Power device for air jet loom

A power unit, air-jet loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of poor braking stability, low transmission efficiency, etc., achieve convenient adjustment and maintenance, improve transmission efficiency, and simplify the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

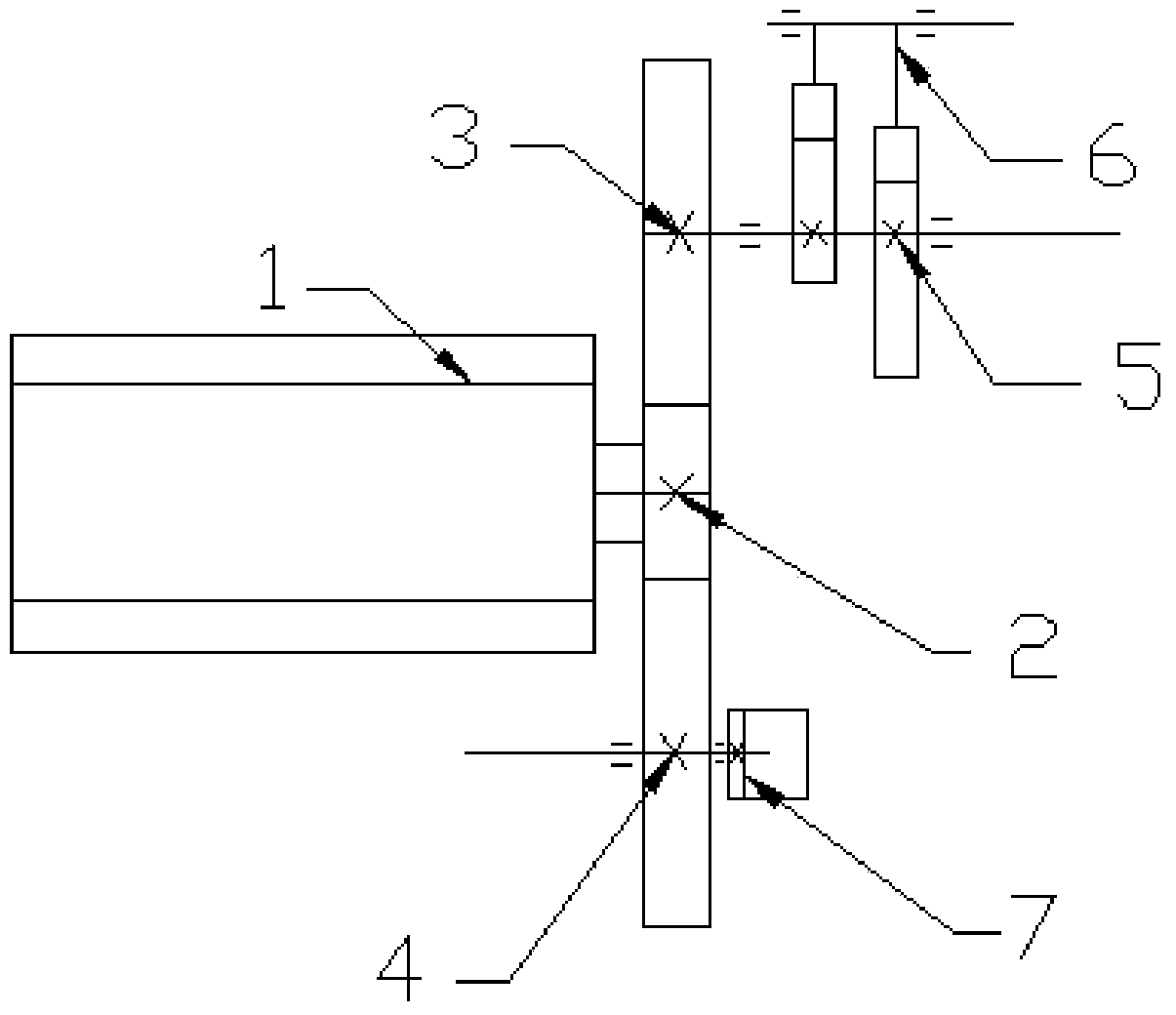

[0012] Such as figure 1 As shown, a power device of an air-jet loom includes a servo motor 1, and a main drive gear 2 is installed on the output shaft of the servo motor 1, and the main drive gear 2 is simultaneously connected with the beating-up transmission gear 3 and the opening transmission. Gear 4 meshes and drives, and the main drive gear, the beating-up drive gear and the open drive gear are all spur gears. Described opening transmission gear 4 is installed on the opening transmission gear shaft, and power-off brake 7 is installed on the described opening transmission gear shaft, and described beating-up transmission gear 3 is installed on the transmission shaft, and beating is also installed on the transmission shaft. Weft conjugate cam 5, the servo motor 1 drives the beating transmission gear 3 and the shedding transmission gear 4 to rotate through the main drive gear 2 simultaneously, the shedding transmission gear 4 drives the shedding mechanism to move to realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com