Waterproof material for cement concrete bridge floor and preparation method of waterproof material

A technology of cement concrete and waterproof materials, applied in asphalt coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as single composition structure, poor high temperature resistance, and pavement layer shifting, and achieve firm bonding and smooth construction The operation is safe and convenient, and the effect of reducing the damage of the bridge structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

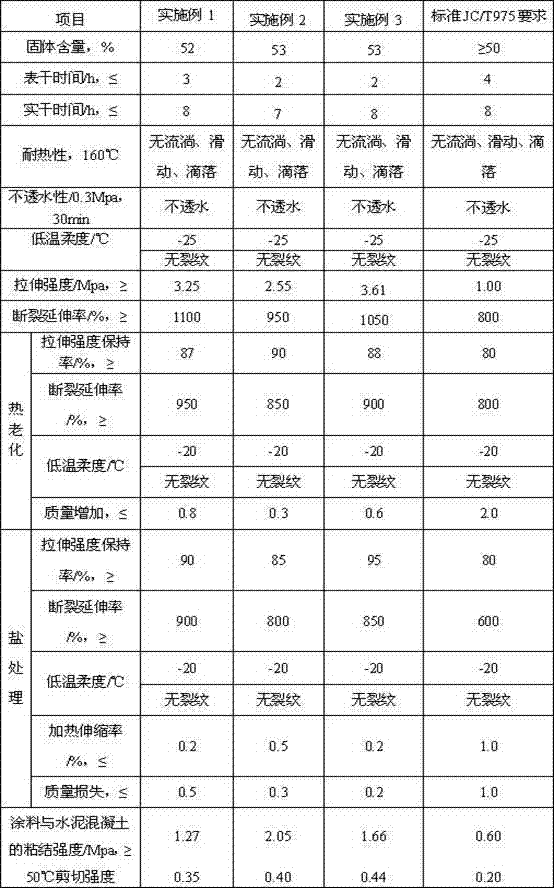

Examples

Embodiment 1

[0022] Embodiment 1: A waterproof material for cement concrete bridge deck, said waterproof material is 4,4-diphenylmethane diisocyanate MDI and composite polyol to generate amino methyl ester, then add No. 70 ordinary heavy traffic asphalt Modified by stannous octoate, compound defoamer and ethyl acetate;

[0023] Wherein the composite polyol oxidized polypropylene diol and oxidized polypropylene triol are mixed with a mass ratio of 3:1, the isocyanate group of the 4,4-diphenylmethane diisocyanate MDI and the hydroxyl group in the composite polyol The molar ratio is controlled to be 3:1.

[0024] The composite defoamer is Ca(OH)2 and emulsified silicone oil in a mass ratio of 1:1, and the consumption is 0.4% of the isocyanate.

[0025] The No. 70 common heavy traffic asphalt consumption is 80% of the carbamate;

[0026] Described stannous octoate consumption is 0.5% of isocyanate;

[0027] A method for preparing a waterproof material for cement concrete bridge decks, the s...

Embodiment 2

[0028] Embodiment 2: a kind of waterproofing material for cement concrete bridge deck, described waterproofing material is to generate carbamate by toluene diisocyanate TDI and composite polyol, add No. 90 common heavy traffic asphalt again through dibutyltin dilaurate, Composite defoamer and ethyl acetate composite modification;

[0029] Wherein the composite polyol oxidized polypropylene diol and oxidized polypropylene triol are mixed with a mass ratio of 2:1, and the molar ratio of the isocyanate group of the toluene diisocyanate TDI to the hydroxyl group in the composite polyol is controlled to be 5:1 .

[0030] The composite defoamer is Ca(OH)2 and emulsified silicone oil in a mass ratio of 1:1, and the consumption is 0.5% of the isocyanate.

[0031] The No. 90 common heavy traffic asphalt consumption is 85% of the carbamate;

[0032] Described dibutyltin dilaurate consumption is 0.6% of isocyanate;

[0033] A method for preparing a waterproof material for a cement con...

Embodiment 3

[0034] Embodiment 3: A kind of waterproof material for cement concrete bridge deck, described waterproof material is to generate amino methyl ester by 4,4-diphenylmethane diisocyanate MDI and composite polyol, then add No. 90 ordinary heavy-duty asphalt Modified by stannous octoate, dibutyltin dilaurate, compound defoamer and ethyl acetate;

[0035] Wherein the composite polyol oxidized polypropylene diol and oxidized polypropylene triol are mixed with a mass ratio of 4:1, the isocyanate group of the 4,4-diphenylmethane diisocyanate MDI and the hydroxyl group in the composite polyol The molar ratio is controlled to be 4:1.

[0036] The composite defoamer is Ca(OH)2 and emulsified silicone oil in a mass ratio of 1:1.3, and the consumption is 0.3% of the isocyanate.

[0037] The No. 90 common heavy traffic asphalt consumption is 75% of the carbamate;

[0038] Described dibutyltin dilaurate consumption is 0.6% of isocyanate;

[0039]A method for preparing a waterproof material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com