Forging forming process of flange pipe yoke and flange pipe yoke formed by this process

A flanged pipe and pre-forming technology, applied in the field of flanged pipe forks, can solve the problems of difficulty in ensuring the coaxial accuracy of two through holes, difficulty in opening two through holes of a fork arm, easy drilling deviation of the fork arm, etc. Achieve the effect of ensuring accuracy and processing efficiency, low forming difficulty, and increasing the strength of the fork arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

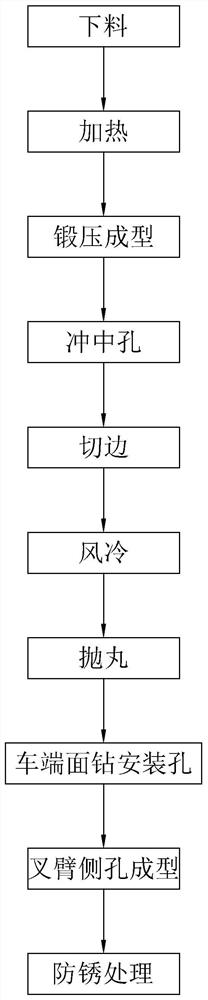

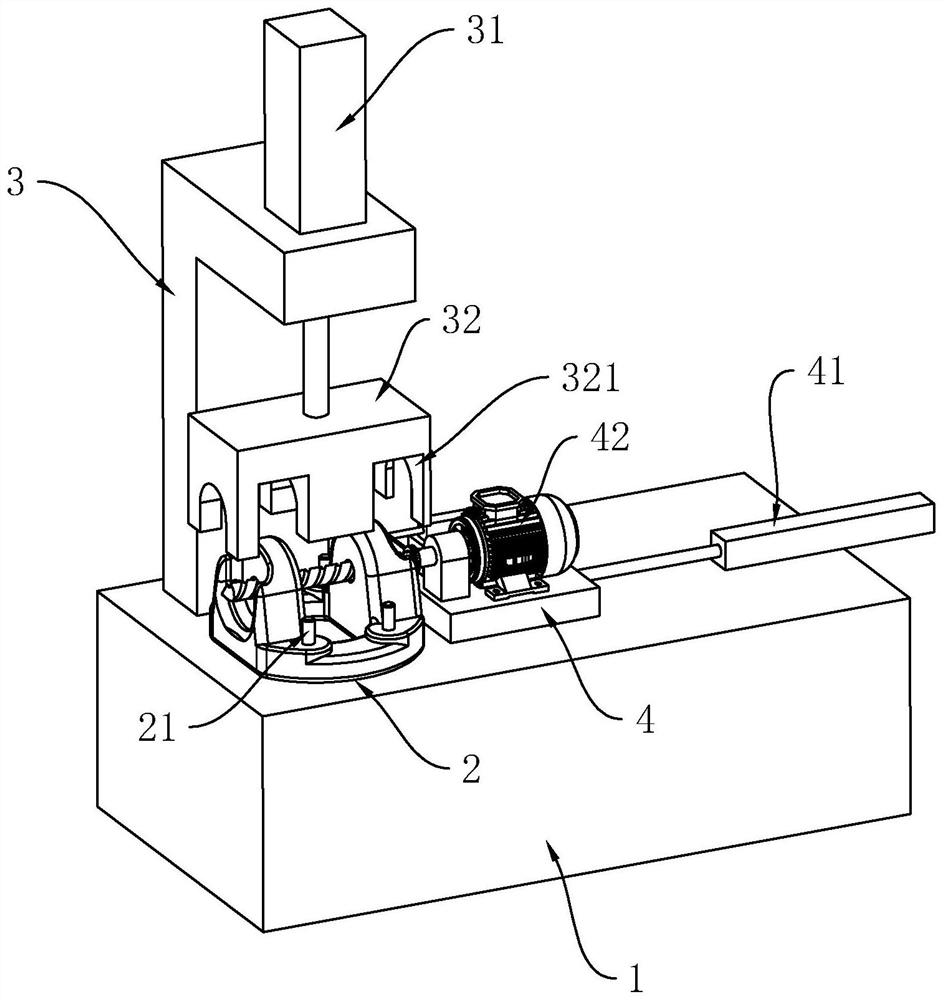

[0052] Embodiment one: refer to figure 1 , is the forging processing method of a kind of flange pipe fork disclosed by the present invention, comprises the following steps:

[0053] Step 1, blanking, according to the size of the flange pipe fork to be processed, the cut material is used as the raw material.

