Frostless multivariable coupled type heat pump hot blast stove system

A coupled type hot blast stove technology, applied in fluid heaters, climate change adaptation, lighting and heating equipment, etc., can solve the problems of heat waste, easy frosting of evaporating side fins, and difficulty in raising the wind temperature, etc., to achieve improved Stability and reliability, effect of increasing heat exchange effect, effect of increasing condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

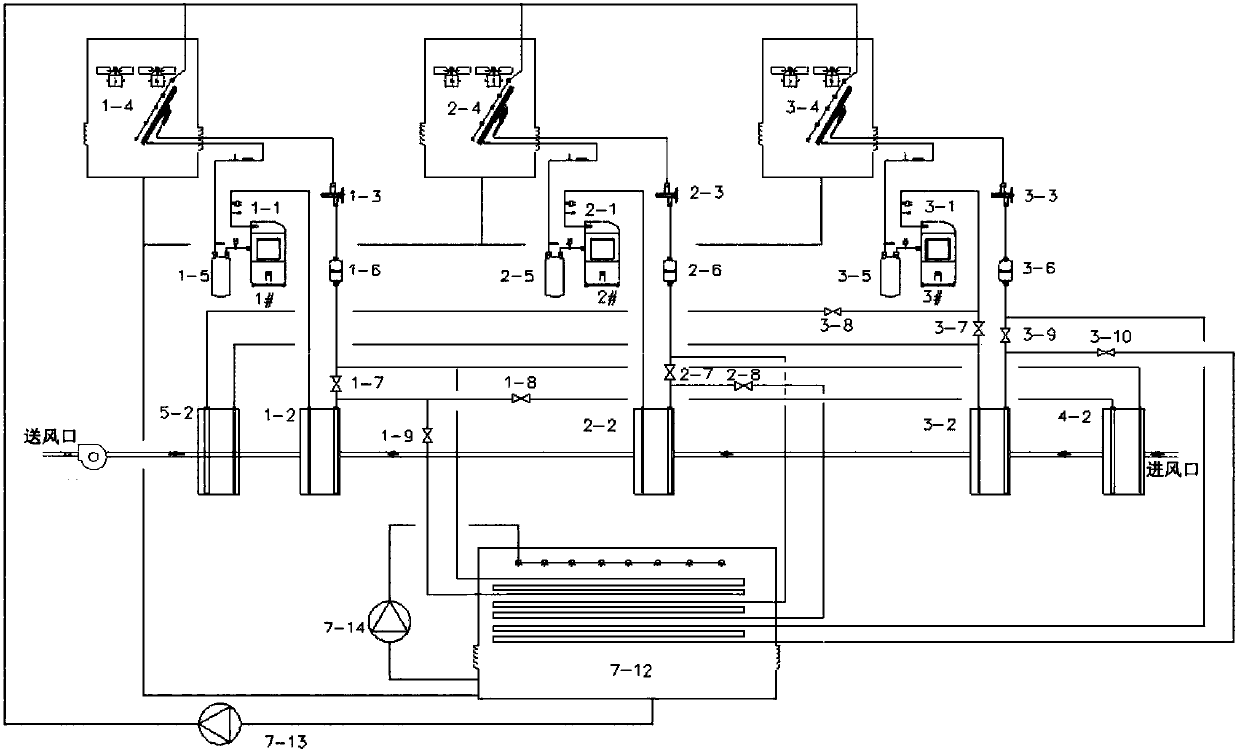

[0058] Hereinafter, a frost-free, multi-variable coupling type heat pump hot blast stove system of the present invention will be further described in detail according to the accompanying drawings and specific embodiments.

[0059] like figure 1 Shown is a frost-free, multi-variable coupled heat pump hot blast stove system used to provide hot air for grain drying,

