Fluorine insulating wire and manufacturing method and applications thereof

A manufacturing method and technology of insulated wires, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of stress cracking and insufficient adhesion of fluorine insulated wires, and achieve the effect of large market application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Wire specification: cross-sectional area 0.35mm 2 , the thickness of the wire insulation layer is 0.2mm;

[0027] Material selection: fluorine insulating material NP20 with a melt index of 12-16;

[0028] Conductor: twisted by annealed annealed copper wire with a purity of 99.99%.

[0029] The preparation steps of the wire are as follows:

[0030] (1) Preheat the conductor to a temperature of 90°C;

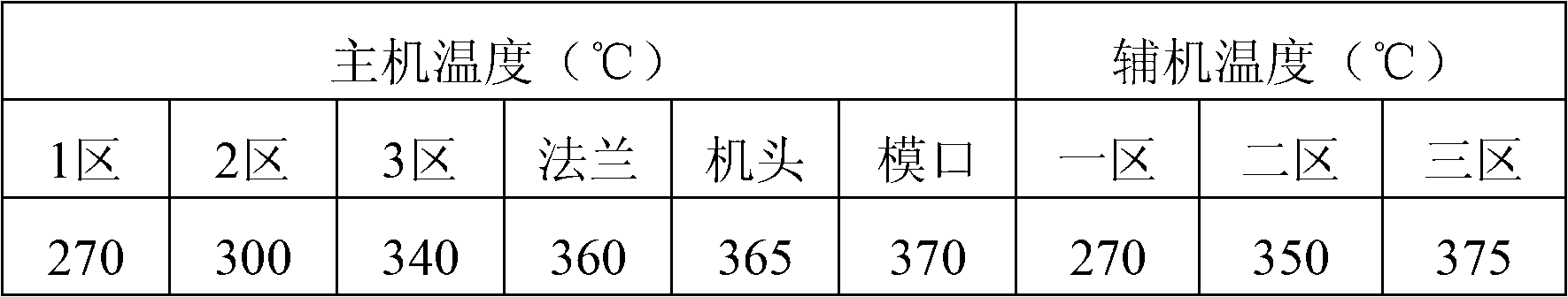

[0031] (2) Using a 45-type extruder, extrude the fluorine insulating material NP20 on the preheated conductor to obtain an extrudate; the extrusion temperature of the extruder is shown in Table 1;

[0032] (3) The extruded extrudate passes through the cooling zone sequentially from high temperature to low temperature: the first water cooling zone at 70°C; the second air cooling zone at 50°C; the third water cooling zone at 25°C.

[0033] Wherein, (2) the extrusion speed in the extrusion process is 40m / min; the mold core angle used in the extrusion process is 10°; the mo...

Embodiment 2

[0043] Wire specification: cross-sectional area 0.5mm 2 , the thickness of the wire insulation layer is 0.22mm;

[0044] Material selection: fluorine insulating material NP20 with a melt index of 12-16;

[0045] Conductor: twisted by annealed soft copper wire.

[0046] The preparation steps of the wire are as follows:

[0047] (1) Preheat the conductor to a temperature of 70°C;

[0048] (2) Using a 45-type extruder, extrude the fluorine insulating material NP20 on the preheated conductor to obtain an extrudate; the extrusion temperature of the extruder is shown in Table 3;

[0049] (3) The extruded extrudate passes through the cooling zone sequentially from high temperature to low temperature: the first water cooling zone at 60°C; the second air cooling zone at 30°C; the third water cooling zone at 20°C.

[0050] Wherein, (2) the extrusion speed in the extrusion process is 20m / min; the mold core angle used in the extrusion process is 24°; the mold sleeve angle is 25°.

[...

Embodiment 3

[0055] Wire specification: cross-sectional area 0.45mm 2 , the thickness of the wire insulation layer is 0.22mm;

[0056] Material selection: fluorine insulating material NP30 with a melt index of 3-6;

[0057] Conductor: The material is copper, twisted by annealed soft copper wire.

[0058] The preparation steps of the wire are as follows:

[0059] (1) Preheat the conductor to a temperature of 120°C;

[0060] (2) Use a 45-type extruder to extrude the fluorine insulating material NP30 on the preheated conductor to obtain an extrudate; the extrusion temperature of the extruder is shown in Table 4;

[0061] (3) The extruded extrudate passes through the cooling zone sequentially from high temperature to low temperature: the first water cooling zone at 80°C; the second air cooling zone at 50°C; the third water cooling zone at 25°C.

[0062] Wherein, (2) the extrusion speed in the process of extrusion is 60m / min; the angle of the mold core used in the process of extrusion is 16°;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com