Cleaning-type oil-resistant cable

A clean and oil-resistant technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of low mechanical performance index, short service life of cables, poor sheath coating, etc., and achieve strong anti-interference performance and large leakage current , Strong effect of blocking water and damp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

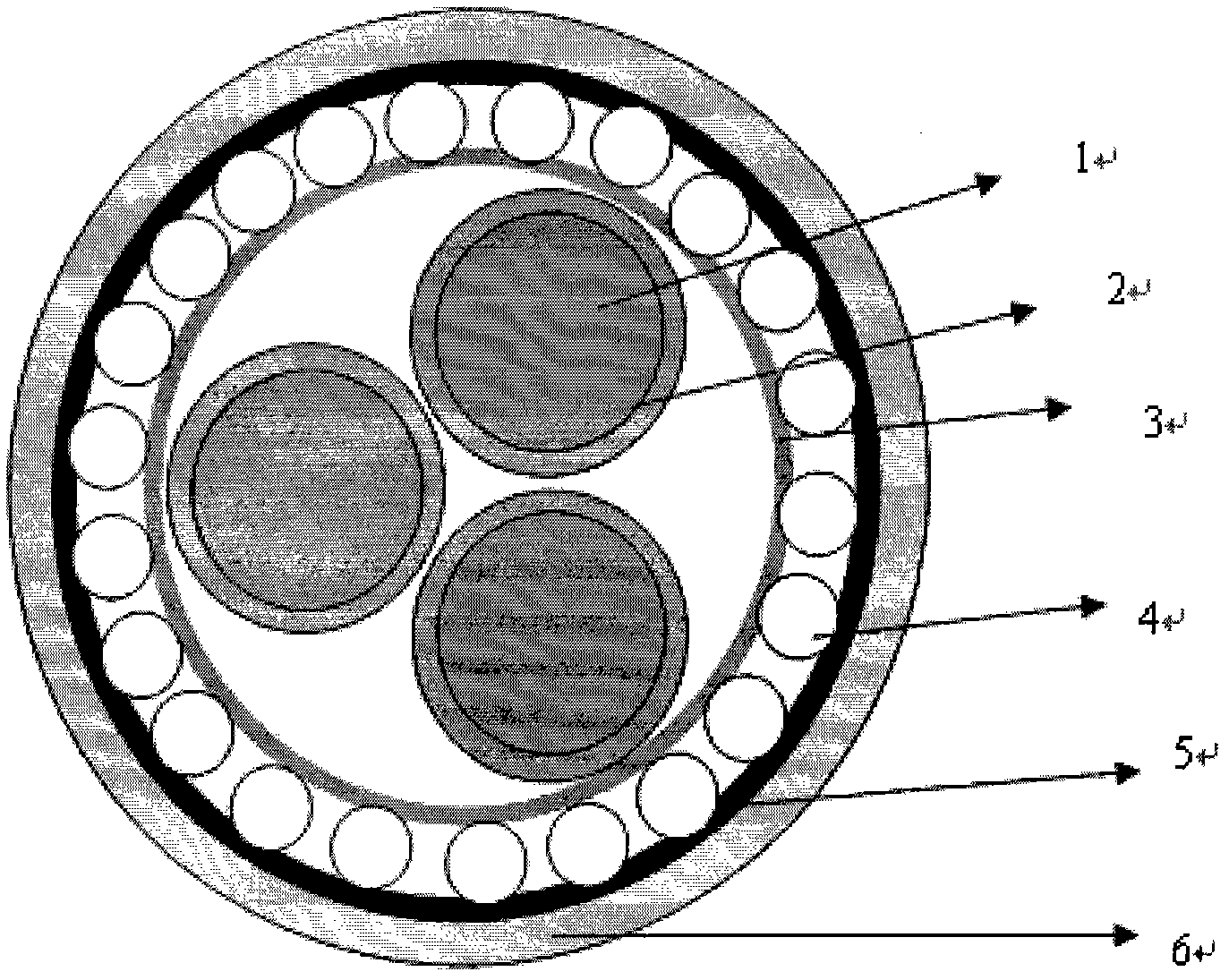

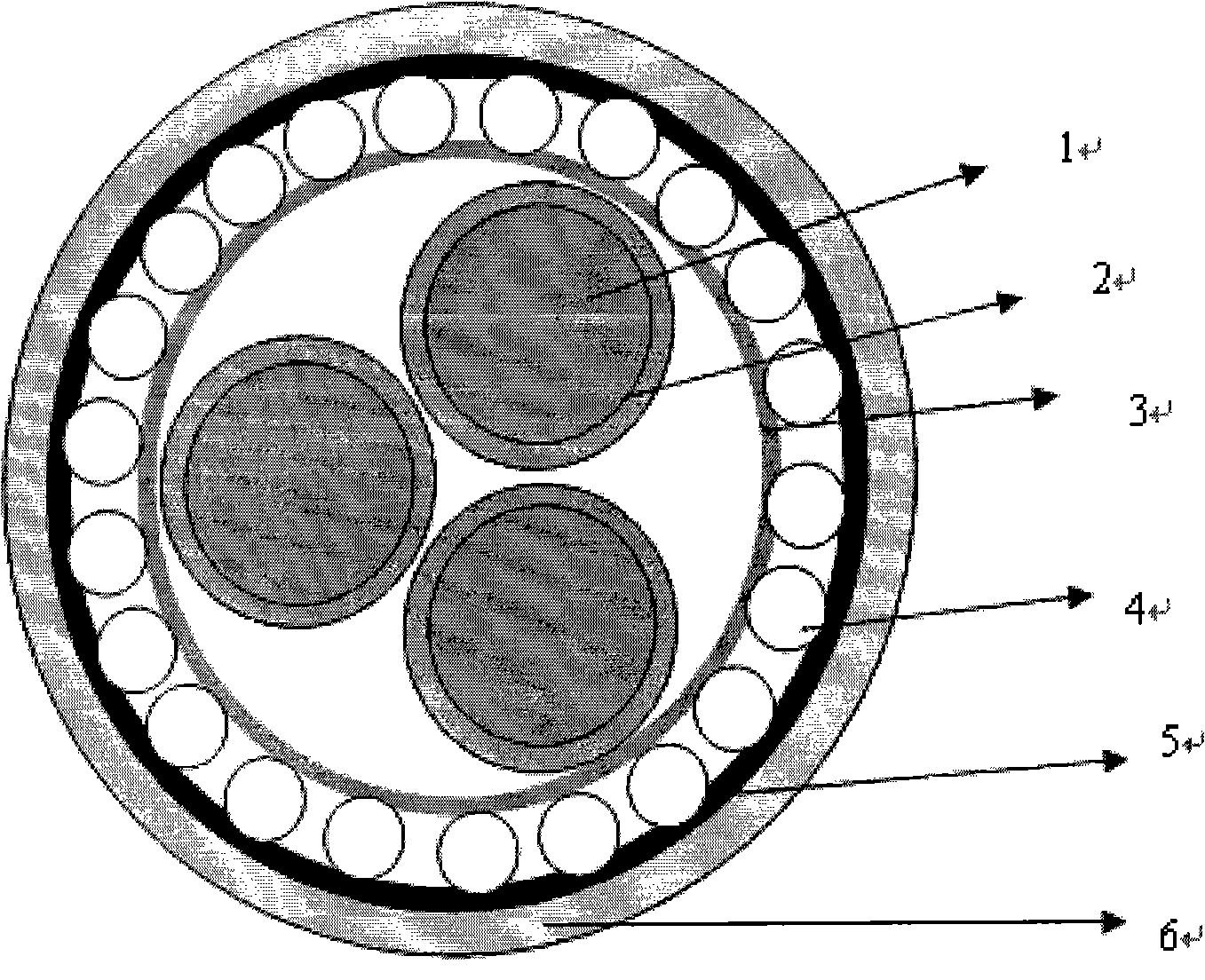

[0008] Below, the present invention will be further described by taking the three-core cable of the clean type oil-resistant cable as an example, as figure 1 Shown: Extrude a layer of cross-linked polyethylene insulating layer (2) extruded by warm water cross-linking process on the three copper conductors (1); extrude a layer of oil-resistant nitrile compound on the periphery of the cable core ( 3); outside the inner lining layer, it is armored by fine steel wire back twisting (4); outside the armor layer, it is longitudinally welded with water-blocking aluminum-plastic composite tape (5); outside the water-blocking and moisture-proof layer, it is simultaneously extruded with double-layer oil resistance High flame retardant nitrile compound jacketing compound (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com