Patents

Literature

138results about How to "Strong high and low temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

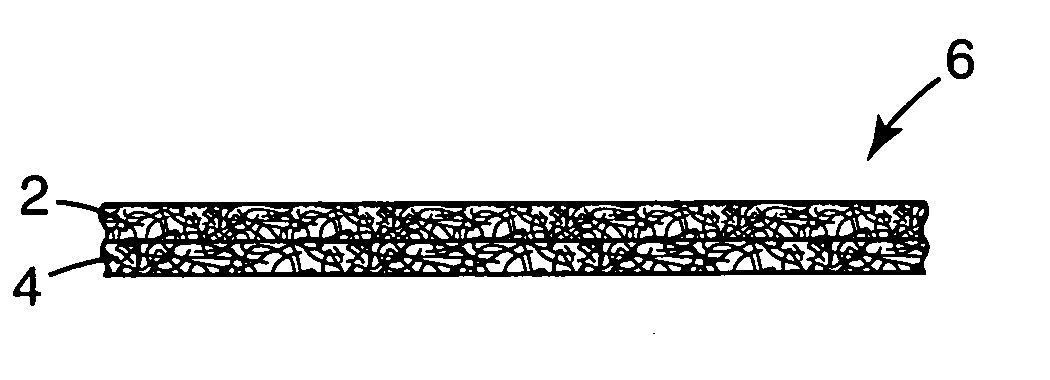

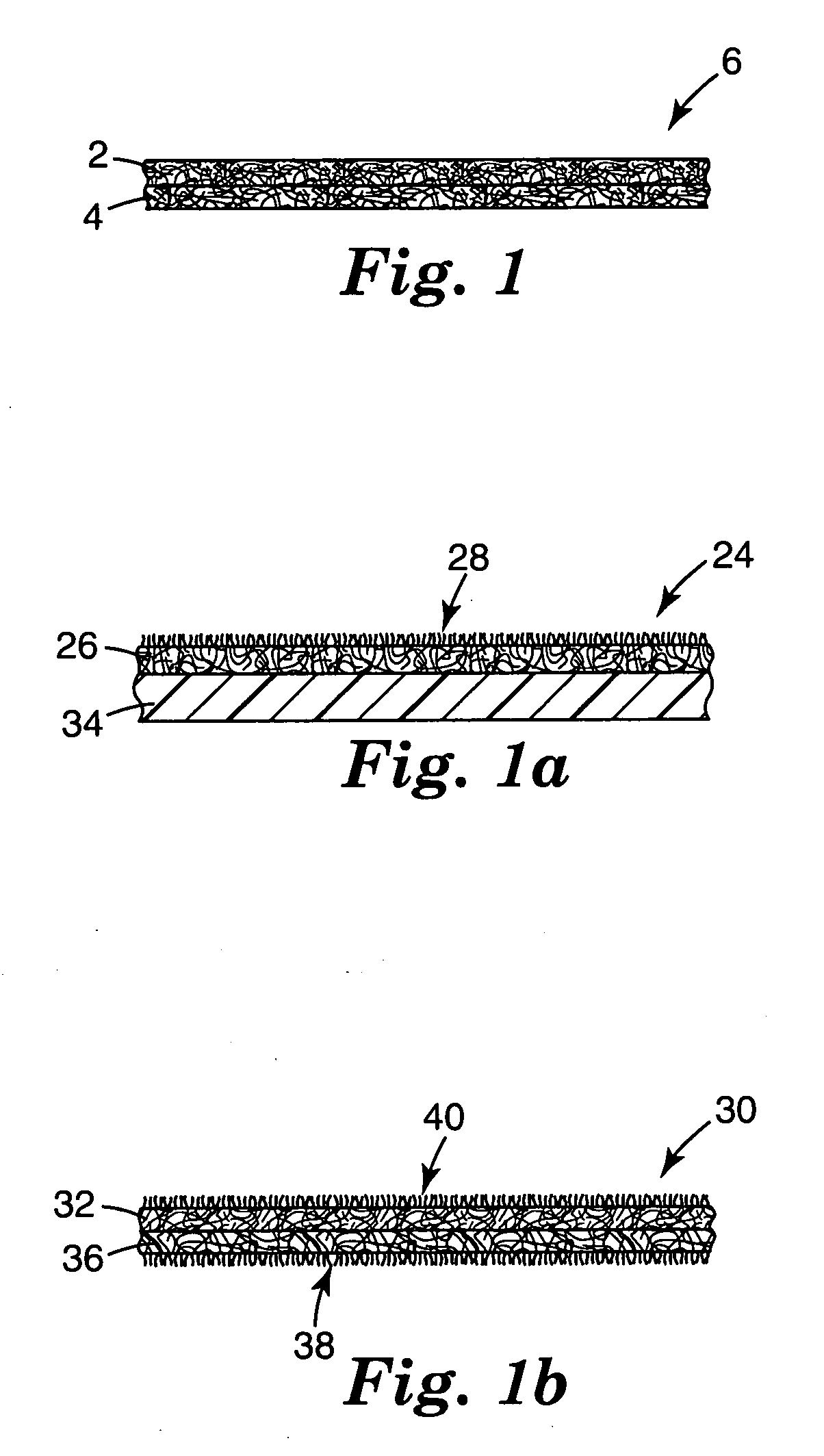

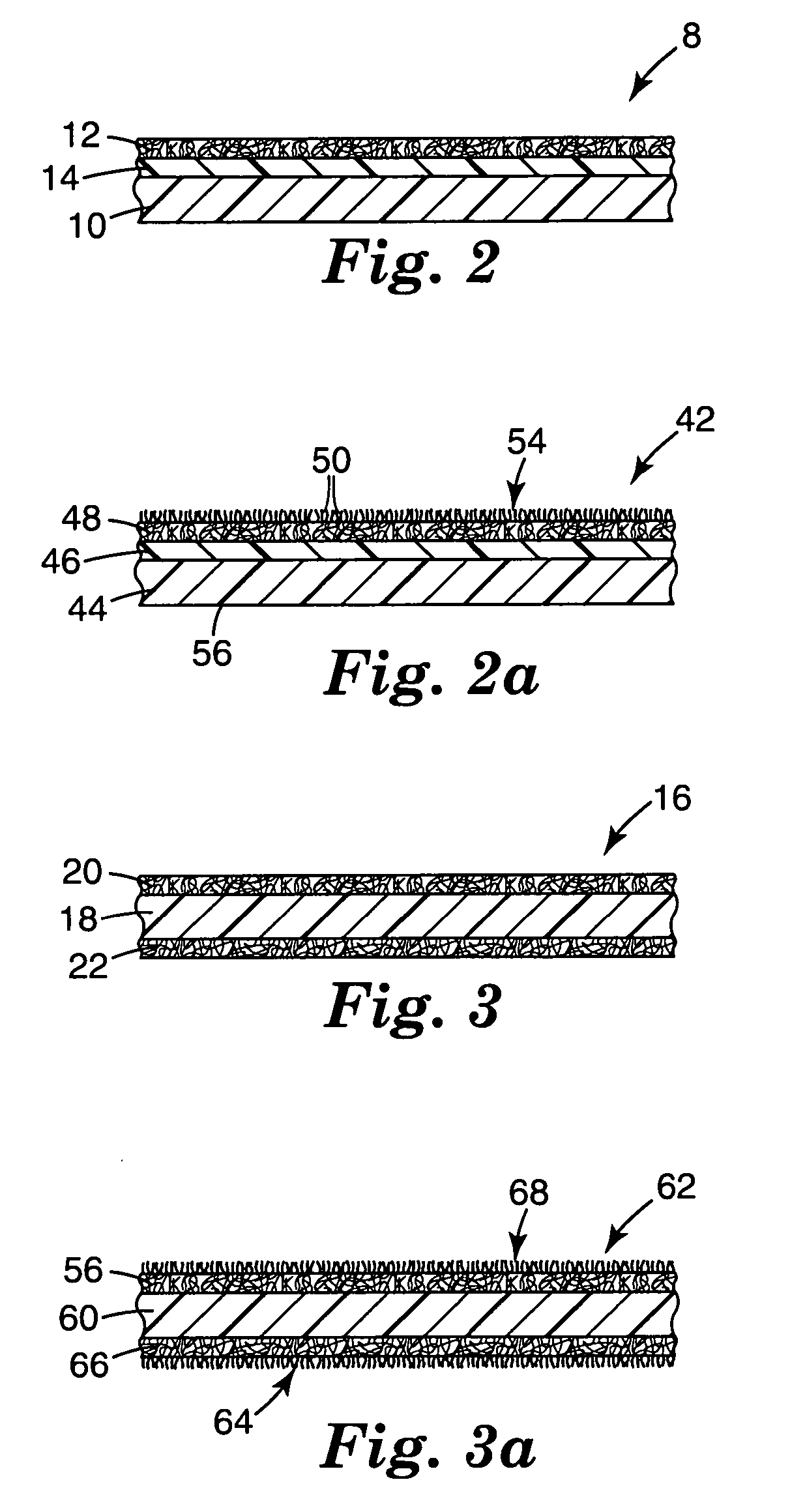

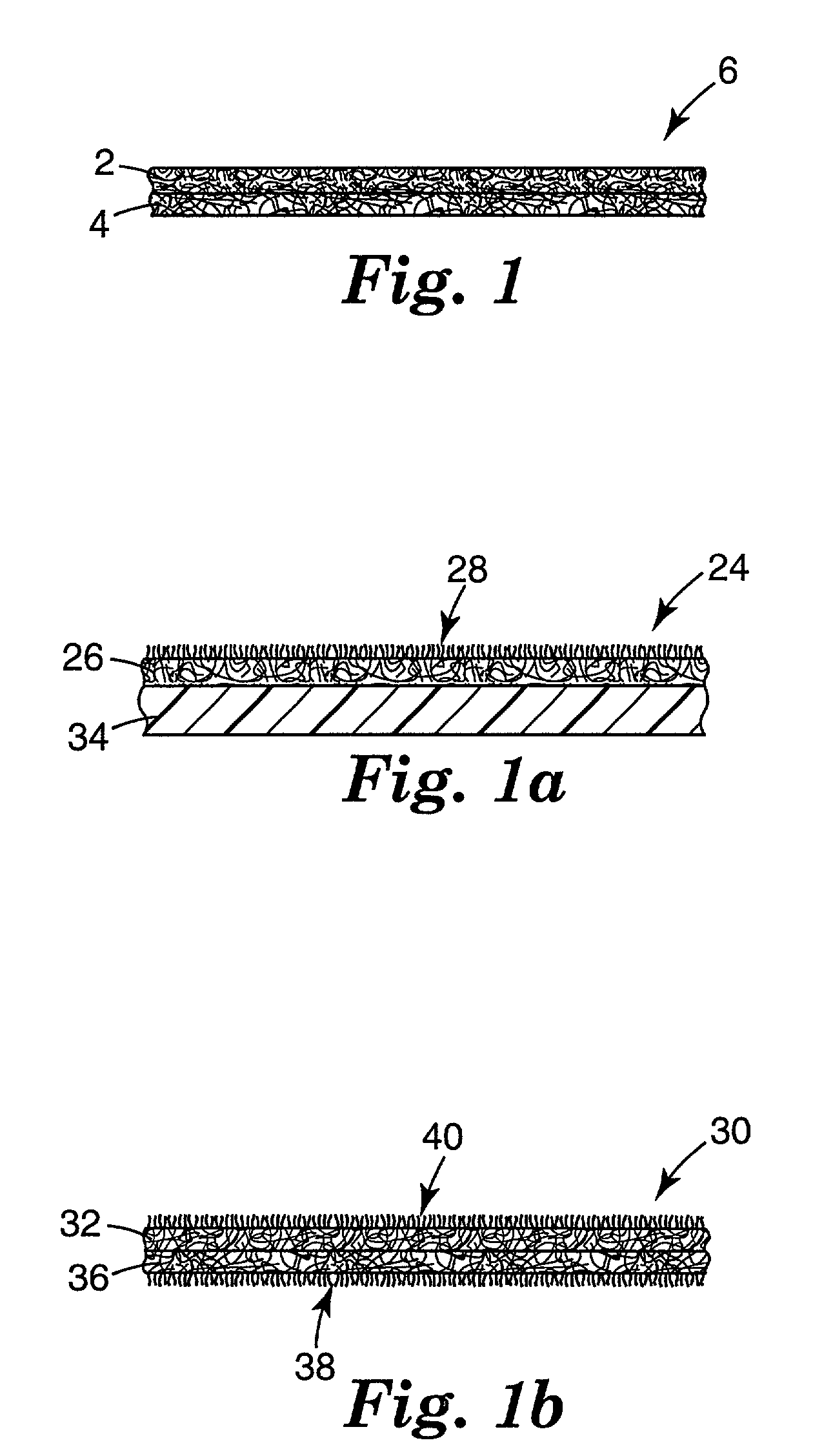

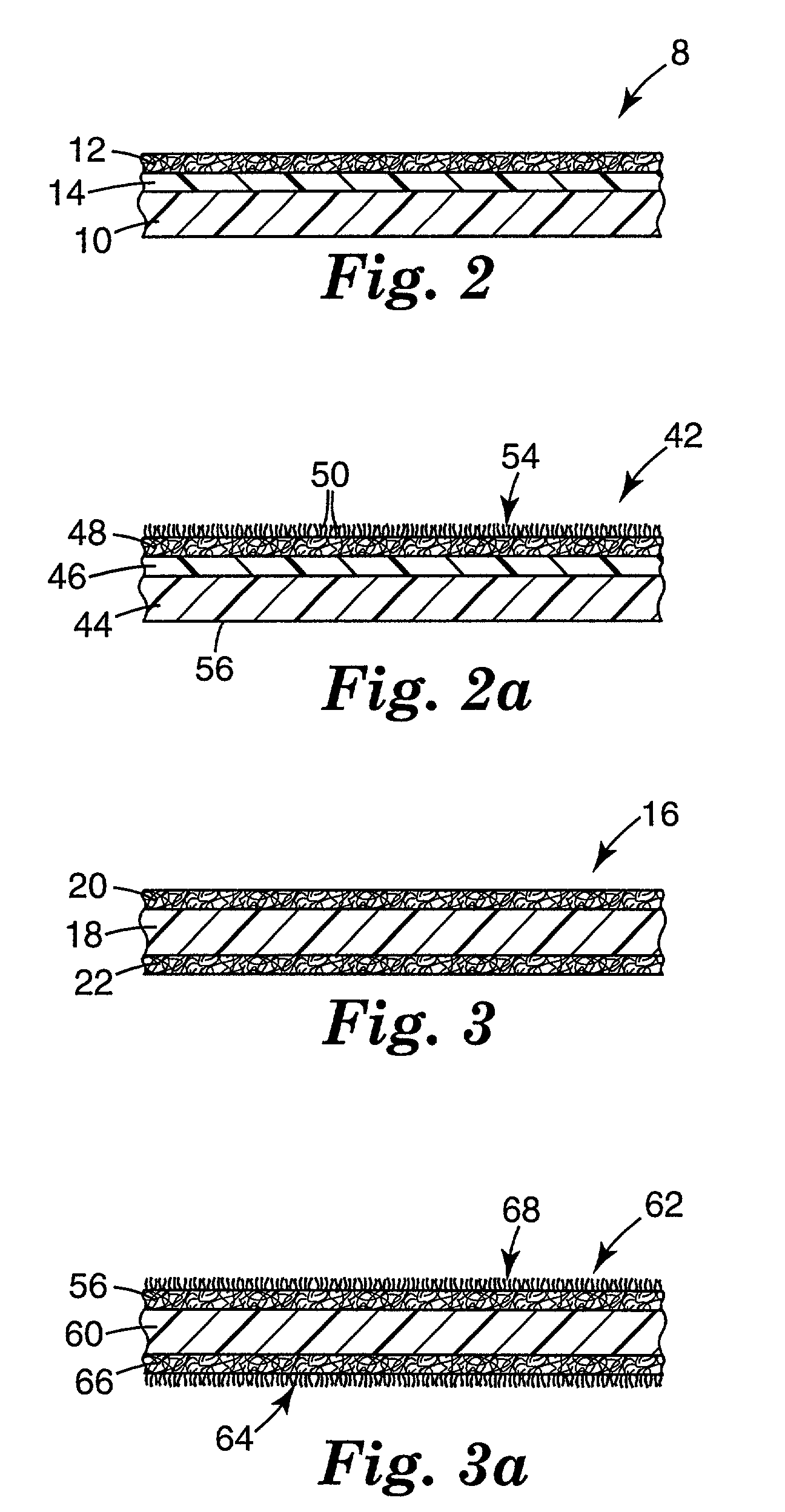

Microfiber articles from multi-layer substrates

InactiveUS20060049386A1High and low elasticityHigh and low strengthMaterial nanotechnologyOrganic chemistryPolymer scienceMicrofiber

Owner:3M INNOVATIVE PROPERTIES CO

Microfiber articles from multi-layer substrates

InactiveUS6977113B2Efficient and economicalHigh and low elasticityLamination ancillary operationsSynthetic resin layered productsMicrofiberMaterials science

Microfiber articles and methods and intermediates for their production, the microfiber articles being preferably produced from co-extruded multi-layer films, and the articles having a multi-layer construction that allows selection of the different layers to have different properties.

