Novel barrier-free quantum dot film and preparation method thereof

A quantum dot film and quantum dot technology, which are applied in the field of new unblocked quantum dot film and its preparation, can solve the problem of high cost of quantum dot film, and achieve the effect of realizing precise control and satisfying optical requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

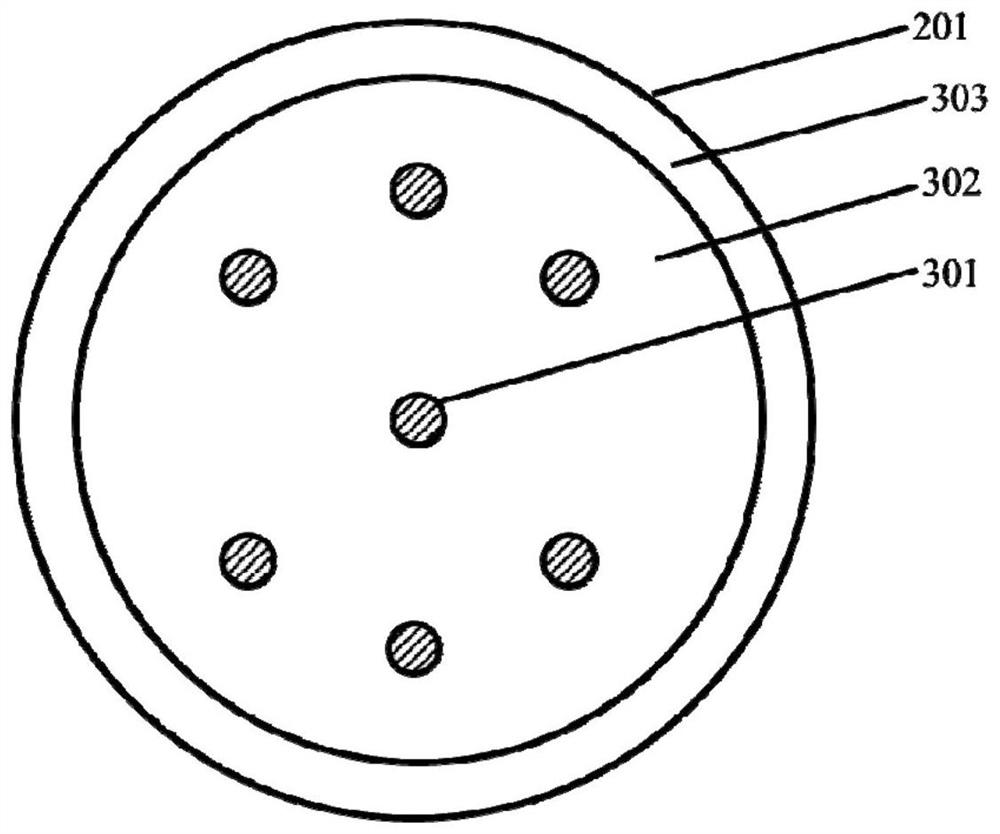

[0052] For the first preparation method, it includes the following steps: uniformly mixing the matrix 302 heated to a molten state with the quantum dots, forming and granulating to obtain quantum dot matrix particles; pulverizing the quantum dot matrix particles to obtain the first micron-sized quantum dot matrix microspheres Spray the coating solution in mist form evenly on the surface of the first quantum dot matrix microsphere, vacuum dry after fully stirring, and obtain the first quantum dot matrix microsphere of the surface coating coating 303, which is denoted as the second quantum dot matrix microsphere ball; the coating solution is SiO 2 , SiO x N y , Si, azotriazolone, AlO x , silane, silicon nitride, silicon oxynitride, polyvinylidene chloride, ethylene, vinyl alcohol copolymer, polyamide, acrylic resin, polyurethane resin, polyimide and one or more organic solvents, polyurethane resin, Acrylic resins are uniformly mixed in proportion to obtain a mixed solution wi...

