street lamp, comprising a housing, LED light-emitting modules, secondary optical lens modules, a hinge mounting head, a connecting rod, a fastening hinge and a lithium battery, wherein the housing is a straightly grooved aluminum alloy housing, and each LED light-emitting module comprises an LED light source assembly; the straight groove face of the housing is a light-emitting face, and the LED light source assemblies are fixedly arranged on the light-emitting face in an array; the secondary optical lens modules are arranged on the peripheries of the LED light source assemblies, and the hinge mounting head is fixedly arranged at one end of the housing and is connected with the fastening hinge through the connecting rod; the lithium battery is connected with the LED light-emitting module. According to the LED high pole street lamp provided by the invention, the conversion efficiency and utilization ratio of a light source are fully improved, so that the power consumption of the product is lower than that of similar products; the characteristics of good heat dissipation, low wind resistance, strong wind resistance, light weight and the like are structurally achieved, and the street lamp can be combined and used more flexibly and reliably.

Owner:DUJIANGYAN HUAGANG ELECTRONICS TECH

Contact image scanner with multi focallength and multi resolution

ActiveCN100461816CMeet the needs of scanning surfaces of different heightsReach scan capacityPictoral communicationLensImage resolutionMulti resolution

The image scanner includes following parts: a circuit board; at least two sets of sensitizing element array (SEA) including first set of SEA and second set of SEA, and the two sets of SEA arranged parallel to each other located above the circuit board; at least one set of columnar lens composed of first and second columnar lenses; first columnar lens and second columnar lens suspended on the corresponding first set of SEA and second set of SEA; a first glass is suspended on the set of columnar lens; a second glass is suspended between the first columnar lens and the first set of SEA. Using two sets of SEA, the set of columnar lens, and the second glass forms at least two focuses and resolutions in order to scan different objects to be scanned on the glass.