Owner:3M INNOVATIVE PROPERTIES CO

Radiation curing silicon fluoride coating and preparation method and application thereof

ActiveCN105885494AGood weather resistanceImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesWeather resistanceHeat resistance

The invention belongs to the field of coatings, relates to a radiation curing silicon fluoride coating and a preparation method and application thereof, and particularly discloses a radiation curing silicon fluoride coating. The coating is prepared from 30-70wt% of reactive acrylate prepolymer, 15-50wt% of reactive acrylate monomer, 3-8wt% of photoinitiator, 0-35wt% of pigment, 0-10wt% of filler and 0-5wt% of additive. Compared with the prior art, the radiation curing silicon fluoride coating has better color and pattern expressive force when carrying out surface treatment on decorative materials, has good antibacterial, anti-pollution, self-cleaning, waterproof and anti-mold properties and better weather resistance, heat resistance and mechanical performance, is wider is application range and can be widely applied to surface treatment, beautifying and protection of indoor and outdoor decoration materials.

Owner:ZHUHAI JIAWEILI ENVIRONMENTAL PROTECTION SCI & TECH

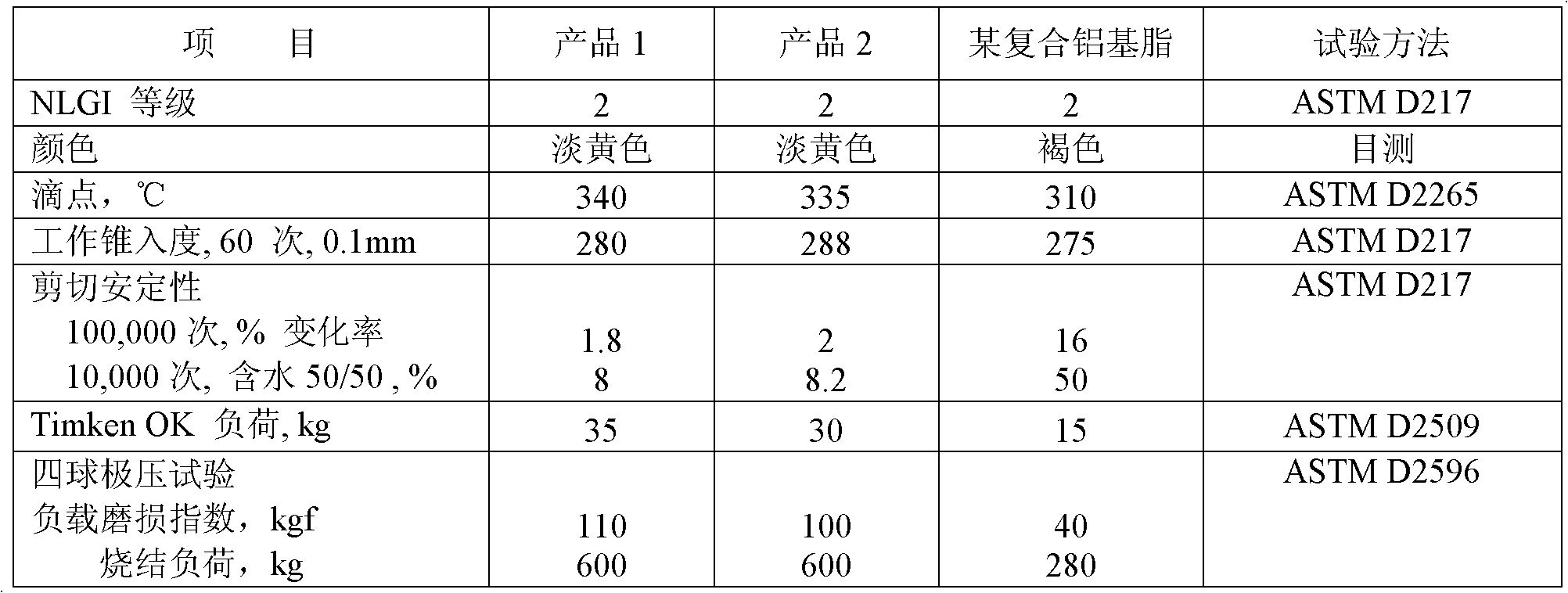

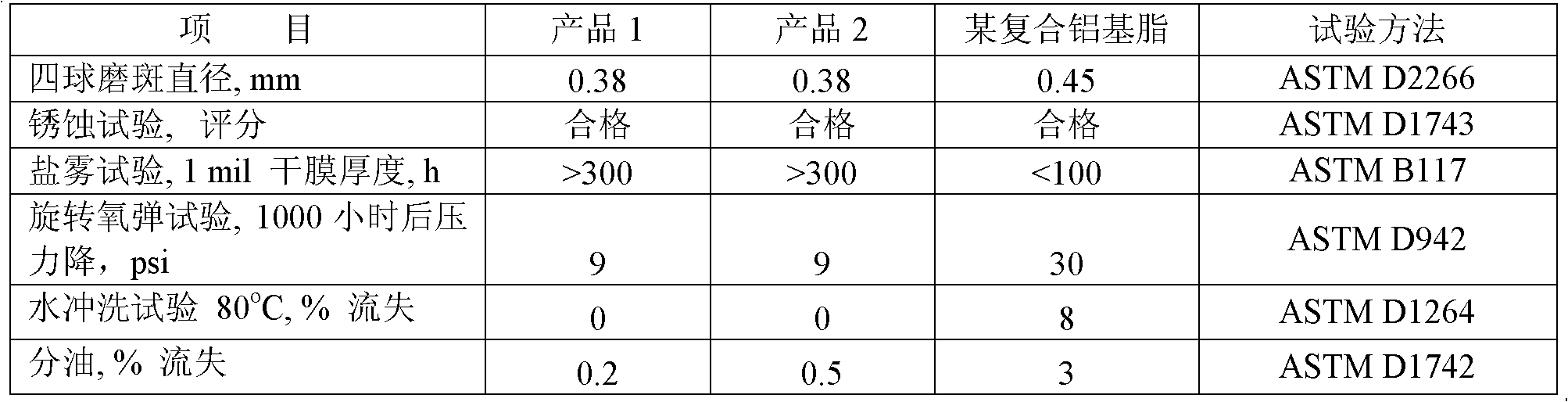

Multifunctional superstrong extreme pressure antiwear lubricating grease and preparation method thereof

InactiveCN102690716AStrong extreme pressureWear scar diameter is smallLubricant compositionAcetic acidCalcium hydroxide

The invention relates to superstrong extreme pressure antiwear lubricating grease and a preparation method thereof; particularly, a densifier is generated by calcium sulfonate with a high base number through a phase inversion reaction, and the lubricating grease is prepared by combining base oil with other functional additives, wherein the base oil is combined by base oil with high viscosity and medium viscosity. The method comprises the following steps: stirring and mixing the composite base oil and the calcium sulfonate in a reaction vessel, heating, adding a phase inversion promoter, glacial acetic acid, and water, heating and reacting at a constant temperature, adding calcium hydrate, aliphatic acid and boric acid after the phase inversion is completed, reacting at a constant temperature, heating and dehydrating, adding an anti-oxidant, refining, transferring the materials into a blending vessel, adding an eutectic rolling additive and an adhesion improver, dispersing and homogenizing the mixture, filtering, and degassing to obtain the finished product. The lubricating grease of the invention has excellent water sprinkling resistance, excellent high and low temperature performance, superstrong extreme pressure antiwear performance, excellent pumping performance, outstanding shearing stability, and antirust performance.

Owner:超美科技(深圳)有限公司

Multifunctional green building materials

ActiveCN105220779AGood thermal insulation performanceGood heat preservation and energy saving effectSynthetic resin layered productsHeat proofingThermal insulationCorrosion resistant

The invention discloses multifunctional green building materials with functions of fire prevention, thermal insulation and sound insulation and aims to overcome the defect that current building materials are poor in thermal insulation and sound insulation effects. The green building materials comprise an inner fire preventing layer, an outer sound insulation layer and a thermal insulation layer between the inner fire preventing layer and the outer sound insulation layer, wherein the thermal insulation layer is connected with the fire preventing layer through an adhering layer, and the thermal insulation layer is connected with the sound insulation layer through an adhering layer. The multifunctional green building materials have the advantages that the building materials are good in thermal insulation performance, the heat conductivity coefficient of the building materials is 0.01-0.05W / (m*K), the building materials are good in thermal insulation and energy saving effects and good in fire preventing performance, the fire resistance duration of the building materials is larger than 3 hours, an A-level fire preventing standard can be reached, good fire resistance is achieved, a good sound insulation performance is achieved, noise influence can be reduced greatly, good durability is achieved, and the building materials are resistant to high temperature and low temperature and good in corrosion resistance and weather resistance.

Owner:FENGLIN ENVIRONMENTAL PROTECTION TECH CO LTD

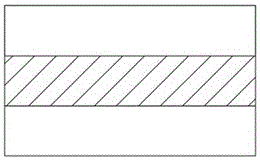

Basalt fiber friction material and preparation method thereof

InactiveCN106084646AImprove high and low temperature resistanceReduce friction lossOther chemical processesBrake torqueFriction loss

The invention discloses a basalt fiber friction material which comprises a mixed fiber framework, binders, reinforced fibers and fillers. The mixed fiber framework and the reinforced fibers take basalt as a main raw material, high and low temperature resistance of the friction material can be enhanced, friction loss is reduced, and the temperature strain performance of the friction material is improved. No asbestos is added into the friction material, the cost is low, base materials are better in overall combination, metal wires are uniformly distributed, and the friction material is rapider and better in heat conduction and heat dissipation. Dimensional accuracy of a friction element made of the friction material is higher than that of an existing friction material. The problems of buddle swelling, layering, warping and the like in the production process of laminated products are completely avoided. The friction material has the advantages of high and low temperature resistance, wear resistance, low noise, stable friction brake torque, environmental protection and the like.

