Steel hinge positioning device

A positioning device and hinge technology, which is applied in the direction of workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of reducing work efficiency, heavy adjustment workload, inconsistent hinge coaxiality, etc., so as to improve work efficiency and reduce The workload and the effect of ensuring coaxial accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention are described with reference to the above drawings.

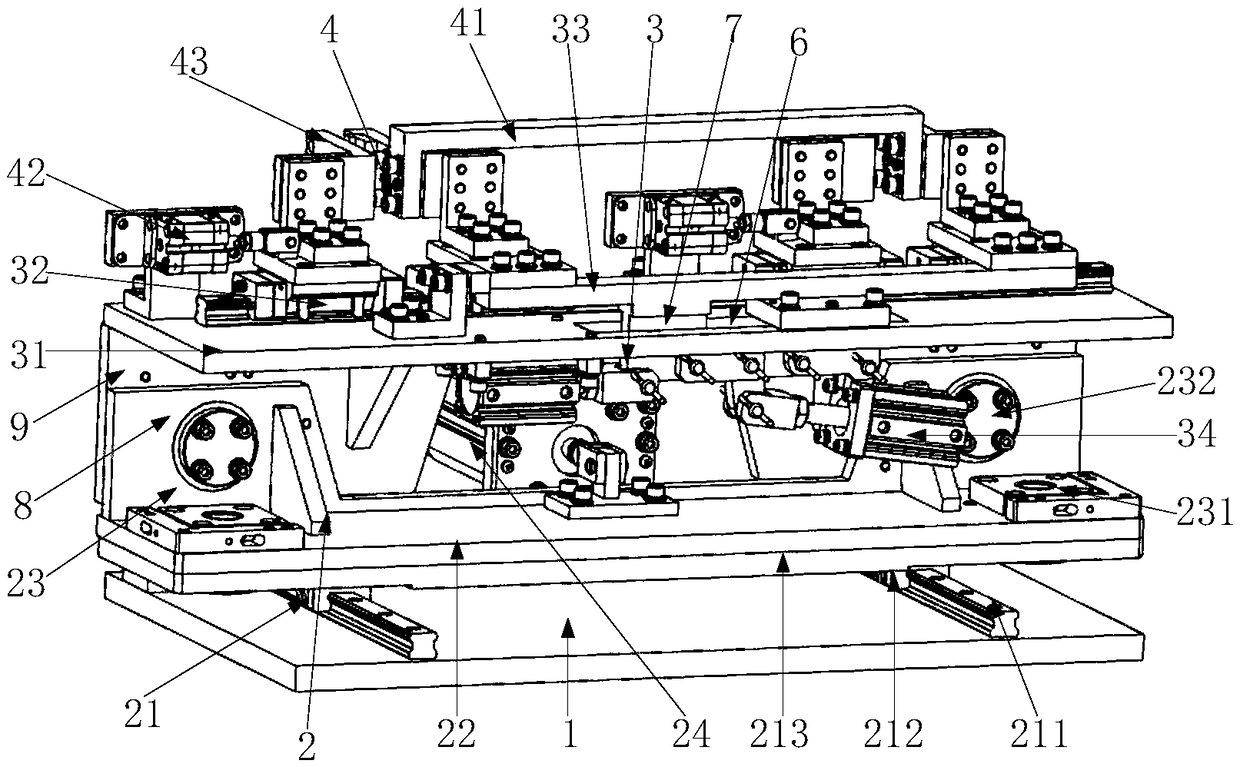

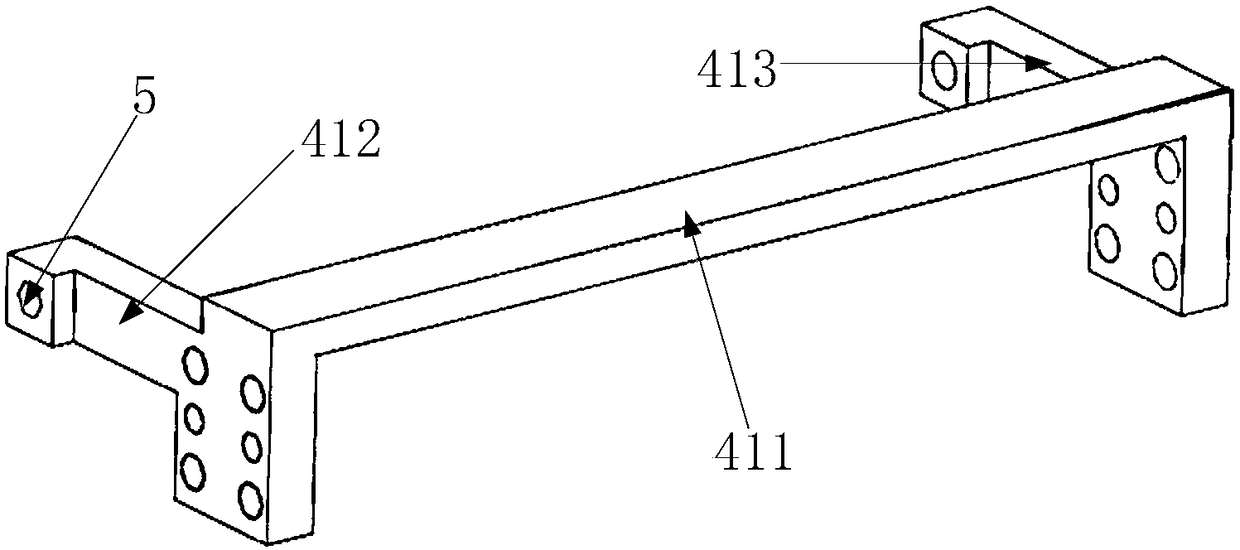

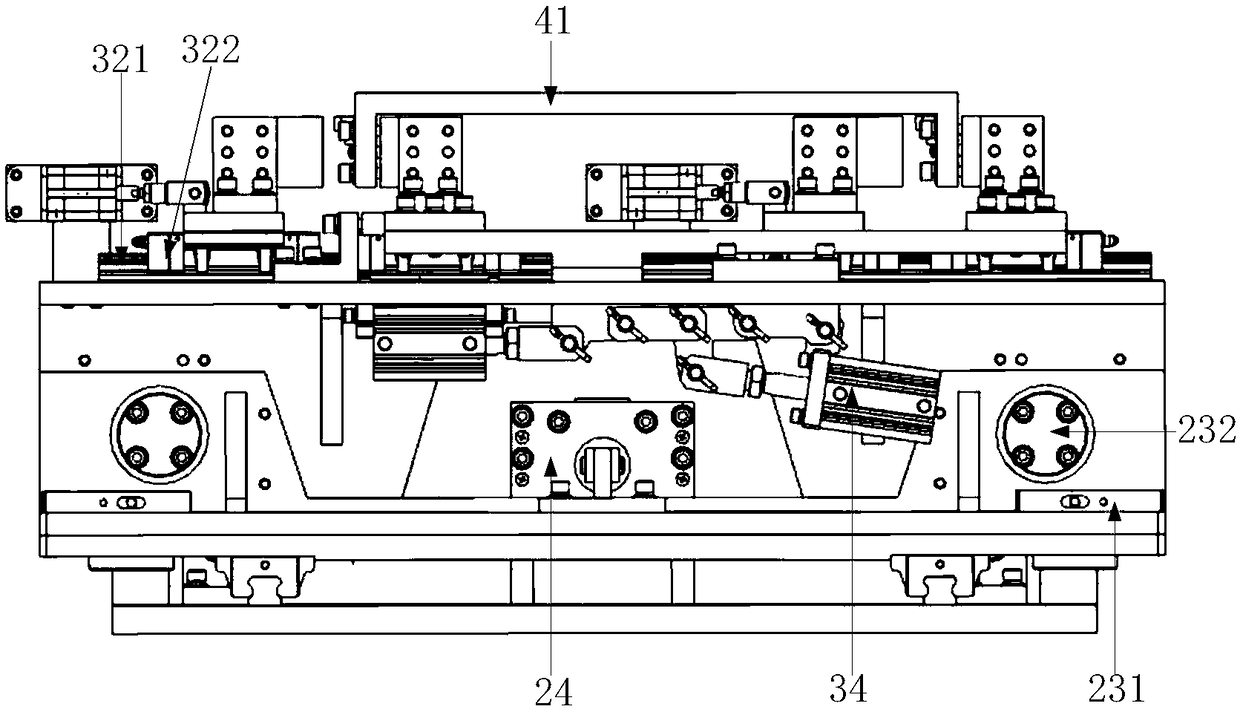

[0024] A section steel hinge positioning device in this embodiment includes a base 1, an adjustment mechanism 2, a pressing mechanism 3 and a positioning mechanism 4, the adjustment mechanism 2 is installed on the base 1, and the pressing mechanism 3 includes a set The upper mounting plate 31 above the adjustment mechanism 2, the first sliding mechanism 32 disposed on the upper mounting plate 31, the connecting piece 33 disposed on the first sliding mechanism 32 and the connection with the The compression cylinder 34 connected with the connecting piece 33, the positioning mechanism 4 includes a positioning workpiece 41 arranged on the connecting piece 33 and pressing blocks 43 respectively arranged at both ends of the upper mounting plate 31, the positioning mechanism 4 Both ends of the positioning workpiece 41 are provided with pin positioning holes 5, and the two hinges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com