Owner:WUXI CREATIVE SENSOR TECH

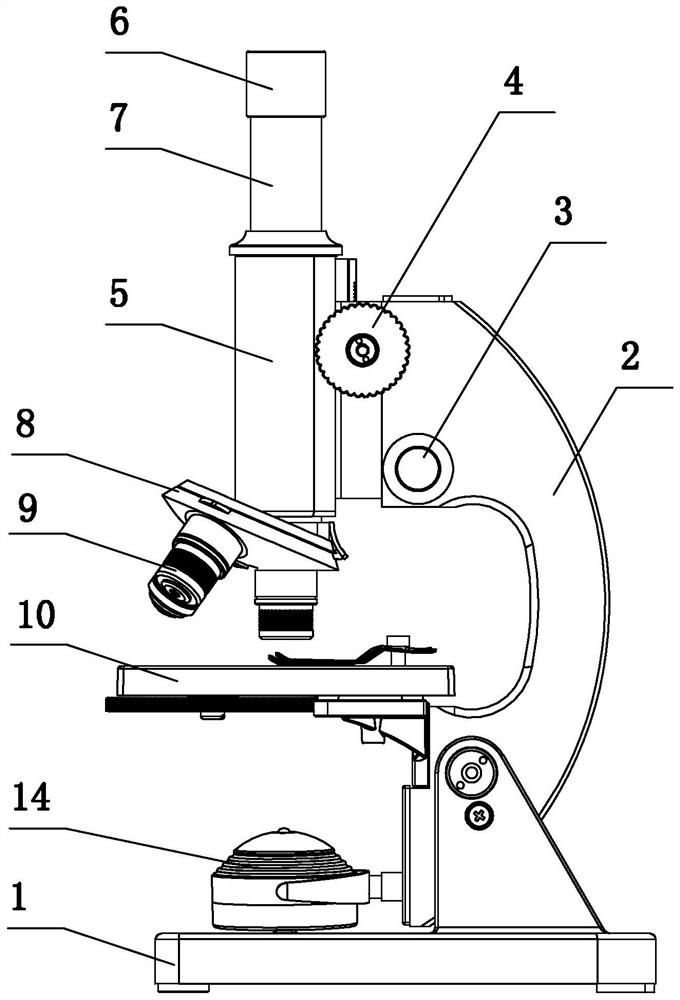

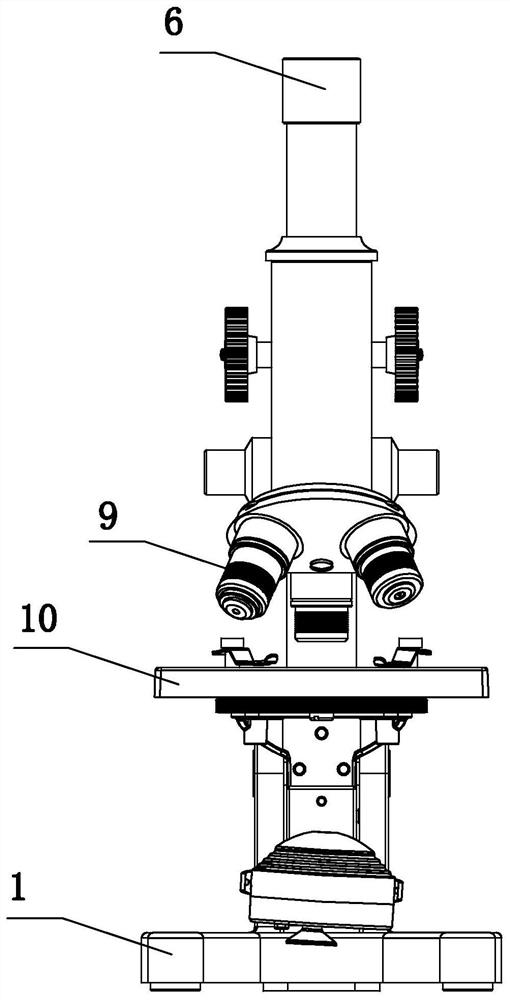

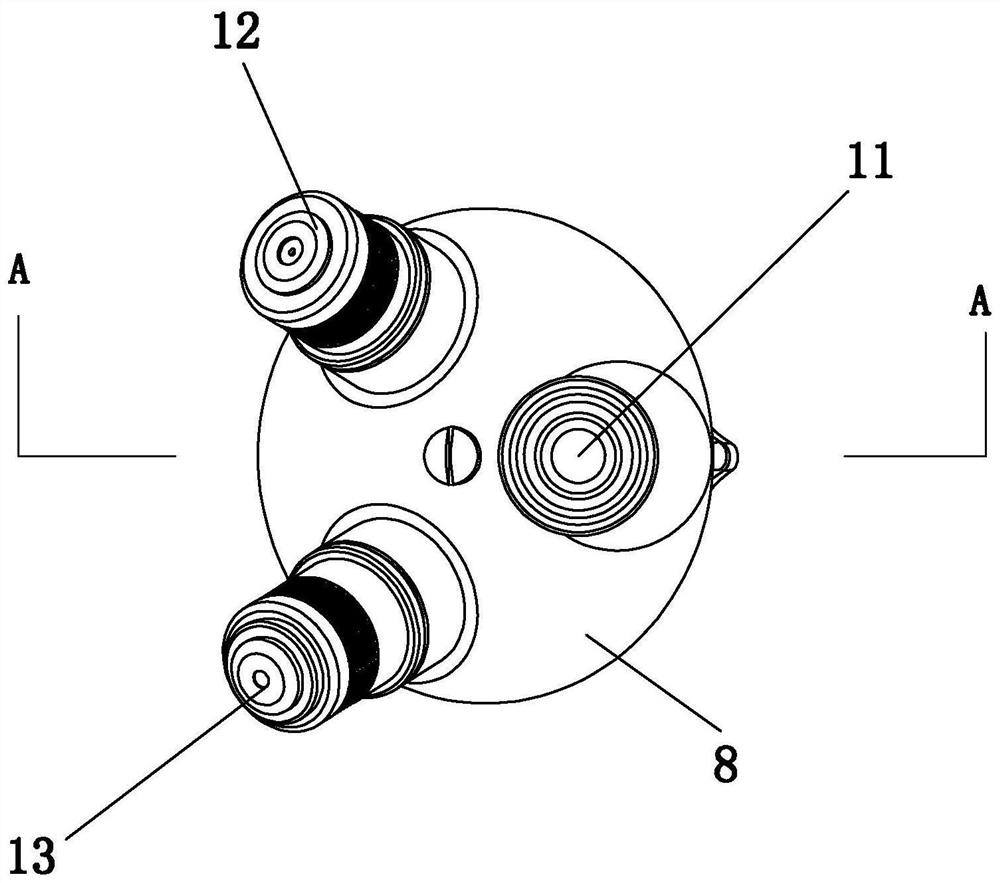

Biological microscope provided with aspheric lens objective lens

PendingCN112034607ASimple structureMeet the expected optical requirementsMicroscopesMountingsEyepieceOphthalmology

The biological microscope with an aspheric lens objective which belongs to the technical field of biological microscopes comprises a base, a bent wall, a coarse hand wheel, a fine hand wheel, a lifting cylinder, an ocular lens, an ocular lens barrel, a converter, an objective lens group, an objective table and a movable light source. The objective lens group comprises an objective lens A with an aspheric lens, an objective lens A for short, an objective lens B with an aspheric lens, an objective lens B for short, an objective lens C with an aspheric lens and an objective lens C for short; andthe objective lens A is a 4X objective lens, namely a quadruple objective lens, the objective lens B is a 10X objective lens, namely a ten-fold objective lens, and the objective lens C is a 40X objective lens, namely a 40-fold objective lens. The microsope has the beneficial effects that the working distance is long, and the object is convenient to observe.

Owner:NINGBO ZHANJING OPTICAL INSTR

An optical design method for a circular spot with a half light intensity angle of 8 degrees

An optical design method enabling a half-intensity angle to be located on a 8-degree round spot comprises the steps that (1) a reflection cup and a light guiding pillar are designed, wherein the light guiding pillar is arranged at the center of the reflection cup, the reflection surface of the reflection cup is a second free-form surface, one end of the light guiding pillar is a plane