Owner:DONGTAI HUAYANG GLASS FIBER

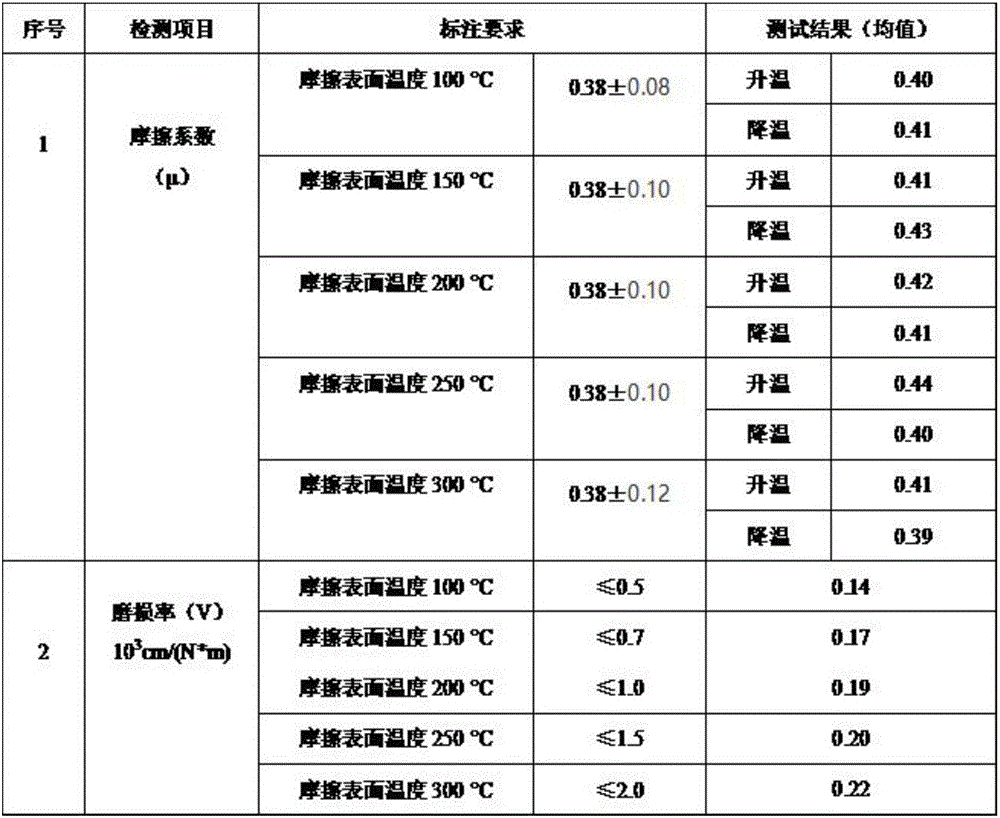

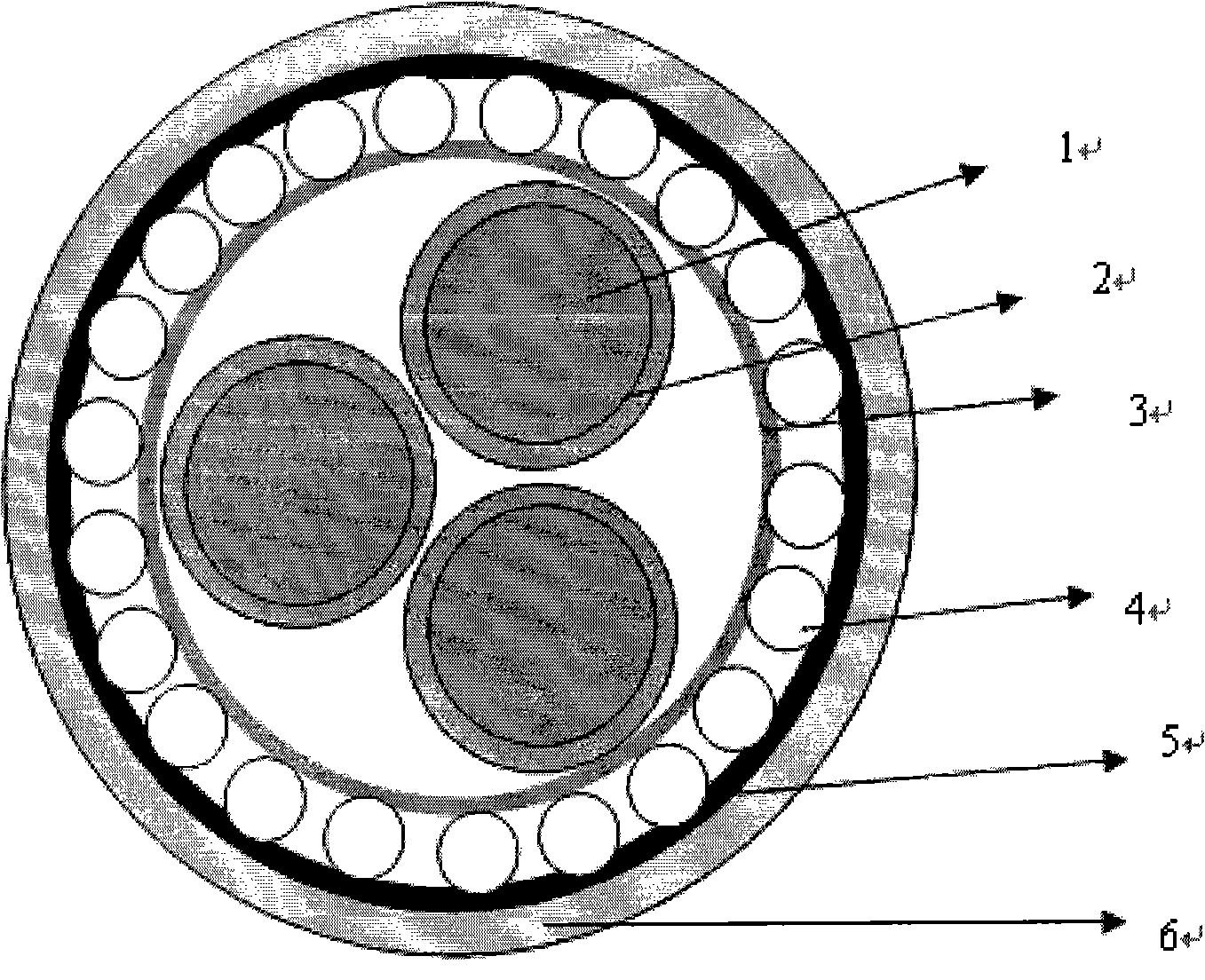

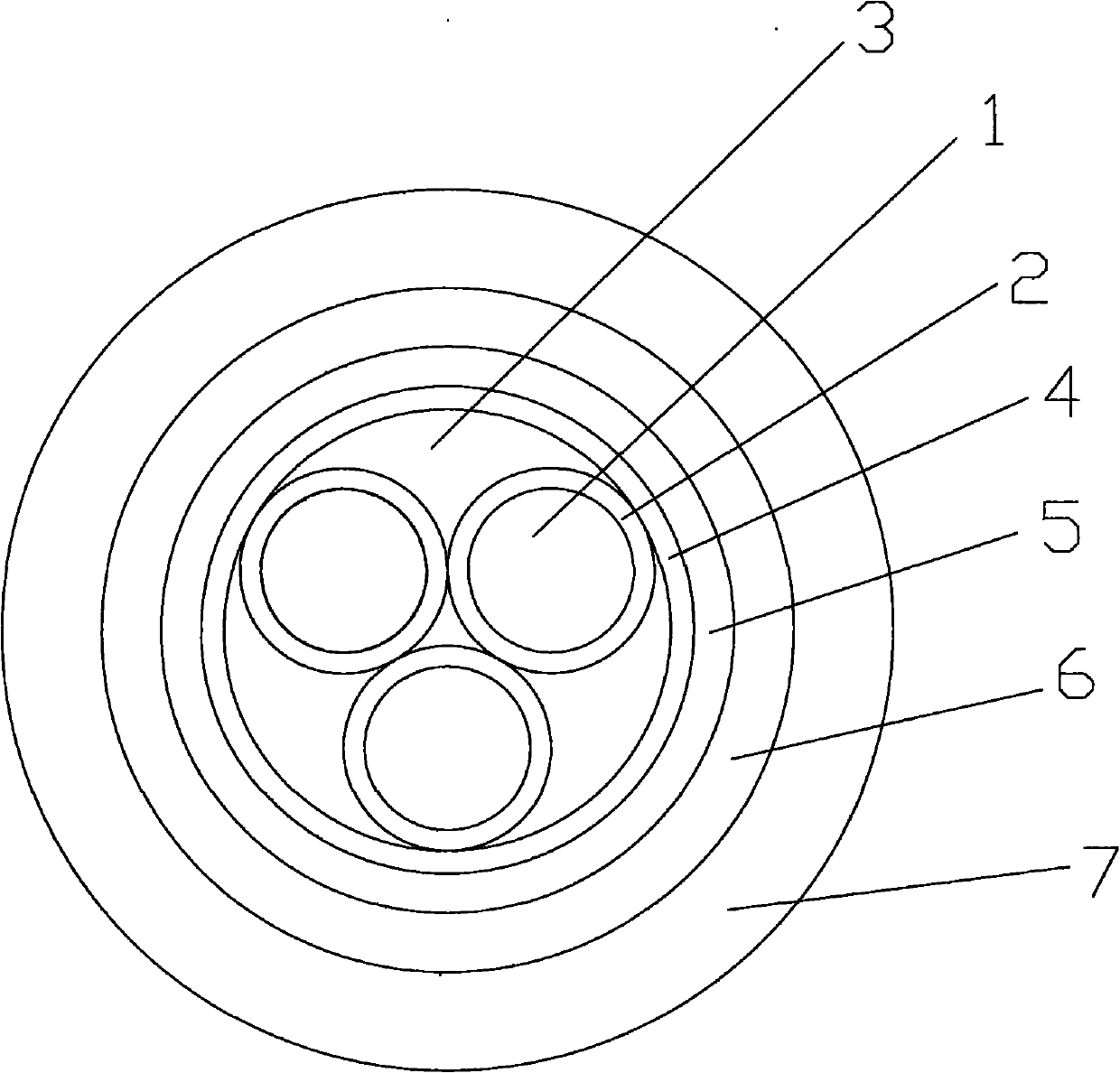

Cleaning-type oil-resistant cable

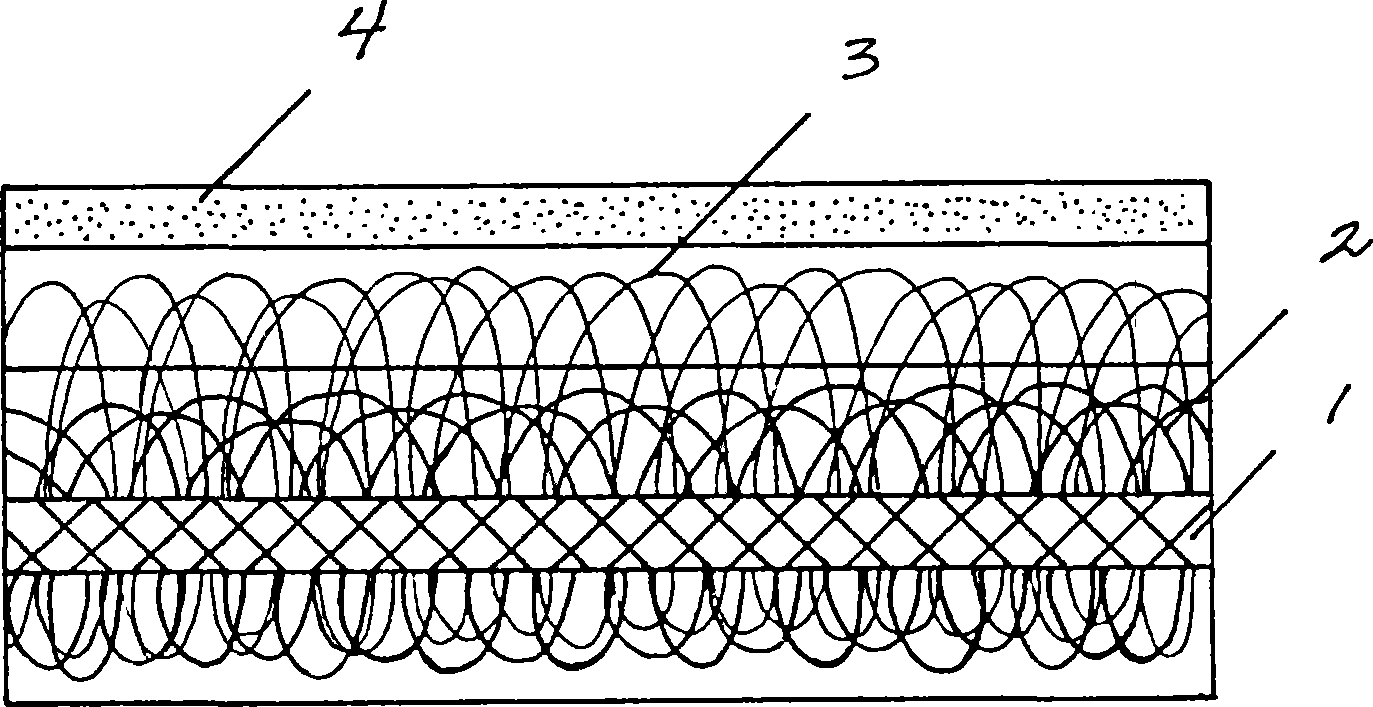

InactiveCN102082004ALarge leakage currentWear-resistantClimate change adaptationInsulated cablesCopper conductorCross-link

The invention belongs to the technical field of electrical wire and cable production processes, and particularly relates to a cleaning-type oil-resistant cable. Conductors (1) are copper conductors, the structures of the conductors adopt a first type or a second type, a cross-linked polyethylene insulating layer (2) is extruded on the conductors (1) respectively by applying a warm water cross-linking technology to serve as a cable core, an inner lining layer (3) is arranged outside the cable core, an armor layer (4) is armored by back-twist type galvanized fine steel wires, aluminum-plastic composite tapes are longitudinally coated and welded outside the armor layer (4) to form a water and tide blocking layer (5), and a flame-retardant jacket layer (6) made of a butyronitrile material is arranged at the outermost layer. With a double-layer co-extrusion mode to extrude, the arrangement of the high-strength water and tide blocking layer capable of longitudinally preventing tension in the overall cable and a process of double-layer co-extrusion protection layers, the cleaning-type oil-resistant cable has not only very strong resistance to abrasion and oil, but also better resistance to cleaning, thereby the quality stability of the oil-resistant cable is improved and a new technical field is developed for the development of the cleaning-type oil-resistant cable.

Owner:HENAN HUATAI SPECIAL CABLE

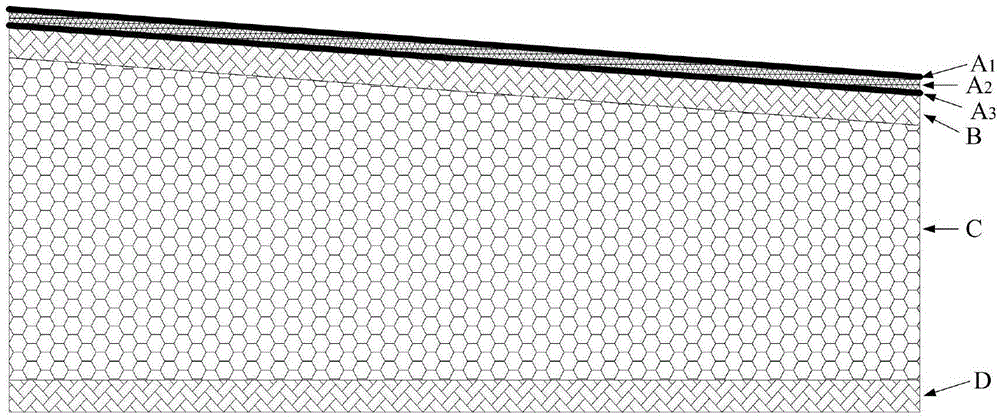

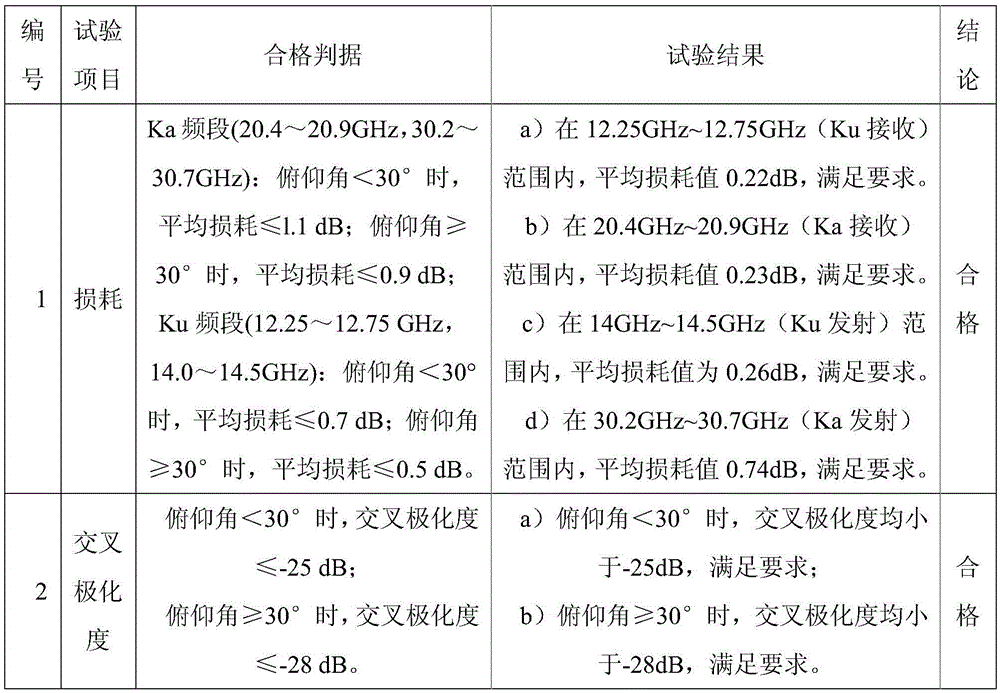

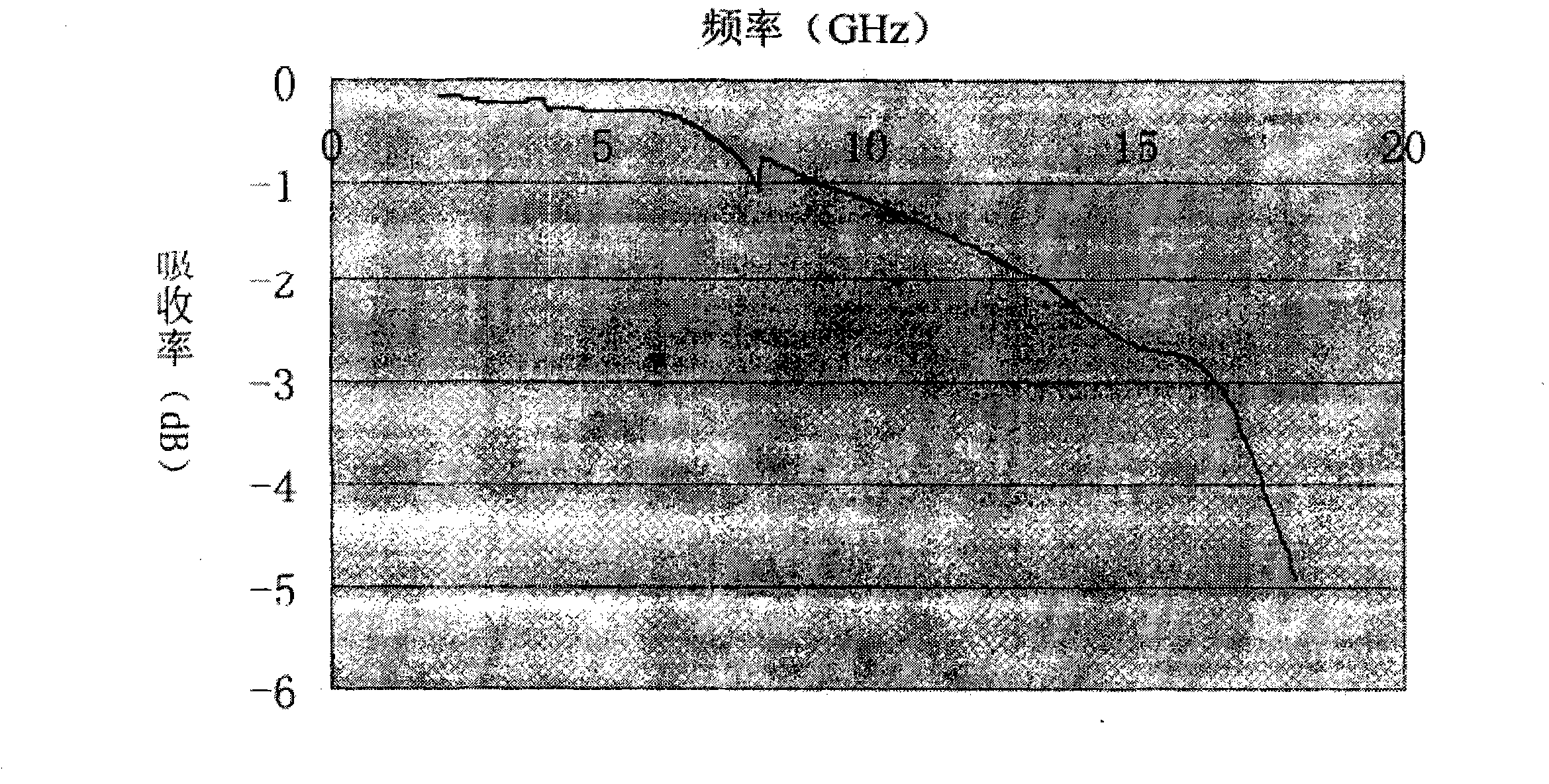

Composite material for airborne radomes, and preparation method thereof

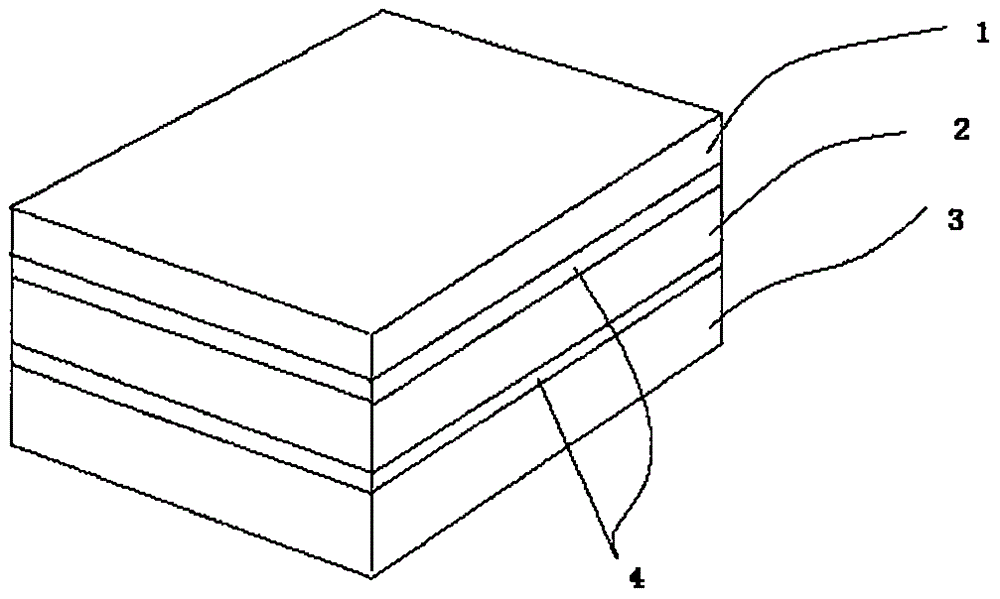

ActiveCN105563964AImprove environmental resistanceStrong high and low temperature resistanceSynthetic resin layered productsRadiating element housingsRight trapezoidRadome

