Modified acrylic emulsion for electrically conductive printing ink and preparation method thereof

A technology of acrylic emulsion and conductive ink, which is applied in ink, applications, household appliances, etc. It can solve the problems of graphene oxide easy to agglomerate, affect the performance of composite materials, and endanger human health, and achieve excellent anti-adhesion performance and fast drying speed , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

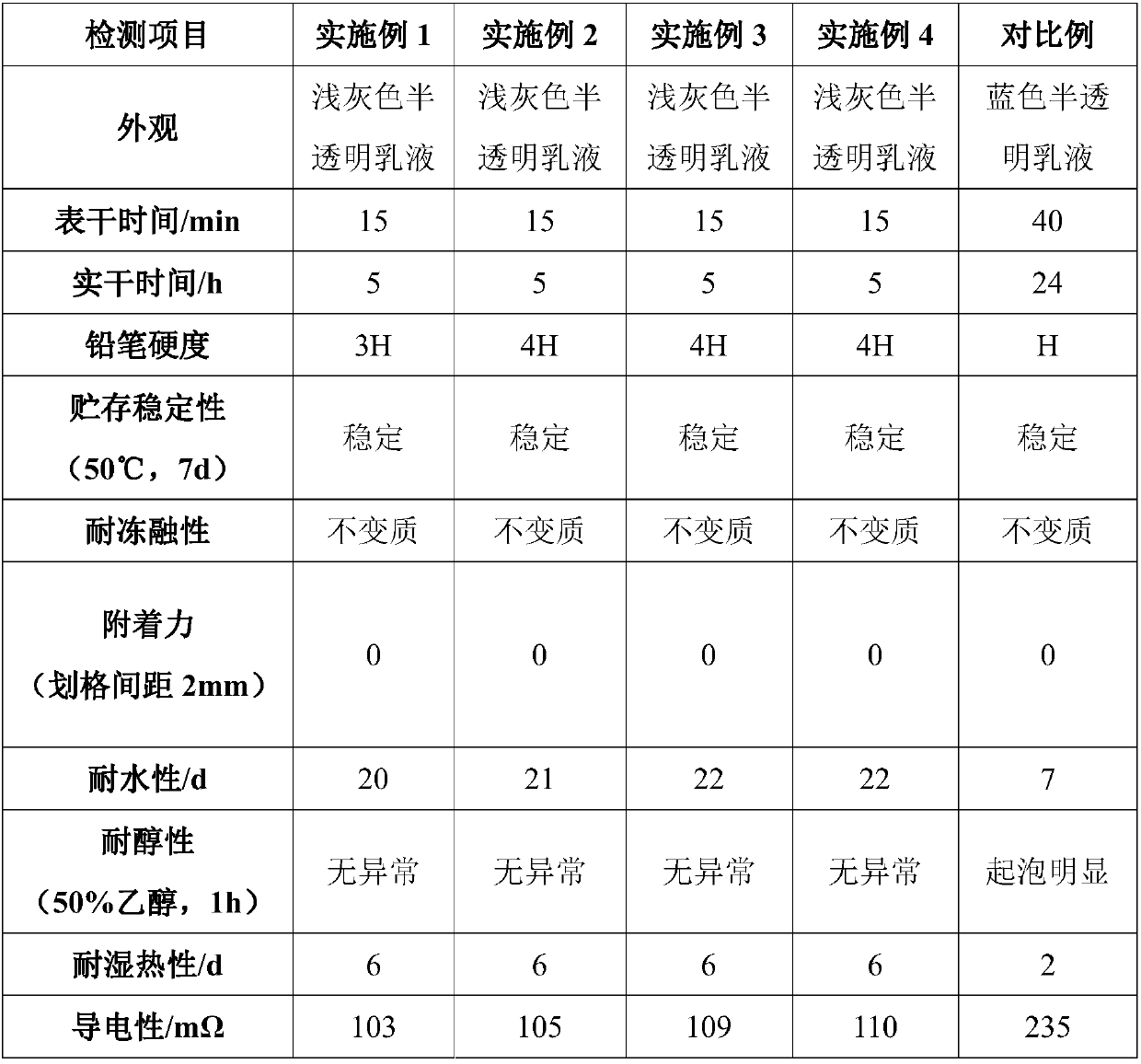

Examples

preparation example Construction

[0031] The preparation method of above-mentioned conductive ink with modified acrylic acid emulsion comprises the following steps:

[0032] 1) Mix graphene oxide, silane coupling agent and hydrochloric acid, react at 65-85°C for 0.5-3 hours, and then add hydrazine hydrate aqueous solution for reduction reaction to obtain modified graphene;

[0033] 2) Mix the diisocyanate and the chain extender, evacuate the reaction at 55-75°C for 25-45 minutes, and then react at 65-85°C for 2-4 hours to obtain a polyurethane prepolymer, and then add 2-hydroxyethyl acrylate to the polyurethane The prepolymer is end-capped to obtain a double-bond-terminated polyurethane crosslinking agent;

[0034] 3) mixing the modified graphene of acrylate, styrene, step 1) and the double-bond-terminated polyurethane crosslinking agent of step 2), to obtain a mixed solution;

[0035] 4) Mix the anionic emulsifier, nonionic emulsifier, pH buffer and water evenly, raise the temperature to 65-80°C, add the mix...

Embodiment 1

[0038] A preparation method of modified acrylic acid emulsion for conductive ink, comprising the following steps:

[0039] 1) Mix 0.5g graphene oxide, 2mL 3-(methacryloyloxy)propyltrimethoxysilane and 2mL hydrochloric acid with a mass fraction of 35%, sonicate for 1h, react at 75°C for 2h, then add 3mL with a mass fraction of 60% The hydrazine hydrate aqueous solution carries out reduction reaction, obtains modified graphene;

[0040] 2) Mix 3.5g of isophorone diisocyanate (IPDI) and 7g of polyoxypropylene diol with a number average molecular weight of 2000, react in a vacuum at 55°C for 45min, then heat up to 85°C for 4h to obtain a polyurethane prepolymer, Then add 2g of acrylate-2-hydroxyethyl ester to block the polyurethane prepolymer, and react for 2h to obtain a double bond-blocked type polyurethane crosslinking agent;

[0041] 3) 5g methyl methacrylate, 15g butyl methacrylate, 10g styrene, the modified graphene of step 1) and the double-bond-terminated polyurethane cro...

Embodiment 2

[0044] A preparation method of modified acrylic acid emulsion for conductive ink, comprising the following steps:

[0045]1) Mix 0.7g graphene oxide, 3mL 3-(methacryloyloxy)propyltrimethoxysilane and 3mL hydrochloric acid with a mass fraction of 35%, sonicate for 1h, react at 75°C for 3h, then add 4mL with a mass fraction of 70% The hydrazine hydrate aqueous solution carries out reduction reaction, obtains modified graphene;

[0046] 2) Mix 4g of 4,4'-dicyclohexylmethane diisocyanate (HMDI) and 8g of polyoxyethylene diol with a number average molecular weight of 4000, react in a vacuum at 70°C for 40min, then heat up to 85°C for 4h to obtain polyurethane Add 3g of 2-hydroxyethyl acrylate to the prepolymer to block the polyurethane prepolymer, and react for 2 hours to obtain a double-bond-blocked polyurethane crosslinking agent;

[0047] 3) 15g methyl methacrylate, 10g butyl methacrylate, 15g styrene, the modified graphene of step 1) and the double-bond-terminated polyurethane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com