and serves as an incident plane, the other end of the light guiding pillar is concave and serves as an exit surface which is a first free-form surface, and the side face of the light guiding pillar is a reflection surface; (2) light enters through the incident plane of the light guiding pillar and is refracted to the reflection surface on the side face of the light guiding pillar, reflected to the first free-form surface of the light guiding pillar, refracted to the second free-form surface of the reflection cup, and finally emitted in the direction parallel to the optical axis; (3) the relationship between the energy obtained after light passes through the light guiding pillar and the reflection cup and the energy irradiated on a light distribution screen is established according to the energy conservation law, the second free-form surface of the reflection cup and the first free-form surface of the light guiding pillar are adjusted, and the half-intensity angle is obtained on the 8-degree round spot of the light distribution screen.

Owner:GUANGDONG RAYTON INTELLIGENT OPTO CO LTD

Fixing device of array laser device

ActiveCN102868081BMeet optical requirementsReduce manufacturing costLaser arrangementsLaser constructional detailsOptoelectronicsMachining

The invention discloses a fixing device of an array laser device. The fixing device of the array laser device disclosed by the invention comprises a laser device bottom plate, a laser device pressing plate, a plurality of mirror holders, a plurality of elastic gaskets and mirror holder pressing plates. With the adoption of the fixing device of the array laser device disclosed by the invention, optical requirements of the array laser device can be met and the requirements on the machining precision can be lowered at the same time.

