Carbon nanotube epoxy resin static conductive coating material and fabrication method thereof

A technology of epoxy resin and carbon nanotubes, which is applied in the direction of epoxy resin coatings, conductive coatings, coatings, etc., can solve the problem of oil pollution, conductive functional bodies that cannot reach safe static conductivity, and affect the quality of metal recycling, etc. problem, to achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

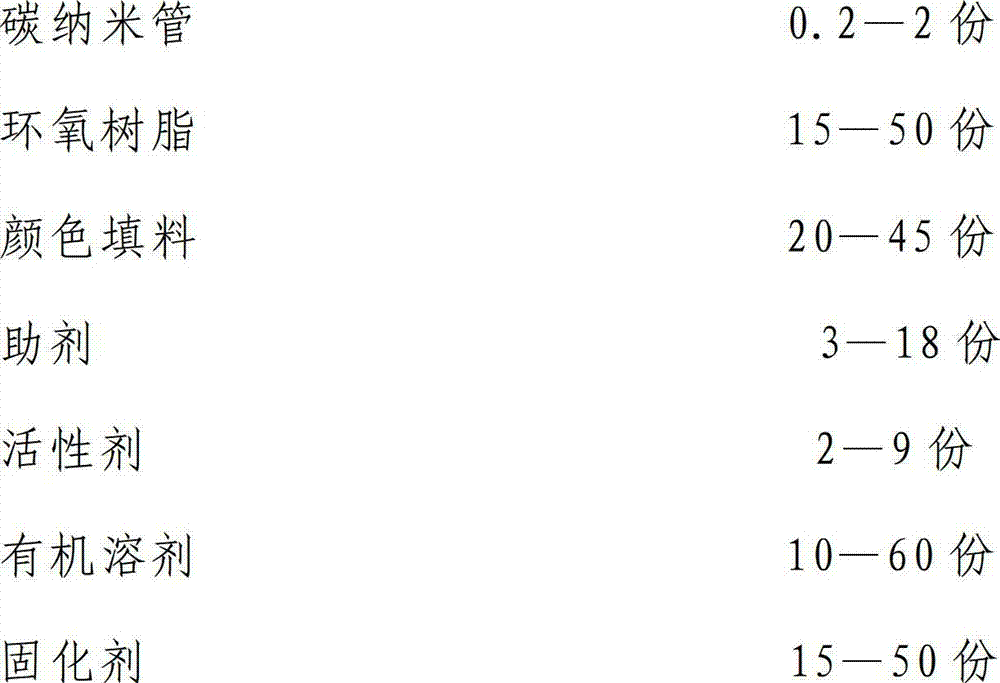

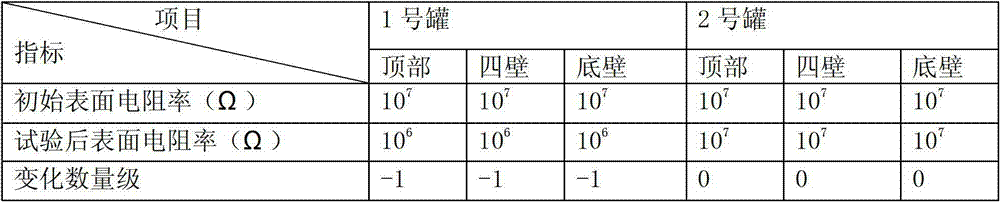

[0021] Put 0.2g of single-walled carbon nanotubes with a diameter of 0.6-2nm in the mixed solution of 0.1g of dicarboxyl epoxy active diluent, 0.1g of EFKA2022 auxiliary agent and 6.5g of mixed solvent of xylene and n-butanol, stir at a low speed Mixing, chemical activation and composite treatment under state for 35 minutes, then, add 0.3g of dicarboxylate reactive diluent, 0.2g of hard epoxy resin (epoxy resin E20) and 3g of mixed solvent of xylene and n-butanol, stir at low speed Composite for 30 minutes, then use ultrasonic waves to treat for 50 minutes at a constant temperature of 18°C-60°C with additional shearing conditions, then place the above mixed solution in a disperser, and add hard epoxy resin in sequence at a medium speed ( Epoxy resin E20) and soft epoxy resin (epoxy resin E20) mixture 9g, xylene and n-butanol mixed solvent 3.5g, titanium dioxide 3.8g, zinc phosphate 1.2g, talc powder 1.1g and zinc oxide 0.8g , after 30 minutes of dispersion and compounding trea...

Embodiment 2

[0023] Put 0.2g of single-walled carbon nanotubes with a diameter of 0.6-2nm into the mixed solution of 0.1g of 6690 reactive diluent, 0.1g of EFKA2022 auxiliary agent and 6.5g of mixed solvent of xylene, n-butanol and cyclohexane, at a low speed Mixing, chemical activation and composite treatment for 35 minutes under stirring, then, add 0.3g of 6690 reactive diluent, 0.2g of hard epoxy resin (a mixture of DCPO-phenol epoxy resin and epoxy resin E20) and xylene, n-butyl Mixed solvent 3g of alcohol and cycloheximide, mixed at a low speed for 30 minutes, then treated with ultrasonic waves at a constant temperature of 18°C-60°C with additional shear conditions for 50 minutes, and then put the above mixed solution in a disperser, in the medium In the fast state, add 9g of the mixture of hard epoxy resin (the mixture of DCPO-phenol epoxy resin and epoxy resin E20) and soft epoxy resin (the mixture of DCPO-phenol epoxy resin and epoxy resin E20) successively, Xylene, n-butanol and c...

Embodiment 3

[0025] Put 0.3g of single-walled carbon nanotubes with a diameter of 0.6-2nm in the mixed solution of 0.4g of dioxin epoxy active diluent, 0.2g of EFKA2022 auxiliary agent and 6.5g of mixed solvent of xylene, n-butanol and cyclohexane , mixed, chemically activated and compounded for 50 minutes under low-speed stirring, then added 0.3g of dicarboxylate reactive diluent and 0.2g of hard epoxy resin (a mixture of DCPO-phenol epoxy resin and epoxy resin E20) and 3g of mixed solvent of xylene, n-butanol and cyclohexene, mixed at a low speed for 30 minutes, then treated with ultrasonic waves at a constant temperature of 18°C-60°C with additional shear conditions for 50 minutes, and then put the above mixed solution in In the disperser, add hard epoxy resin (a mixture of DCPO-phenol epoxy resin and epoxy resin E20) and soft epoxy resin (a mixture of DCPO-phenol epoxy resin and epoxy resin E20) in sequence at a medium speed. Mixture) of mixture 9g, xylene, n-butanol and cyclohexane mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com