Fixing device of array laser device

A fixed device and laser technology, applied in the field of lasers, can solve the problems of difficult to meet the strict requirements of array lasers, high cost, and very high processing accuracy requirements, to achieve the requirements of reducing machining accuracy, reduce production costs, and meet optical requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

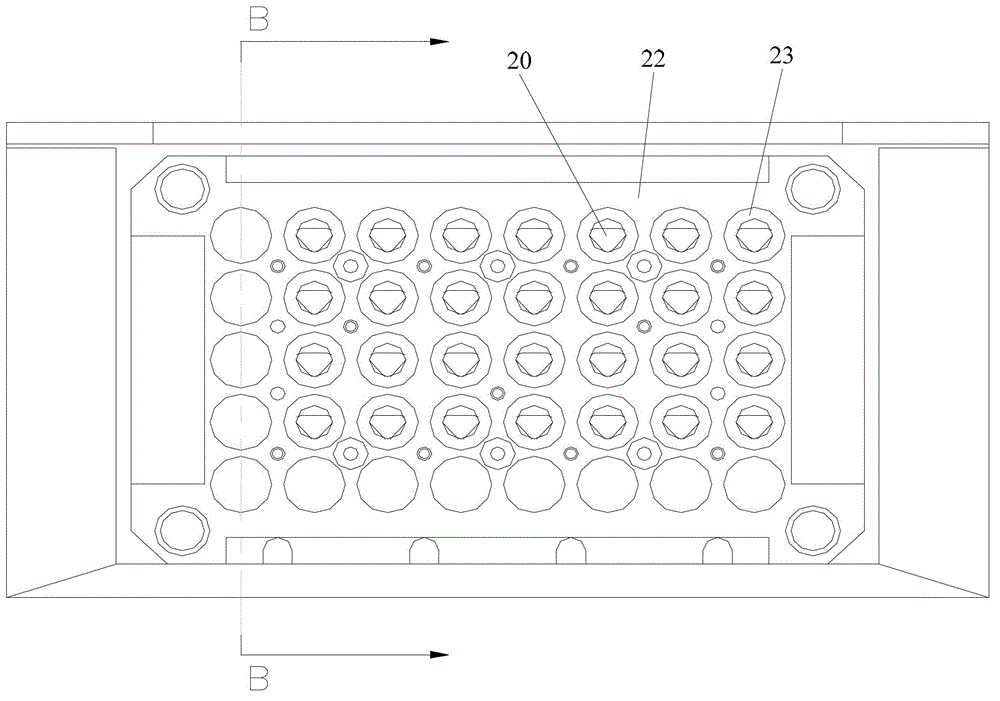

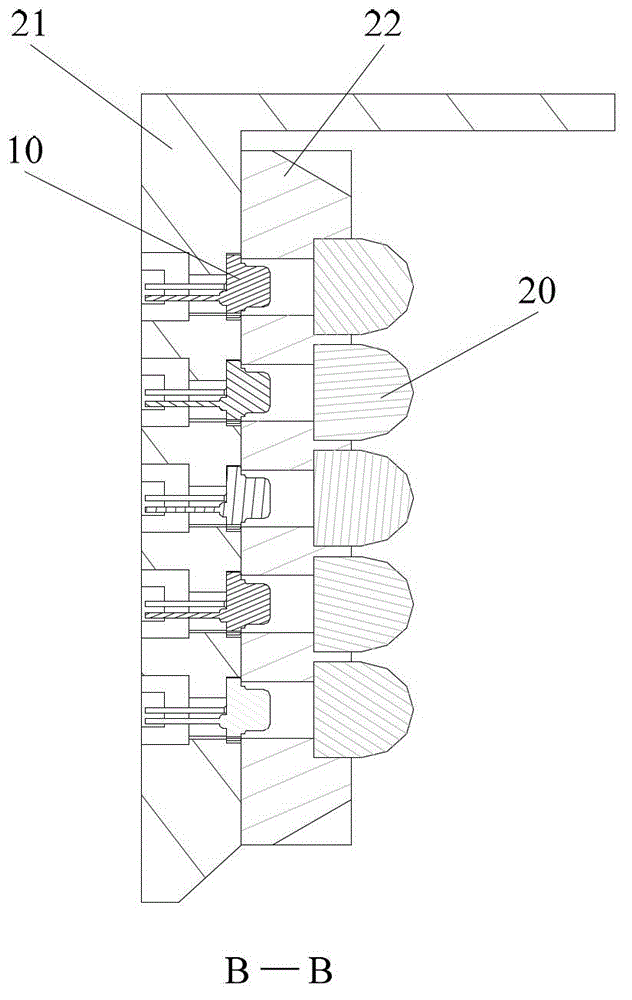

[0050] see Figure 3 to Figure 10 , The fixing device of the array laser in this embodiment includes: a laser base plate 31 , a laser pressure plate 32 , a plurality of mirror holders 33 , a plurality of elastic washers 34 and a mirror holder pressure plate 35 .

