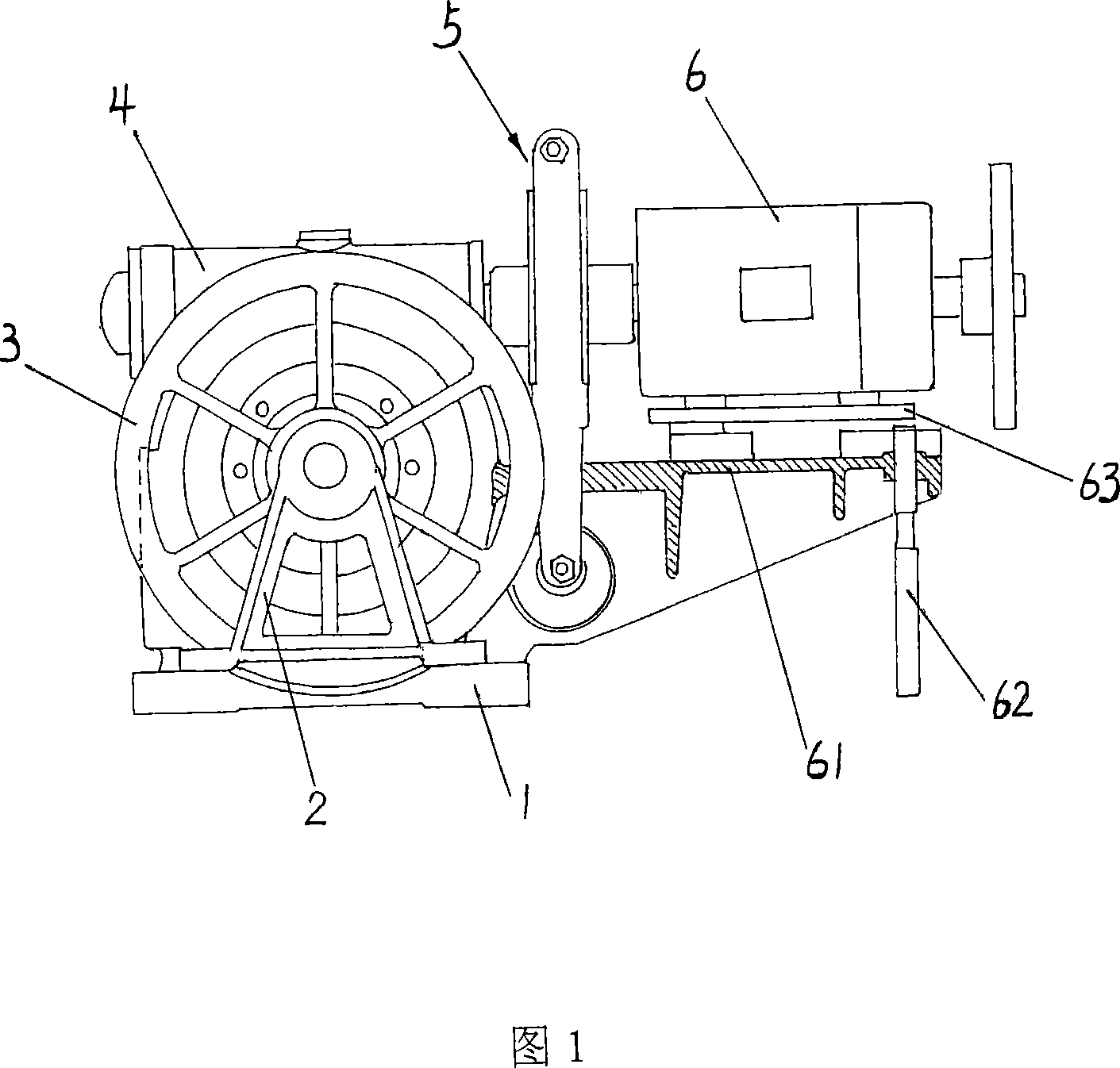

Drag for service elevator

An elevator traction machine and traction machine technology, applied in the field of elevator traction machines, can solve the problems of reduced traction machine efficiency, poor coaxial precision, center offset, etc., to improve braking stability and efficacy, and use Long life, correct positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

