Basalt fiber friction material and preparation method thereof

A basalt fiber and friction material technology, applied in the field of friction materials, can solve the problems of reduced friction performance, insufficient high temperature resistance and high temperature stability of plied yarn, and achieve stable friction braking torque, improved temperature deformation performance, and overall bonding. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

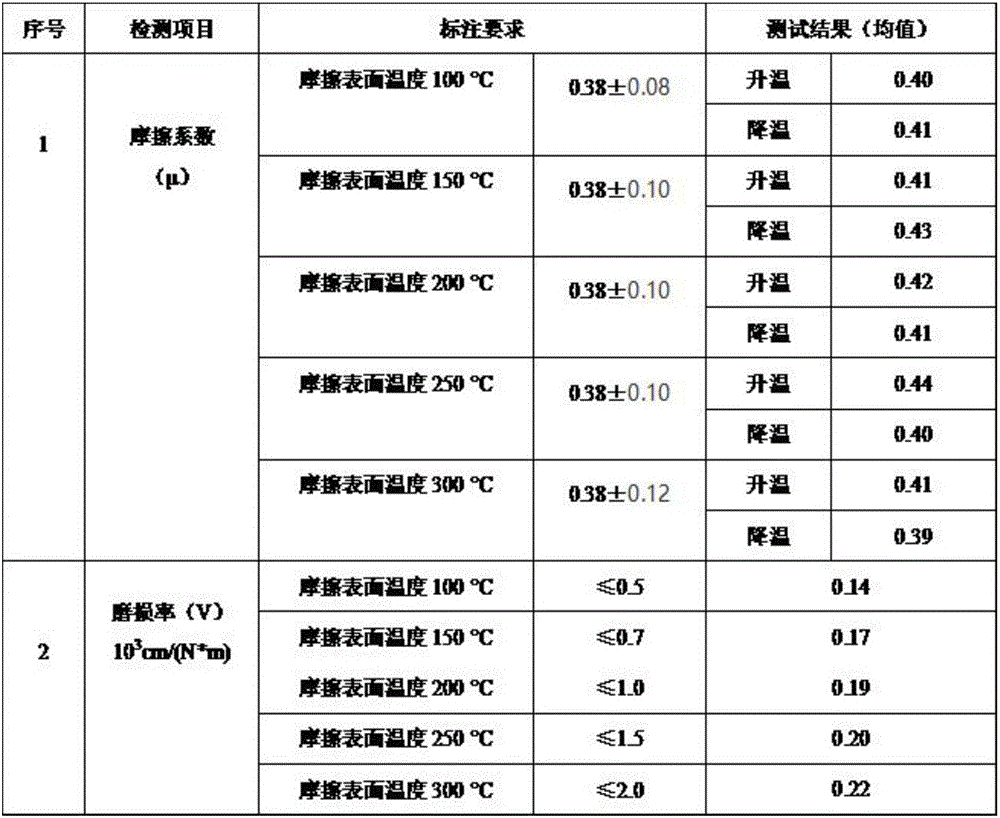

Examples

Embodiment

[0026] Embodiment: the preparation method of basalt fiber friction material, comprises the following steps:

[0027] (1) Preparation of mixed fiber skeleton: take basalt fiber, aramid fiber, carbon fiber and potassium titanate fiber according to the weight ratio of 3:2:2:1, and take an appropriate amount of viscous material composed of nitrile modified phenolic resin and nitrile rubber powder. Put the agent into the high-speed mixer and stir for 5-7 minutes, and the speed of the high-speed mixer is 3300 rpm; after mixing evenly, send it into the mold cavity of the hot-press molding machine, and heat-press at a temperature of 160 degrees Celsius and a pressure of 35MPa In 200 seconds, a mixed fiber skeleton was prepared;

[0028] (2) Ingredients and mixing: According to the weight ratio of 1:1, take reinforcing fibers and fillers that are 1.2-2 times the weight of the mixed fiber skeleton, put them into a high-speed mixer, and add an appropriate amount of binder to stir for 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com