Temperature-resistant oil-resistant polyvinyl chloride elastomer cable material and preparing method thereof

An oil-resistant polyvinyl chloride and elastic technology, which is applied in the field of temperature-resistant and oil-resistant polyvinyl chloride elastomer cable material and its preparation, can solve the problems that the degree of polymerization cannot be too high, cannot meet the requirements and restrictions of wear resistance and oil resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

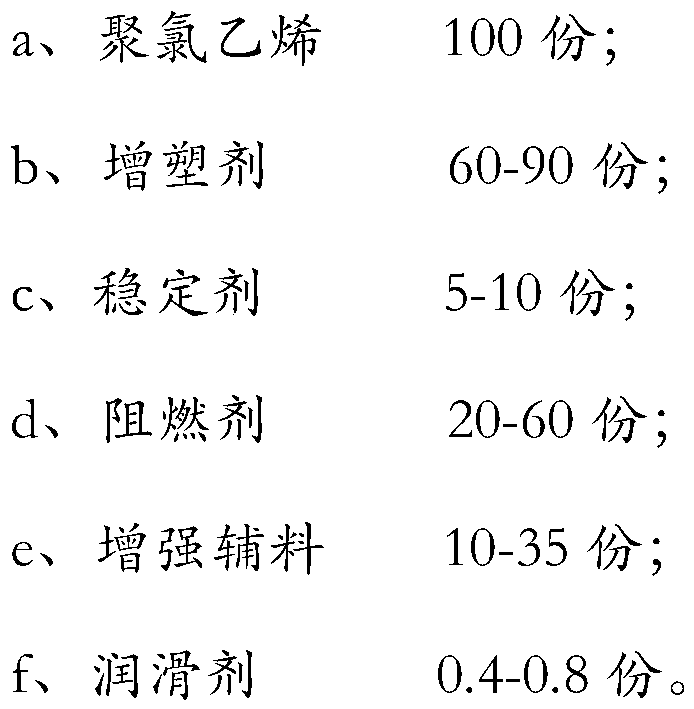

[0025] A temperature-resistant and oil-resistant polyvinyl chloride elastomer cable material, the formula of which is by weight:

[0026]

[0027]

[0028] The composite stabilizer used is Ca-Zn stabilizer.

[0029] The composite flame retardant used is zinc borate.

[0030] The preparation method of the heat-resistant and oil-resistant polyvinyl chloride elastomer cable material comprises the following steps:

[0031] (1) Add polyvinyl chloride to the high-speed mixer, then add the Ca-Zn stabilizer, run the high-speed mixer at a low speed and mix for 1 minute, then add half of trioctyl trimellitate and epoxidized soybean oil , the high-speed mixer is turned from low speed to high-speed operation and mixed for 5 minutes, and then the other half of the components of trioctyl trimellitate and epoxy soybean oil are added after the shutdown, and the high-speed mixer is turned from low speed to high speed after mixing to 90°C , add antimony trioxide, zinc borate, silicon ma...