Owner:HISENSE

Welded type COB (chip on board)-LED light source module

InactiveCN102853298BEasy to assemble and disassembleCompact structurePoint-like light sourceElectric circuit arrangementsOn boardPrinted circuit board

The invention relates to a welded type COB (chip on board)-LED light source module which comprises a reflection cup, a radiator, a COB-LED light source component, an electrical interface support and a welding core wire. When the welded type COB-LED light source module is assembled, ends of two single-core wires of the welding core wire are correspondingly welded on corresponding welding points on a PCB (printed circuit board), the PCB in the COB-LED light source component is mounted in a mounting groove on the bottom surface of the electrical interface support, an LED chip in the COB-LED light source component exposes outside through a through hole in the middle of the electrical interface support, the two single-core wires welded on the PCB are led out through corresponding lead grooves respectively, and a plurality of screws penetrate through corresponding mounting holes to enable the electrical interface support and the COB-LED light source component to be in threaded connection on corresponding threaded holes of the radiator. By the structure, the welded type COB-LED light source module is compact in structure, convenient to assemble and disassemble, space-saving and good in radiating effect.

Owner:KINGSUN OPTOELECTRONIC CO LTD

Car lamp lens component and car with same

ActiveCN104033842AGuaranteed molding requirementsGuaranteed optical designPoint-like light sourceRoad vehiclesThick wallEngineering

Owner:曼德汽车零部件(荆门)有限公司

Contact type image scanner with multi-focus and multi resolution ratio

ActiveCN100361491CMeet the needs of scanning surfaces of different heightsReach scan capacityPictoral communicationLensImage resolutionEngineering

This invention provides a contact image scanner with multi focus and resolution, which comprises: a circuit board, at least two set of photosensitive element arrays composed of first and second set photosensitive element arrays arranged on circuit board of single row, at least one set of cylinder lens of first and second lens opposite separately to the said photosensitive element arrays and upper suspended, and a first glass suspended upper the cylinder lens. The combination of circuit board, photosensitive element arrays and cylinder lens matches with the position regulation, variety, thickness, and vertical distance, to form more than two focus and resolution for scanning to image with different focus.

