Manufacturing method of precision metal reflection grating

A technology of metal reflection and manufacturing method, applied in the directions of diffraction grating, optics, optical components, etc., can solve the problems of raising the cost and taking time, and achieve the effect of good consistency, improved effective utilization rate and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

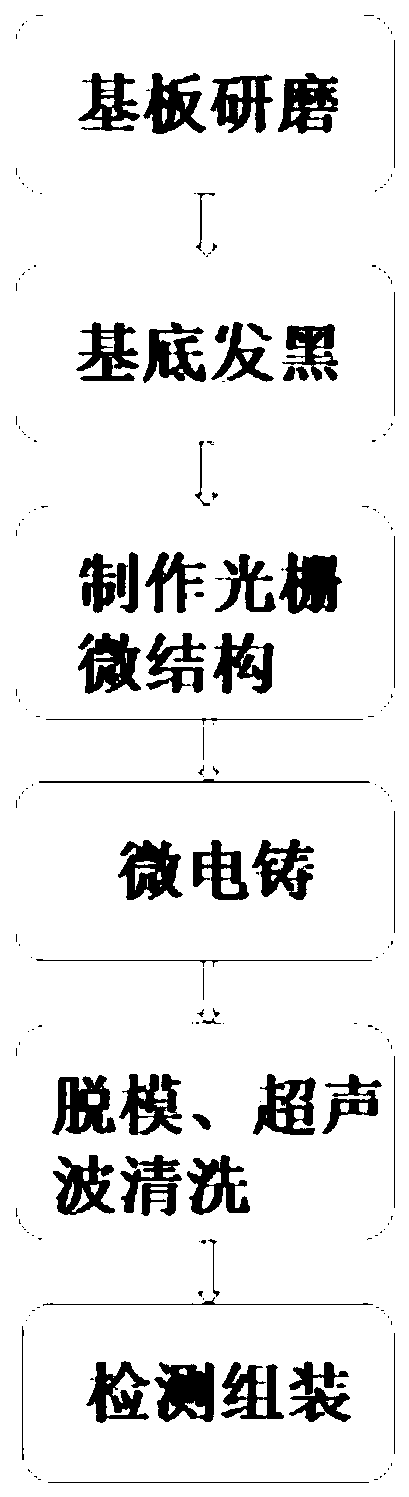

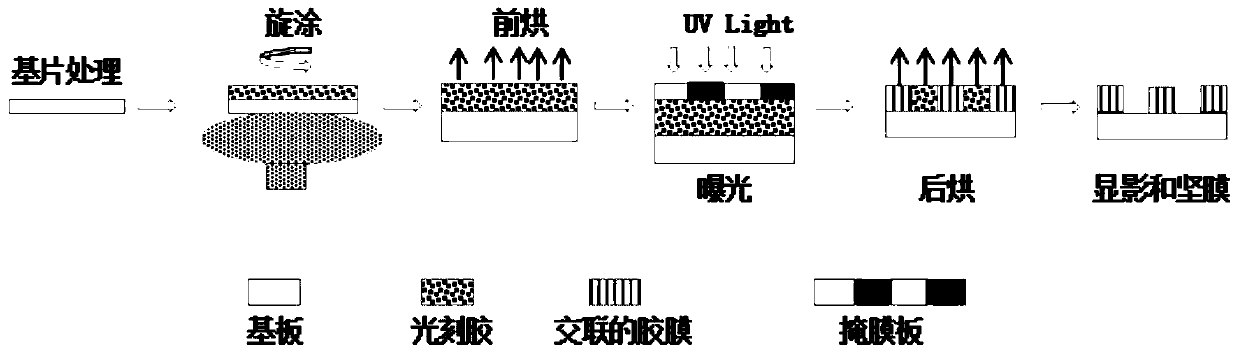

[0043] See figure 1 and figure 2 As shown, the entire process flow of manufacturing a precision metal reflective grating is shown, including the following steps:

[0044] Step 1. Substrate grinding:

[0045] Select a flat metal substrate. The metal substrate can be stainless steel, nickel, copper, aluminum, etc., and the surface of the substrate is cleaned and ground by electrolytic polishing to remove surface impurities, scratches and uneven points. After cleaning and grinding, place it in an oven for baking. It is 150-180°C.

[0046] Step 2, the base is blackened:

[0047] The polished metal substrate is blackened by electroplating, and the blackened metal substrate Ra≤0.02 is produced, and the surface f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com