The invention discloses a composite material for airborne radomes, and a preparation method thereof. The composite material for airborne radomes comprises a surface coating layer, an outer skin layer, a sandwich layer and an inner skin layer, the sandwich layer is arranged between the outer skin layer and the inner skin layer, and the surface of the outer skin layer is coated with the surface coating layer; the thickness of the outer skin layer is 0.2-1mm; the sandwich layer is made of polymethacrylimide, and has a right trapezoid structure, the short edge thickness is 4-30mm, and the long edge thickness is 4.5-34mm; and the thickness of the inner coating layer is 0.2-1mm. The preparation method comprises the following steps: preparing an inner skin layer prepreg through manual pasting dipping, overlaying a sandwich layer material, solidifying, preparing an outer skin layer prepreg through manual pasting dipping, solidifying, spraying the surface coating layer, and solidifying. The composite material for airborne radomes has the advantages of excellent environment resistance, good whole bearing ability, and maintenance of a high wave penetration rate in double wavebands.

Owner:NAT UNIV OF DEFENSE TECH

Missile-borne data testing system

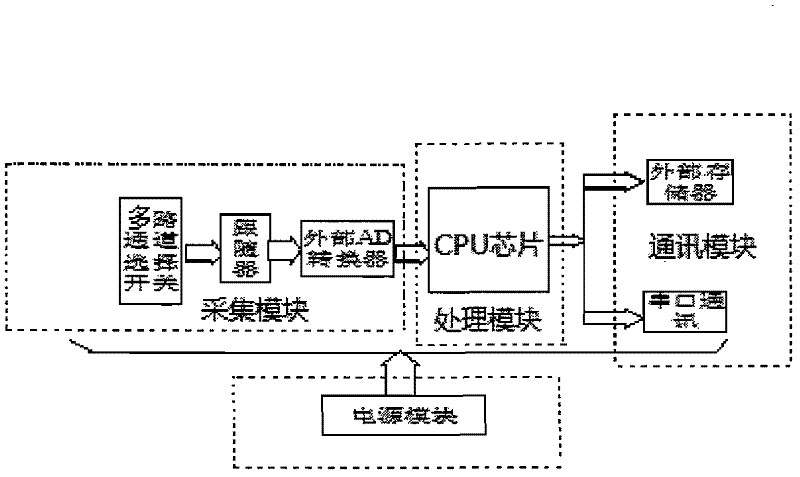

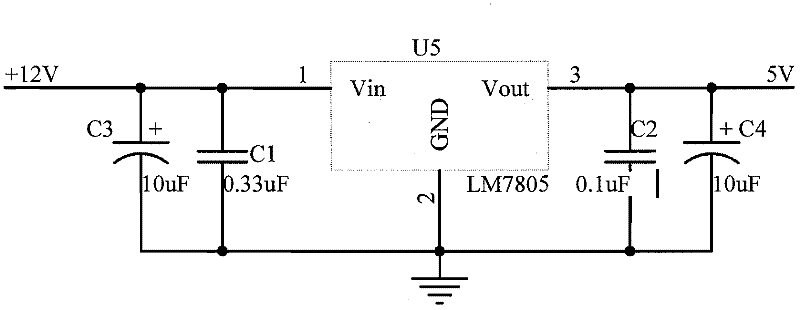

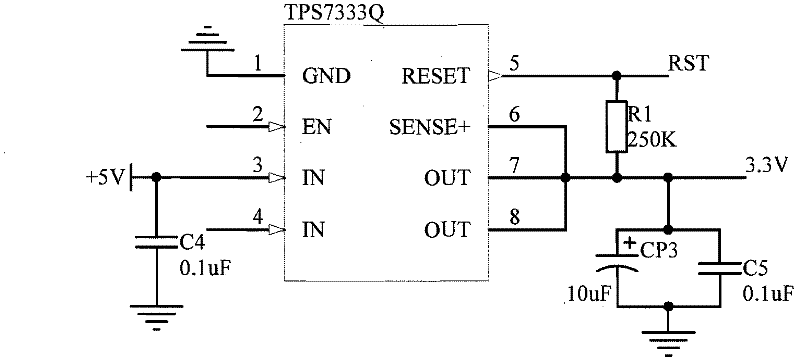

InactiveCN102506617AShorten the development cycleReduce development costsAmmunition testingMiniaturizationComputer module

The invention discloses a missile-borne data testing system, comprising a collection module, a processing module, a communication module and a power supply module. The missile-borne data testing system further comprises a shell, wherein the shell comprises an inner shell and an outer shell; and by encapsulating a measurement module, the processing module and an output control module through the inner shell, the outer shell and an end cover are encapsulated outside the inner shell. The missile-borne data testing system provided by the invention has very strong capability of resisting high overloading; the system disclosed by the invention has stronger anti-interference, high-temperature and low-temperature resistance, and dustproof capabilities; and furthermore, the system has the advantages of multi-channel variability, high capacity of a storage space, miniaturization, reutilization, low cost, high reliability, low power consumption and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Encapsulating composition and encapsulating film comprising same and electronic component assembly

ActiveUS20200216647A1Improve reflectivityHigh light transmittanceNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsPolymer scienceEthylene Homopolymers

The present invention discloses an encapsulation composition, an encapsulation film including the encapsulation composition, and an electronic device module. The encapsulation composition includes a polymer matrix, a tackifier and a free radical initiator. Based on 100 parts by weight of the polymer matrix, the polymer matrix includes 5 to 100 parts by weight of highly branched polyethylene (P1), 0 to 95 parts by weight of an ethylene-α-olefin copolymer, and 0 to 70 parts by weight of an ethylene-polar monomer copolymer. The highly branched polyethylene (P1) is an ethylene homopolymer having a branch structure and has a degree of branching of not less than 40 branches / 1,000 carbon atoms. A density of the ethylene-α-olefin copolymer is not higher than 0.91 g / cm3. The encapsulation composition provided by the present invention has good volume resistivity, aging resistance, processability and low cost.

Owner:HANGZHOU XINGLU TECH CO LTD +1

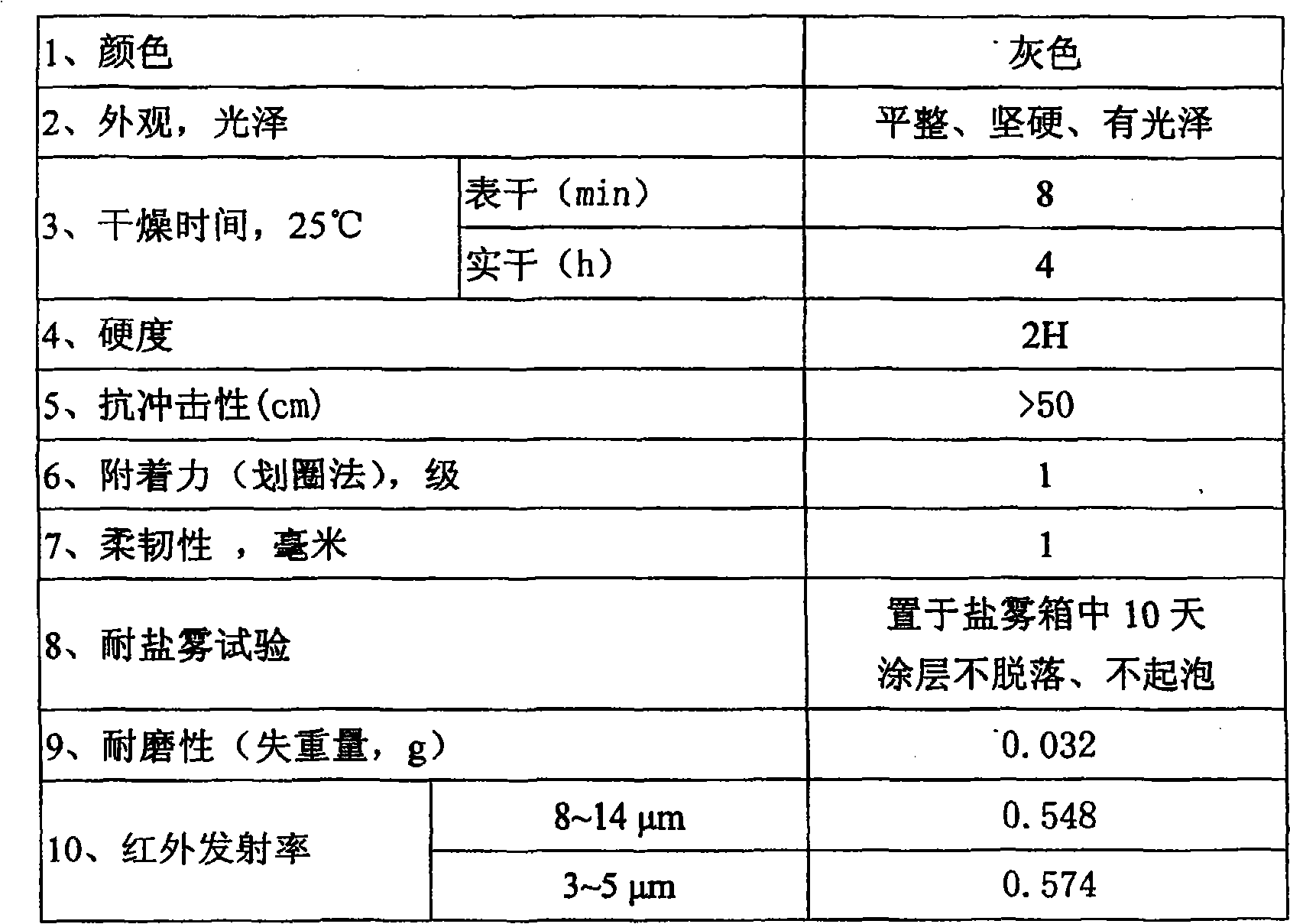

Preparation method and product of infrared stealth wave-absorbing composite protective paint

InactiveCN102108237AReduce needWorking conditions are easy to controlRadiation-absorbing paintsEpoxy resin coatingsElastomerEpoxy

The invention discloses a preparation method of infrared stealth wave-absorbing composite protective paint, which is characterized by comprising the following steps: pretreatment of raw materials: weighing the following raw materials: 20-35% of zinc powder, 20-30% of nickel powder, 5-8% of graphite powder, 5-8% of indium tin oxide, 15-20% of epoxy resin, 5-10% of metallocene polyolefin elastomer, 0.2-0.4% of polyether defoaming agent, 10-15% of amine curing agent and the balance of viscosity regulating agent; grinding of powder: performing solid-liquid mixing and grinding: adding the epoxy resin, the metallocene polyolefin elastomer, the polyether defoaming agent and the amine curing agent into a ball mill and grinding continuously till the particle size of powder achieves 1-2 microns; and regulation of viscosity: filtering, filling, sealing, storing and preparing the paint. The invention further discloses the infrared stealth wave-absorbing composite protective paint prepared by adopting the method. The infrared stealth wave-absorbing composite protective paint can be widely used for comprehensive protection to metal surfaces.

Owner:广东高鑫信息股份有限公司 +1

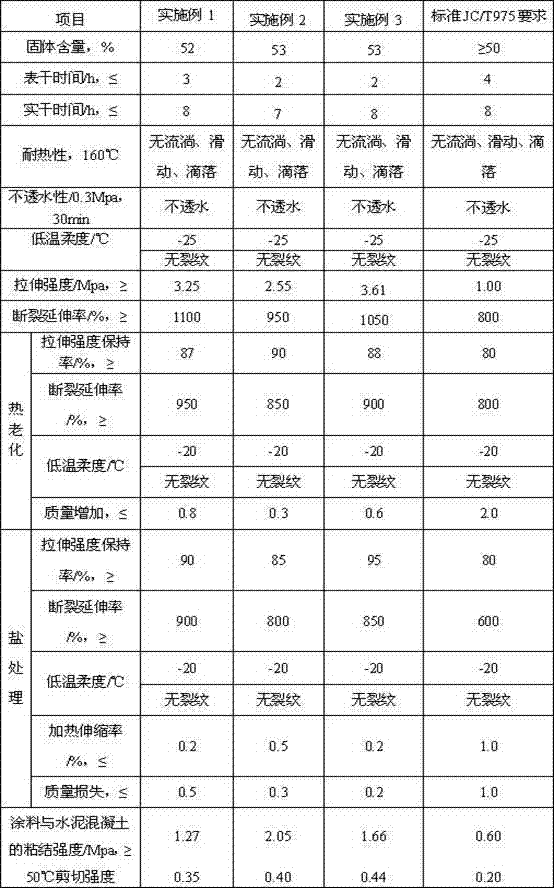

Waterproof material for cement concrete bridge floor and preparation method of waterproof material

ActiveCN103045067AStrong bondStrong high and low temperature resistancePolyurea/polyurethane coatingsBituminous coatingsEthyl acetateIsocyanate compound

The invention relates to a waterproof material for a cement concrete bridge floor and a preparation method of the waterproof material. The waterproof material is obtained by the following steps of: generating amino methyl acid ester by using isocyanate and compound polyalcohol, then adding ordinary heavy-traffic paving asphalt, and compounding and modifying by a tertiary amine catalyst, a compound antifoaming agent and ethyl acetate. The waterproof material can be firmly bonded with the cement concrete bridge floor, the resistance to high temperature and low temperature is good, the waterproof material can undergo comprehensive function requirements of temperature transforming and long-term loading, the destruction of the bridge structure caused by water seepage is alleviated, the service life of the road bridge is prolonged, the construction operation is safe and simple, the construction speed is high, the film forming time is short, the requirement on bridge floor construction is not high, and the construction can be carried out fast. The preparation method of the waterproof material is simple and easy to operate, the isocyanate, the compound polyalcohol and the ethyl acetate in a dehydrated state are not decomposed or oxidized in vacuum, so that the stability of each component is guaranteed and the prepared waterproof material has high solid content and good material performance.

Owner:重庆市智翔铺道技术工程有限公司

Nano water-based functional ceramic composite coating and preparation method thereof

ActiveCN103588443AGood physical and chemical stabilityExcellent abnormal temperature mechanical propertiesEmulsionPliability

The invention discloses a nano water-based functional ceramic composite coating which comprises raw materials in parts by weight as follows: 10-35 parts of silicate inorganic adhesives, 10-35 parts of main filler, 2-10 parts of stabilizing materials, 5-20 parts of toughness-enhancing emulsion type binding agents, 3-10 parts of film forming assistants and 5-25 parts of water. A preparation method comprises the steps as follows: the silicate inorganic adhesives and diluent are poured into a container and stirred at 350-400 r / min for 10-20 min, so that a mixed liquid is obtained; the main filler and the stabilizing materials are added to the mixed liquid, and the mixture is stirred at 350-400 r / min for 50-60 min; and the toughness-enhancing emulsion type binding agents and the film forming assistants are added sequentially, and the mixture is filtered by gauze with 400-600 meshes, so that the composite coating is obtained. A film of the coating is formed at the normal temperature, and the nano water-based functional ceramic composite coating has the characteristics of infiltration, large adhesive force, high density, stone hit resistance, impact resistance, high and low temperature resistance, superior abrasion resistance, washing resistance and good flexibility.

