Method for manufacturing beam of tray and tray

A pallet and part of the technology, applied in rigid containers, containers, packaging, etc., can solve the problems of low equipment cost and uneven wall thickness of products, and achieve the effects of good waterproof performance, light weight, and improved stability and bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Exemplary embodiments of the present invention are described below in conjunction with the accompanying drawings, which include various details of the embodiments of the present invention to facilitate understanding, and they should be regarded as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted in the following description for clarity and conciseness.

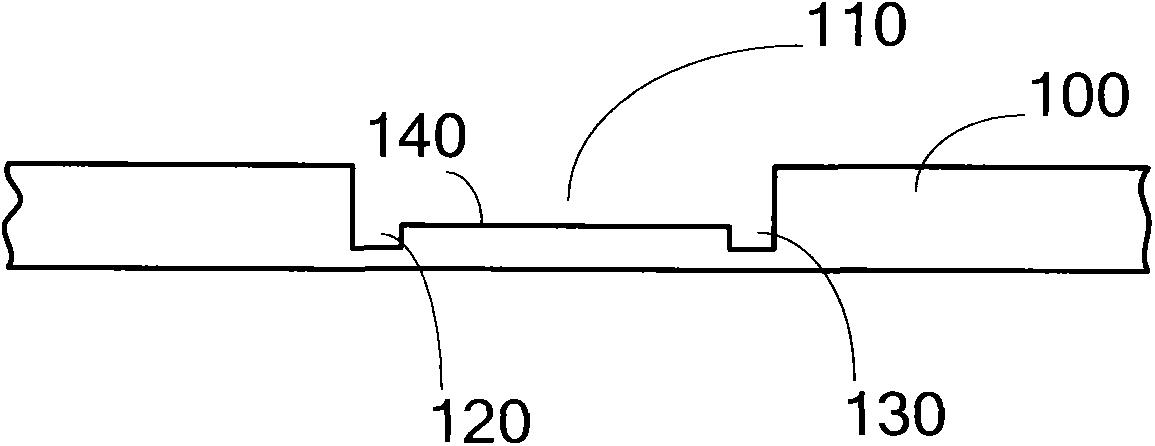

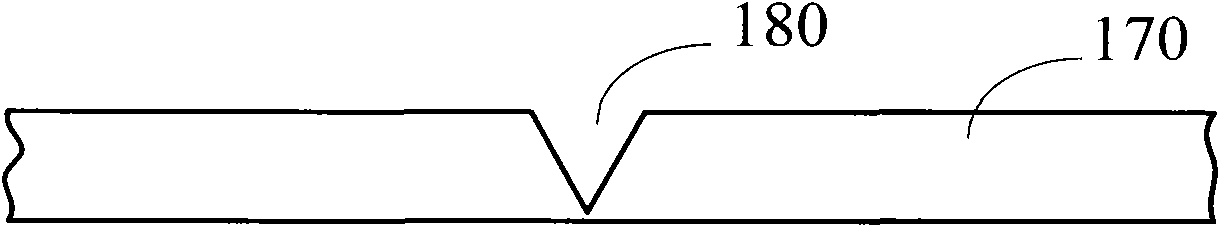

[0053] In this embodiment, the beams of the pallet are formed by folding rectangular plates. Several fold lines are made on this rectangular sheet before folding. refer to Figure 1A , Figure 1A is a schematic diagram of making folding lines on a board according to an embodiment of the present invention. The end face of the panel 100 is shown, which end face is perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com