Water-based binder applied to waterproofing project of building structure and preparation method of water-based binder

A technology for building structures and adhesives, applied in adhesives, monocarboxylate copolymer adhesives, wax adhesives, etc., which can solve the problems of high climate and other conditions, poor performance of high and low temperature resistance, and insufficient bonding performance Strong and other problems, to achieve the effect of improving self-healing performance, good extensibility, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 A kind of water-based adhesive applied to building structure waterproof engineering

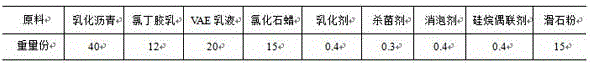

[0041] The raw materials of the water-based adhesive are proportioned according to the formula in Table 1:

[0042] Table 1 Water-based adhesive formula table

[0043]

[0044] The emulsified asphalt described in table 1 is anionic emulsified asphalt, and the solid content is 63.2%;

[0045] The neoprene latex described in Table 1 is anionic neoprene latex of Chongqing Changshou Jieyuan Chemical Industry Co., Ltd., with a solid content of 48%; the viscosity at 25°C is 1900mPa·s~2200mPa·s (rotational viscosity, 3 rotors, 12r / min);

[0046] The VAE emulsion described in Table 1 is from Celanese, with a solid content of 55.6%; the viscosity at 25°C is 3800mPa·s~4200mPa·s (rotational viscosity, 3 rotors, 12r / min);

[0047] The chlorinated paraffin described in Table 1 is No. 52; the viscosity at 25°C is 800mPa·s~900mPa·s (rotational viscosity, 3 rotors, 12r / min);

[0048...

Embodiment 2

[0062] Embodiment 2 A kind of water-based adhesive applied to building structure waterproof engineering

[0063] The raw material of described water-based adhesive carries out proportioning by the formula of table 2:

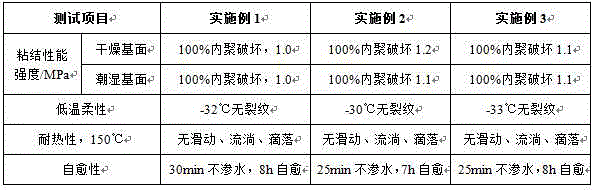

[0064]Table 2 Water-based adhesive formula table

[0065]

[0066] The emulsified asphalt described in table 2 is anionic emulsified asphalt, and the solid content is 63.2%;

[0067] The neoprene latex described in Table 2 is Chongqing Changshou Jieyuan Chemical anionic neoprene latex with a solid content of 48%; the viscosity at 25°C is 1900mPa·s~2200mPa·s (rotational viscosity, 3 rotors, 12r / min);

[0068] The VAE emulsion described in Table 2 is from Celanese, with a solid content of 55.6%; the viscosity at 25°C is 3800mPa·s~4200mPa·s (rotational viscosity, 3 rotors, 12r / min);

[0069] The chlorinated paraffin described in Table 2 is No. 52; the viscosity at 25°C is 800mPa·s~900mPa·s (rotational viscosity, 3 rotors, 12r / min);

[0070] The emulsifying ag...

Embodiment 3

[0084] Embodiment 3 A kind of water-based adhesive applied to building structure waterproof engineering

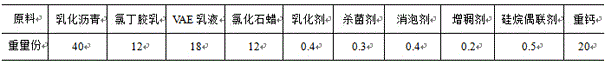

[0085] The raw material of described water-based adhesive carries out proportioning by the formula of table 3:

[0086] Table 3 water-based adhesive formula table

[0087]

[0088] The emulsified asphalt described in table 3 is anionic emulsified asphalt, and the solid content is 63.2%;

[0089] The neoprene latex described in Table 3 is anionic neoprene latex of Chongqing Changshou Jieyuan Chemical Industry Co., Ltd., with a solid content of 48%, and a viscosity of 1900mPa·s~2200mPa·s at 25°C (rotational viscosity, 3 rotors, 12r / min);

[0090] The VAE emulsion described in Table 3 is from Celanese, with a solid content of 55.6%, and a viscosity of 3800mPa·s~4200mPa·s at 25°C (rotational viscosity, 3 rotors, 12r / min);

[0091] The chlorinated paraffin described in Table 3 is No. 52, and its viscosity at 25°C is 800mPa·s~900mPa·s (rotational viscosity, 3 rotors, 12r / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com