Owner:WUHAN ZHUOYI TECH DEV CO LTD

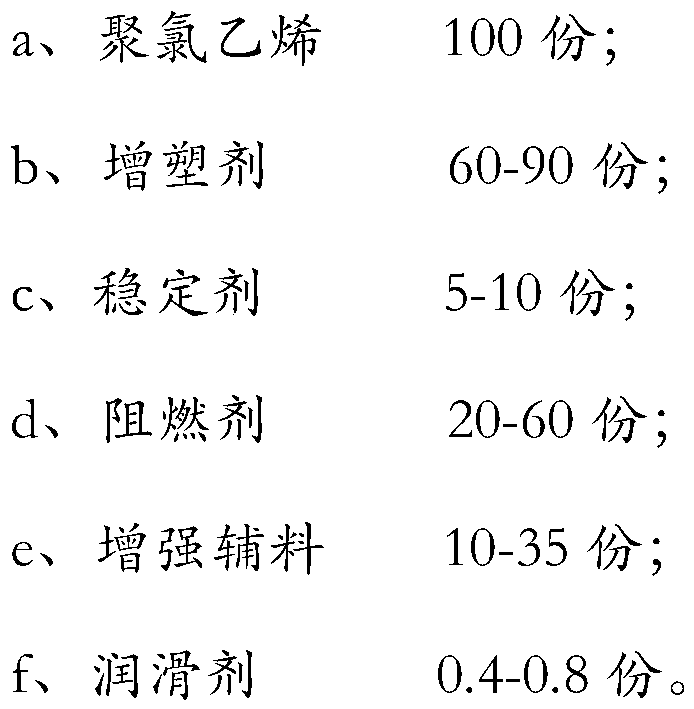

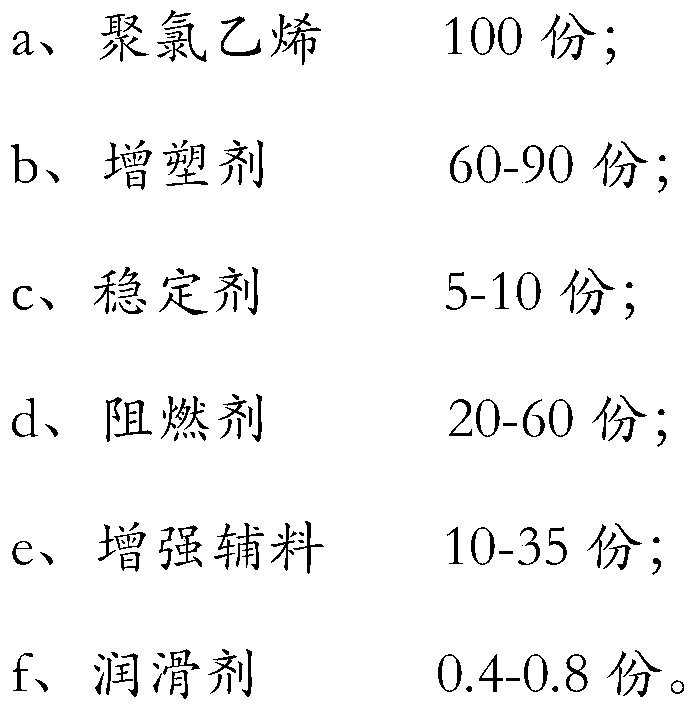

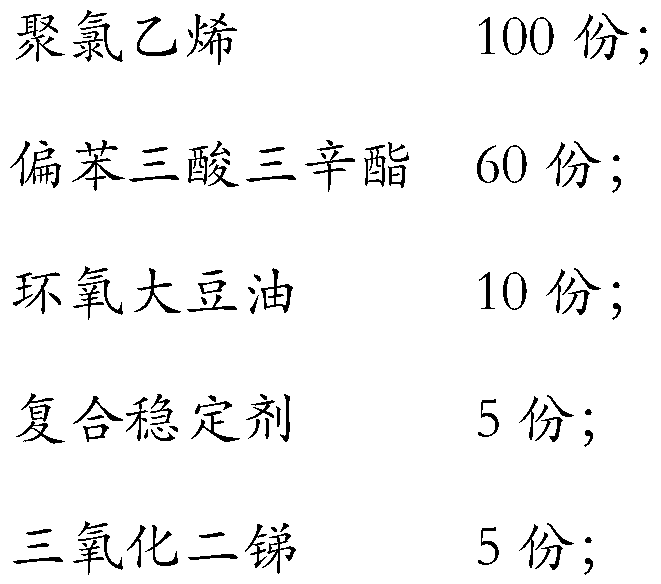

Temperature-resistant oil-resistant polyvinyl chloride elastomer cable material and preparing method thereof

InactiveCN105504593AOil resistantWith high and low temperature resistancePlastic/resin/waxes insulatorsElastomerPlasticizer

The invention belongs to the field of wire and cable manufacturing, and discloses a temperature-resistant oil-resistant polyvinyl chloride elastomer cable material and a preparing method thereof. According to a formula, the temperature-resistant oil-resistant polyvinyl chloride elastomer cable material is prepared from, by weight, 100 parts of polyvinyl chloride, 60-90 parts of plasticizer, 5-10 parts of a stabilizer, 20-60 parts of stabilizer, 10-35 parts of a reinforcing auxiliary material and 0.4-0.8 part of a lubricating agent. The preparing method of the temperature-resistant oil-resistant polyvinyl chloride elastomer cable material includes the steps that all the raw materials are added into a high-speed mixer in order and mixed to obtain a mixed material, and the mixed material is prepared into a cured material to obtain the temperature-resistant oil-resistant polyvinyl chloride elastomer cable material. The temperature-resistant oil-resistant polyvinyl chloride elastomer cable material has high and low temperature resistance, oil resistance, abrasion resistance and flame retardance.

Owner:HUIZHOU LTK ELECTRONICS CABLE +3

Magic color pearl water-in-water paint and preparation method thereof

InactiveCN109777231AStrong high and low temperature resistanceImprove stabilityAntifouling/underwater paintsPaints with biocidesLacquerUltraviolet

The invention discloses a magic color pearl water-in-water paint and a preparation method thereof, and belongs to the technical field of architectural coatings. The magic color pearl water-in-water paint is prepared from, by weight, 100-300 parts of a 6% protective glue solution, 300-500 parts of a magic color pearl powder base paint and 400-800 parts of a continuous phase; the magic color pearl powder base paint is prepared from hydroxyethyl cellulose, a multifunctional additive, an ammonium salt dispersant, magic color pearl powder, a silicone emulsion, the 6% protective glue solution and the like; the continuous phase is prepared from the multifunctional additive, the silicone emulsion, an antifoaming agent, a thickener and the like; the invention also provides a preparation method forthe magic color pearl water-in-water paint. The magic color pearl water-in-water paint and the preparation method thereof have the advantages of simple and easy operation, easy mass production, prepared products with good stability, high and low temperature resistance, ultraviolet resistance, antibacterial and anti-corrosion performance, no toxicity, smooth and flat paint film, good hand feeling and improved weather resistance.

Owner:福建居家逸材料科技有限公司

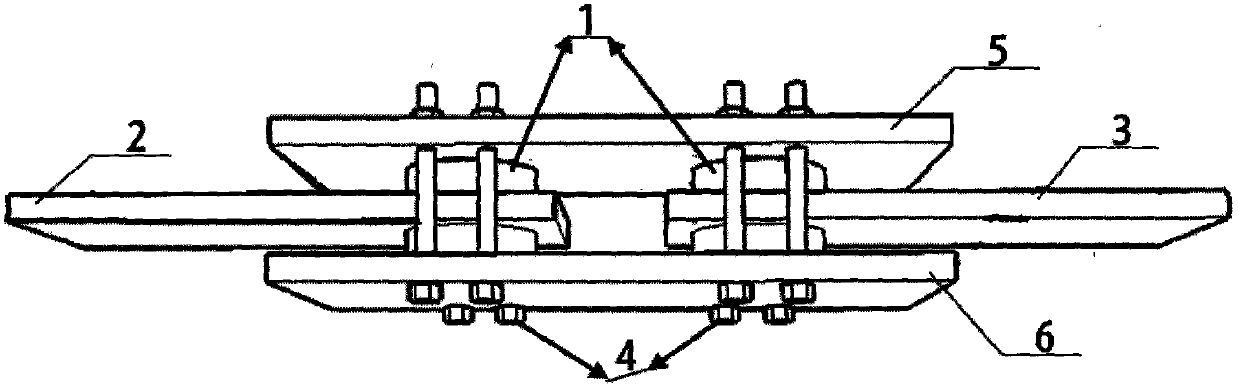

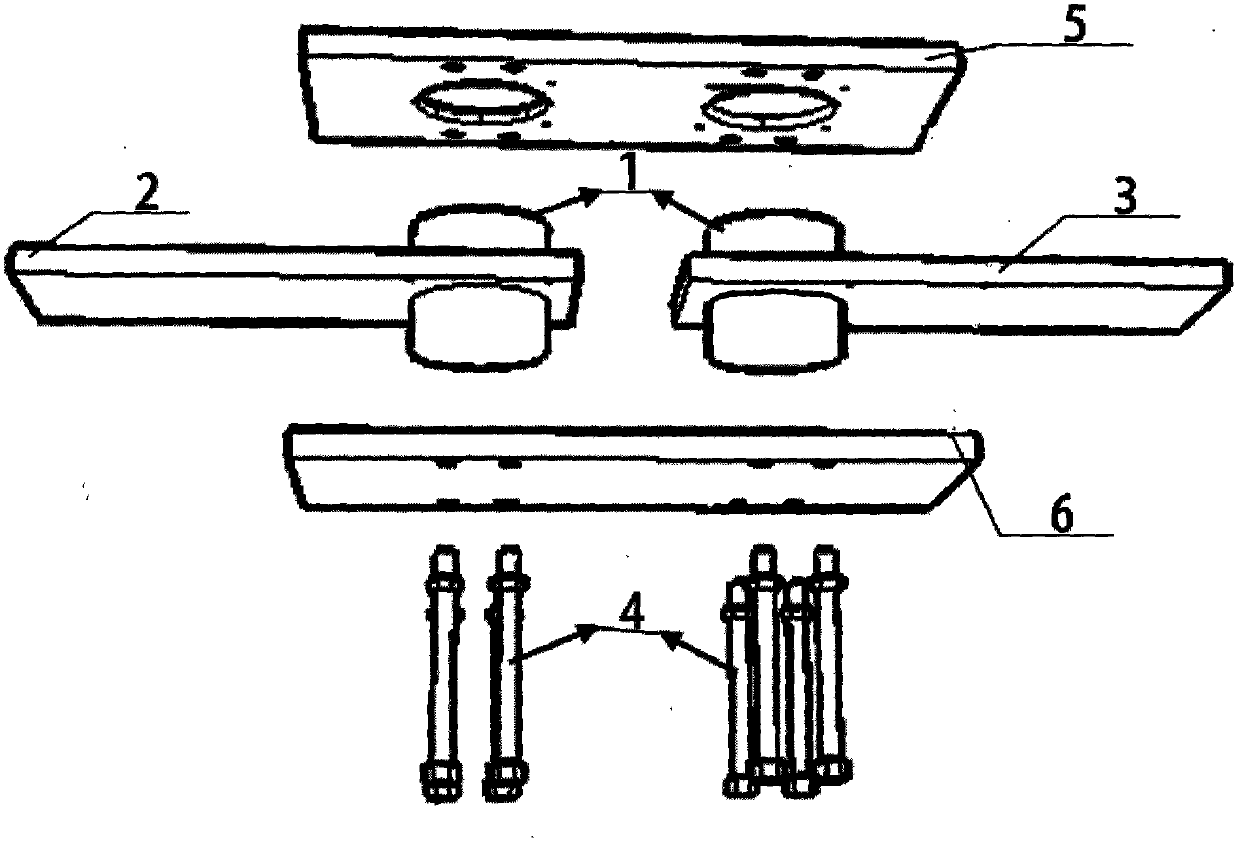

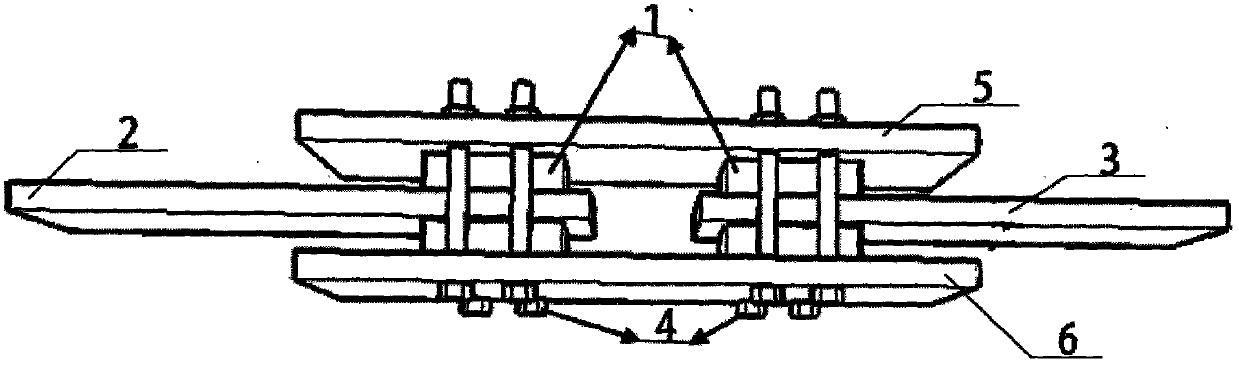

Plate type metal-rubber shear friction damper

InactiveCN103696506AHigh initial stiffnessGood energy consumptionShock proofingType metalEngineering

The invention provides a plate type metal-rubber shear friction damper. The plate type metal-rubber shear friction damper comprises two same metal-rubber blocks, a left steel force-application plate, a right steel force-application plate, fastening bolts, an upper steel clamping plate and a lower steel clamping plate. The left and the right steel force-application plate are provided with holes in the size the same with the metal-rubber blocks, and the two metal-rubber blocks are respectively arranged in the holes of the left and the right steel force-application plate. The upper and the lower steel clamping plate are provided with multiple bolt holes and also provided with recesses in the size the same the top surfaces of the metal-rubber blocks. The left and the right steel force-application plate with the metal-rubber blocks are disposed between the upper and the lower steel clamping plate, and the metal-rubber blocks are in bolt fastening with the upper and the lower steel clamping plate through the recesses and the bolt holes formed on the upper and the lower steel clamping plate. The plate type metal-rubber shear friction damper has the advantages of high-and-low temperature resistance, corrosions resistance, ageing resistance, high intensity, impact resistance, long service life and the like.

Owner:HARBIN INST OF TECH

Pure polyfluortetraethylene gradient overlay film filter material with high intensity

The invention relates to a high-strength pure polytetrafluoroethylene gradient coating filter material, which comprises base cloth, and is characterized in that the base cloth is a polytetrafluoroethylene base cloth; a polytetrafluoroethylene coarse fiber layer and a polytetrafluoroethylene superfine fiber layer are pricked on the polytetrafluoroethylene base cloth; and a polytetrafluoroethylene film is coated on the polytetrafluoroethylene superfine fiber layer. The high-strength pure polytetrafluoroethylene gradient coating filter material has the characteristics of high and low temperature resistance, high acid and alkaline resistance, high humidity resistance, good chemical stability, high filtration efficiency, quick filtration speed, long service life and the like, can be used in various bag-type dusters for flue gas purification, dust removal, dust treatment and material recovery, and has wide application scope.