Owner:南昌菱光科技有限公司

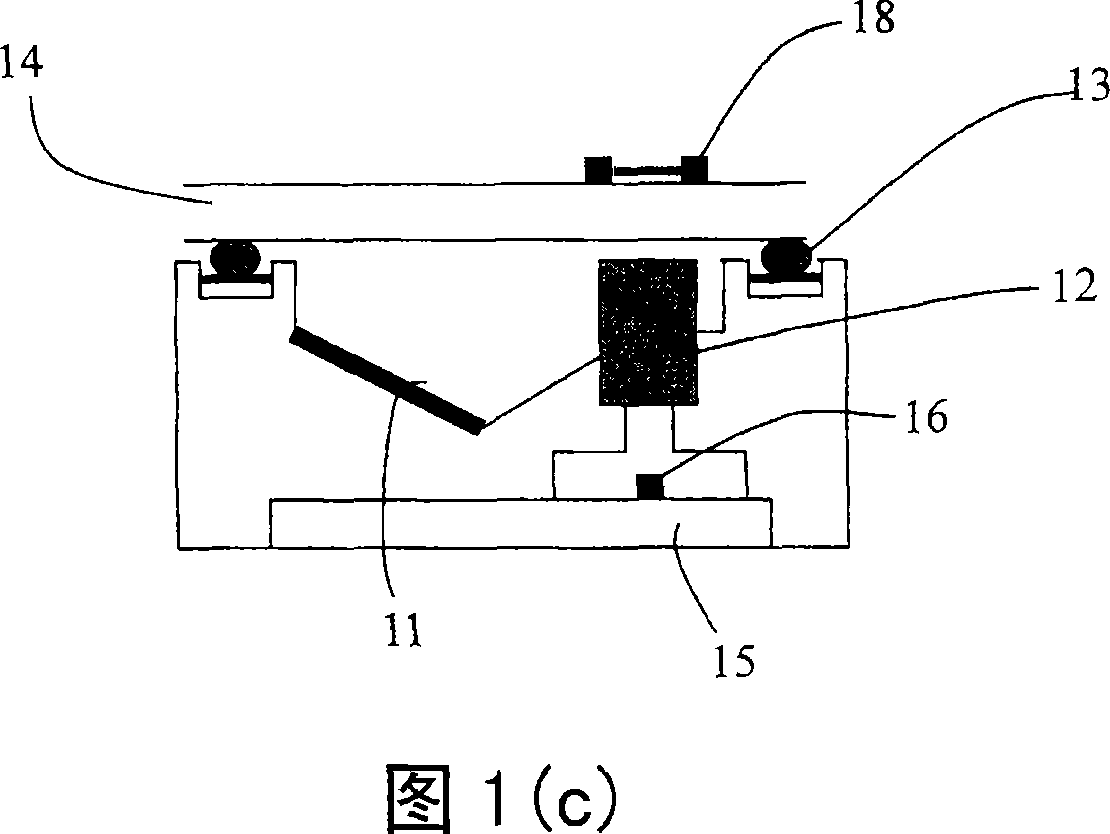

Contact image scanner with multi focal length and multi resolution

InactiveCN101026672AMeet the needs of scanning surfaces of different heightsReach scan capacityLensPictoral communicationPhysicsImage resolution

The image scanner includes following parts: at least a first circuit board and a second circuit board; at least two sets of sensitizing element array (SEA) composed of first set of SEA and second set of SEA located on the first circuit board and the second circuit board respectively; at least one set of columnar lens composed of first and second columnar lenses; first columnar lens and second columnar lens suspended on the corresponding first set of SEA and second set of SEA; a glass is suspended on the set of columnar lens; adjusting relative position between the first circuit board and the second circuit board makes the two sets of SEA and the set of columnar lens form at least two focuses and resolutions in order to scan different objects to be scanned on the glass.