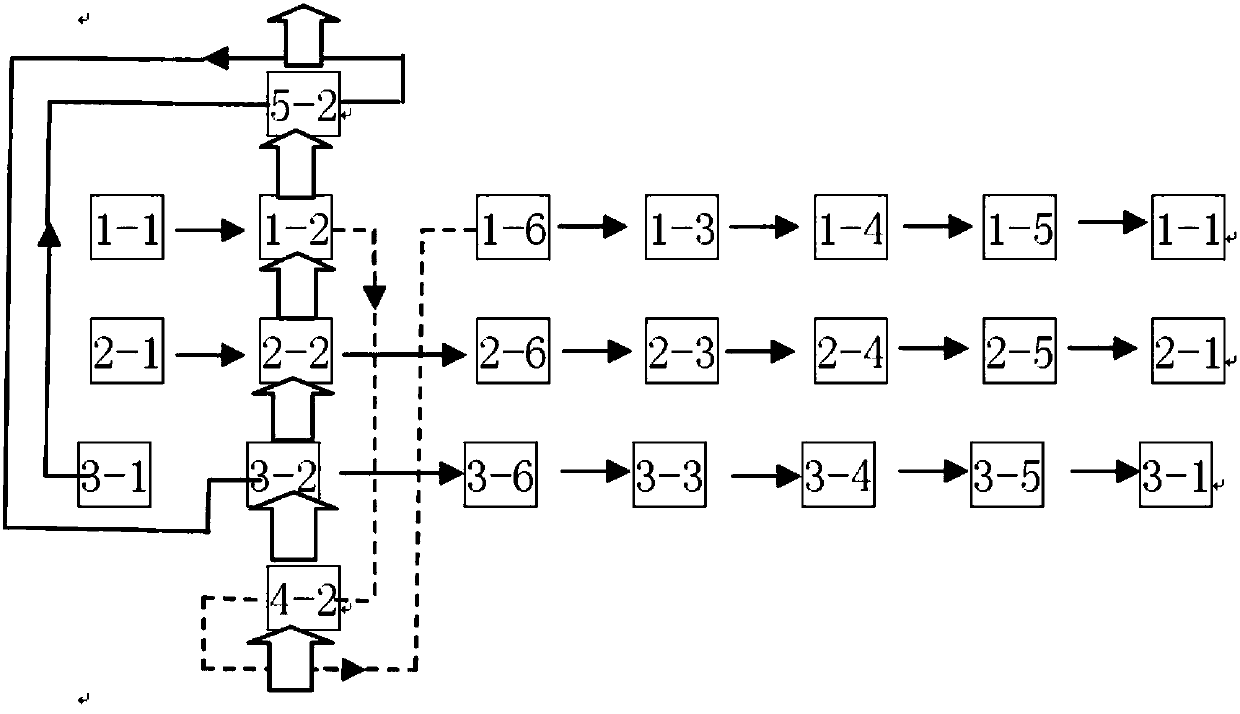

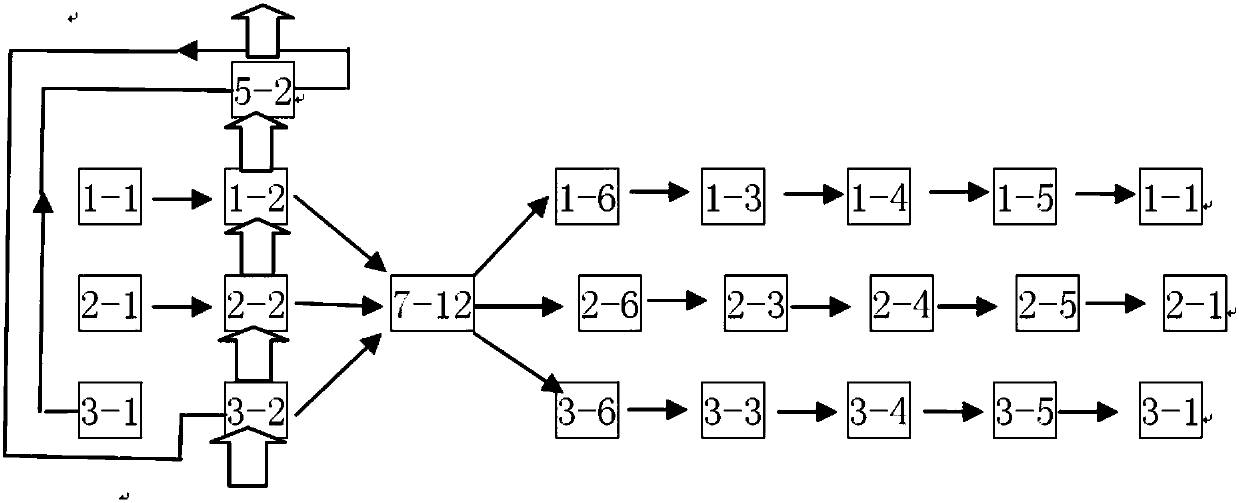

[0060] The system is provided with a first heat exchanger, a second heat exchanger and a heat pump unit composed of a compressor, a condenser, a throttle, an evaporator and a gas-liquid separator. The heat exchanger is connected with the heat pipeline of the heat pump unit to form a preheating zone, a low temperature zone, a medium temperature zone and a high temperature zone on the air supply pipeline, with a heat gradient rising sequentially from the fresh air inlet to the fresh air supply;

[0061] Through the above settings, the temperature gradient of the fresh air from the fresh air inlet to the fresh air sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com