Main lug structure and crawler hoisting rotary table with same

A lug and re-turn technology, applied in cranes and other directions, can solve the problems of unguaranteed coaxial accuracy, difficult to control the matching accuracy, and reduce the assembly efficiency of the bottom section of the main boom, so as to ensure the coaxial accuracy, improve the Assembly efficiency, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

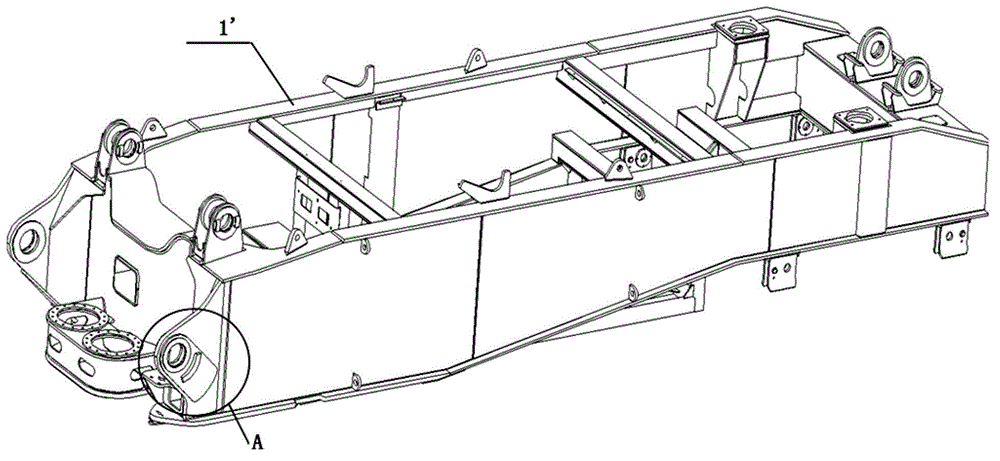

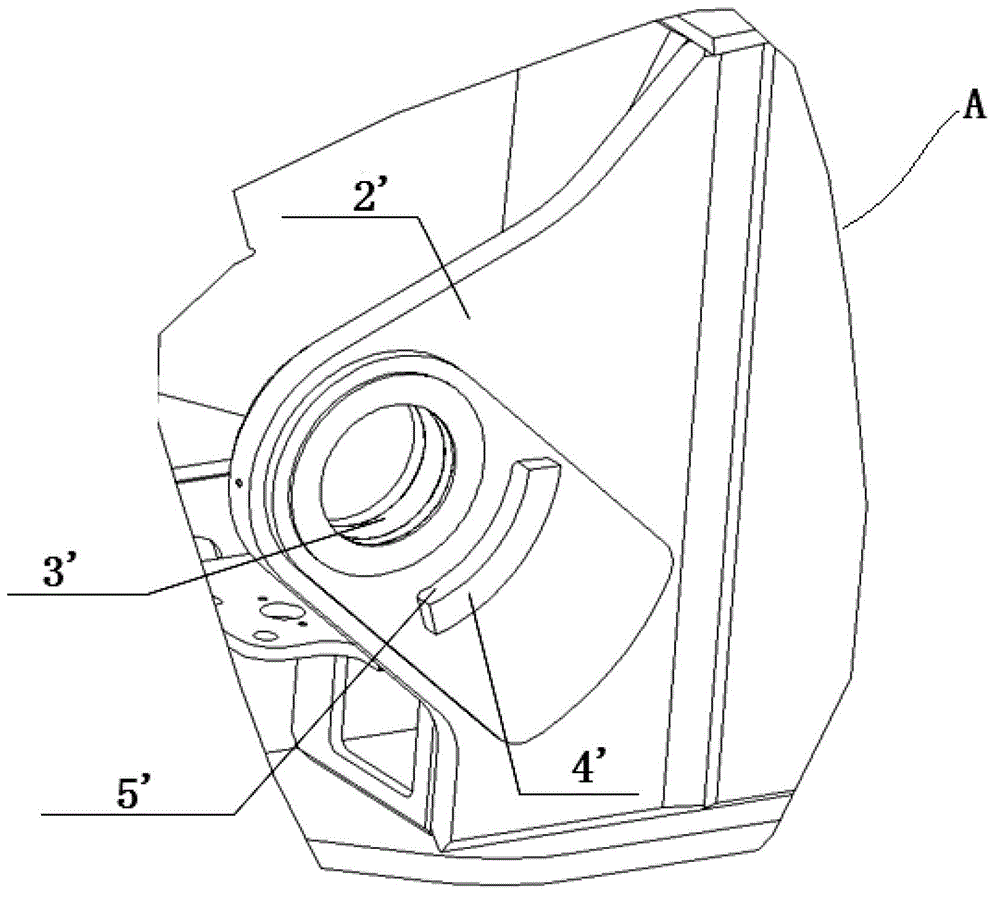

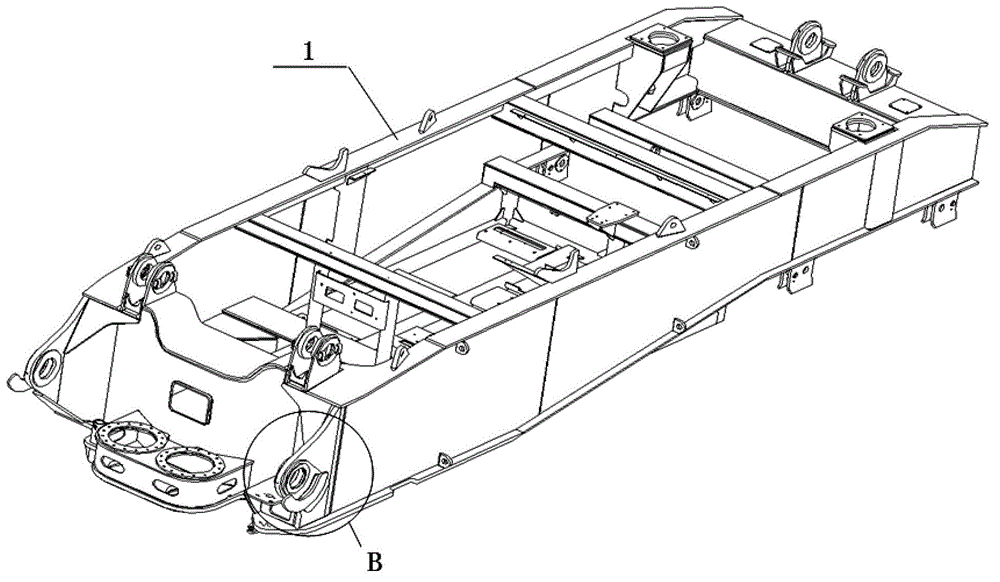

[0026] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0027] The present invention is mainly aimed at the inability to make the limit structure of the bottom section of the main arm coaxial with the hinge point hole of the main arm caused by welding the limit structure of the bottom section of the main arm after the bottom section of the main arm is assembled for the first time in the prior art The problem. The present invention firstly determines the position of the hinge point hole of the main arm and the limit structure of the bottom section of the main arm on the main ear plate; then, according to the determined position of the limit structure of the bottom section of the main arm, the limit The structure is welded to the corresponding position; finally, according to the determined position of the hinge point hole of the main arm, the hinge point hole of the main arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com