Method for manufacturing enhanced flat cable for wagon dumper

A manufacturing method and reinforced technology, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., can solve the problems of inability to provide tensile reinforcement for cables, cracking of sheath layer, etc., and achieve effective physical and mechanical protection. Improve the longitudinal tensile strength and satisfy the effect of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

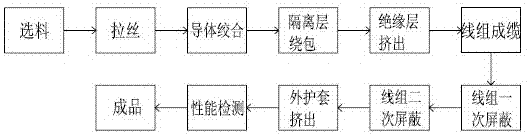

[0024] A method for manufacturing reinforced flat cables for car dumpers, characterized in that the manufacturing process is as follows: material selection—wire drawing—conductor stranding—isolating layer wrapping—insulating layer extruding—wire forming cable—wire group primary shielding—wire Group secondary shielding—outer sheath extrusion—performance testing—finished product. The conductor stranding adopts a steel wire rope in the center layer, and a twisted copper wire strand in the outer layer. double the stranding pitch to form a conductor, the diameter of the steel wire rope must ensure that the arrangement structure of the outer layer conductor is suitable; Weaving on wire machine and high-speed braiding machine, 7 thin round copper wires per strand, braiding angle 65° o , The weaving density of primary shielding is 80%, and the weaving density of secondary shielding is 85%.

[0025] The raw material selected in the material selection is an electrical round copper rod....

Embodiment 2

[0037]A method for manufacturing reinforced flat cables for car dumpers, characterized in that the manufacturing process is as follows: material selection—wire drawing—conductor stranding—isolating layer wrapping—insulating layer extruding—wire forming cable—wire group primary shielding—wire Group secondary shielding—outer sheath extrusion—performance testing—finished product. The conductor stranding adopts a steel wire rope in the center layer, and a twisted copper wire strand in the outer layer. double the stranding pitch to form a conductor, the diameter of the steel wire rope must ensure that the arrangement structure of the outer layer conductor is suitable; Weaving on wire machine and high-speed braiding machine, 6 thin round copper wires per strand, braiding angle 55° o , The weaving density of primary shielding is 90%, and the weaving density of secondary shielding is 85%.

[0038] The raw material selected in the material selection is an electrical round copper rod. ...

Embodiment 3

[0050] A method for manufacturing reinforced flat cables for car dumpers, characterized in that the manufacturing process is as follows: material selection—wire drawing—conductor stranding—isolating layer wrapping—insulating layer extruding—wire forming cable—wire group primary shielding—wire Group secondary shielding—outer sheath extrusion—performance testing—finished product. The conductor stranding adopts a steel wire rope in the center layer and a twisted copper wire strand in the outer layer. double the stranding pitch to form a conductor, the diameter of the steel wire rope must ensure that the arrangement structure of the outer layer conductor is suitable; Weaving on wire machine and high-speed braiding machine, paralleling 5 thin round copper wires per share, braiding angle 60° o , The weaving density of primary shielding is 90%, and the weaving density of secondary shielding is 95%.

[0051] The raw material selected in the material selection is an electrical round c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com