Flexible cable

A flexible cable and copper core technology, which is applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of inconvenient mobile construction, insufficient wear resistance of cable movement, and cable damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

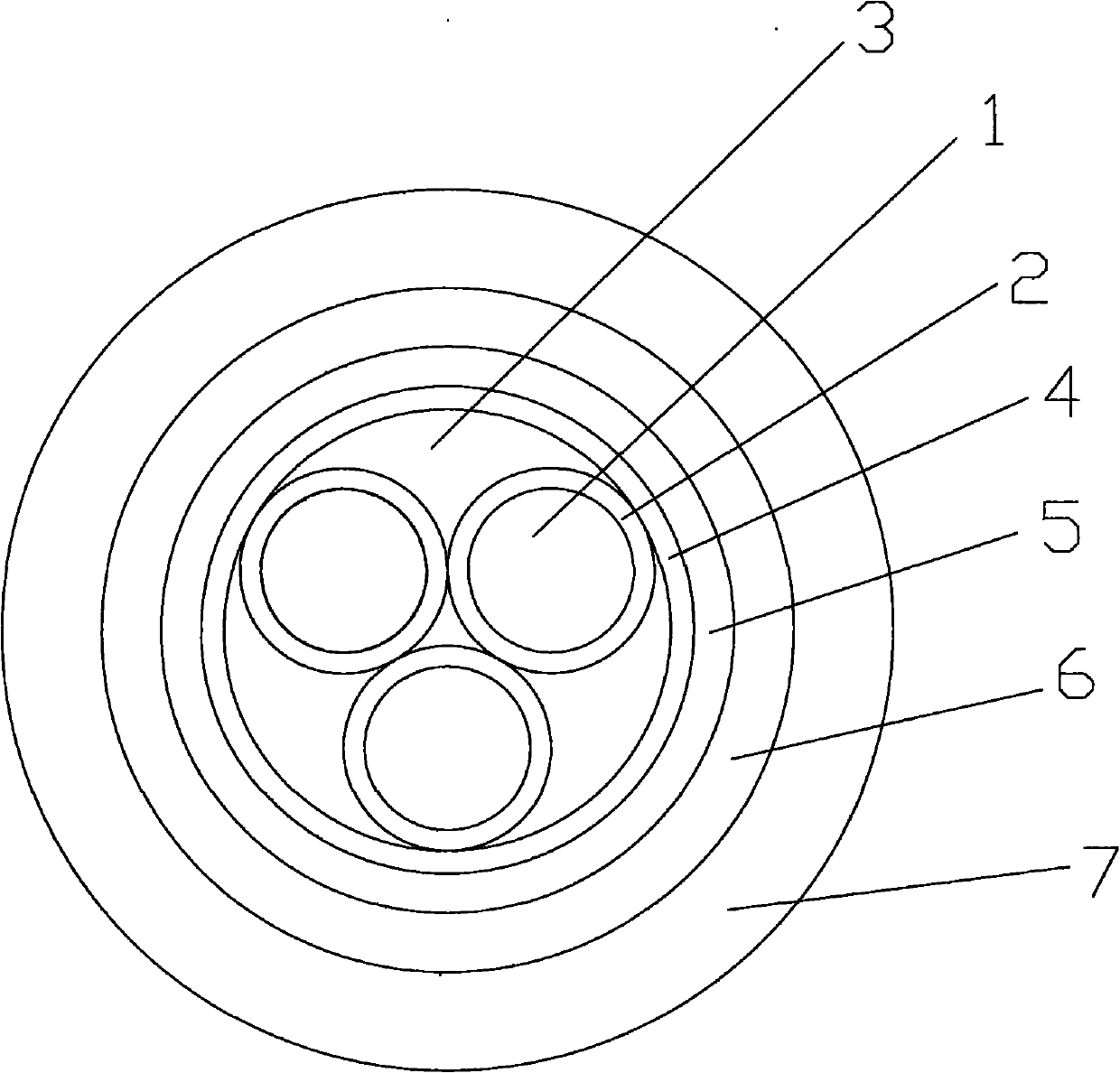

[0015] Example: such as figure 1 As shown, in the flexible cable described in this embodiment, the copper core stranded conductor 1 adopts the second type of structure conductive core; It can make the cable have fire resistance and make the cable move better; the filling layer 3 uses a flame-retardant filling rope, and its function is to ensure the flame retardancy and roundness of the cable; the wrapping layer uses mica tape to wrap around the wrapping layer 4 and glass fiber tape Wrapping layer 5, the production form adopts overlapping wrapping, and the covering rate is not less than 15%. It is mainly used to tighten the cable core and isolate the armor layer; the armor layer 6 uses copper sleeve threads, which have two functions , one is to play the role of anti-compression, to protect the core from being crushed by external pressure; the other is to prevent the fire source from entering the cable core directly when the cable catches fire, and to play a role in fire prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com