Owner:LINGQI ENVIRONMENTAL PROTECTION EQUIP FACTORY SHANGHAI

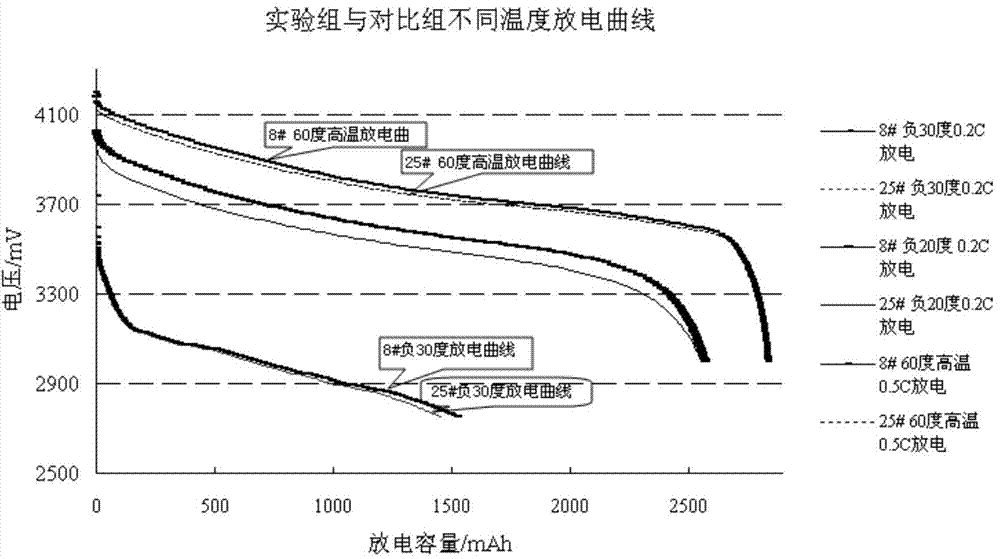

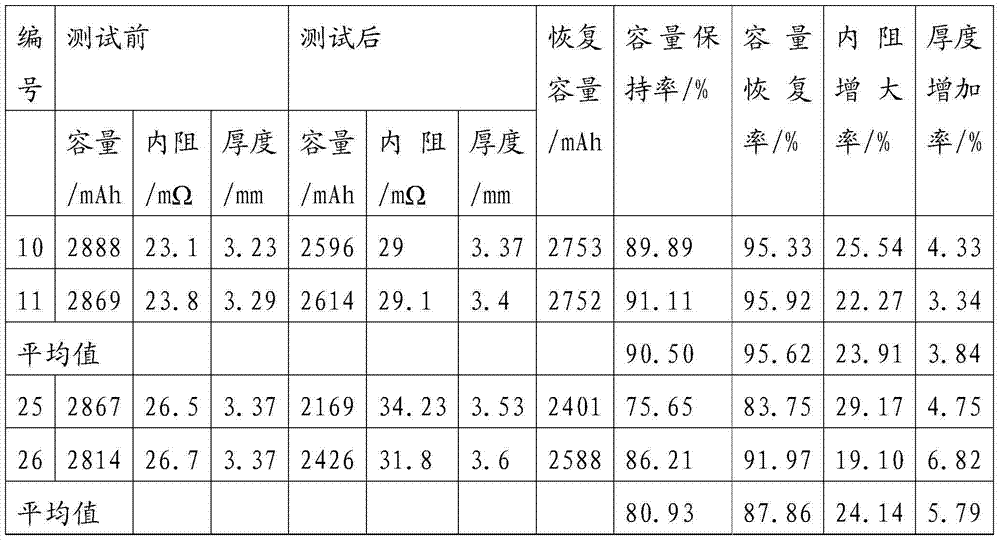

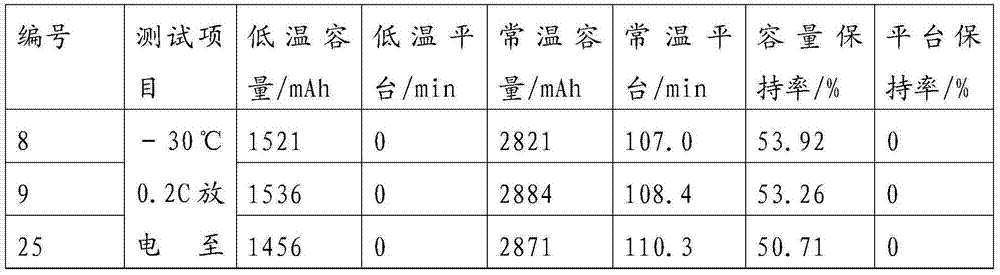

Gel lithium ion battery with high and low temperature balance and fabrication method thereof

InactiveCN103579665AImprove electrochemical performanceImprove securityFinal product manufactureCell component detailsMethyl carbonateHexafluoropropylene

The invention relates to the technical field of manufacturing of a lithium ion battery, and particularly relates to a gel lithium ion battery with high and low temperature balance. The gel lithium ion battery comprises a positive electrode, a negative electrode, a diaphragm and electrolyte, wherein the positive electrode contains a positive active material; the negative electrode contains a negative active material; the diaphragm is arranged between the anode positive electrode and the negative electrode; the diaphragm is a gel diaphragm of which two sides are coated by kynar-hexafluoropropylene; the electrolyte comprises electrolyte and a solvent; the electrolyte is a lithium salt; the concentration is 1.0-1.2 mol / L; the solvent comprises 15-20% of ethylene carbonate, 50-60% of ethyl methyl carbonate, 8-15% of propylene carbonate and 8-15% of diethyl carbonate by mass fraction. The gel lithium ion battery is simple in formula, and matched with the electrolyte with high and low temperature resistance by gelatinization of the diaphragm of the lithium ion battery, so as to improve the characteristics of the high and low temperature resistance of the battery.

Owner:DONGGUAN ADF BATTERY

Flexible cable

InactiveCN103730197AImprove fire resistanceCrush blockFlexible cablesFlexible conductorsChemical industryElectrical conductor

The invention discloses a flexible cable which integrates the wear-resistant function, the flame retardant function, the fire prevention function, the high temperature and low temperature resistant function, the acid and alkali resistant function, the oil and water resistant function, the tearing prevention function and the good and stable signal transmission function. The flexible cable is composed of copper core stranded conductors, an insulating layer, a packing layer, a wrapping tape layer, an armor layer and a protective sleeve layer from inside to outside. The second type of copper core conductors are adopted for the copper core stranded conductors, mica tape is wound to form the insulating layer, flame-retardant filling ropes are adopted for materials of the packing layer, the wrapping tape layer comprises a mica tape wrapped layer and a glass fiber belt wrapped layer, and 125 DEG C low-smoke halogen-free flame retardant TPU materials are adopted for materials of the protective sleeve layer. The flexible cable is suitable for being applied to industrial and mining enterprises such as electricity generation enterprises, metallurgy enterprises, electronic enterprises, automobile enterprises, petroleum enterprises, chemical industry enterprises and large-scale construction enterprises, and the flexible cable can meet the requirements for the abrasion resistance performance, the fire prevention performance and other types of performance of cables, and can be used in special environments such as high-temperature environments, low-temperature environments, acid environments, alkali environments and environments where movement exists.

Owner:ANHUI HUAXING CABLE GROUP

Modified forming cement board

ActiveCN104829193AImprove thermal insulationImprove thermal insulation and energy savingCeramicwareThermal insulationCement board

The present invention discloses a modified foaming cement board, wherein the raw materials comprise a ordinary silicate cement, fly ash, hydrogen peroxide, bis(pentabromophenyl) ethane, a sulfonated acetone formaldehyde polycondensate, a multi-component copolymer dispersing agent, polyurethane, a foam stabilizer, a coupling agent, alkali-resistant fibers, bis(2,2,6,6,-tetramethyl-4-piperidyl)sebacate, 2-hydroxy-4-methoxy benzophenone, and an ultraviolet ray absorber. The modified foaming cement board has the following characteristics that the thermal insulation property is good, the product dry density is 150-200 kg / m<3>, the thermal conductivity is 0.05-0.06 W / (m*K), and the good thermal-insulation and energy-saving effect is provided; the fire prevention performance is good, the fire resistance limit is more than 3 h, and the material can meet the grade A fire prevention standard so as to provide good fire resistance; the sound insulation performance is good so as to substantially reduce the noise impact; the durability is good, and characteristics of high temperature resistance, low temperature resistance, corrosion resistance, ultraviolet ray radiation resistance, and good weathering resistance are provided; the 1 day strength of the product with the dry density of 170 kg / m<3> can achieve 0.3 mpa, and the 28-day strength can achieve 0.4 mpa; and characteristics of early strength and high strength are provided, and problems of high brittleness and easy damage are overcome.

Owner:CHONGQING BANGRUI NEW MATERIAL CO LTD

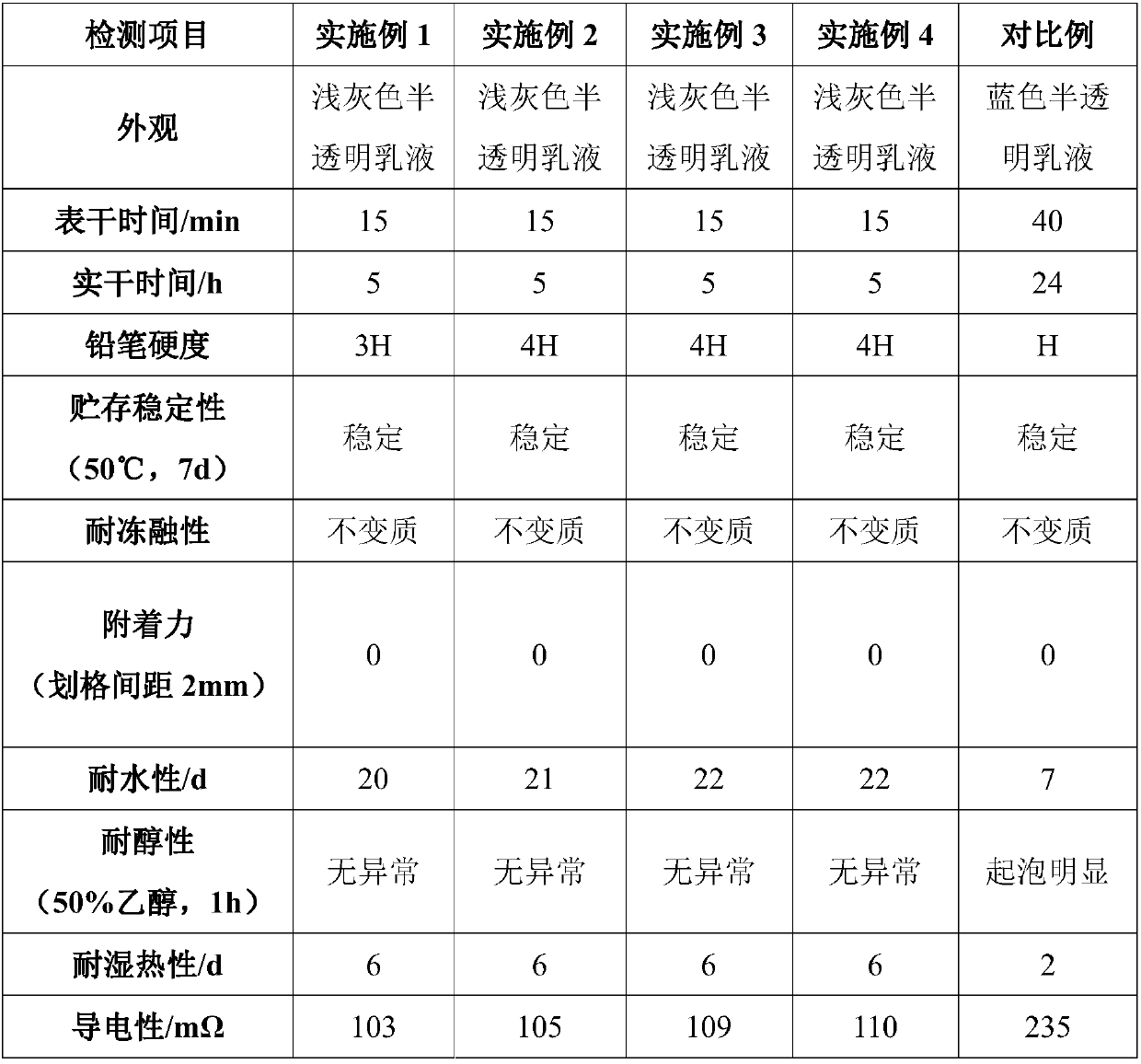

Modified acrylic emulsion for electrically conductive printing ink and preparation method thereof

The invention discloses a modified acrylic emulsion for electrically conductive printing ink and a preparation method thereof; the modified acrylic emulsion is prepared from acrylate, styrene, diisocyanate, 2-hydroxyethyl acrylate, graphene oxide, a chain extender, a silane coupling agent, hydrochloric acid, a hydrazine hydrate aqueous solution, a pH buffering agent, an initiator, an anion emulsifier, a nonionic emulsifier and water. The preparation method comprises the following steps: 1) preparation of modified graphene; 2) preparation of a double-bond terminated polyurethane cross-linking agent; 3) preparation of an acrylate, modified graphene and double-bond terminated polyurethane cross-linking agent mixed solution; and 4) polymerization reaction. The modified acrylic emulsion for theelectrically conductive printing ink has the advantages of both the polyurethane emulsion and the acrylic emulsion, avoids the graphene oxide from generating aggregation, has no use of organic solvents, and is safe and environmentally friendly; the drying speed is fast during film formation, and an obtained paint film has excellent physical and mechanical properties and electrical conductivity.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

Antibacterial wear-resistant flame-resistant plastic, and preparation method thereof

The invention discloses an antibacterial wear-resistant flame-resistant plastic, and a preparation method thereof. The antibacterial wear-resistant flame-resistant plastic comprises, by weight, 25 to30 parts of polypropylene, 15 to 20 parts of polycarbonate, 12 to 18 parts of polystyrene, 16 to 22 parts of polyimide, 6 to 10 parts of polyvinylpyrrolidone, 5 to 10 parts of polyvinyl acetate, 7 to12 parts of cellulose acetate fiber, 4 to 10 parts of silica sol, 4 to 10 parts of nanometer bauxite, 5 to 10 parts of shell powder, 3 to 8 parts of sillimanite powder, 4 to 10 parts of glass fiber, 4to 8 parts of hydroxymethyl cellulose, 2 to 4 parts of molybdenum disulfide, 1.8 to 3.2 parts of carbon black, 1.5 to 3 parts of expandable graphite, 3 to 6 parts of nanometer silicon carbide, 3 to 6parts of nanometer titanium dioxide, 2.5 to 4.5 parts of a silane coupling agent, and 2.4 to 4.5 parts of an antiseptic. The antibacterial wear-resistant flame-resistant plastic is excellent in performance, aging resistance, wear resistance, mechanical impact resistance, and flame resistance, and cracking is not easily caused.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

High polymer elastomer material for balloon catheter type medical apparatuses and instruments and preparation method thereof

The invention discloses a high polymer elastomer material for balloon catheter type medical apparatuses and instruments and a preparation method thereof. The product comprises SEBS (Styrene Ethylene Butadiene) I, SEBS II, medical-grade polypropylene, a polyolefin elastomer, medical-grade extending oil, an antioxidant and other auxiliaries. The material disclosed by the invention has high tensile strength, excellent rebound resilience, high and low temperature resistance, high transparency, non-toxicity, excellent biocompatibility and blood compatibility and no anaphylactic reaction with a human body, and is easy to process. Besides, the production technology is advanced, the process is reasonable and simplified, the investment scale is small, the energy consumption is low, the production efficiency is high, and the preparation method is safe and environment-friendly.

Owner:NANTONG POLYMAX ELASTOMER TECH

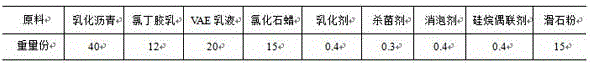

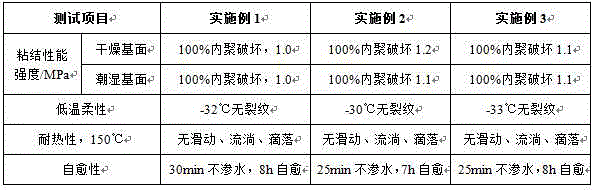

Water-based binder applied to waterproofing project of building structure and preparation method of water-based binder

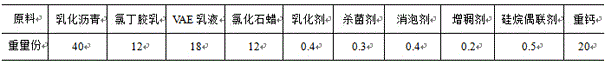

ActiveCN105462540AImprove adhesionStrong high and low temperature resistanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesFungicideEmulsion

The invention provides a water-based binder applied to a waterproofing project of a building structure. The water-based binder is prepared from the following raw material components in parts by weight: 30 to 45 parts of emulsified asphalt, 10 to 20 parts of neoprene latex, 10 to 20 parts of chlorinated paraffin, 8 to 25 parts of filler, 15 to 25 parts of VAE (Vinyl Acetate-Ethylene Emulsion), 0.4 to 0.6 part of silane coupling agent, 0.2 to 0.5 part of defoamer, 0.3 to 0.6 part of emulsifier and 0.2 to 0.4 part of fungicide. According to the water-based binder provided by the invention, good binding property is realized, the binding property strength on a dry base surface is 1.0 to 1.2MPa (100 percent cohesive failure), and the binding property strength on a moisture base surface is 1.0 to 1.1MPa (100 percent cohesive failure). The water-based binder provided by the invention is high in high-low-temperature resistance.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

Method for manufacturing enhanced flat cable for wagon dumper

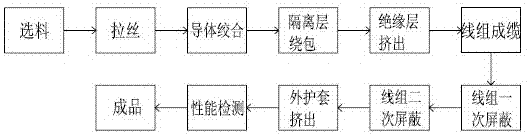

ActiveCN102347111AImprove the extrusion effectGood flexibilityInsulating conductors/cablesElectrical conductorElectric cables

The invention discloses a method for manufacturing an enhanced flat cable for a wagon dumper, and the method is characterized by comprising the following steps: material selection, wire drawing, conductor twisting, winding and wrapping of an isolating layer, extrusion of the insulating layer, cabling of wiring harness, primary shield of wiring harness, secondary shield of wiring harness, extrusion of an outer sheath, performance detection and finished products. In the method, the conductor center of the cable is provided with a steel wire rope stiffener so as to improve the longitudinal stretching resistance of the cable; and a wire braid is used as a metal shielding layer, the primary shielding braid density is not less than 80%, and the secondary shielding braid density is not less than85%, thus not only improving shielding factors of a cable core but also providing effective physical and mechanical protective actions for the cable. The cable manufactured by the method has the advantages of good flexibleness, salt mist resistance, greasy dirt resistance and inflaming retarding property, no cracking and no deformation for long term use, and no core breaking at the movable operating mode speed of 1.2m / s.