[0054] Step 2, heating, heating the raw material to the forging temperature;

[0055] Step 3, forging and forming, using die forging to forge the flange pipe fork blank,

[0056] 1) Upsetting, forging the heated original raw material to increase its diameter and shorten its length;

[0057] 2) Preforming, according to the shape of the flange pipe fork to be processed, set the corresponding preforming forging die, and use the preforming forging die to forge the flange pipe forging, preform the chassis of the flange pipe fork and the two fork arms 62 ;

[0058] 3) Forming, according to the shape of the flange pipe fork to be processed, set the corresponding precision fo...

Embodiment 2

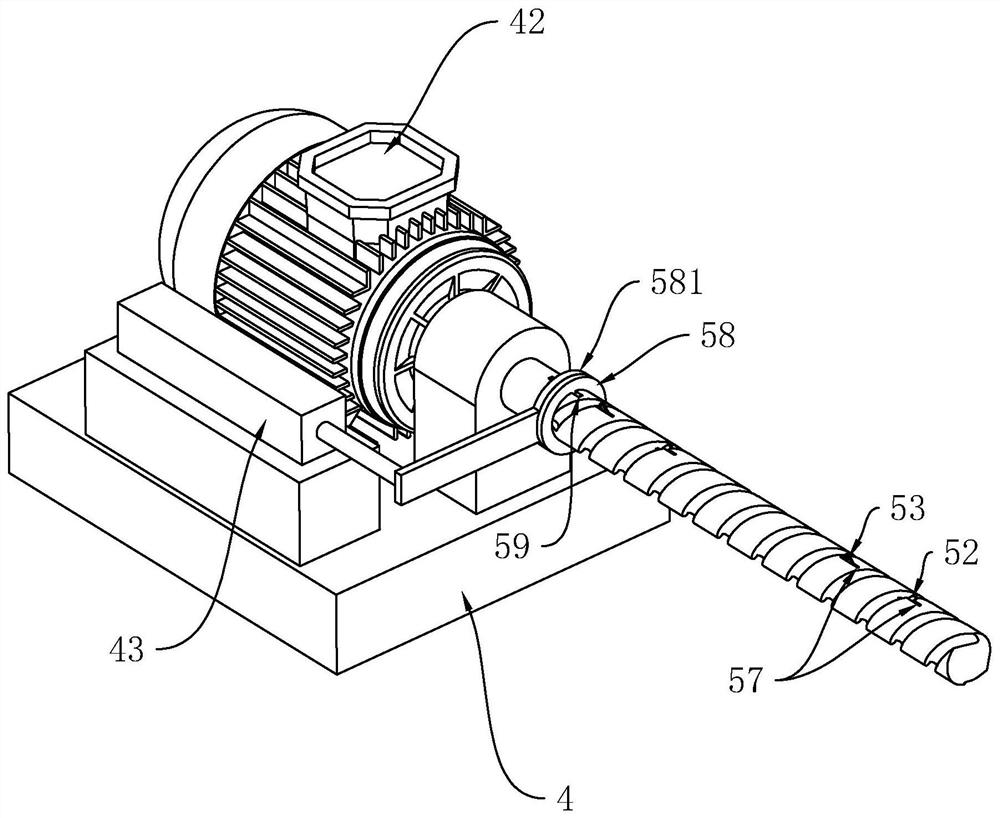

[0072] Embodiment two: refer to Image 6, a flanged pipe fork, comprising a bottom ring 61, both sides of a surface of the bottom ring 61 are vertically fixed with fork arms 62, both fork arms 62 are provided with through holes 621, and the axes of the two through holes 621 are at On the same line, bosses 611 are fixed on both sides of the bottom ring 61 corresponding to the fork arm 62 , and installation holes 612 penetrating the bottom ring 61 are opened on the bosses 611 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com