Numerical control double-rotation working table driven by double globoidal cams

A technology of double rotary table and cambered cam, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high processing cost and low transmission efficiency, and achieve a compact structure, stable transmission and high transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

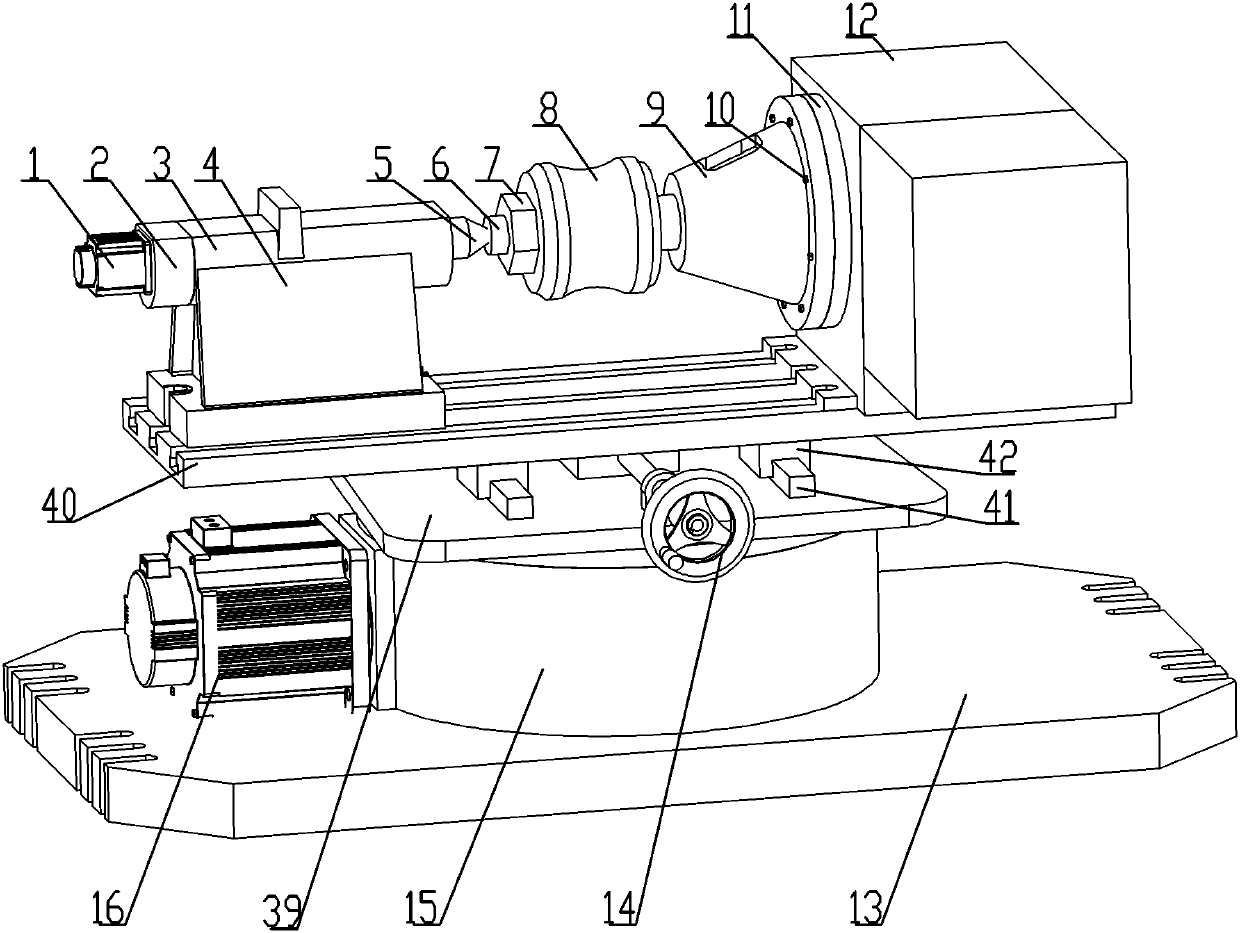

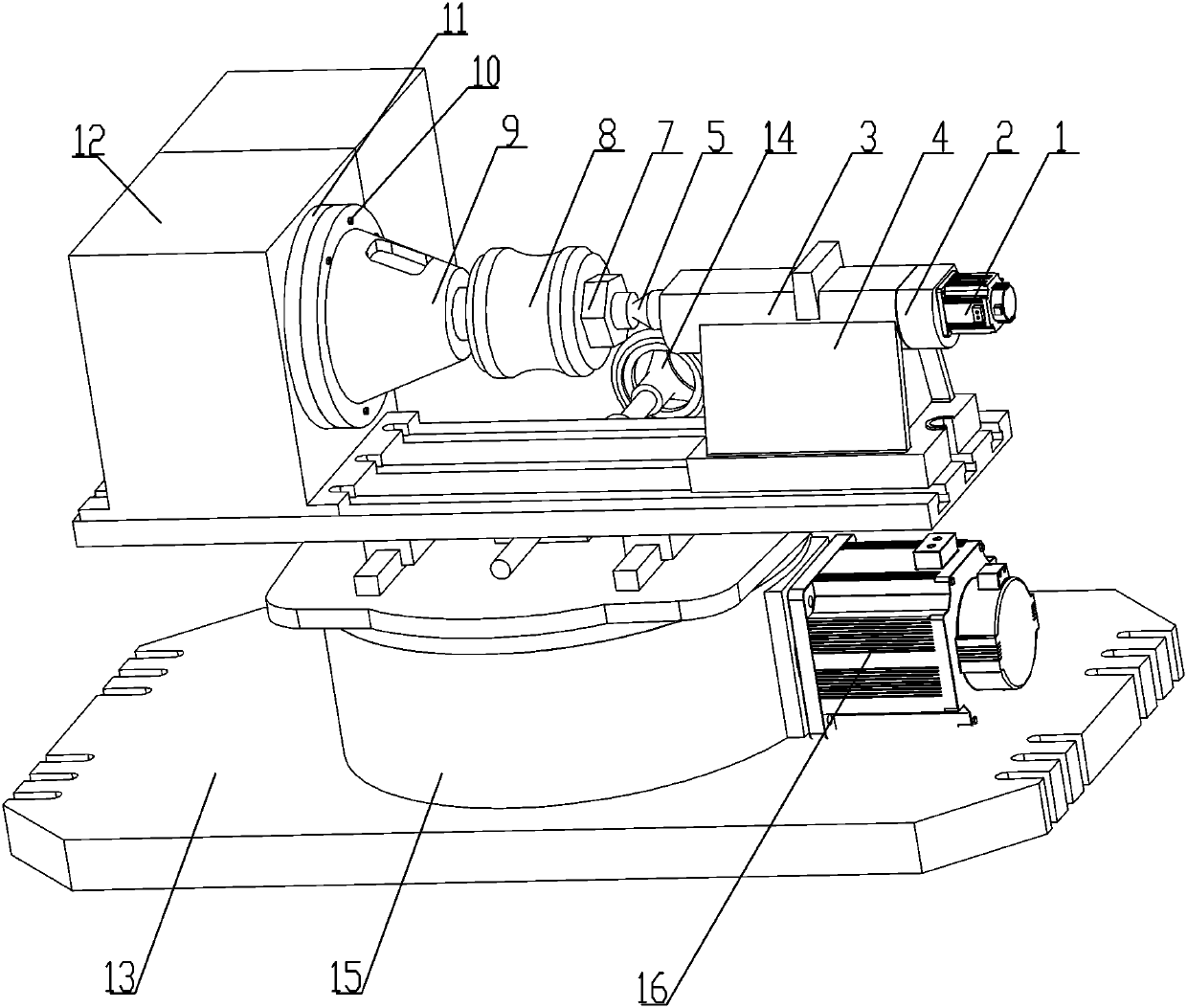

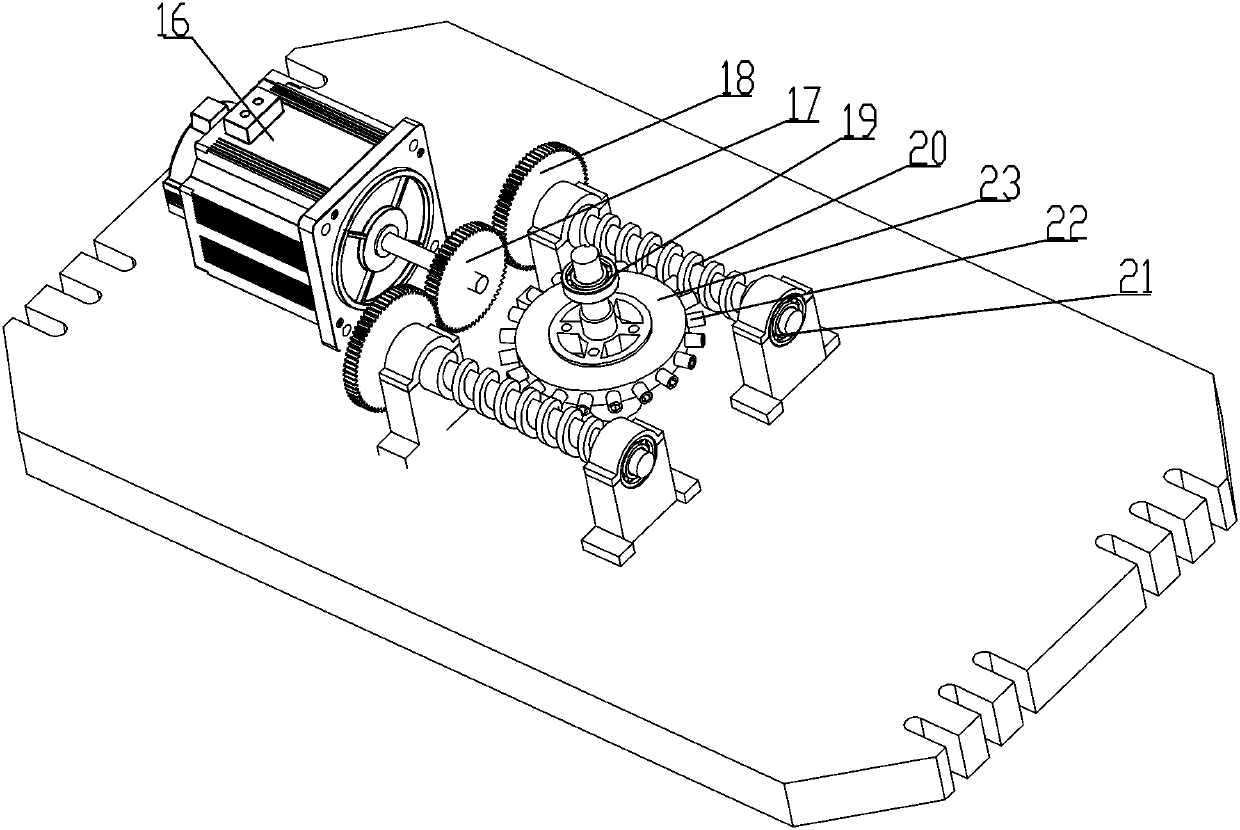

[0031] see Figure 1-5, a double-arc cam-driven numerical control double-rotary workbench, which includes a bottom plate 13, a first box 15 is fixedly installed on the top of the bottom plate 13, and a rotary shaft 25 is installed at the center of the first box 15 , the first driven disk 23 is installed on the rotary shaft 25, and the first driven disk 23 is connected with a two-stage transmission mechanism for driving its rotation, and the two-stage transmission mechanism is arranged inside the box body 15 And link to each other with the first servomotor 16 that provides power; The top of described rotary shaft 25 is equipped with turntable 39, and the top of described turntable 39 is adjustable to be installed with top clamping table 40 by screw adjusting mechanism, and is installed on top A workpiece rotation mechanism for driving the workpiece to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com