Metal damper provided with multiple shearing webs

A metal damper and shear web technology, which is applied to building components, shockproof and other directions, can solve the problems of out-of-plane buckling, increased length and weight of large-tonnage metal dampers, and achieves reduced weight and length, guaranteed consumption. performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

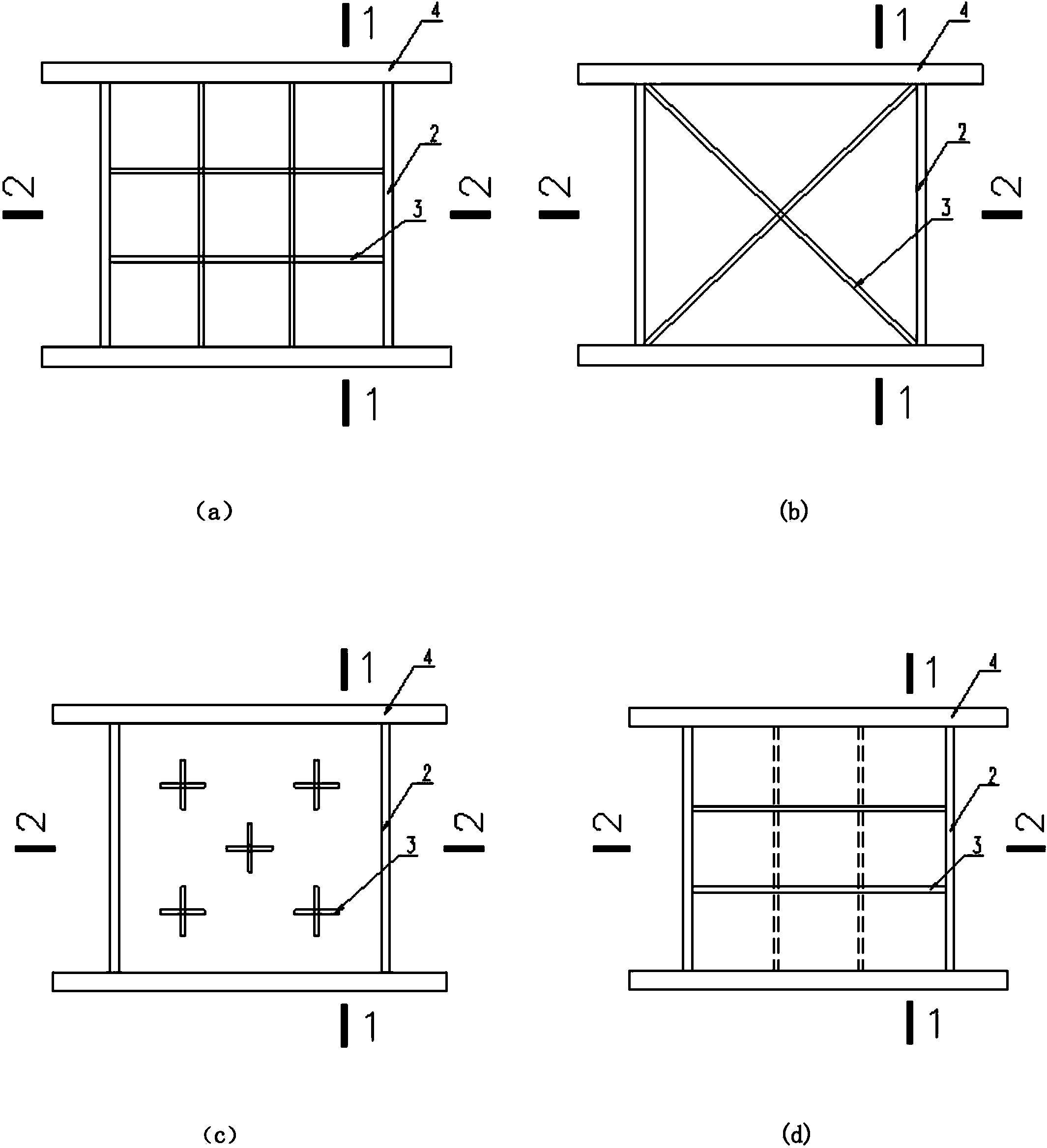

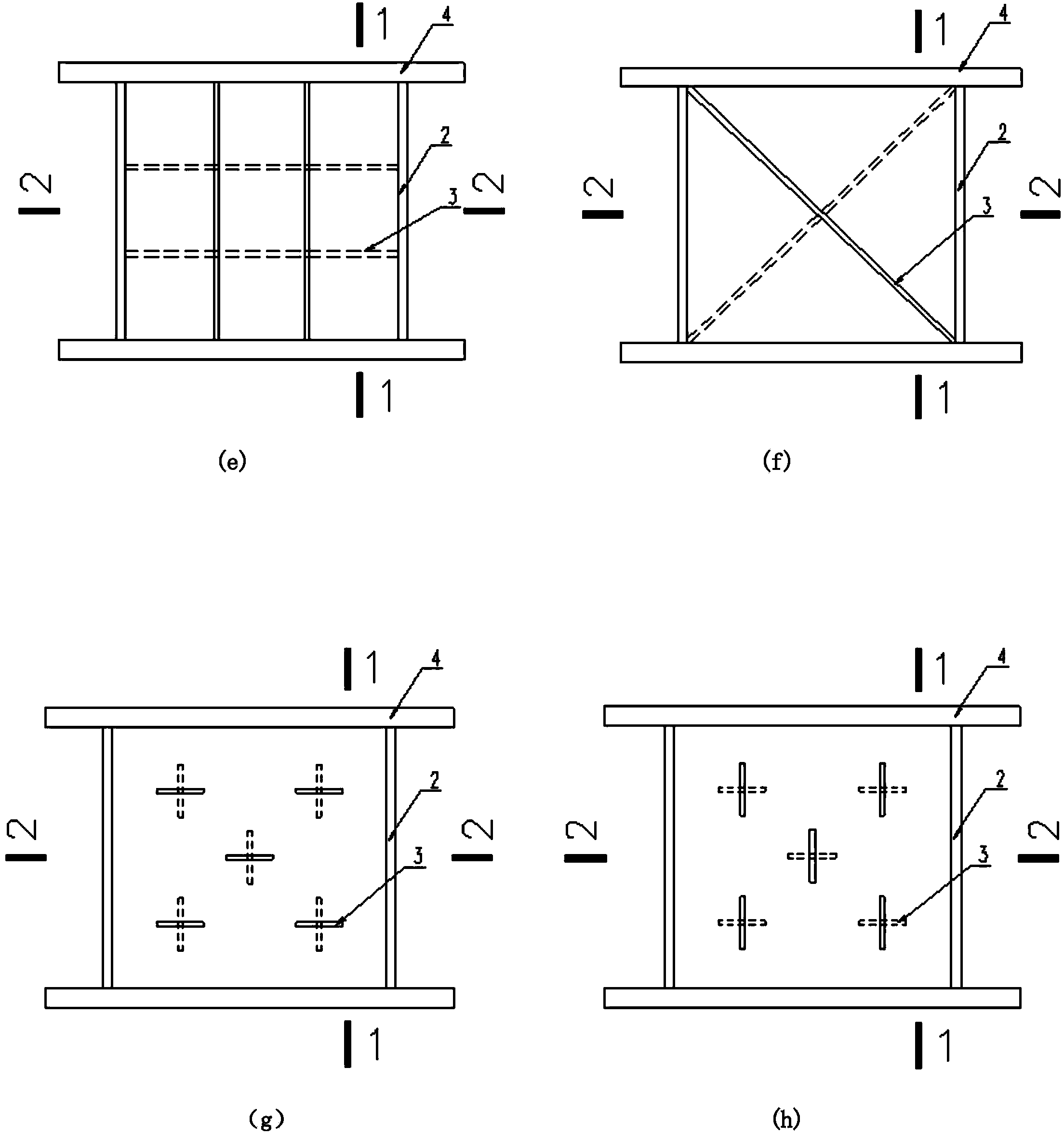

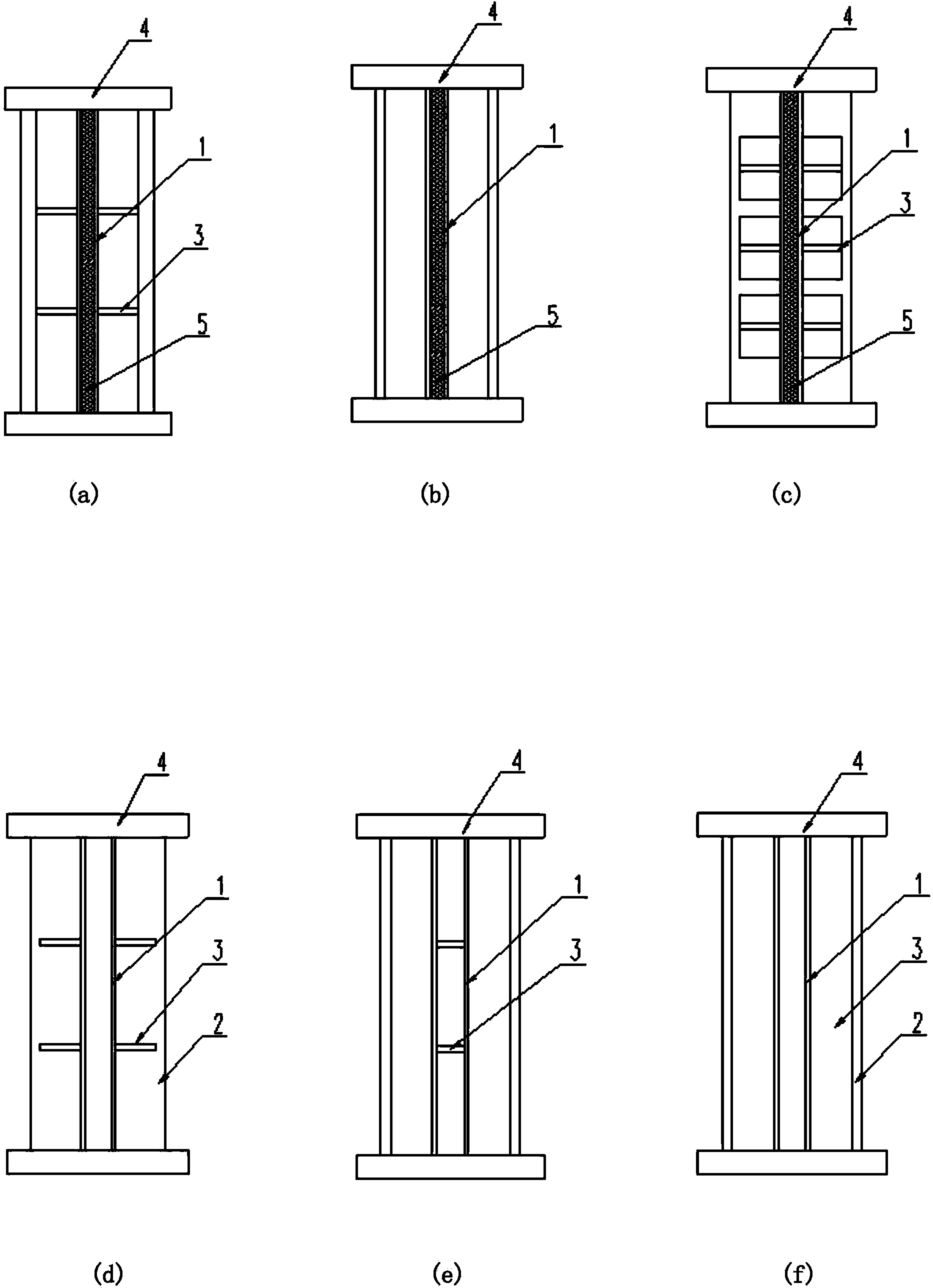

[0027] Such as figure 1 (a), figure 2 (a), image 3 As shown in (a), on the outer surfaces of the two shear webs 1, there are two vertical stiffeners 3, two horizontal stiffeners 3, and two vertical stiffeners 3. The plate 3 and the two stiffening plates 3 in the horizontal direction intersect each other in a cross shape.

Embodiment 2

[0029] Such as figure 1 (b), figure 2 (b), image 3 As shown in (b), on the outer surfaces of the two shear webs 1, two stiffening plates 3 intersecting along different diagonals are respectively provided throughout the entire length, and the two stiffening plates 3 intersecting along different diagonals are connected to each other. Cruciform cross.

Embodiment 3

[0031] Such as figure 1 (c), figure 2 (c), image 3 As shown in (c), on the outer surfaces of the two shear webs 1, five pairs of cross-shaped stiffening plates 3 are partially provided, and the five pairs of cross-shaped stiffening plates 3 are located on the outer surfaces of the shear webs 1. Set symmetrically on the sides. One pair is located at the center of the outer surface of the shear web 1 , and the remaining four pairs are located at the inner sides of the four right angles of the shear web 1 .

[0032] see figure 1 (d-h), figure 2 (d-h), image 3 (d-h) are five embodiments in the case where the distance between two shear webs 1 is relatively large. A stiffening plate 3 is arranged between the two shearing webs 1 , and the two sides of the stiffening plate 3 are respectively welded to the inner surfaces of the two shearing webs 1 . The stiffeners 3 on the outer sides of the two shear webs 1 are designed symmetrically, and the number, direction and size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com