Preparation method for modified carbon quantum dot/silicone rubber fluorescent composite material

A technology of carbon quantum dots and composite materials, which is applied in the field of preparation of modified carbon quantum dots/silicone rubber fluorescent composite materials, which can solve the problems of fluorescence quenching and fluorescence performance reduction, so as to prolong the service life, prevent precipitation and improve strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of carbon quantum dots

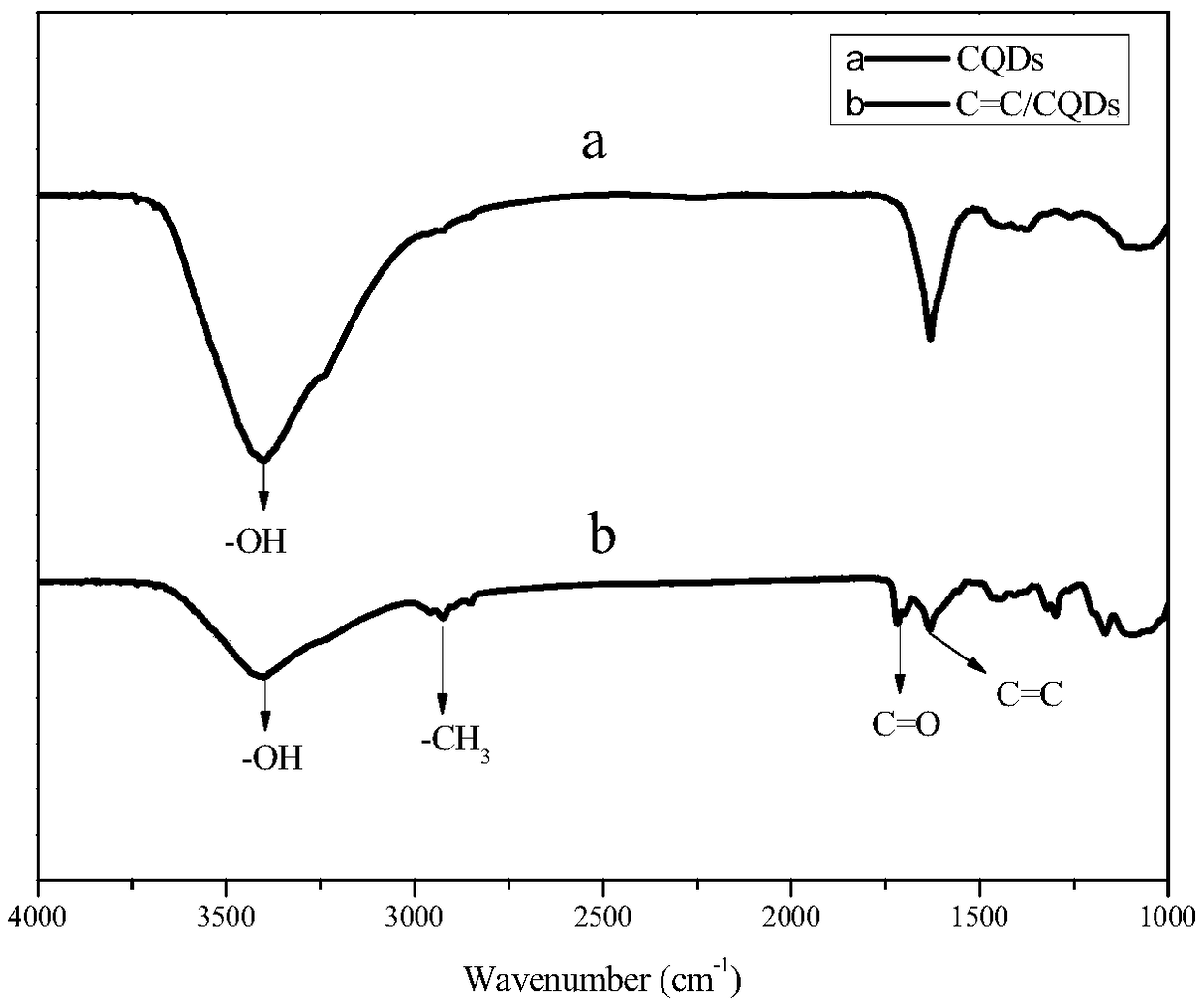

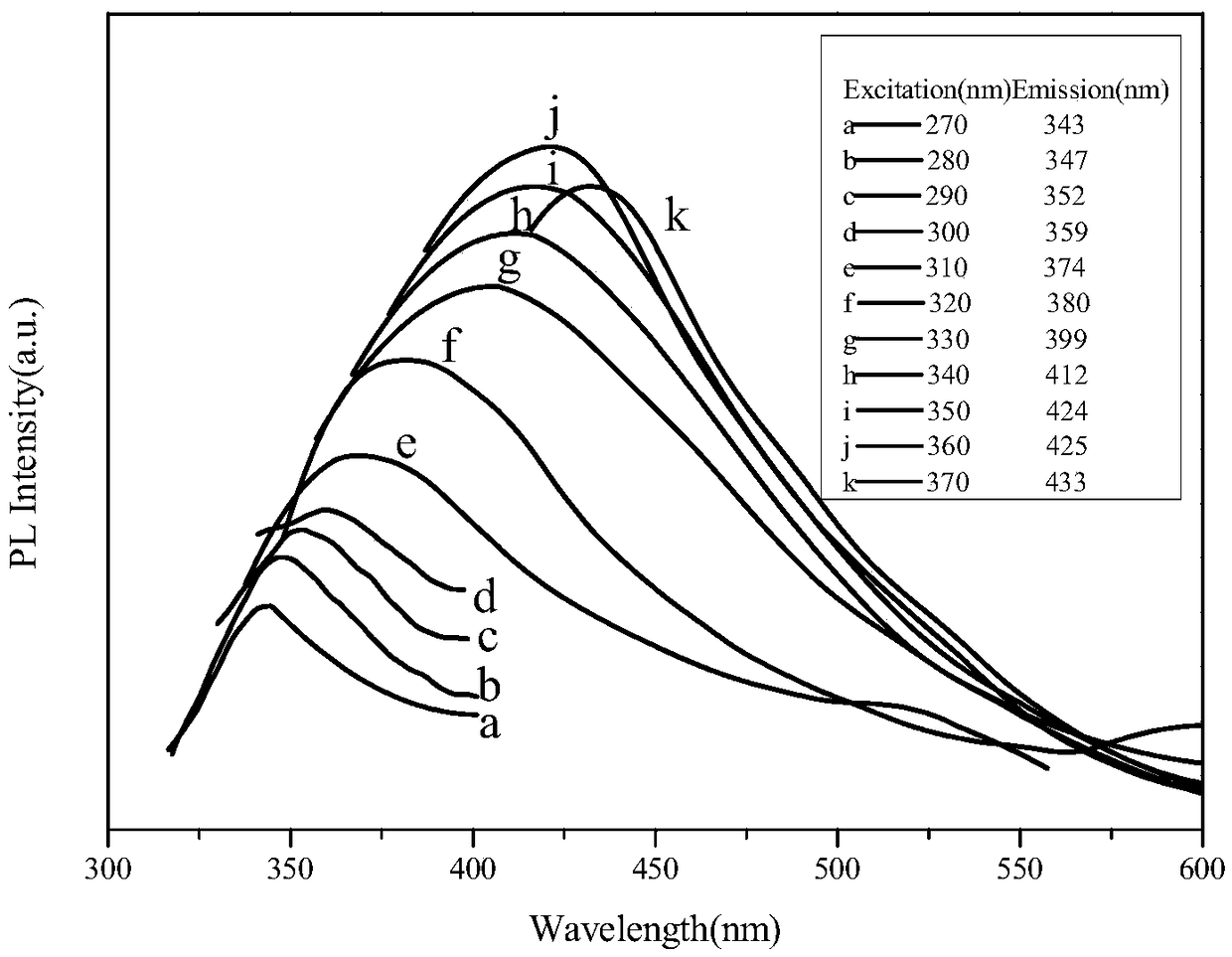

[0030] Prepare 1mol / L water-soluble starch solution and 1mol / L NaOH solution, take 10mL each, mix evenly and ultrasonically treat for 10h, adjust the pH of the solution to neutral with HCl, add 100mL absolute ethanol drop by drop and stir, then add 16g Remove water with anhydrous magnesium sulfate, let it stand for 24 hours, take the supernatant and centrifuge at 10000r / min for 20 minutes at a high speed and filter with a 0.22μm filter membrane to remove macromolecular particles and non-luminescent substances, and obtain a pure ethanol solution of fluorescent carbon quantum dots. An infrared test was carried out on the obtained fluorescent carbon quantum dot ethanol solution, and the test results are shown in figure 1 In (a), by figure 1 In (a), it can be seen that the surface of the prepared carbon quantum dots contains functional groups such as -OH, C=O and -COOH.

