Sealing plate and sealing hole viscous damper

A technology of viscous damper and dense plate, which is applied in the direction of building components and earthquake resistance, can solve the problems of not considering the dynamic characteristics of the structure, the increase in the number of mechanical parts, and the difficulty of realizing the structural system, so as to reduce the seismic response and improve the reliability. and the effect of high stability and large initial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

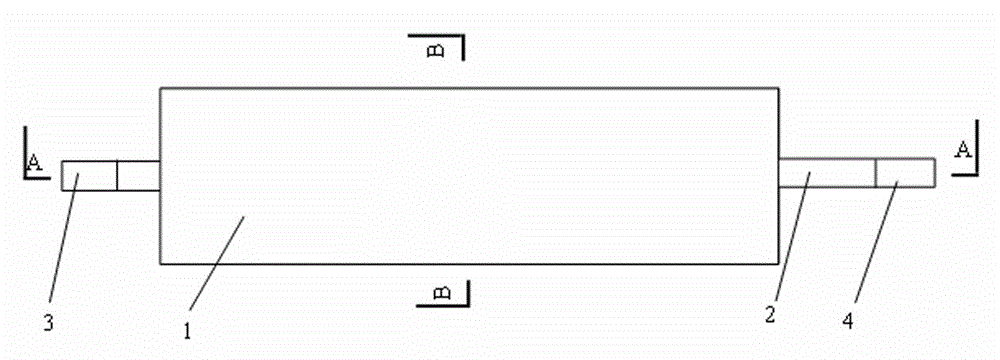

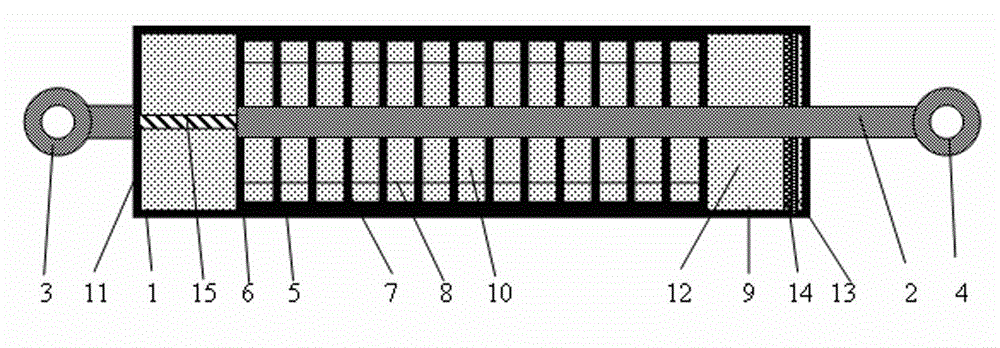

[0017] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

[0018] Such as Figure 1~Figure 4 As shown, a viscous damper with dense plates and dense holes in the present invention includes a main cylinder 1, a guide rod 2, a main cylinder connecting earring 3, an auxiliary cylinder connecting earring 4, an auxiliary cylinder 5, and an auxiliary cylinder end Plate 6, built-in dense plate of auxiliary cylinder 7, dense plate connecting rib 8, sub-cylinder cavity of main cylinder 9, sub-cylinder cavity of auxiliary cylinder 10, end plate of main cylinder 11, viscous liquid 12, sealing ring 13, polyurethane An oil seal 14, a return spring 15 and a fine hole 16. The auxiliary cylinder 5 is arranged in the main cylinder 1 and connected with the main cylinder 1 through a spring. The auxiliary cylinder 5 includes two auxiliary cylinder end plates 6 and Several auxiliary cylinders have built-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com