Owner:SICHUAN MINGXING CABLE

PBT (polybutylene terephthalate) material for optical cable and preparation method thereof

InactiveCN103980678AFacilitate flow velocityExcellent crystallization speedPlastic/resin/waxes insulatorsPolymer scienceAluminium hydroxide

The invention belongs to the technical field of optical cable materials, and particularly relates to a PBT (polybutylene terephthalate) material for optical cables. The PBT material is characterized by comprising following raw materials in parts by weight: 35-50 parts of PBT, 20-30 parts of polypropylene, 6-20 parts of polyethylene, 2-4 parts of aluminum hydroxide, 4-6 parts of triphenyl phosphate, 3-5 parts of talcum powder, 1-3 parts of mica powder, 3-9 parts of maleic anhydride, 2-6 parts of decabromodiphenylethane, 2-4 parts of white oil, 1-3 parts of zinc oxide, 2-4 parts of titanium dioxide and 2-6 parts of polyethylene wax. The invention also discloses a preparation method of the PBT material. The PBT material has the main beneficial effects of low density, small thermal contraction, high melt index, high lateral pressure resistance, and strong resistance to high and low temperatures; and the preparation method is simple and easy to control.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Energy-saving material with thermal insulation function

ActiveCN104803657AImprove thermal insulationImprove thermal insulation and energy savingFiberThermal insulation

The invention discloses an energy-saving material with a thermal insulation function. The energy-saving material comprises raw materials as follows: aerogel, coal ash, isocyanate, decabromodiphenyl ethane, sulfonated acetone formaldehyde, a liquid epoxy resin dispersing agent, polyurethane, rice hulls, a coupling agent, mullite fibers, ceramic microbeads, bis(2,2,6,6-tetramethyl-4-piperidyl) sebacate, 2-hydroxy-4-methoxybenzophenone and an ultraviolet light absorber. According to the energy-saving material, the thermal insulation performance is good, the dry density of a product is 160-200 kg / m<3>, the heat conductivity coefficient is 0.02-0.03 W / (m*K), and the product has good thermal insulation and energy saving effects; the fireproof performance is good, the fire endurance is longer than 3 h and can meet the level-A fire protection standard, and accordingly, good fire resistance is achieved; the sound insulation performance is good, and noise influence can be greatly reduced; the endurance is good, and the material has the characteristics of high-temperature and low-temperature resistance, corrosion resistance, ultraviolet irradiation resistance and good weather fastness.

Owner:CHONGQING JIAOTONG UNIVERSITY

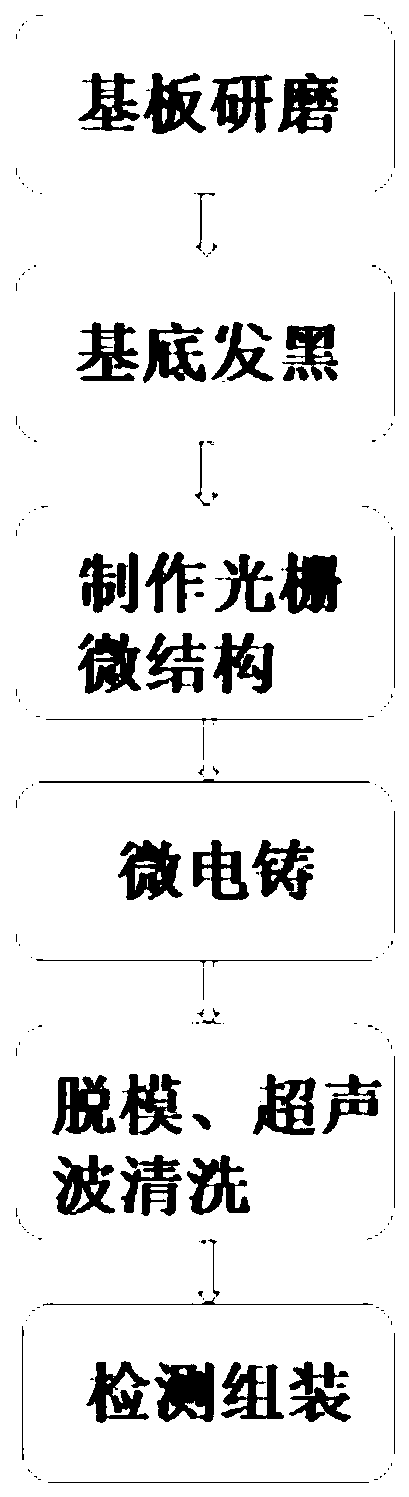

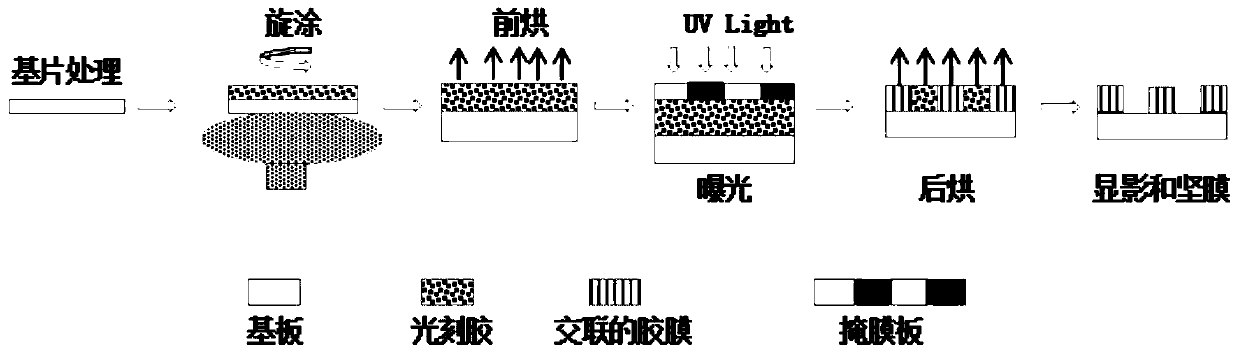

Manufacturing method of precision metal reflection grating

The invention relates to the field of manufacturing of reflection gratings, and discloses a manufacturing method of a precision metal reflection grating. The manufacturing method comprises the following steps: grinding a substrate; blackening the substrate; manufacturing a grating microstructure; carrying out micro electroforming; carrying out demolding and ultrasonic cleaning; and carrying out detection and assembly. According to the manufacturing method, the technologies such as micro electroforming, UV-LIGA technology, electrolytic polishing and electroplating blackening are fused, so thatthe precision metal reflection grating with good reflection effect, high surface smoothness, high reflection line precision, batch production and relatively low cost can be manufactured.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI +1

Fluorine insulating wire and manufacturing method and applications thereof

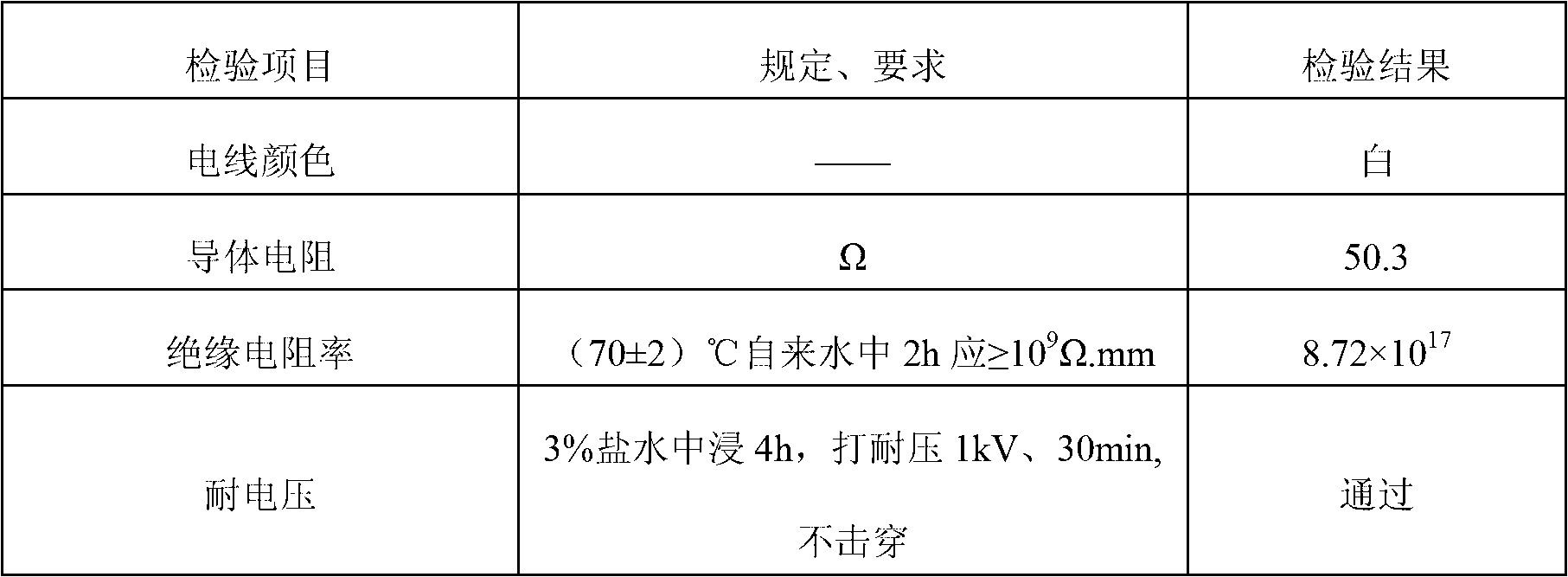

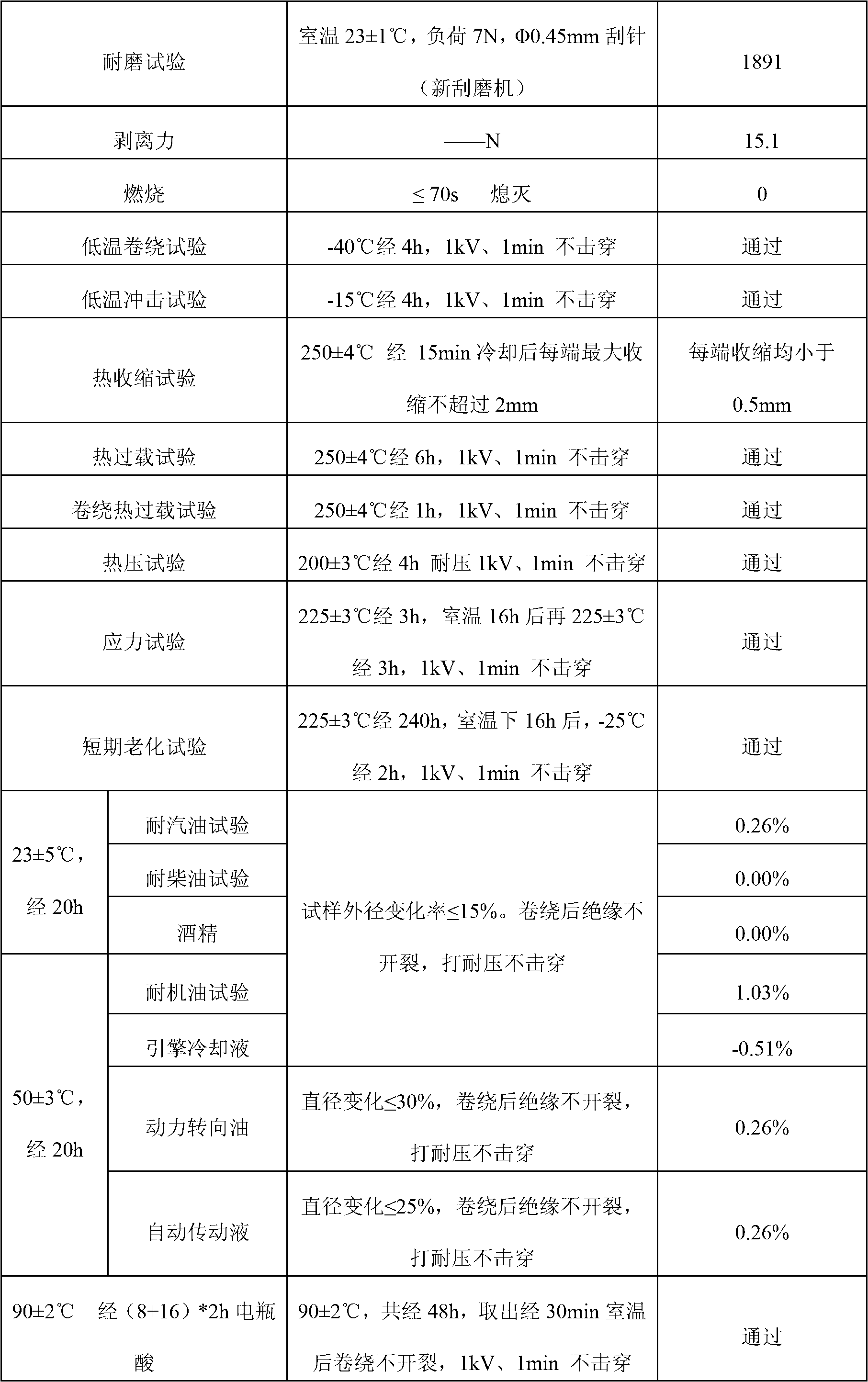

ActiveCN103050185AHigh flexibility requirementsGreat flexibility requirementInsulated cablesInsulated conductorsElectrical conductorRoom temperature