Owner:CREATIVE SENSOR INC

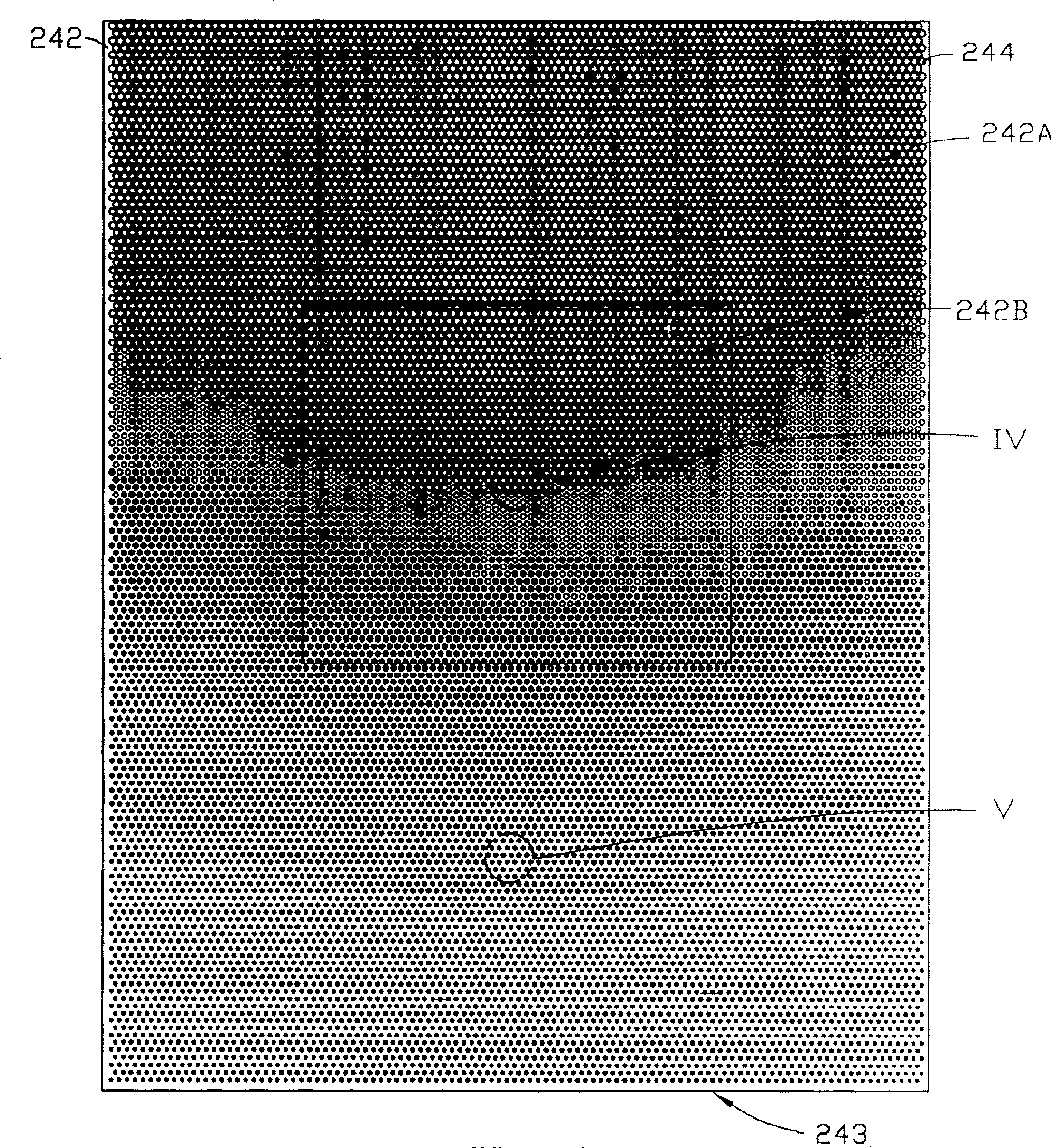

Plate of guiding light, backlight module, and double-faced liquid crystal display device

InactiveCN100405164CImprove design densityDisadvantages of suppression of uneven brightnessStatic indicating devicesDiffusing elementsLiquid-crystal displayLight guide

A light guide plate consists of a light incoming surface, the first light outgoing surface and the second light outgoing surface including a subregion and a master region surrounding said subregion as well as lattice point formed on the second light outgoing surface. It is featured as making density of lattice point in subregion be greater that density of lattice point in adjacent master region along parallel direction of light incoming surface. The back light module prepared by said guide plate and double-face liquid crystal display unit prepared by said guide plate are both disclosed.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Electron gun online disassembly equipment for electron accelerator

ActiveCN103140014BDoes not affect the axial directionDefine the axial directionAcceleratorsVacuum pumpElectron

The invention relates to an electronic gun on-line assembly and disassembly device which does not damage the accelerating tube vacuum environment of an electron accelerator. The electronic gun on-line assembly and disassembly device structurally comprises an airtight tube fitting which is divided into an upper portion and a lower portion by a vacuum isolating part. The lower end of the airtight tube fitting is connected with the inlet end of an accelerating tube, an upper-portion space of the airtight tube fitting is connected with a vacuum pump pumping pipe, an electronic gun positioning part is arranged in a lower-portion space of the airtight tube fitting, an electronic gun is installed at the bottom of the electronic gun positioning part, and the electronic gun positioning part is connected with a vacuum keeping expansion part arranged at the top end of the airtight tube fitting. The accelerating tube vacuum environment is not damaged when the electronic gun is replaced, a distance between the electronic gun and the accelerating tube is short, and accordingly the requirement for beam current transmission optics is met.

Owner:YUANKE HENGHUI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com