Plate type metal-rubber shear friction damper

A technology of friction damper and metal rubber, which is applied in the direction of building components, shockproof, etc., can solve the problems of limited use, small vibration deformation energy consumption effect is not obvious, rubber shock absorber aging, etc., to ensure the vibration reduction effect and hysteresis The effect of full curve and large deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

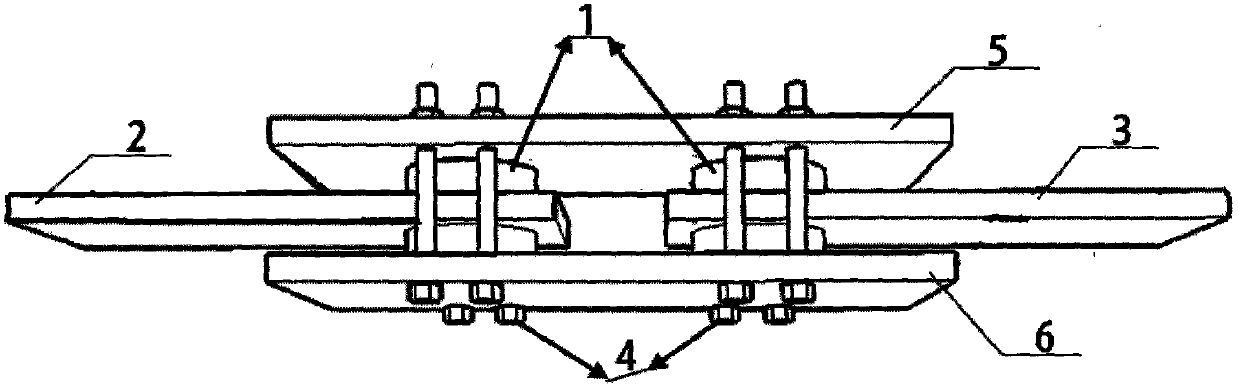

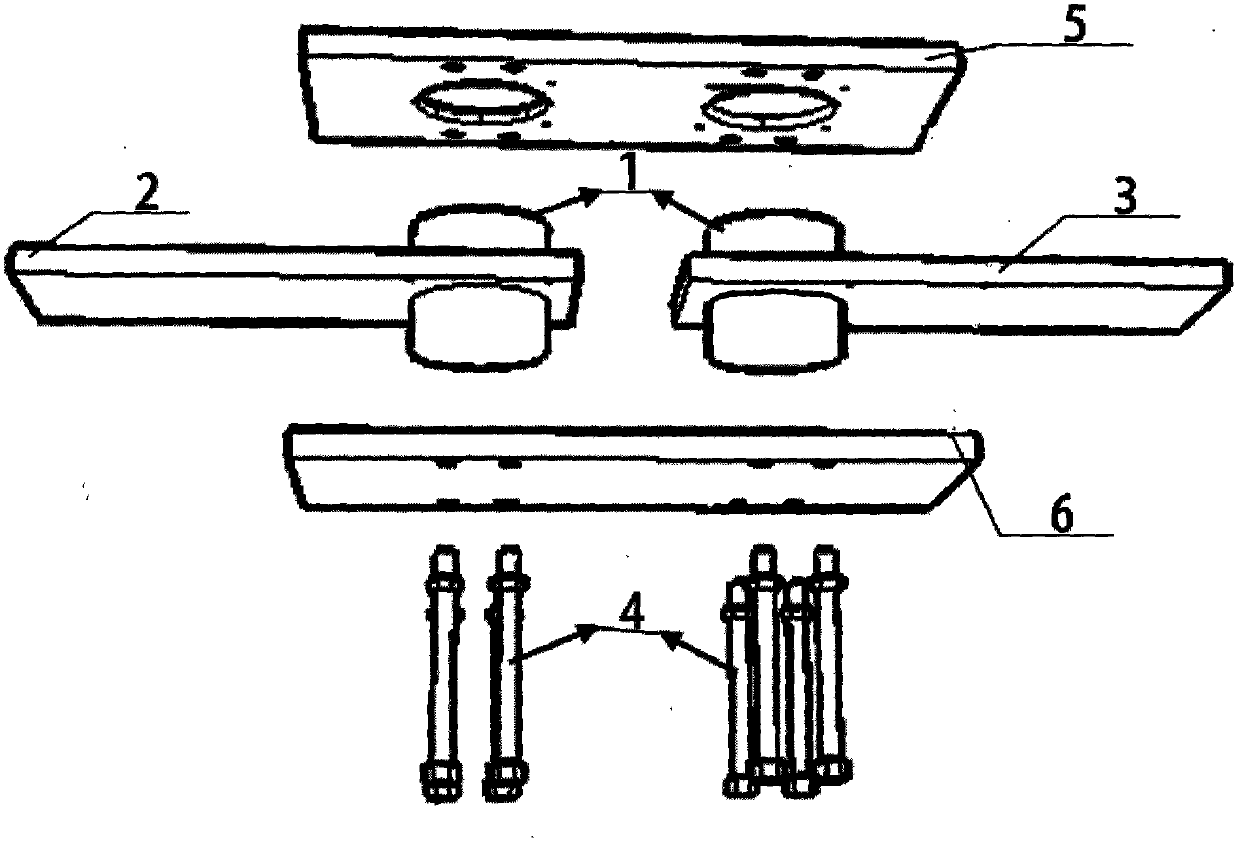

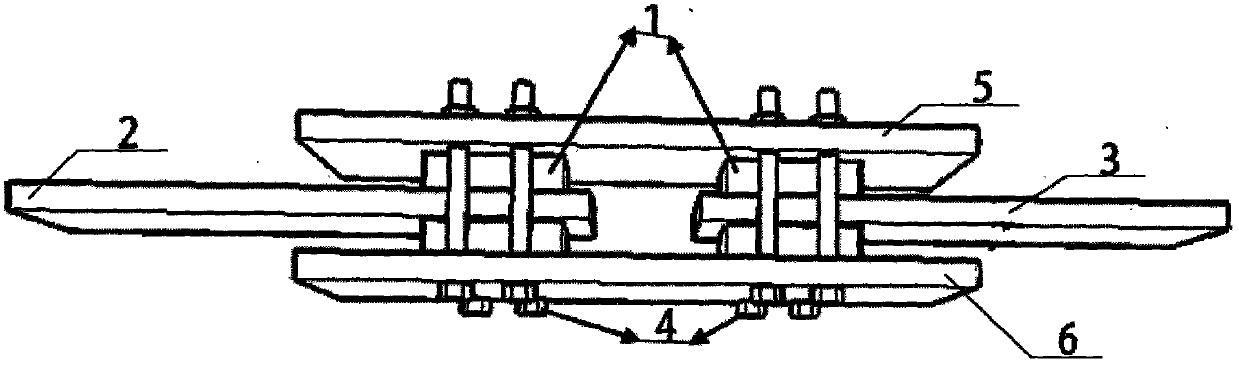

[0016] A plate-type metal-rubber shear friction damper, including two identical cubic metal-rubber blocks 1, left force application plate 2, right force application plate 3, fastening bolts 4, upper clamping plate 5 and lower clamping plate 6 , the left and right force steel plates 2 and 3 have holes of the same size as the two cubic metal rubber blocks 1, and the two cubic metal rubber blocks 1 are respectively placed in the holes of the left and right force force steel plates 2 and 3 Inside, the upper and lower two clamping steel plates 5 and 6 are respectively provided with a plurality of bolt holes and have a dent having the same size as the top surface of the cube metal rubber block 1. The force-applying steel plates 2 and 3 are placed between the upper and lower clamping steel plates 5 and 6, and the space between the cubic metal rubber block 1 and the upper and lower clamping steel plates 5 and 6 passes through the dents on the clamping steel plates Bolt fastening with ...

Embodiment 2

[0018] The metal rubber block is made by weaving the stretched helical metal wire with good quality in a certain way, and then formed by cold stamping process; the upper and lower clamping steel plates are made of ordinary steel, and a certain number of bolt holes are opened for connection. . The cube (cylindrical) metal rubber block is directly placed in the hole opened by the force steel plate; the cubic metal rubber block and the upper and lower clamping steel plates are bolted by the dent in the middle of the two steel plates and the bolt holes reserved between the steel plates.

[0019] Experiments have proved that the plate-type metal-rubber shear friction damper proposed by the present invention appropriately improves the traditional viscous damper, and can improve the performance of the traditional viscous damper by replacing ordinary rubber with metal rubber. , has the advantages of small vibration deformation, obvious energy consumption, full hysteresis curve, and go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com