Embodiment 1

[0061] (1) preparation of quantum dot PMMA microspheres

[0062] Heat the PMMA particles to 200°C to melt, add 10wt% green quantum dot powder to the above-mentioned molten PMMA and mix well, then melt extrusion and granulate; put the formed PMMA quantum dot particles into a planetary ball mill for Pulverize to obtain green quantum dot PMMA microspheres with a particle size of about 5 μm; repeat the above operation to obtain red quantum dot PMMA microspheres with a particle size of about 5 μm.

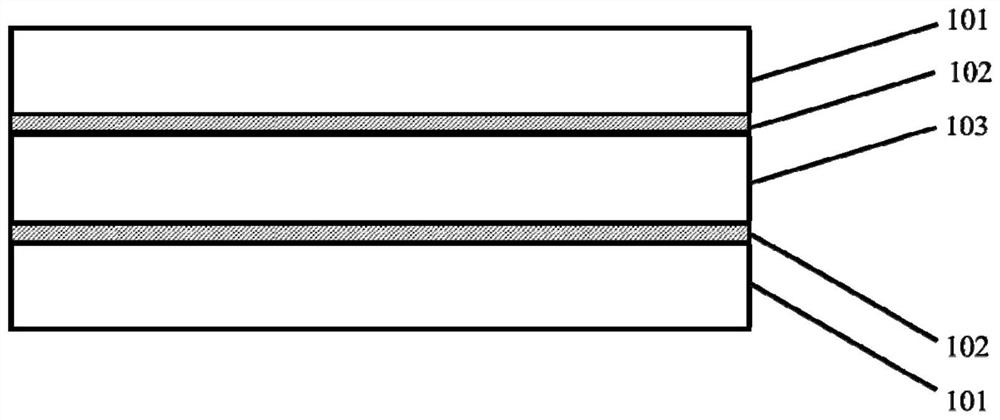

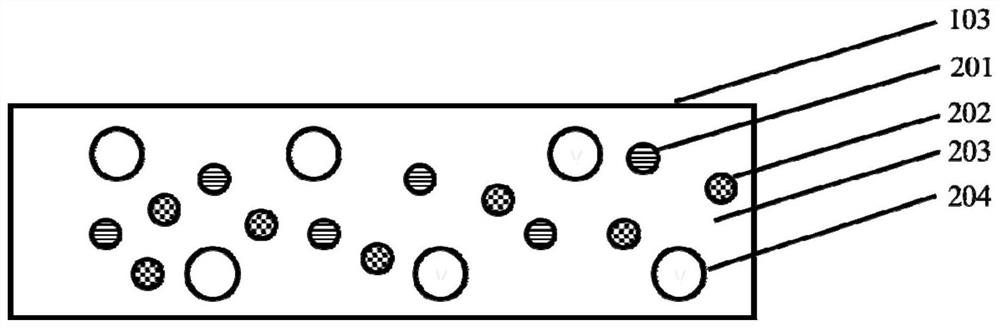

[0063] (2) Preparation of non-barrier quantum dot film

[0064] The above-mentioned green and red quantum dot matrix microspheres are fully mixed with resin glue and 1.0wt% scattering particles according to the ratio of 4.5wt% and 2.0wt%, and then coated between the two substrate layers 101, and using a high-pressure curing process. The curing of the resin glue 203 completes the preparation of the non-barrier quantum dot film.

[0065] (3) Performance characterization of non-barrier q...

Embodiment 2

[0068] (1) Preparation of quantum dot PMMA microspheres

[0069] The PMMA particles are heated to 200° C. to melt, and 10 wt % green quantum dot powder is added to the above-mentioned molten PMMA for thorough mixing, followed by melt extrusion molding and granulation. The shaped PMMA quantum dot particles were put into a planetary ball mill for crushing to obtain green quantum dot PMMA microspheres with a particle size of about 5 μm. The above operations were repeated to obtain red quantum dot PMMA microspheres with a particle size of about 5 μm.

[0070] (2) Treating the surface of quantum dot microspheres

[0071] 10g nano-SiO 2 Disperse the powder (50-100nm in particle size) into 100g of isopropanol, stir well, add 5g of polyurethane resin and 2.5g of phthalate coupling agent for ultrasonic treatment, and obtain a surface treatment solution.

[0072] Sprinkle the above solution on the quantum dot microspheres in the form of a spray through a nozzle, while stirring the qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com