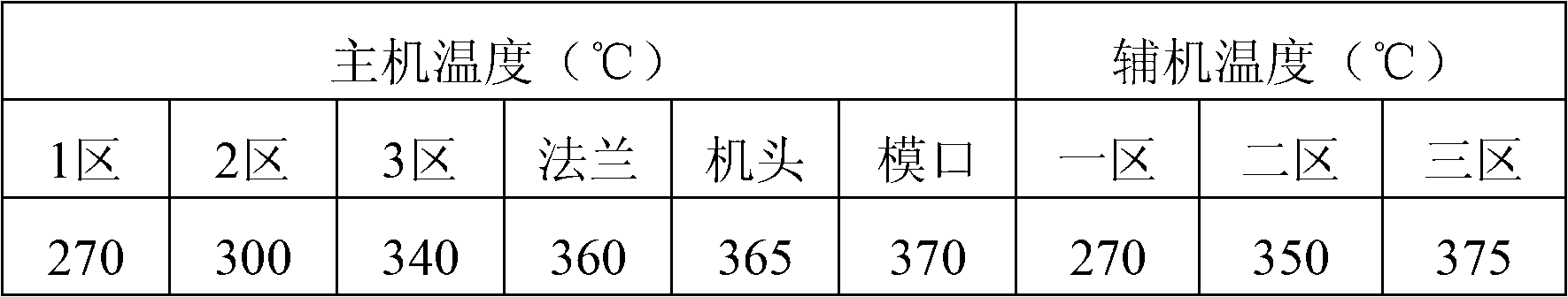

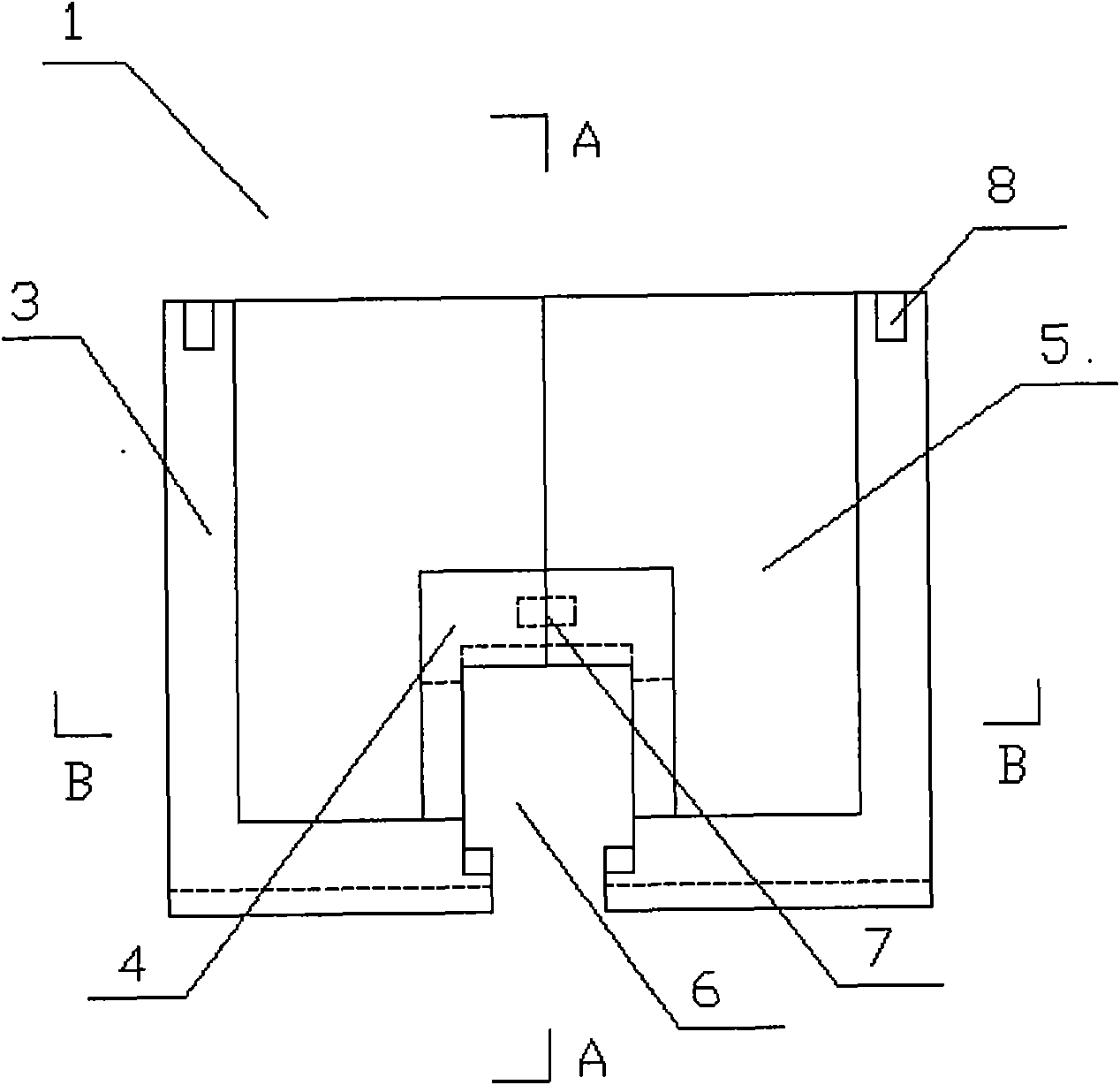

The invention discloses a fluorine insulating wire and a manufacturing method and applications thereof. The method comprises the following steps: (1) preheating a conductor to the temperature of 70-120 DEG C; (2) extruding a fluorine insulating material on the preheated conductor to obtain an extrudate by adopting a 45-type extruder, wherein the extruding temperature of the extruder is as follows: the temperature of a primary extruder area 1 is 265-275 DEG C, the temperature of a primary extruder area 2 is 295-305 DEG C, the temperature of a primary extruder area 3 is 335-345 DEG C, the temperature of a primary extruder flange is 355-365 DEG C, the temperature of a primary extruder head is 360-370 DEG C, the temperature of a primary extruder die opening is 365-375 DEG C, the temperature of an auxiliary extruder area 1 is 265-275 DEG C, the temperature of an auxiliary extruder area 2 is 345-355 DEG C, and the temperature of an auxiliary extruder area 3 is 370-380 DEG C; and (3) enabling the extrudate to pass through three cooling areas from the high temperature to the low temperature in sequence, wherein the temperature of a first cooling area is 60-80 DEG C, the temperature of a second cooling area is 30-50 DEG C, and the temperature of a third cooling area is room temperature. The product manufactured by the invention is good in temperature resistance and softness, has high temperature and low temperature resistance, oil resistance and wear resistance and the like, and has great market application value.

Owner:SHANGHAI FUERXIN CABLE

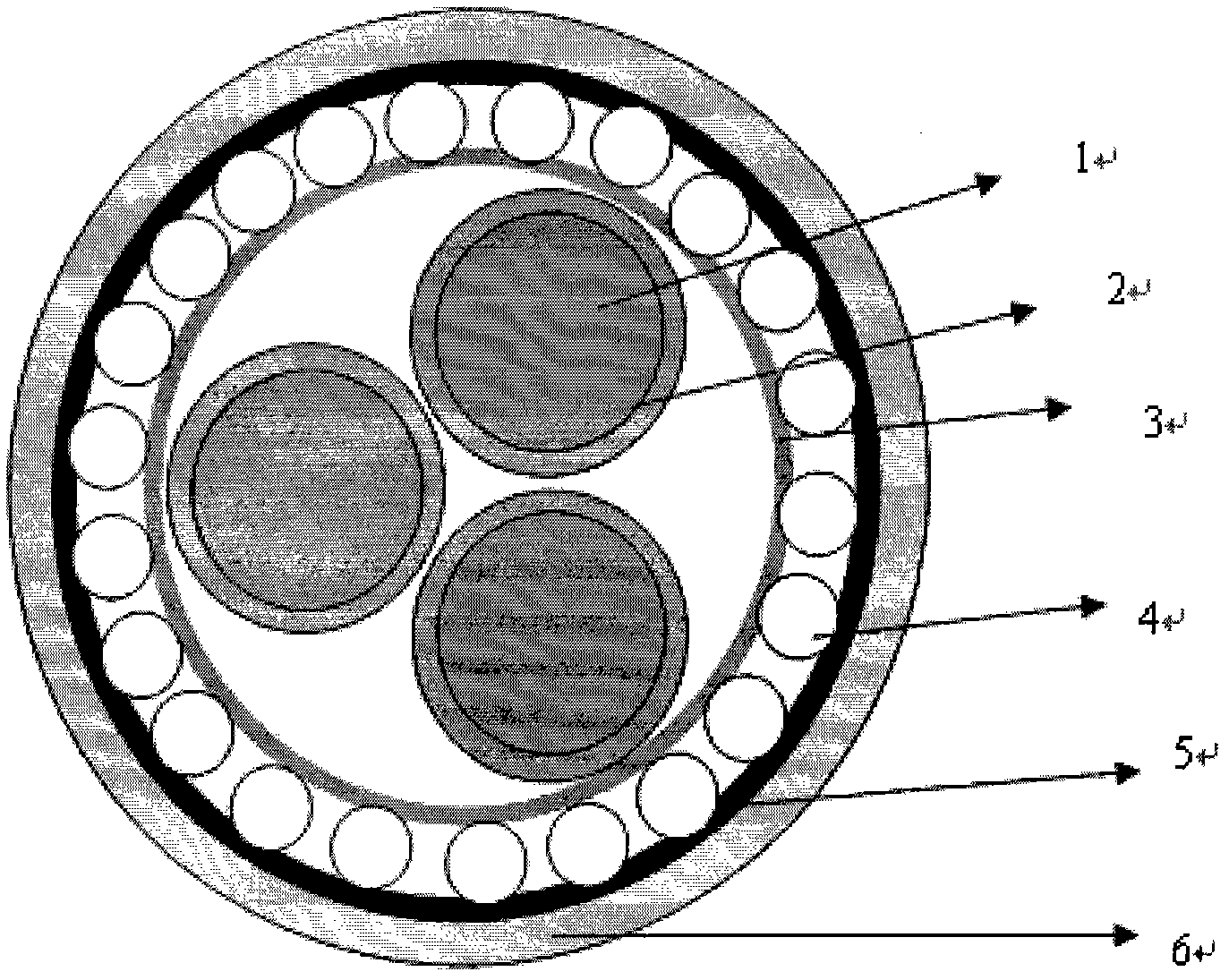

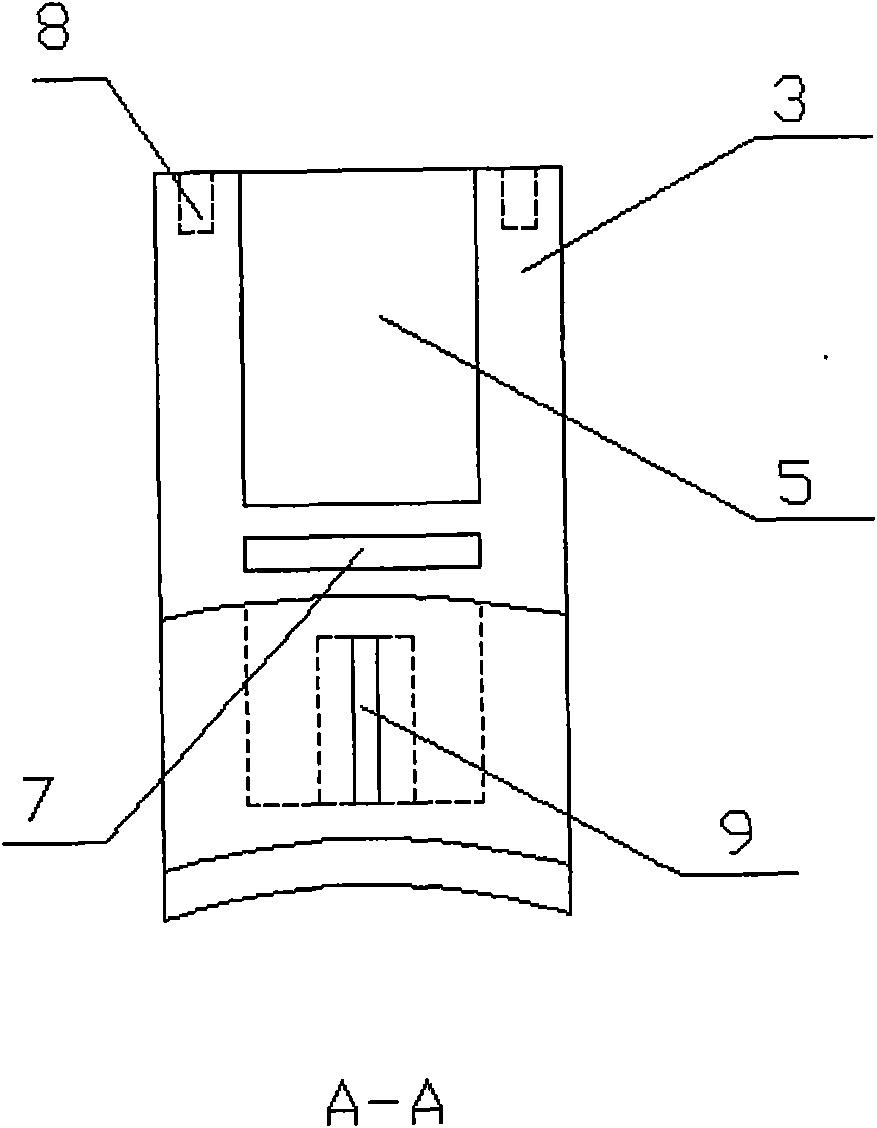

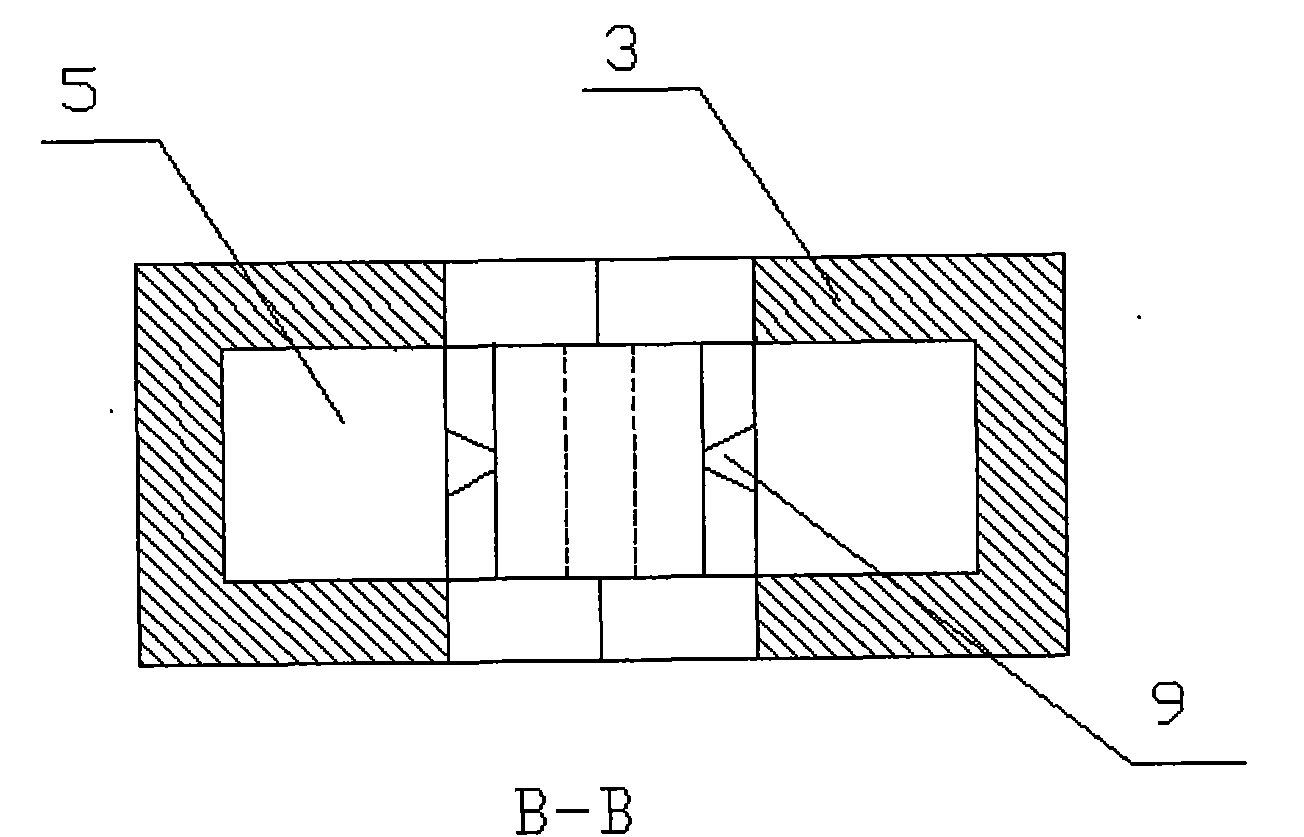

Reading head of ring type spatial array torque sensor

InactiveCN101871827ARealize online dynamic measurementWith dustproofWork measurementTorque measurementRelative displacementExcitation current

The invention relates to a reading head of a ring type spatial array torque sensor, which comprises a reading head shell and a U-shaped armature core. The reading head shell is formed by connecting two completely symmetric parts, and is provided with a chamber used for accommodating the U-shaped armature core and a channel for a ring type spatial array steel pipe to penetrate through, two coils are wound on the U-shaped armature core, one coil is an excitation coil inputting excitation current, and the other coil is an induction coil outputting induced voltage signals. The invention realizes the conversion of torque information into electric signals according to the principle of AC electromagnetic induction. The reading head has complete cycles of relative displacement along the mechanical rotating shaft, thereby realizing online dynamic measurement of torque information on the mechanical rotating shaft. Since the reading head is sealed, test conditions are not subject to constraints of the external environment. Therefore, the invention is applicable to torque tests for the mechanical rotating shaft of the hydraulic turbine, in the geological exploration and under other extreme conditions.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com