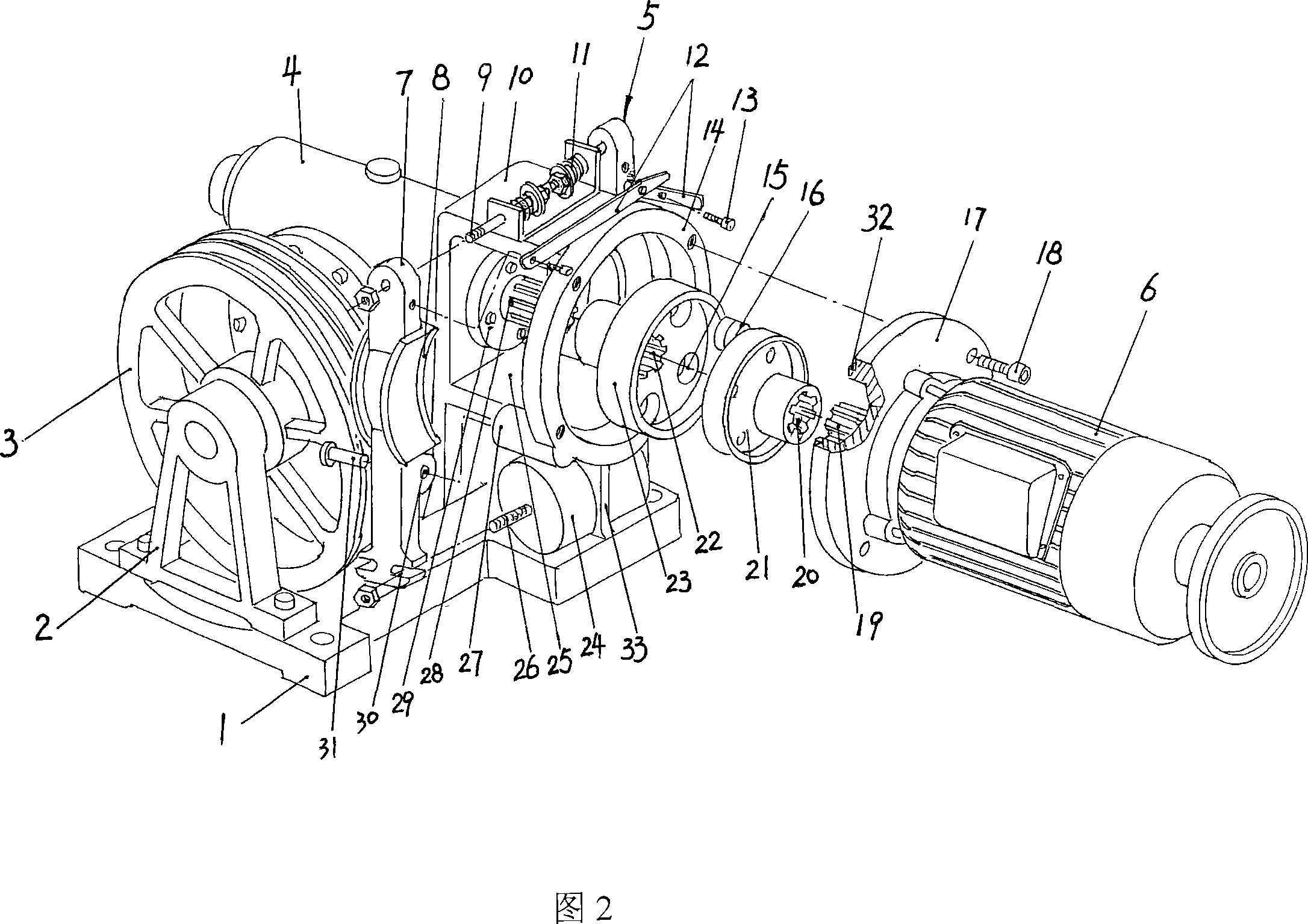

[0018] Through the applicant's detailed description of the embodiments below, it will be more helpful to understand the essence of the present invention, and the advantages and positive effects of the present invention will be clearer, but the embodiments should not constitute any limitation to the solution of the present invention.

[0019] Please refer to Fig. 2, the motor 6 of the present invention is provided with a motor flange seat 17 at the end near one end of the output shaft 19, the cross-sectional shape of the motor flange seat 17 is disc-shaped, and the output shaft 19 is located At the center of the motor flange seat 17, and at the edge of the vertical disc-shaped motor flange seat 17, it is narrowed to form a tooth mouth for tight fitting with the inner ring of the motor flange seat ring 14 for positioning 32. The reducer 4 of the present invention is integrally formed with a traction machine race frame 10 on the box near the worm shaft 28, and a brake disc chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com