[0031] (2) Preparation of modified carbon quantum dots

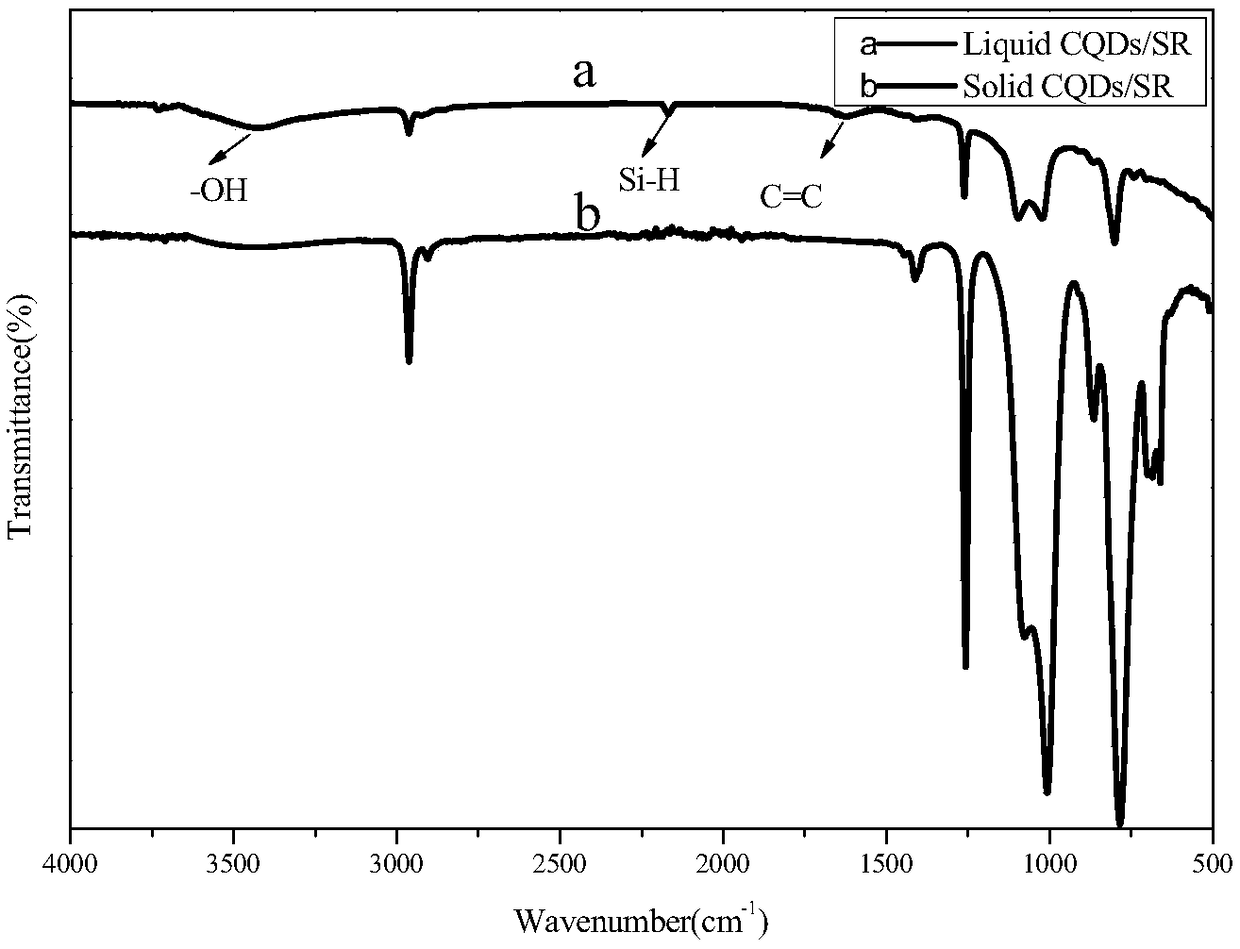

[0...

Embodiment 2

[0040] (1) Preparation of carbon quantum dots

[0041] Prepare 1mol / L water-soluble starch solution and 1mol / L NaOH solution, take 10mL each, mix them evenly, and then ultrasonically treat them for 8h, adjust the pH of the solution to neutral with HCl, add 100mL absolute ethanol drop by drop and stir, then add Remove water with 16g of anhydrous magnesium sulfate, let it stand for 24 hours, take the supernatant and centrifuge at 10,000r / min for 20 minutes at high speed and filter with a 0.22μm filter membrane to remove macromolecular particles and non-luminescent substances, and obtain a pure ethanol solution of fluorescent carbon quantum dots;

[0042] (2) Preparation of modified carbon quantum dots

[0043] Measure 25mL of ethanol solution of carbon quantum dots, 5mL of deionized water and 0.25mL of silane coupling agent KH570, react them in an ice-water bath for 30min, then raise the temperature to 50°C, and stir for 2h to obtain modified carbon quantum dot ethanol solution...

Embodiment 3

[0047] (1) Preparation of carbon quantum dots

[0048] Prepare 1mol / L water-soluble starch solution and 1mol / L NaOH solution, take 10mL each, mix them evenly, and then sonicate for 10h, adjust the pH of the solution to neutral with HCl, add 100mL absolute ethanol drop by drop and stir, then add Remove water with 16g of anhydrous magnesium sulfate, let it stand for 24 hours, take the supernatant and centrifuge at 10,000r / min for 20 minutes at high speed and filter with a 0.22μm filter membrane to remove macromolecular particles and non-luminescent substances, and obtain a pure ethanol solution of fluorescent carbon quantum dots;

[0049] (2) Preparation of modified carbon quantum dots

[0050] Measure 25mL of ethanol solution of carbon quantum dots, 5mL of deionized water and 0.75mL of silane coupling agent KH570, react them in an ice-water bath for 30min, then raise the temperature to 70°C, and stir for 1h to obtain modified carbon quantum dot ethanol solution;

[0051] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com