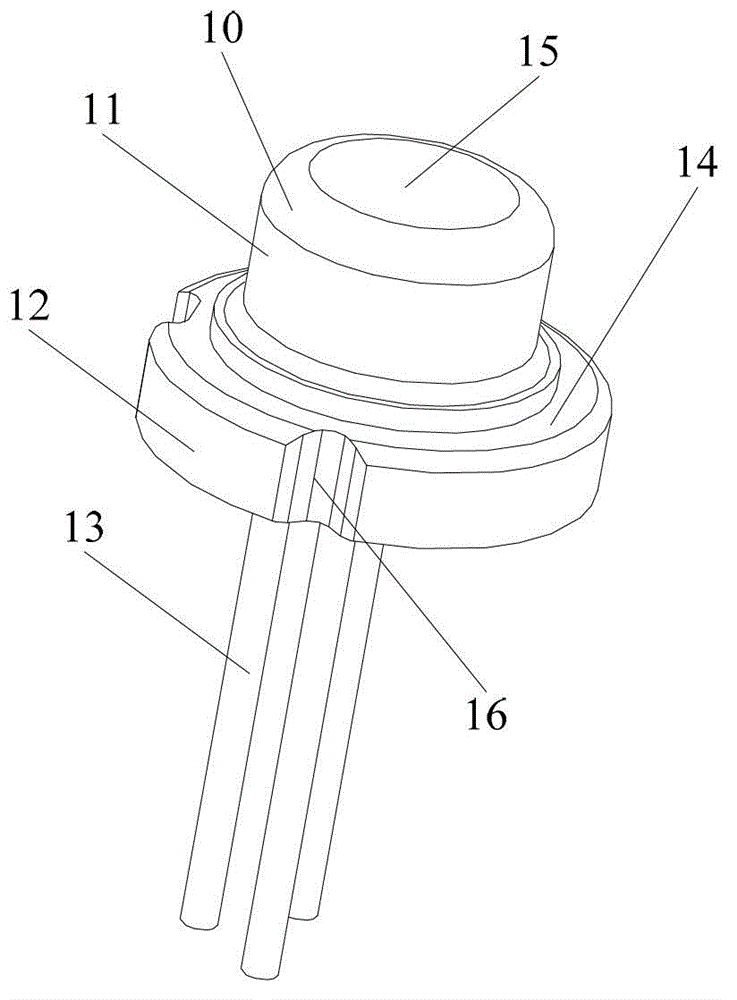

[0051] Wherein, the laser bottom plate 31 is provided with a plurality of first through holes 310 through which the pins 13 of the laser 10 can pass, and is also provided with a bottom that surrounds the first through holes 310 and can accommodate the laser 10 12 first step-like structure 311;

[0052]The laser platen 32 is provided with a plurality of second through holes 320 that can pass through the top 11 of the laser 10; the edge of each second through hole 320 is provided with two oppos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com