Device for correcting well wall and enhancing drill gauge protection effect through rolling

A drill bit and borehole wall technology, which is applied in the field of devices that use rolling action to correct the borehole wall and enhance the drill bit gage effect, can solve problems such as large torque, and achieve the effects of simple manufacturing process, reduced gyration probability, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

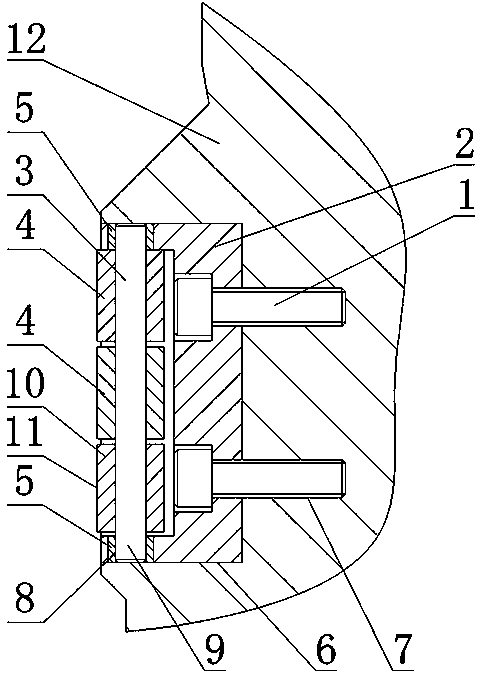

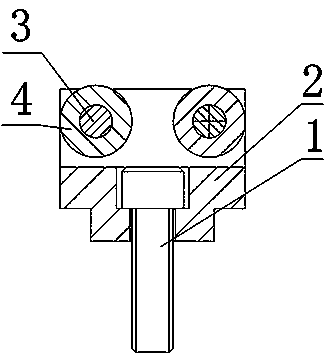

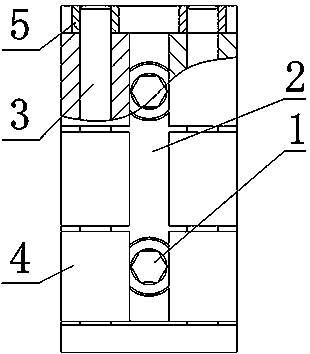

[0064] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the device for correcting the well wall by rolling action to enhance the gage effect of the drill bit includes a roller seat 2 installed on the gauge cutting surface of the drill bit 12 through a screw 1 and a roller seat 2 rotatably installed on the roller seat 2 through a pin shaft 3 Roller 4, at least one pin shaft 3 is arranged on the drum base 2, the drum 4 is set on the pin shaft 3, the two ends of the pin shaft 3 are installed on the drum base 2, and the axis line of the drum 4 is parallel to the vertical plane And the axis line of the drum 4 is parallel to the axis line of the drill bit 12 or there is a space angle less than 90°, that is, the vertical plane is parallel and the axis line of the drum 4 and the axis line of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com