A self-centering two-way rotating cross-axis machining spindle

A bidirectional rotation and processing spindle technology, which is applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems that do not conform to the concept of high-efficiency development, coaxial precision cannot be guaranteed, and the purchase price of machine tools is high. Easy to move and install, compact structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

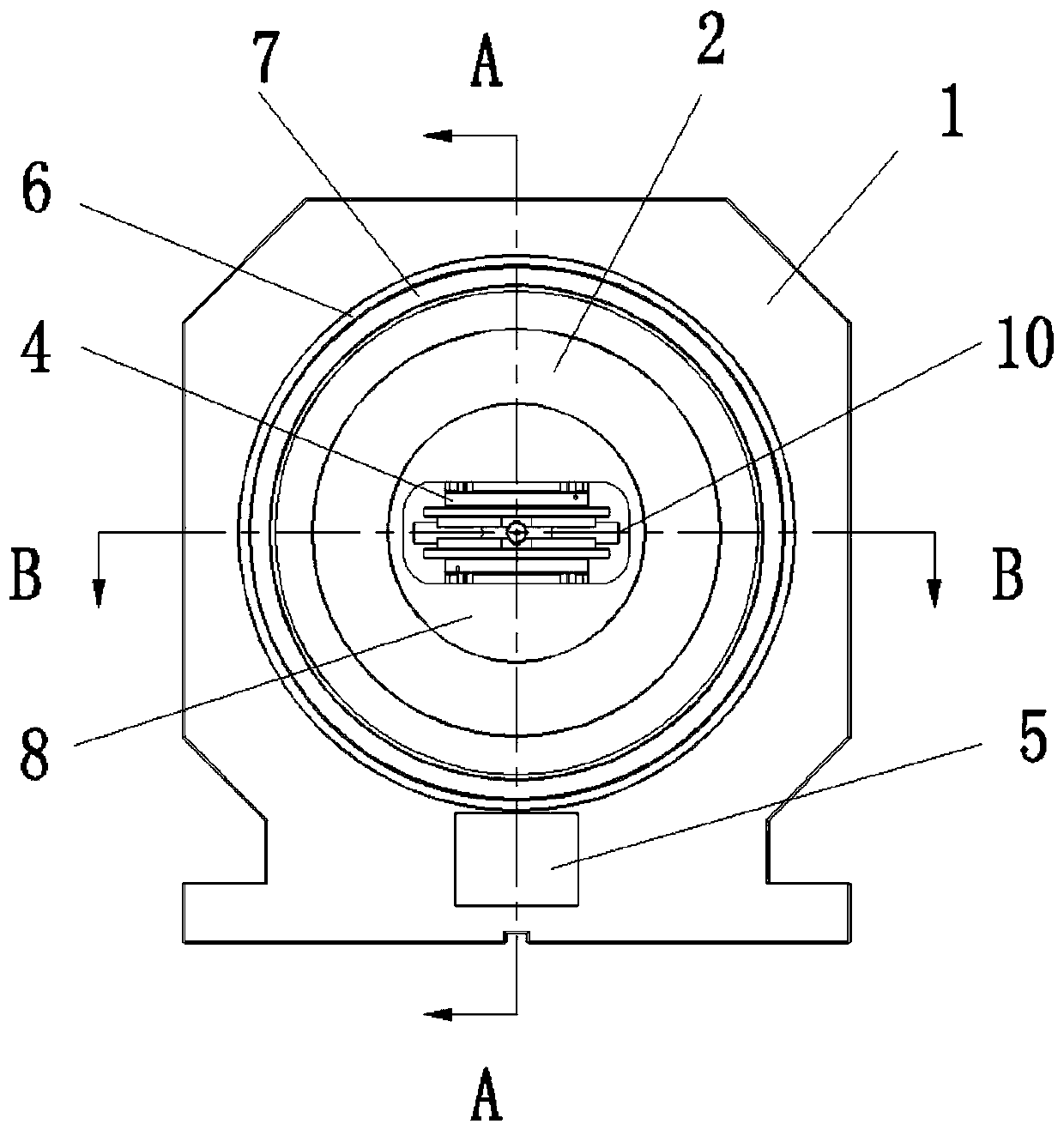

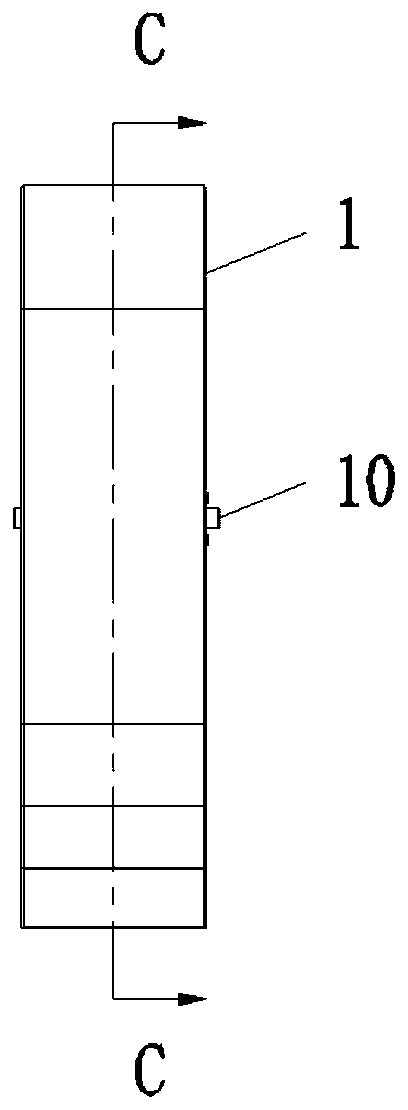

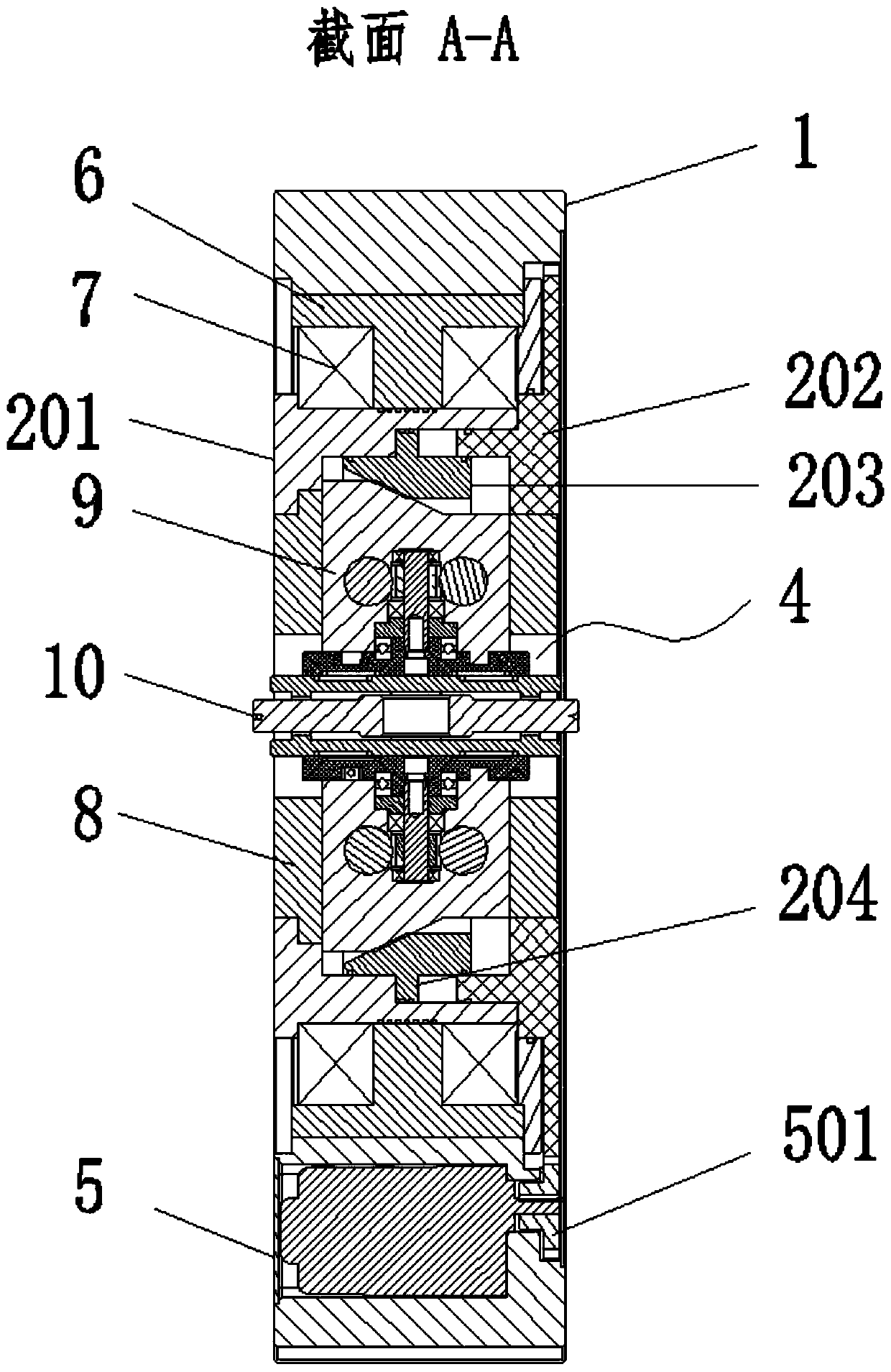

[0059] The present invention is a kind of self-centering two-way rotating cross-axis machining spindle, such as Figure 16 As shown, the device b is installed on the platform a, and the processing spindle c is symmetrically installed on both sides of the device b. The processing spindle c can rotate by itself and move forward and backward along the axial direction. When clamping, the cross-axis workpiece 10 is loaded and unloaded from the workpiece The port 802 is placed between the two groups of reversing clamping discs 406, and the four shafts 101 are respectively dropped into the V-shaped limit blocks on the clamping flange 408, and then the rotary cylinder mechanism 2 is driven to make the rotary cylinder mechanism 2. The piston ring 203 of the middle oil cylinder moves to the left to abut against the lifting installation block 9, and pushes the lifting installation block 9 to move to the middle, that is, to move the clamping reversing mechanism 4 to the middle, and the two...

Embodiment 2

[0061] Different from Embodiment 1, the two groups of processing spindles c in this embodiment do not have the power of rotation, but can only move forward and backward in opposite directions. Under this condition, when processing the cross-axis workpiece 10, the reduction motor 5 needs to be turned on, and the drive gear 501 and the rotary oil cylinder The meshing of the end of the outer wall of the mechanism 2 drives the rotation of the rotary cylinder mechanism 2, that is, drives the clamped cross-axis workpiece 10 to rotate, and can also realize the processing of the end hole 102. At this time, the strength is suitable for use with unpowered external processing tools.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com