Embodiment 2

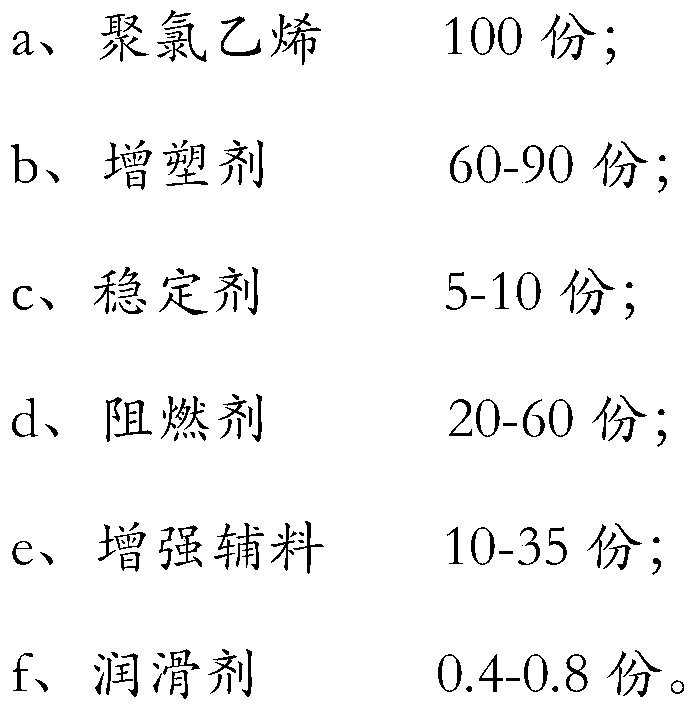

[0035] A temperature-resistant and oil-resistant polyvinyl chloride elastomer cable material, the formula of which is by weight:

[0036]

[0037]

[0038] The composite stabilizer used is Ca-Zn stabilizer.

[0039] The composite flame retardant used is zinc borate.

[0040] The preparation method of the above-mentioned temperature-resistant and oil-resistant polyvinyl chloride elastomer cable material includes the following steps:

[0041] (1) Add polyvinyl chloride to the high-speed mixer, then add the Ca-Zn stabilizer, run the high-speed mixer at a low speed and mix for 1 minute, then add half of the components of dioctyl terephthalate, and the high-speed mixer consists of Turn low speed to high speed and mix for 5 minutes, and then add the remaining half of the dioctyl terephthalate after stopping the machine. After the high speed mixer turns from low speed to high speed and mixes to 90°C, add calcium carbonate, antimony trioxide, Zinc borate, silicon magnesium ore...

Embodiment 3

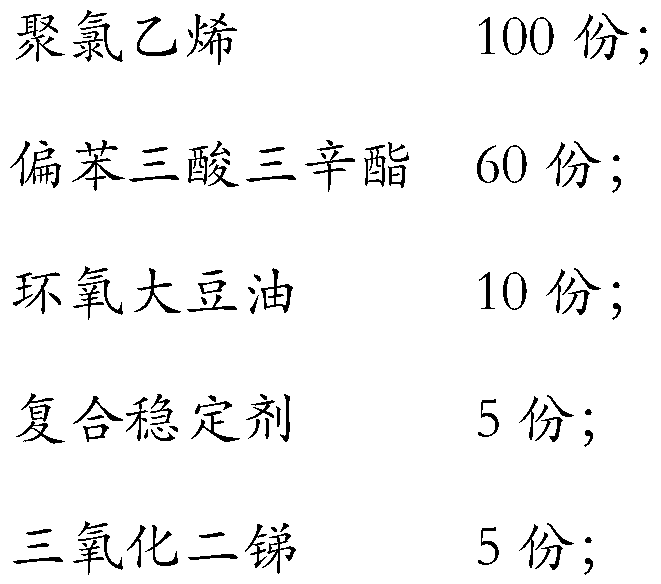

[0045] A temperature-resistant and oil-resistant polyvinyl chloride elastomer cable material, the formula of which is by weight:

[0046]

[0047] The composite stabilizer used is Ca-Zn stabilizer.

[0048] The composite flame retardant used is zinc borate.

[0049] The preparation method of the above-mentioned temperature-resistant and oil-resistant polyvinyl chloride elastomer cable material includes the following steps:

[0050] (1) Polyvinyl chloride is added in the high-speed mixer, and then Ca-Zn stabilizer is added, and after the high-speed mixer is mixed at a low speed for 1 minute, half of the components of trioctyl trimellitate are added, and the high-speed mixer consists of Turn from low speed to high speed and mix for 5 minutes, and then add the other half of trioctyl trimellitate after stopping the machine. After the high speed mixer is turned from low speed to high speed and mixed to 90°C, add antimony trioxide, zinc borate and For compound lubricant, first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com