Welded type COB (chip on board)-LED light source module

A COB-LED and light source module technology, applied in the field of LED lighting, can solve the problems of COB-LED light source components such as unfavorable heat dissipation, many parts, troublesome processing and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

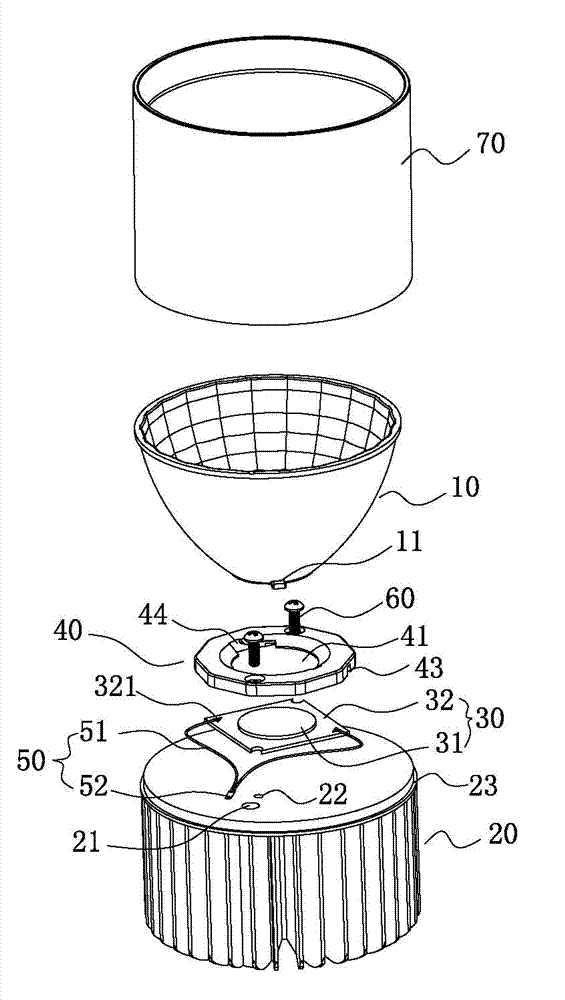

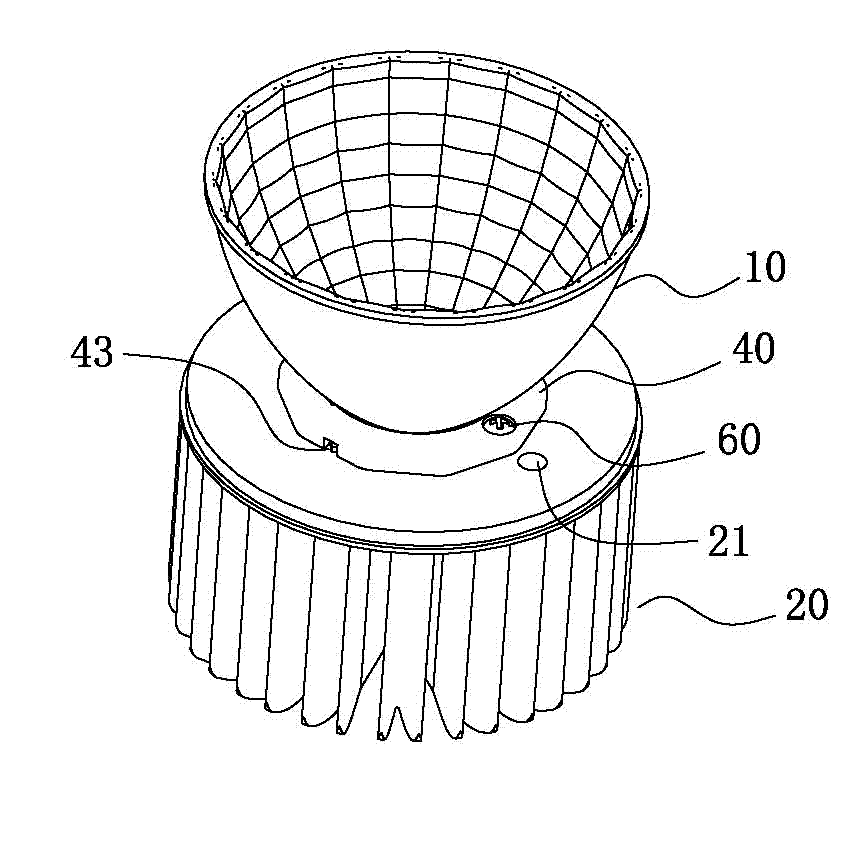

[0024] The following will be combined with Figure 1-6 An example for further details:

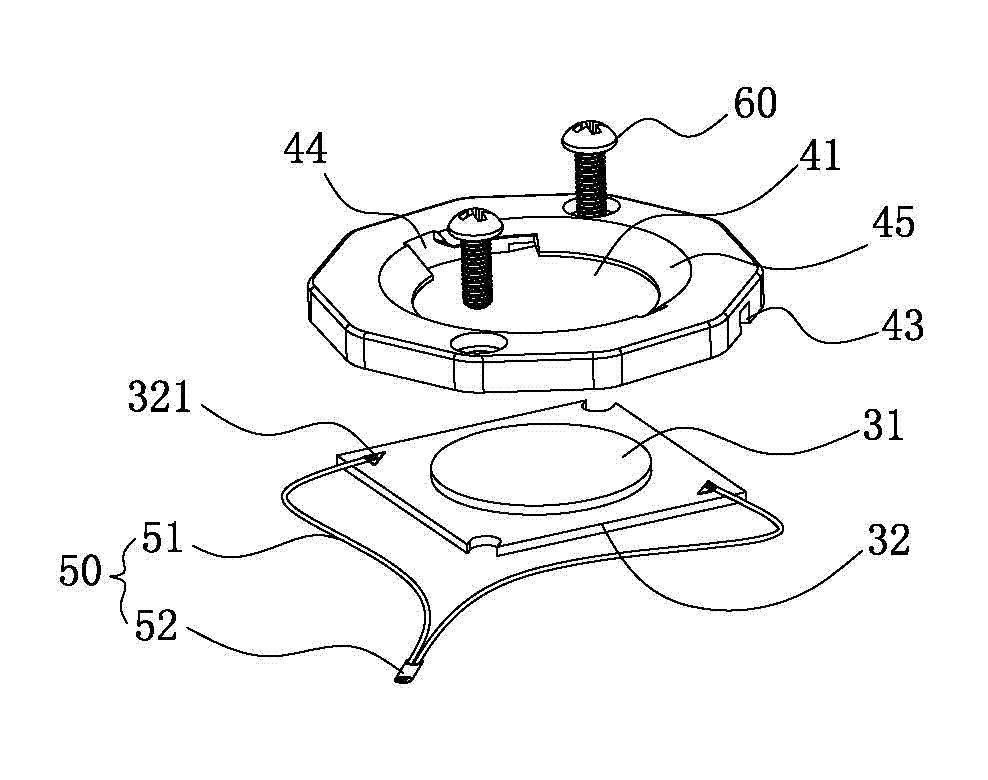

[0025] A welded COB-LED light source module in the embodiment includes a reflector 10, a heat sink 20, a COB-LED light source assembly 30, an electrical interface bracket 40 and a welding core wire 50. The COB-LED light source assembly 30 is The LED chip 31 is directly mounted on the PCB board 32 and then electrically connected and packaged as a whole through lead stitching;

[0026] The middle part of the electrical interface bracket 40 has a through hole 41 corresponding to the LED chip, and the bottom surface of the electrical interface bracket 40 has a mounting groove 42 with the same size and shape as the PCB board 32. Two wire slots 43 respectively corresponding to the two welding points 321 on the PCB board 32 are opened on the side; the welding core wire 50 is composed of two single core wires 51 for welding; the electrical interface bracket 40 The inner wall of the through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com